Double-oil-passage hedging direct injection nozzle

A technology with dual oil circuits and nozzles, applied in combustion methods, combustion chambers, combustion equipment, etc., can solve problems affecting combustion chamber performance, nozzle clogging, small fuel spray expansion angle, etc., to improve atomization effect and increase injection Angle, speed up the effect of broken atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with accompanying drawing:

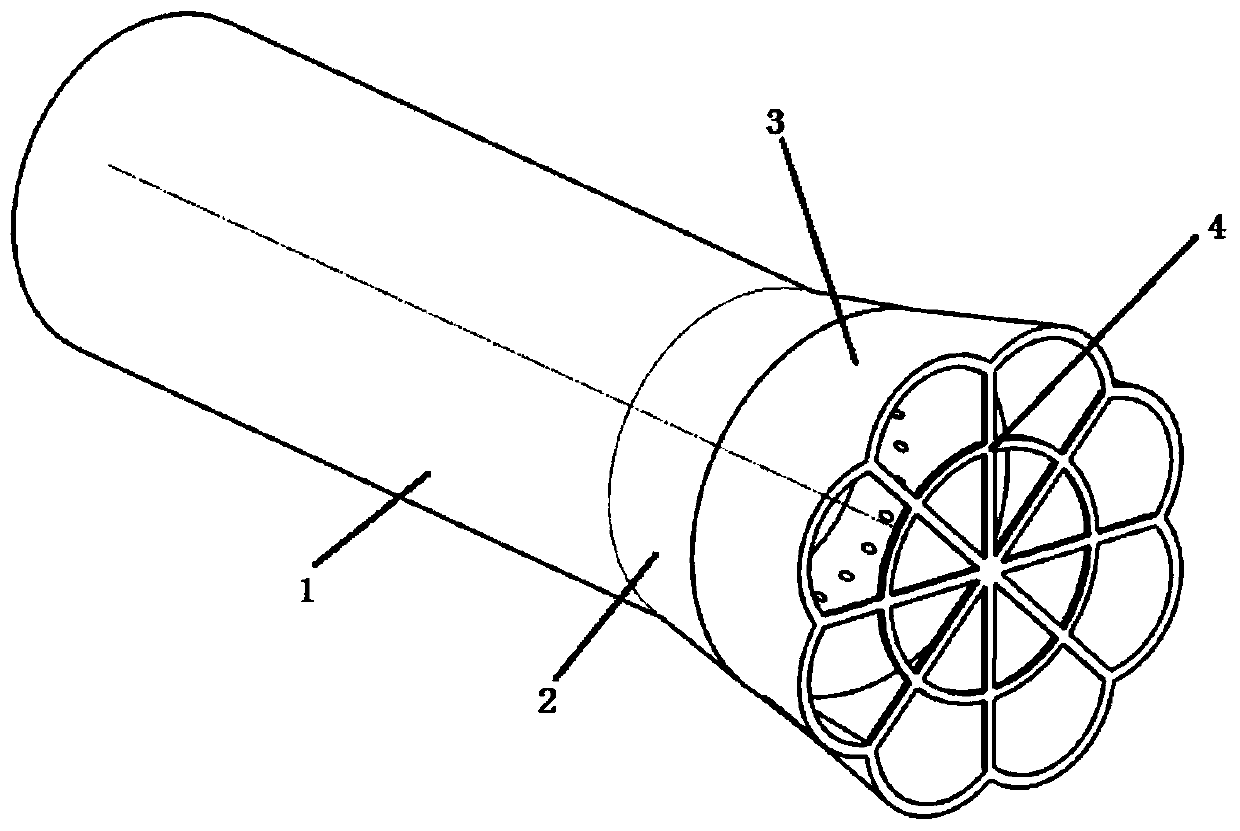

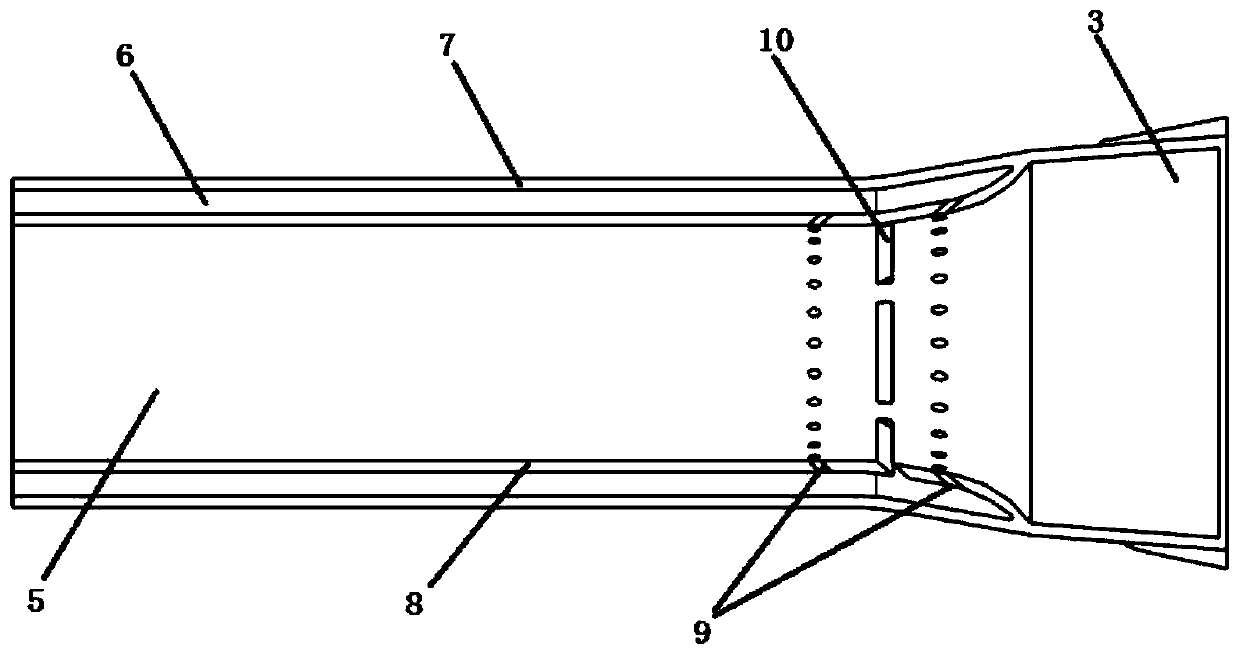

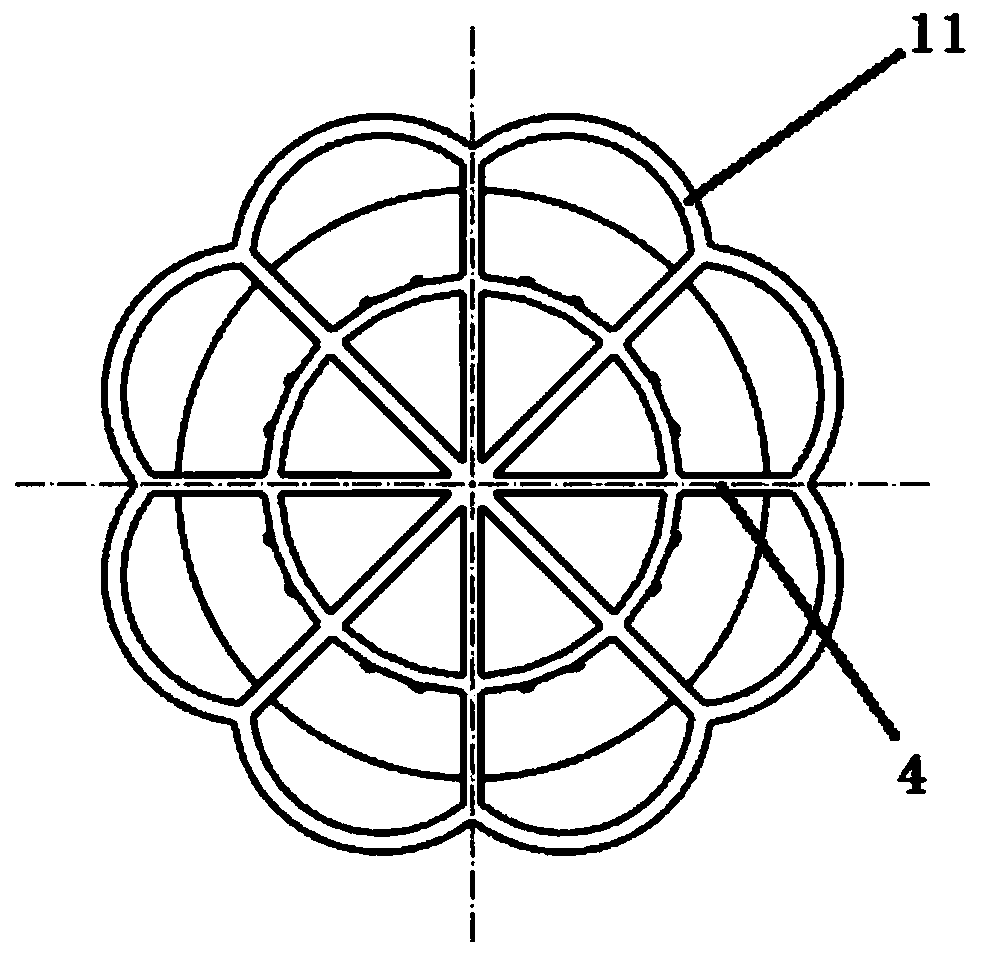

[0018] combine figure 1 , figure 2 , image 3 , the present invention provides a technical solution for double-oil-way opposite direct-injection nozzles. figure 1 It is a schematic diagram of the overall structure of the double-oil-way counterpoint direct-injection nozzle, figure 2 It is a schematic cross-sectional view of the central axis of the double-oil-way counterpoint direct-injection nozzle, image 3 It is a schematic diagram of the outlet cross-section of the double-oil-way counterpoint direct-injection nozzle.

[0019] After the fuel is pressurized, it is divided into two parts at the nozzle inlet and enters the interior of the nozzle, including the central oil circuit and the outer ring oil circuit. The outer ring oil circuit is closed in the nozzle expansion section, and the fuel will pass through two rows of oblique circular hole injection ports and rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com