Method for measuring and processing thickness of gaskets on horizontal base

A technology of levelness and gasket, applied in the field of measuring the thickness of the gasket of the processing level base, can solve the problems of low processing quality and inaccurate measurement, and achieve the effect of improving the service life, ensuring the normal operation, and avoiding the problem of folding angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

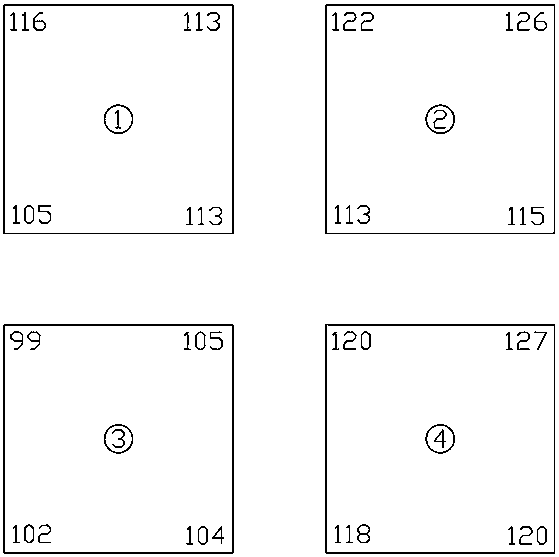

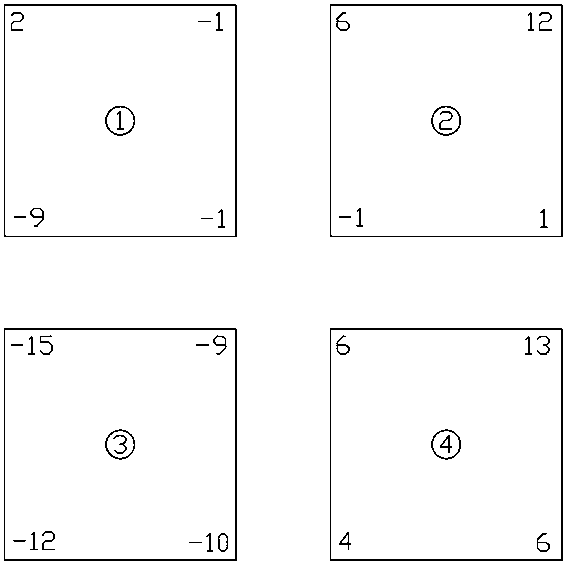

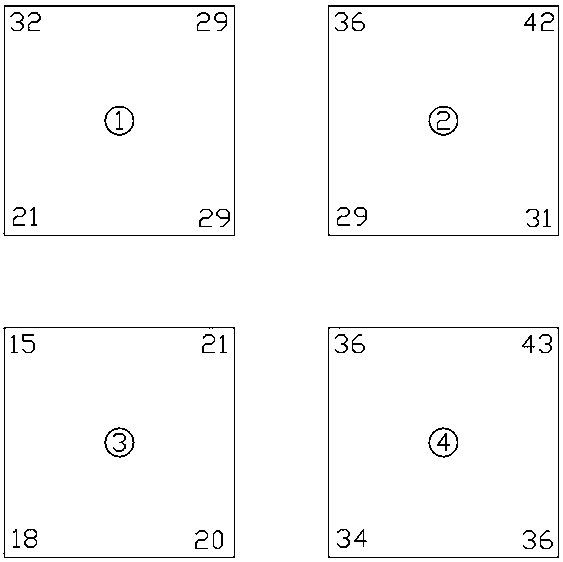

[0088] This embodiment is applied in the construction and installation process of the emergency generator base of a ship. The base of the generator is placed horizontally, and a base level is provided above the base. First set up the laser level, and then measure the height measurement results of the four corners of the four pads on the base panel, such as figure 1 shown. Then calculate the average value of 114mm, and then subtract this average value from all values to obtain the flatness of the base panel, such as figure 2 shown. After adding the theoretical thickness of the gasket 30mm, the theoretical size of the thickness of each gasket is obtained, such as image 3 As mentioned above, then adjust the size of the four corners to ensure that the lower surface of the gasket is on one side, which is the processing data of the gasket, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com