Bolt-connected prefabricated segment shear-resistant assembly concrete pier

A technology of prefabricated assembly and concrete, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problem of incomplete understanding of the seismic performance of segmental prefabricated assembly piers, weak shear performance of segmental joints, and joints of segmental piers Weakness and other problems, to achieve the effect of reducing construction procedures, improving shear performance, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

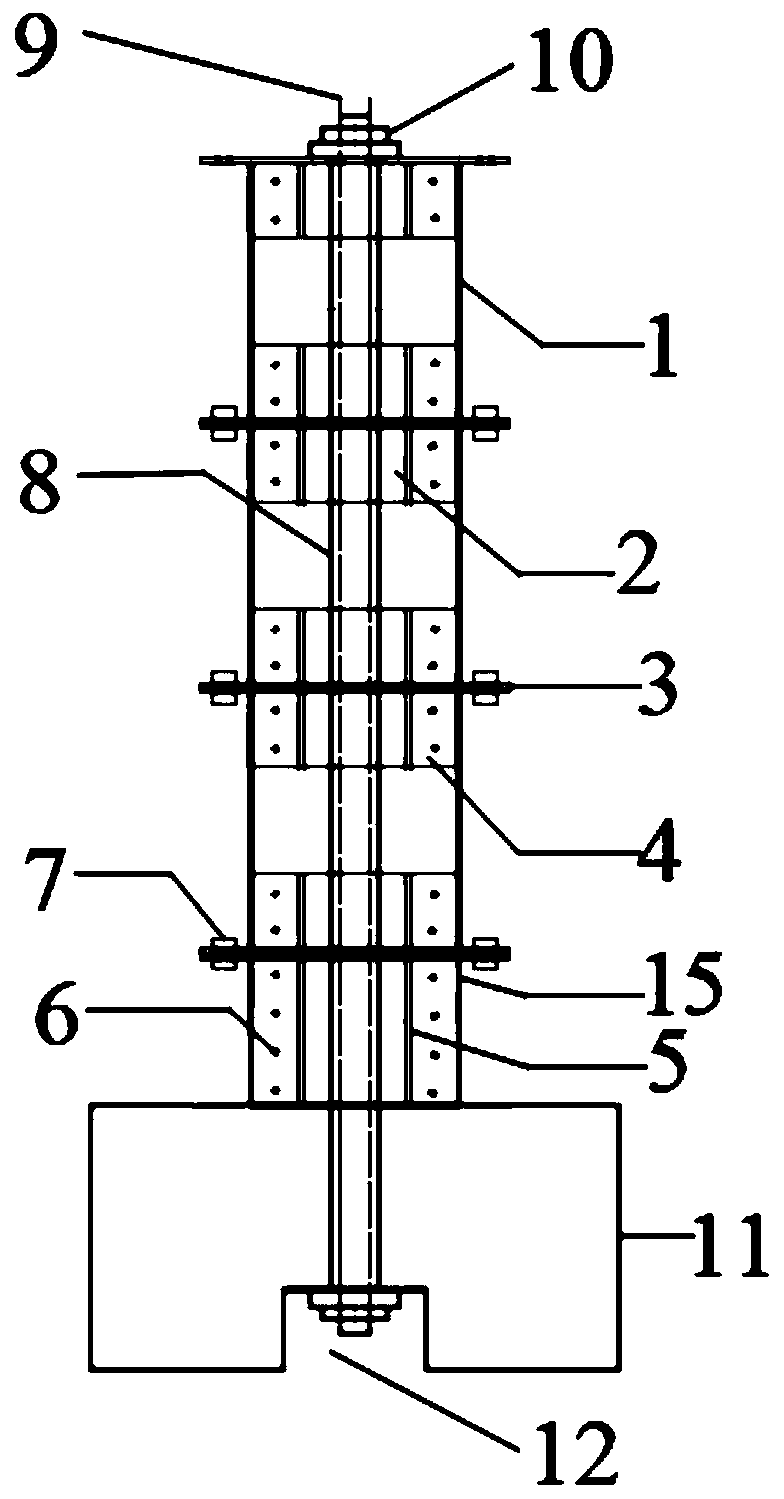

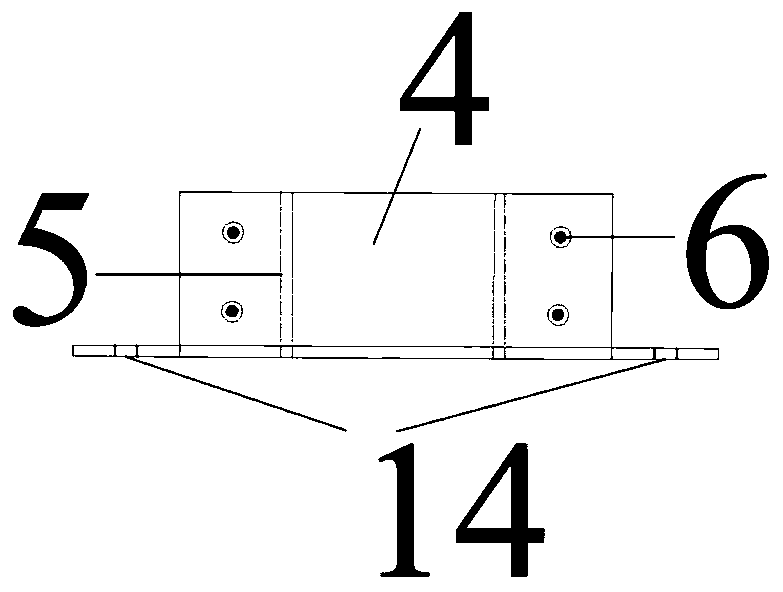

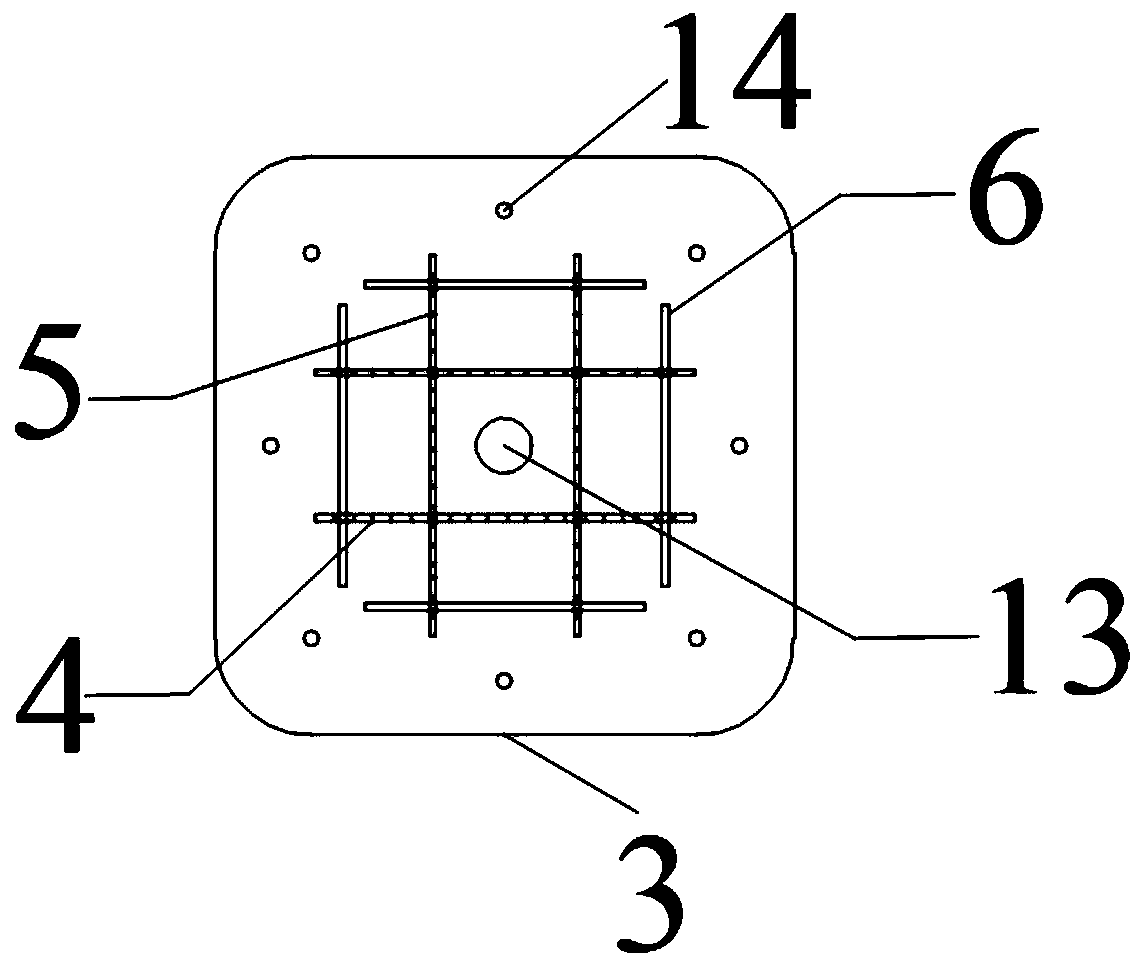

[0030] Such as figure 1 and figure 2 A bolted prefabricated segmental shear-resisting assembled concrete pier is shown, comprising:

[0031] There are several prefabricated rectangular concrete segments 1 with a rectangular cross-section, and the upper and lower ends of each segment are fixedly provided with connection devices 2 at the joints of the segments; among them, the central position of the prefabricated rectangular concrete segment 1 is reserved for interspersed prefabricated A vertical through hole 8 of the stress steel strand 9.

[0032] The cast-in-place cap 11 has a concrete segment 15 provided with a connecting device 2 at the segment splicing point protruding from the upper part, and the concrete segment 15 is encrypted with stirrups to form a device for connecting the lowermost prefabricated rectangular concrete segment 1; A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com