Vertical non-contact sealing device

A sealing device, non-contact technology, applied in the direction of engine sealing, transmission parts, engine components, etc., can solve the problems of easy formation of negative pressure, oil leakage at the output end, etc., and achieve oil leakage, multiple oil return points, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

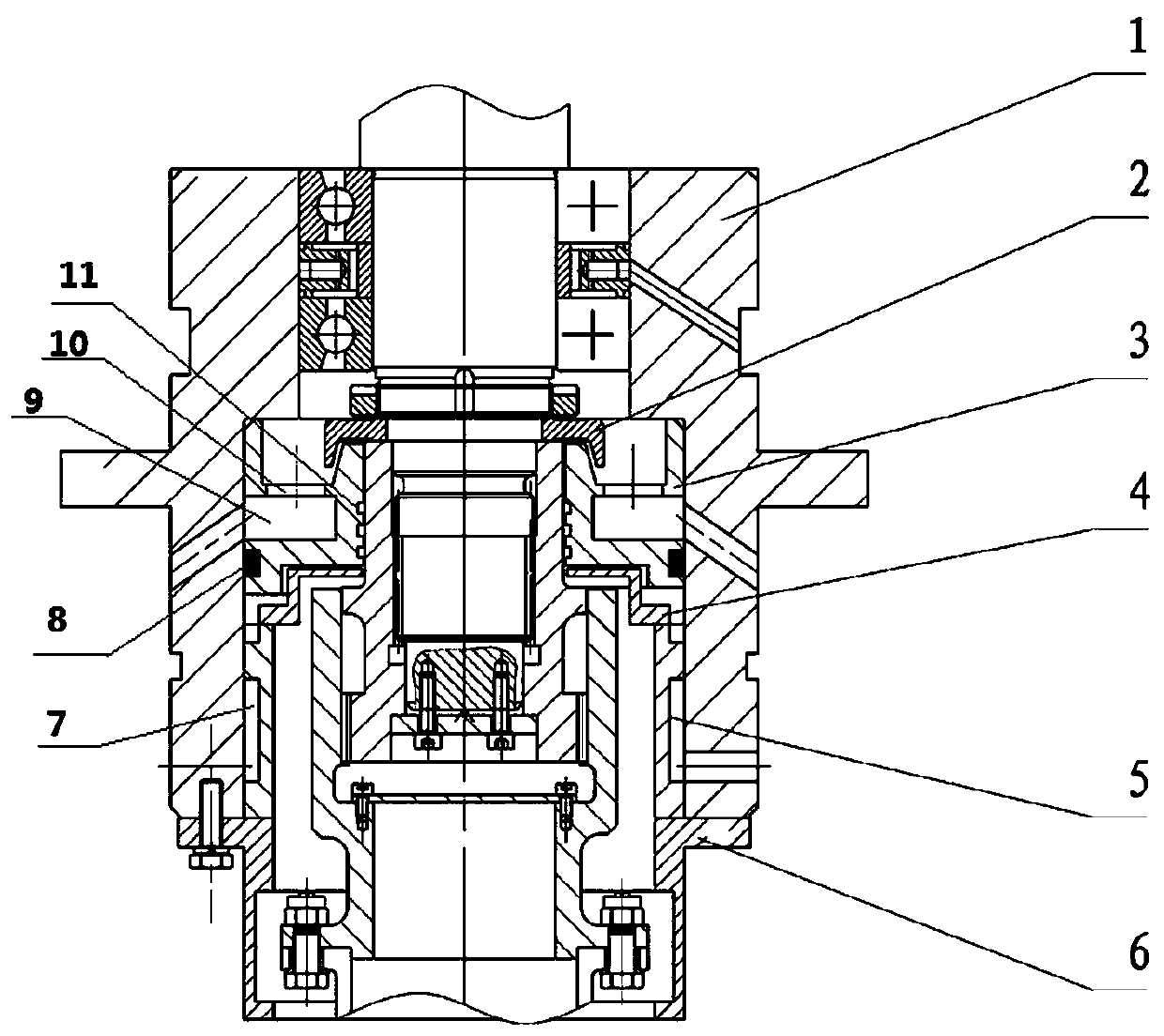

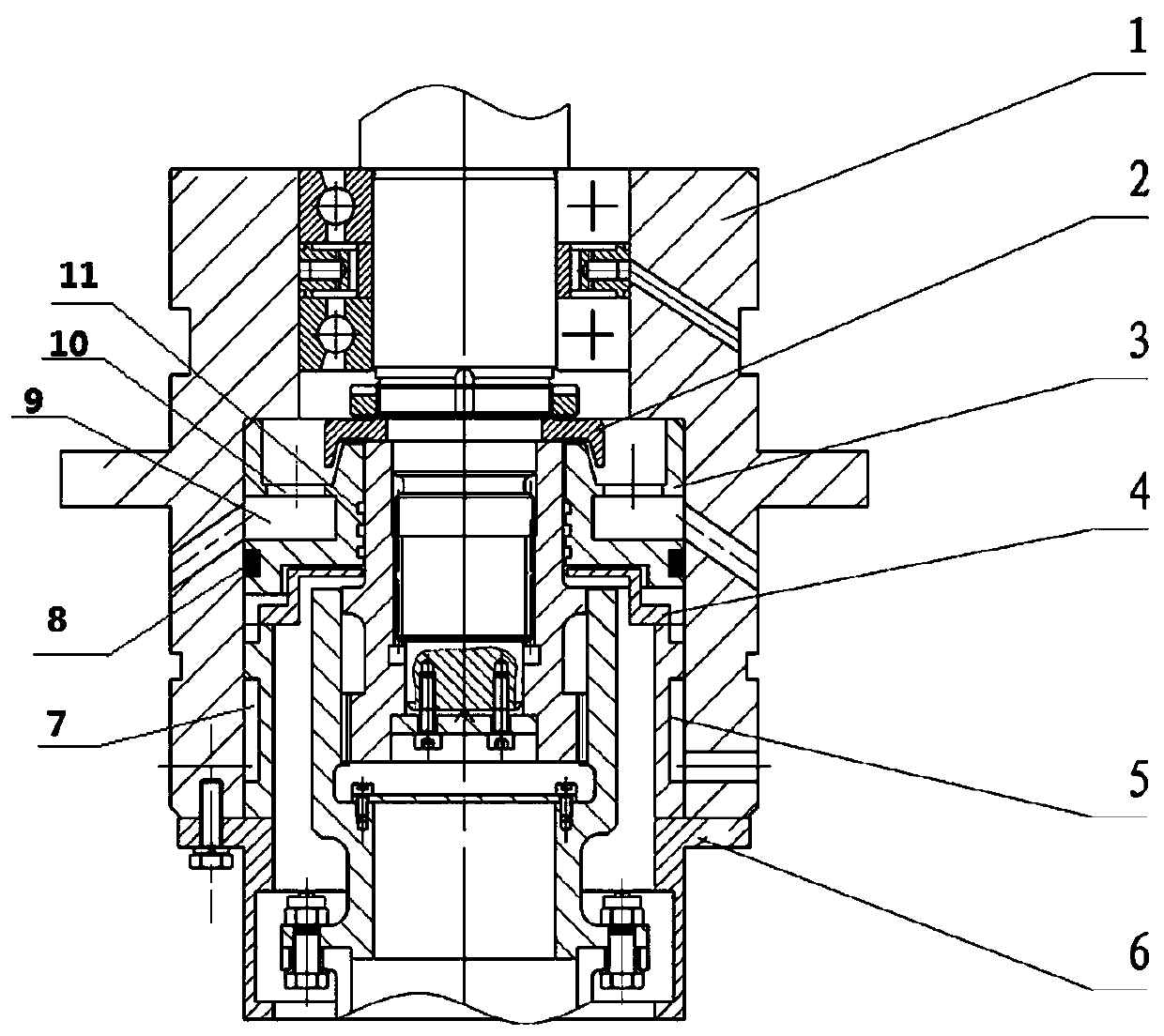

[0018] refer to figure 1 , a vertical non-contact sealing device, including a transfer mechanism 1, and also includes a first oil throwing ring 2, a second oil throwing ring 3 capable of leaking oil, an oil throwing ring 4 capable of leaking oil, and a Oil ring positioning sleeve 5 for oil ring positioning and high-speed output end pressure plate 6; the first oil throwing ring 2 is installed on the vertical output shaft of the adapter mechanism 1, and the second oil throwing ring 3 is installed on the first Under the oil throwing ring 2, the oil throwing ring 4 is installed under the second oil throwing ring 3, the oil throwing ring positioning sleeve 5 is installed under the oil throwing ring 4, and the high-speed output end pressure plate 6 is installed on the oil throwing ring 4 below; the inner ring of the second oil throwing ring 3 is provided with an annular sealing groove 11, and the outer ring is provided with an O-ring ring groove 8, and the middle part of the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com