Contact-type free-form surface structure product eccentricity measuring method

A technology of contact measurement and curved surface structure, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of eccentricity error, position error, tilt error, etc., and achieve the effect of small measurement error and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with specific embodiments.

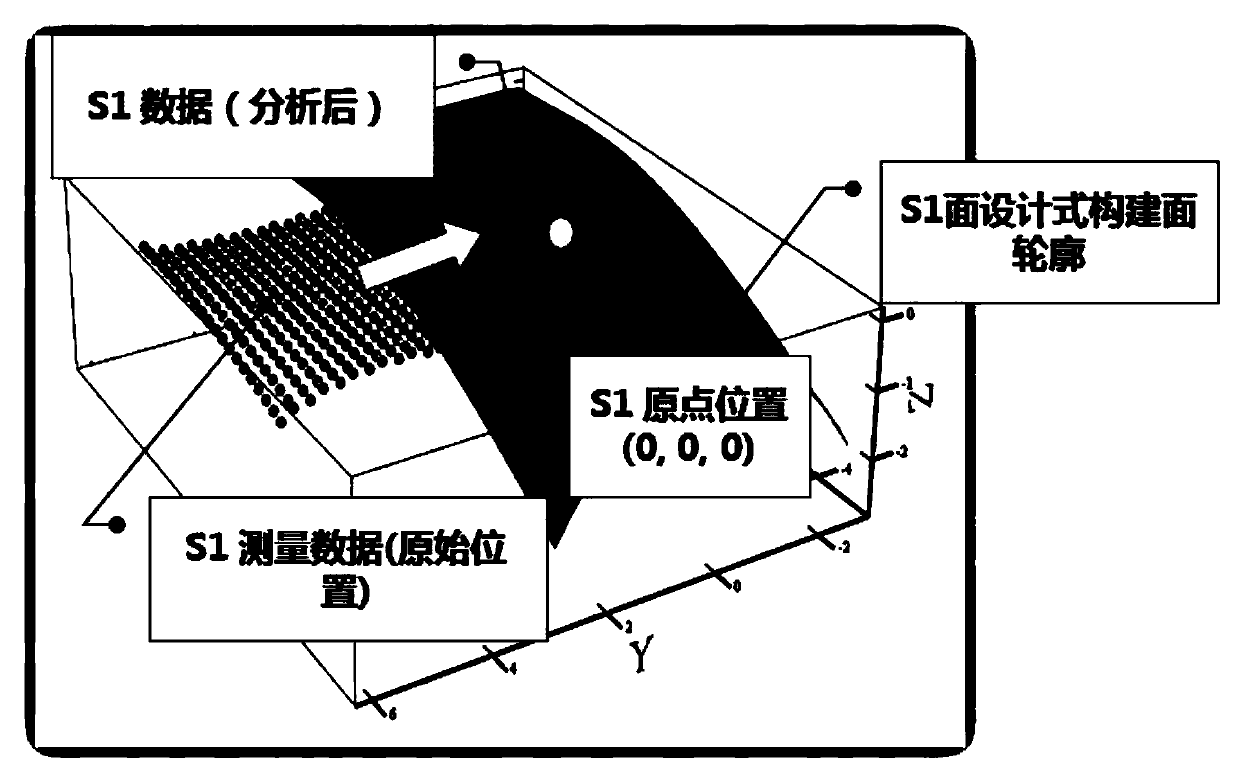

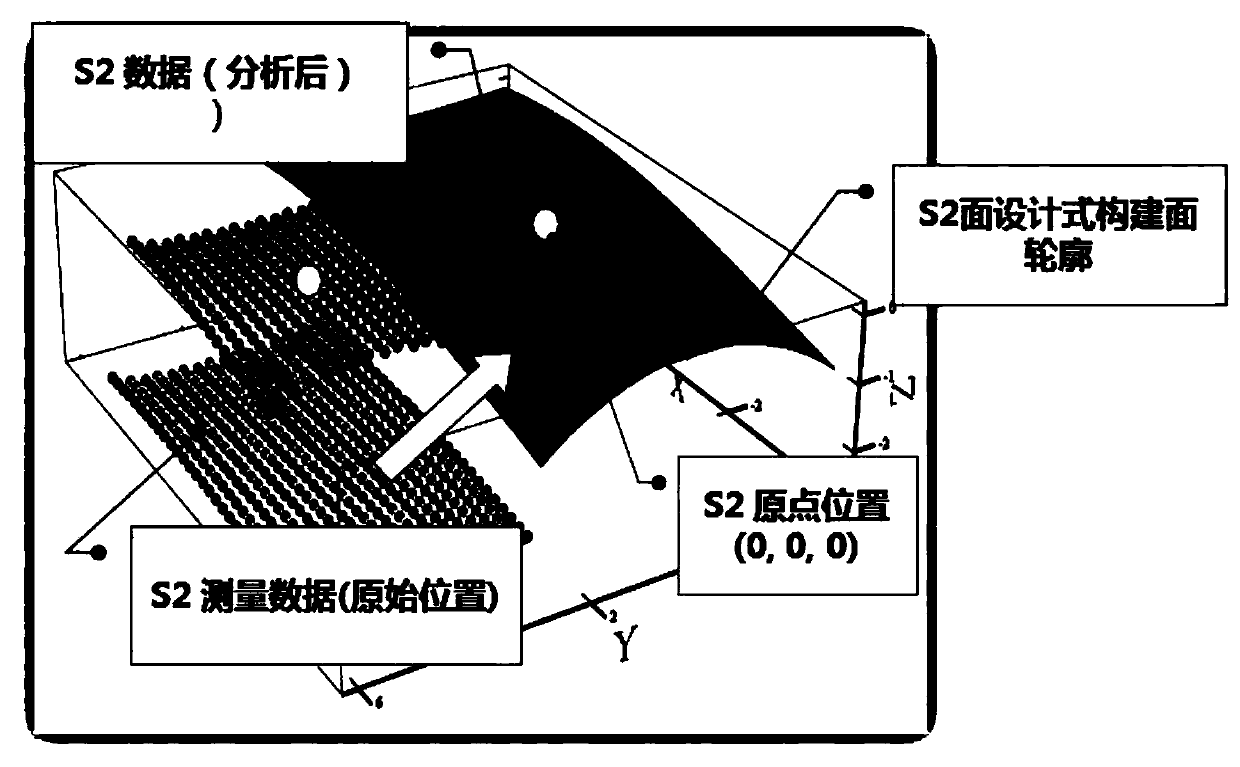

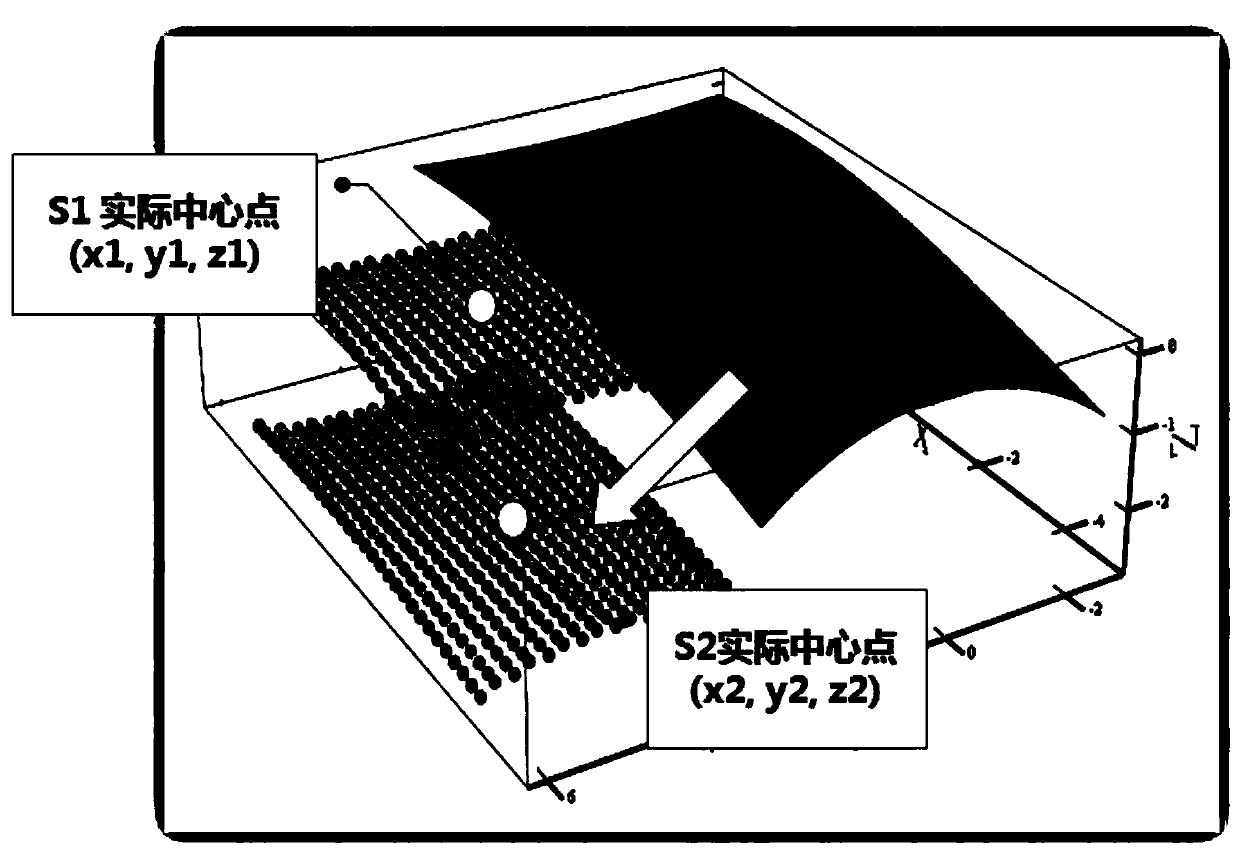

[0019] Such as Figure 1-3 As shown, a contact method for measuring the eccentricity of a free-form surface structure product includes the following steps:

[0020] Step 1, the product is clamped and fixed, and the coordinate system is established according to the product assembly structure;

[0021] Step 2: Offset the zero point of the probe according to the design theoretical position and insert the needle, scan the contour of the S1 surface, and output the coordinates of the S1 surface point;

[0022] Step 3: Offset the zero point of the probe according to the design theoretical position and insert the needle, scan the contour of the S2 surface, and output the coordinates of the S2 surface point;

[0023] Step 4: Bring the actual point coordinates of the S1 and S2 surface contours into the software Mathcad to fit the contours constructed by the S1 and S2 surface design equatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap