Filling pipeline repairing method

A pipeline repair and pipeline technology, which is applied in the direction of filling, pipe components, earthwork drilling and mining, etc. It can solve the problems that small-diameter pipes are not easy to install, slurry is easy to solidify between two pipes, and small-diameter pipes are easy to be worn out, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

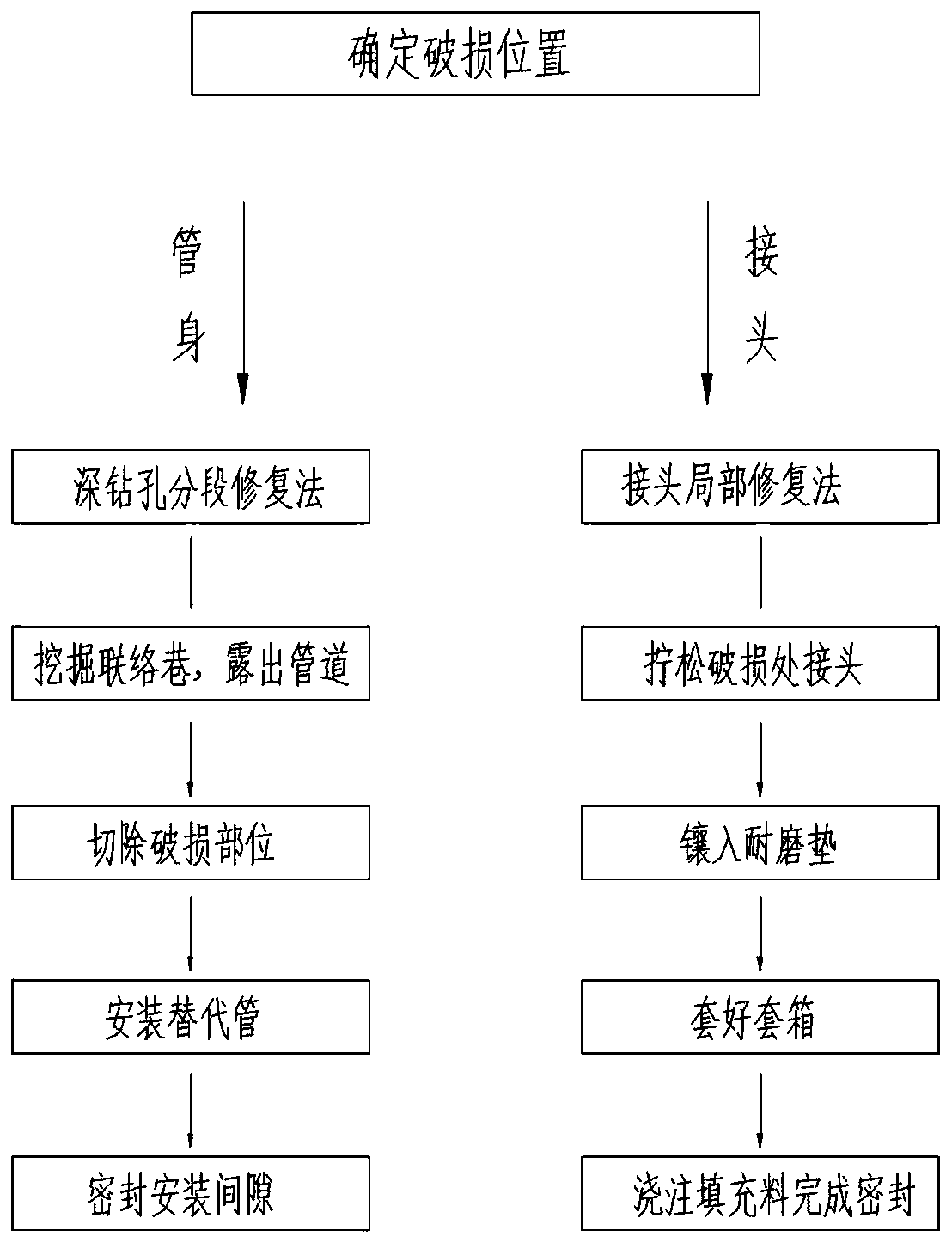

[0035] like figure 1 As shown, the filling pipeline repair method provided in this embodiment firstly determines the position of the damaged pipeline through a video camera. If the damaged position is located in the pipe body, the deep drilling segment repair method is adopted. If the damaged position is located at the pipe joint, then Joint repair method is used.

[0036] The detailed steps of deep drilling segment repair method are as follows:

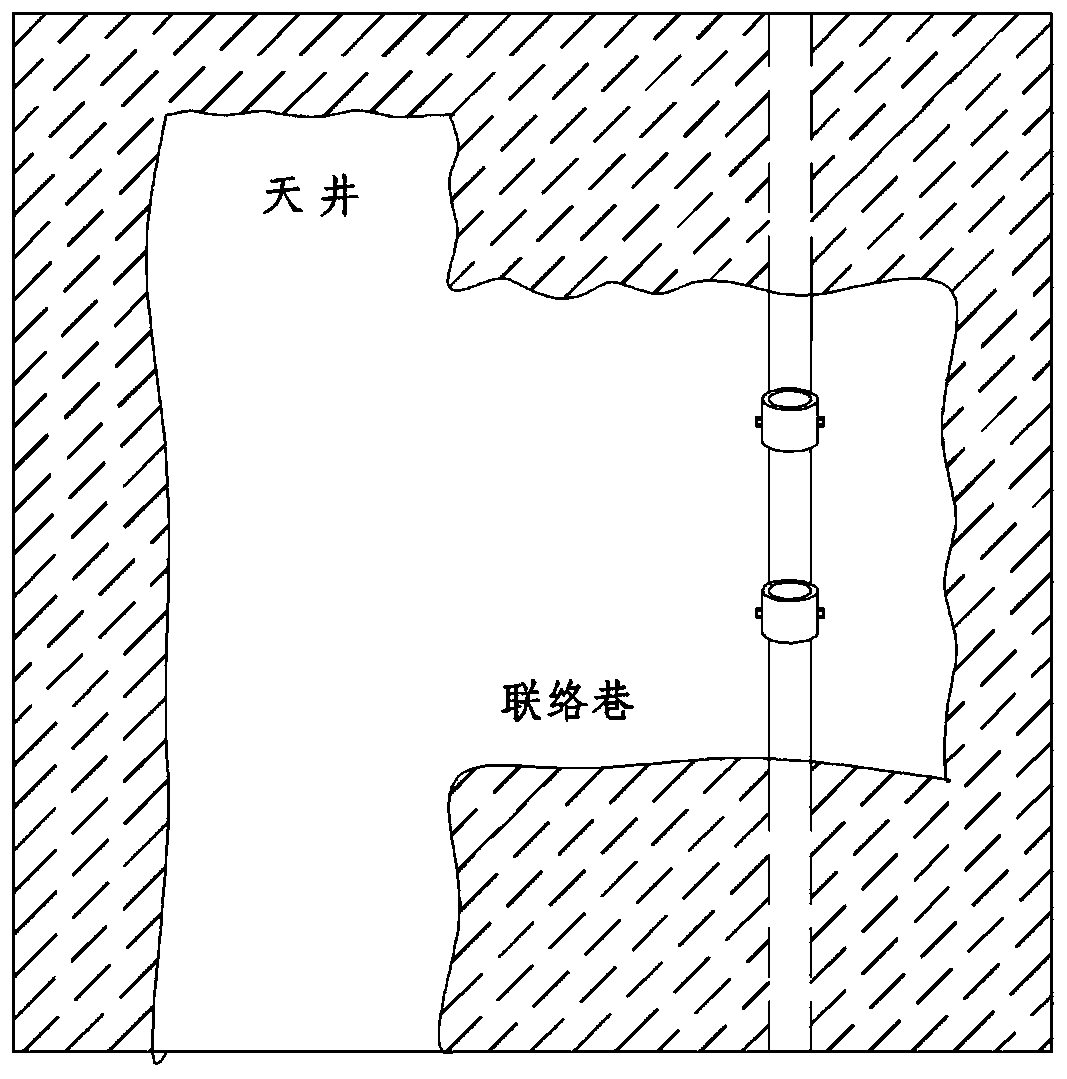

[0037] Step one, as figure 2 As shown, connect the roadway from the patio to the damaged location to construct the excavation, so that the damaged filling pipeline is exposed;

[0038] Step 2: Cut off the damaged part, and the upper incision and the lower incision appear.

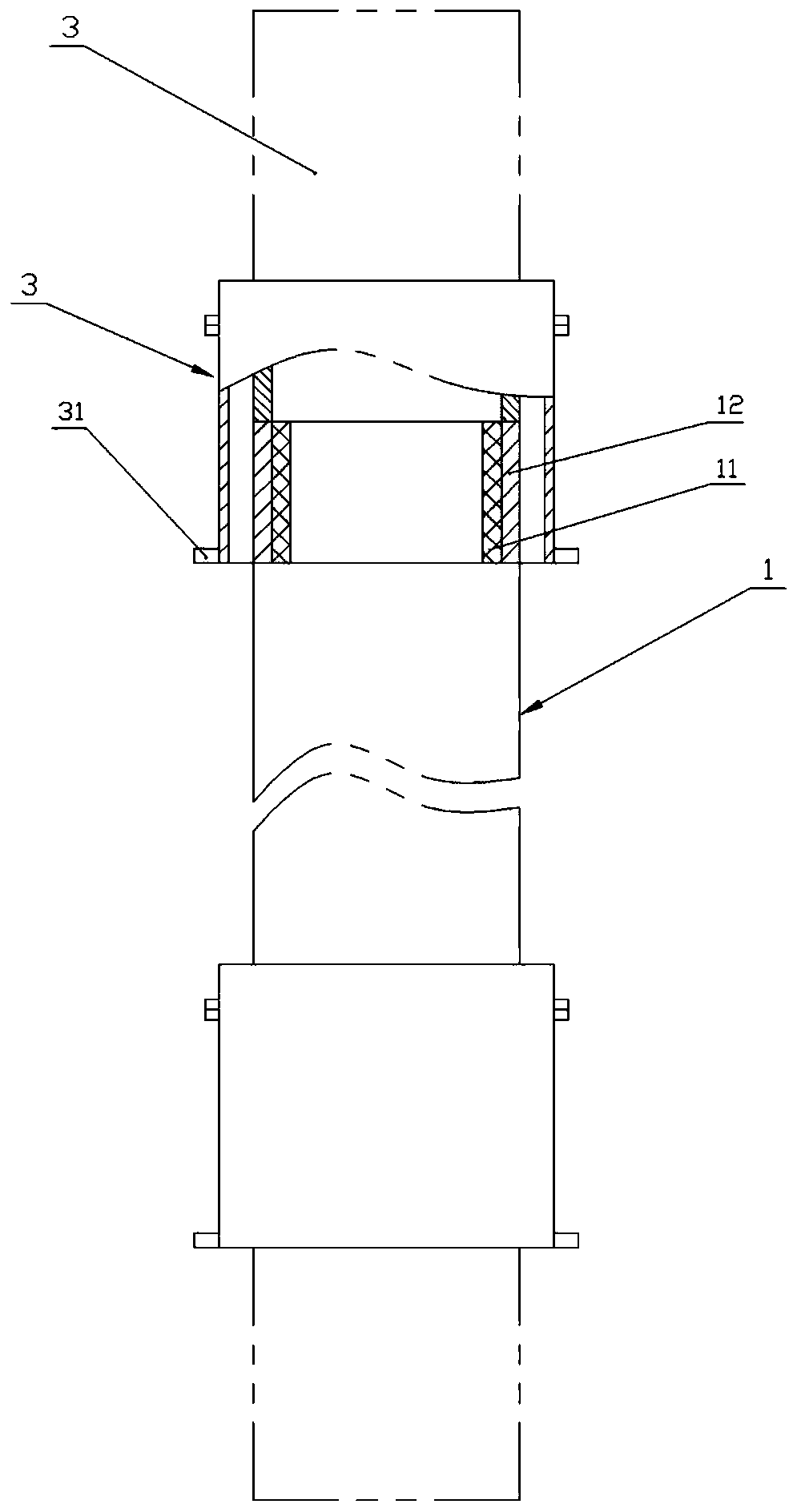

[0039] Step 3, install the replacement tube, and connect the upper and lower ends of the replacement tube to the upper incision and the lower incision through the connecting sleeve respectively;

[0040] Step 4: Pour concrete into the connecting sleeve to sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com