Heating supply system with heat energy storage devices for heating supply network user sides

A technology of thermal energy storage and heating system, applied in heating system, hot water central heating system, household heating, etc., can solve the problems of high idle rate, low utilization rate of thermal pipe network, and high heating cost, etc. achieve the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

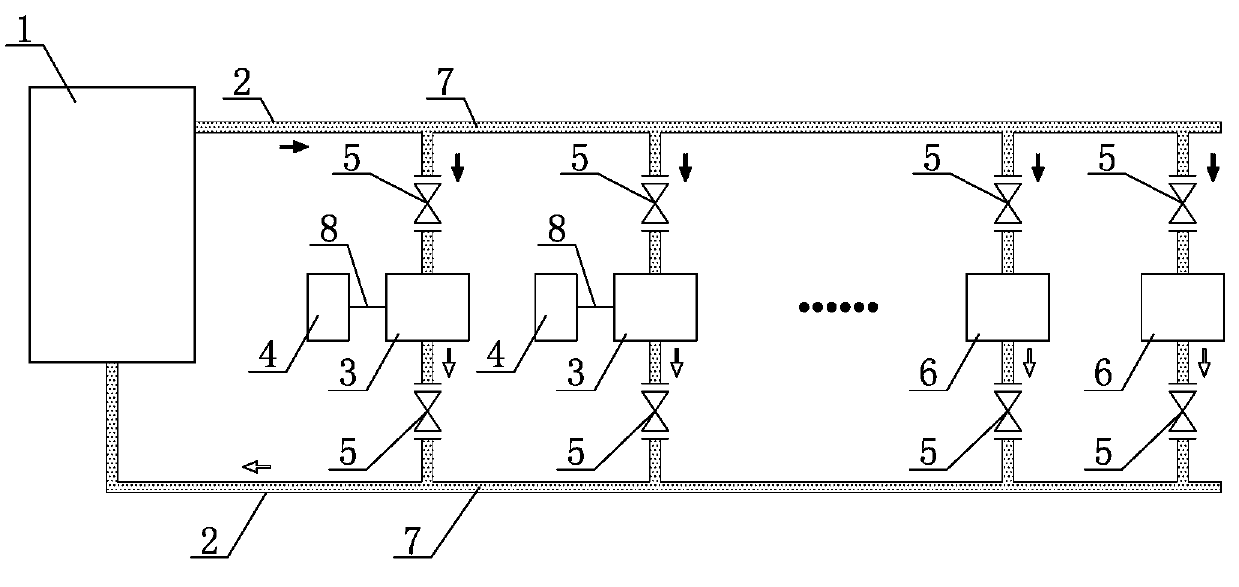

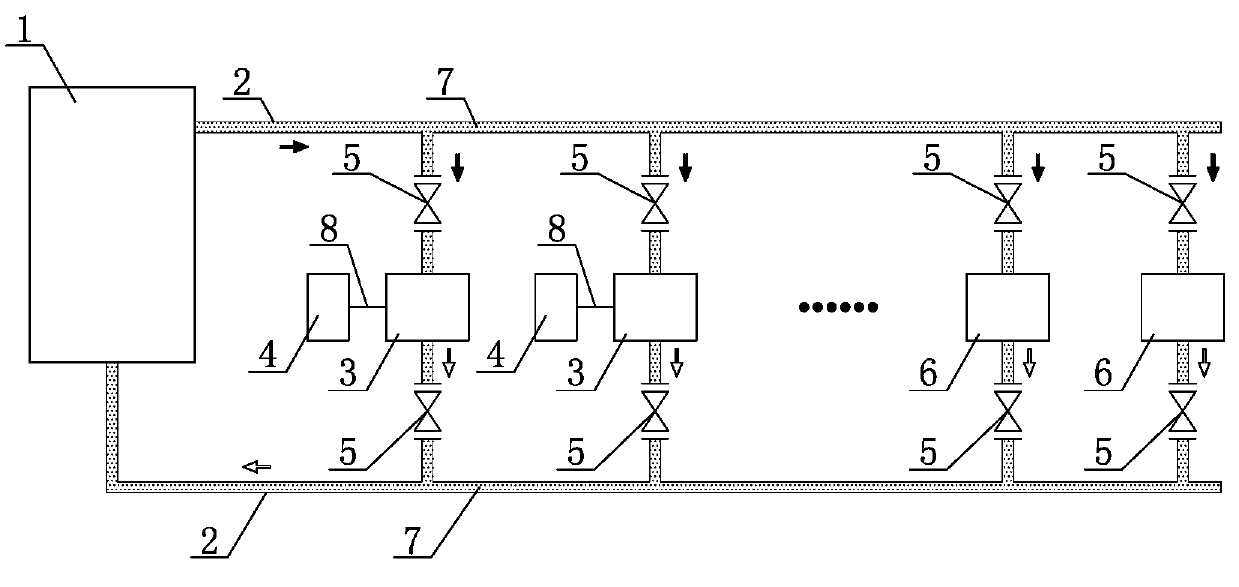

[0017] Depend on figure 1 As shown in the figure, 1 in the figure shows that the large heat source station is the waste heat heating unit of the thermal power plant, 2 shows that the heat pipe network is a circulation pipeline for transmitting superheated steam at a temperature of 280°C and a pressure of 1.6MPa in the thermal power plant, and the solid energy storage body 3 is solidified on two diameter DN50, pouring material with 20G seamless metal pipe outer thickness of 150mm, the 20G seamless metal pipe is connected to the heat pipe network 2, and forms a loop with the heat pipe network 2, while another 20G seamless metal pipe is connected to the The regenerative user 4 is connected to the regenerative user 4 to form a circuit; the heat source required by the regenerative user 4 is 140°C saturated steam, 5 is a valve group, and the heat source required by the 6 direct supply user is 60°C-80 ℃ hot water, 7 heat transfer medium is superheated steam, 8 is the regenerative use...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap