Construction method of 55-m moving framework cast-in-situ super-span continuous box girder

A technology of moving formwork and construction method, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of increasing implementation cost, increasing steel consumption, hidden safety hazards, etc., and achieving the goal of reducing implementation cost and speeding up construction pace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The construction method of a 55m mobile formwork cast-in-place super-span continuous box girder provided by the present invention will be introduced in detail below in conjunction with the accompanying drawings.

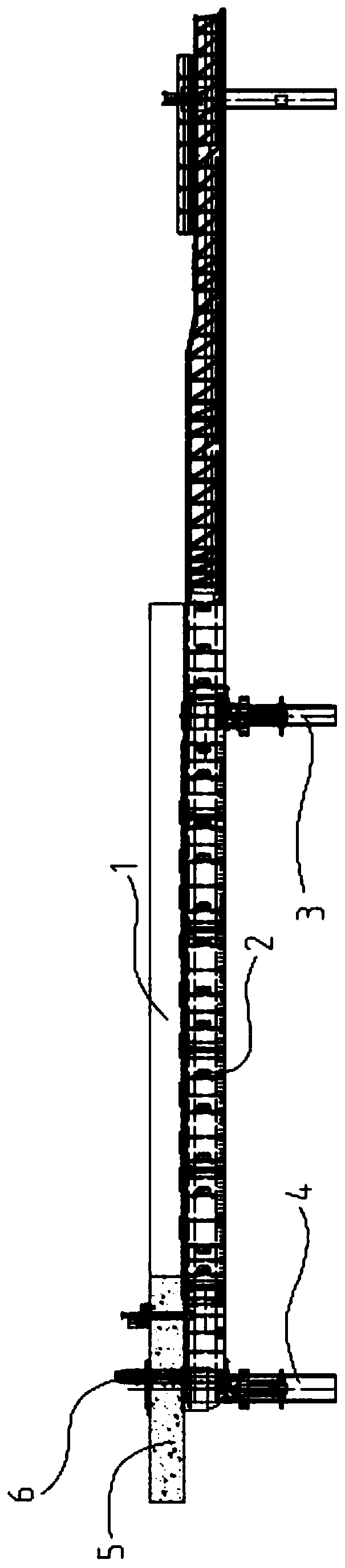

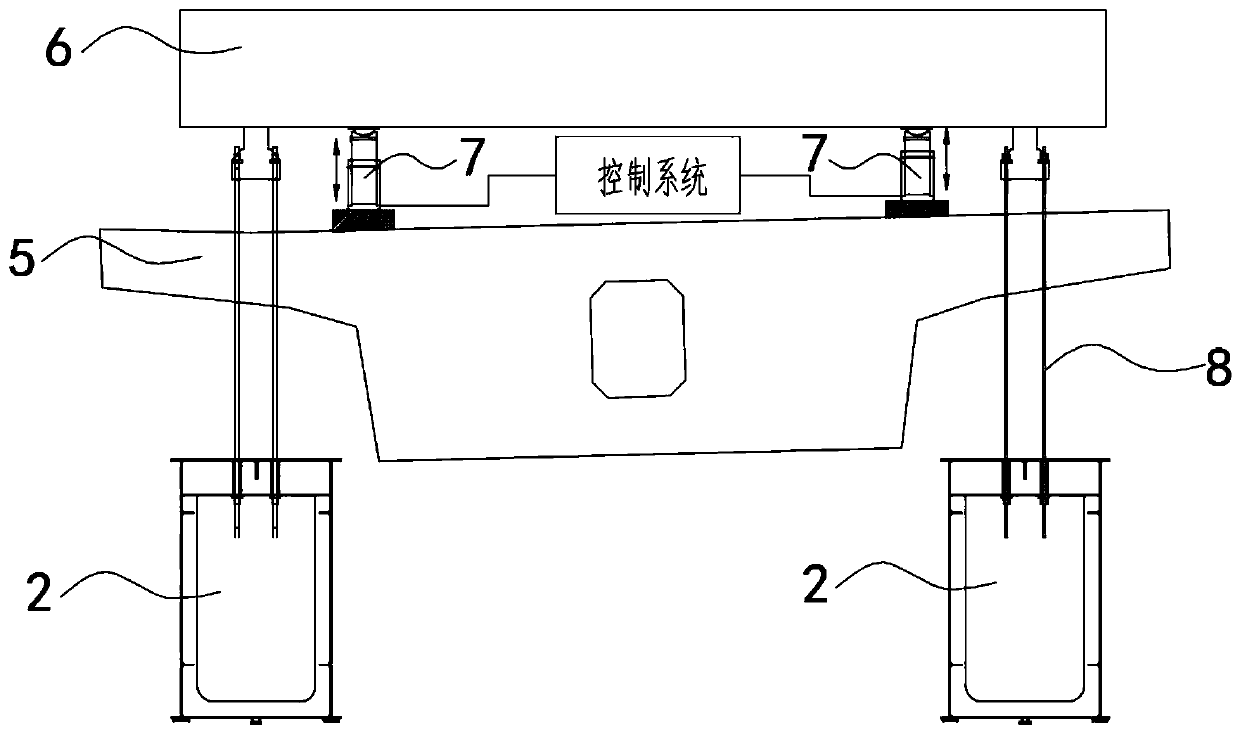

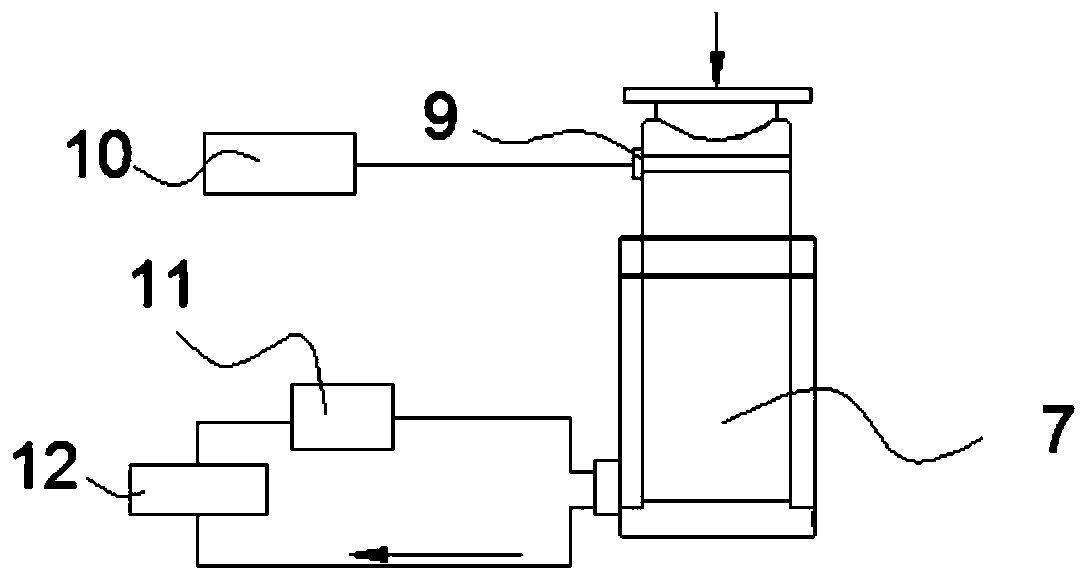

[0027] Such as Figures 1 to 2 As shown, it includes a 55m downward mobile formwork, and the mobile formwork includes a main beam 2, and the main beam 2 is supported by the rear pillar 4 corbels and the front pillar 3 corbels, and the mobile formwork It also includes a reaction force beam 6 horizontally arranged above the main beam, and the reaction force beam 6 is arranged between the rear pillar 4 and the front pillar 3; it also includes a cantilever section 5, and the cantilever section 5 extends to the main beam Between 2 and the reaction force beam 6, a reaction force system is also included, and the reaction force system includes several groups of hydraulic jacks 7, a suspension system, and a control system for controlling the lifting force of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com