Air-tightness detection device for composite steel-plastic pipe fitting

A technology for air tightness detection and composite section steel, which is applied in the use of liquid/vacuum degree for liquid tightness measurement, by detecting the appearance of fluid at the leak point, etc. Excessive force and other problems, to achieve the effect of accurate detection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

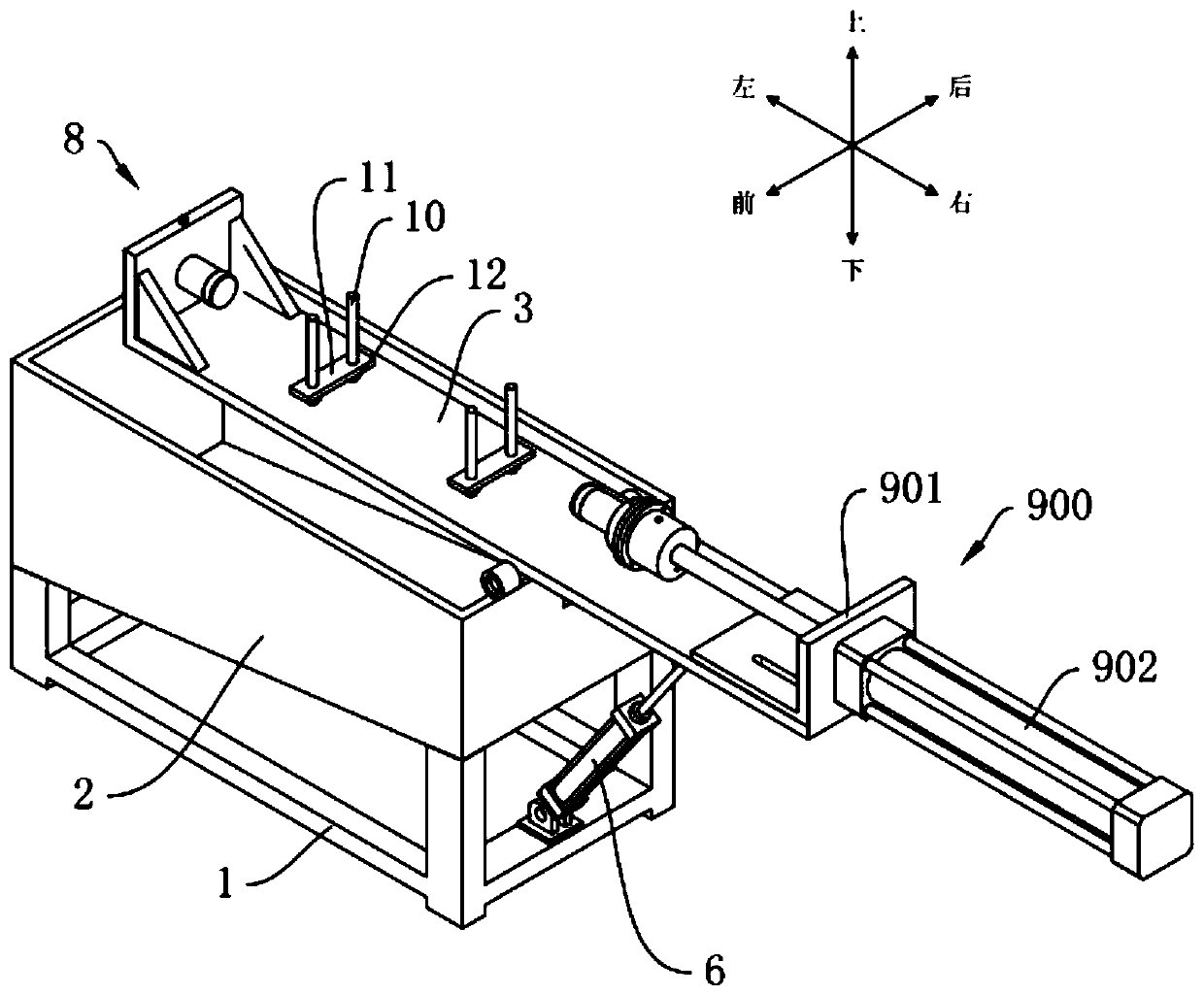

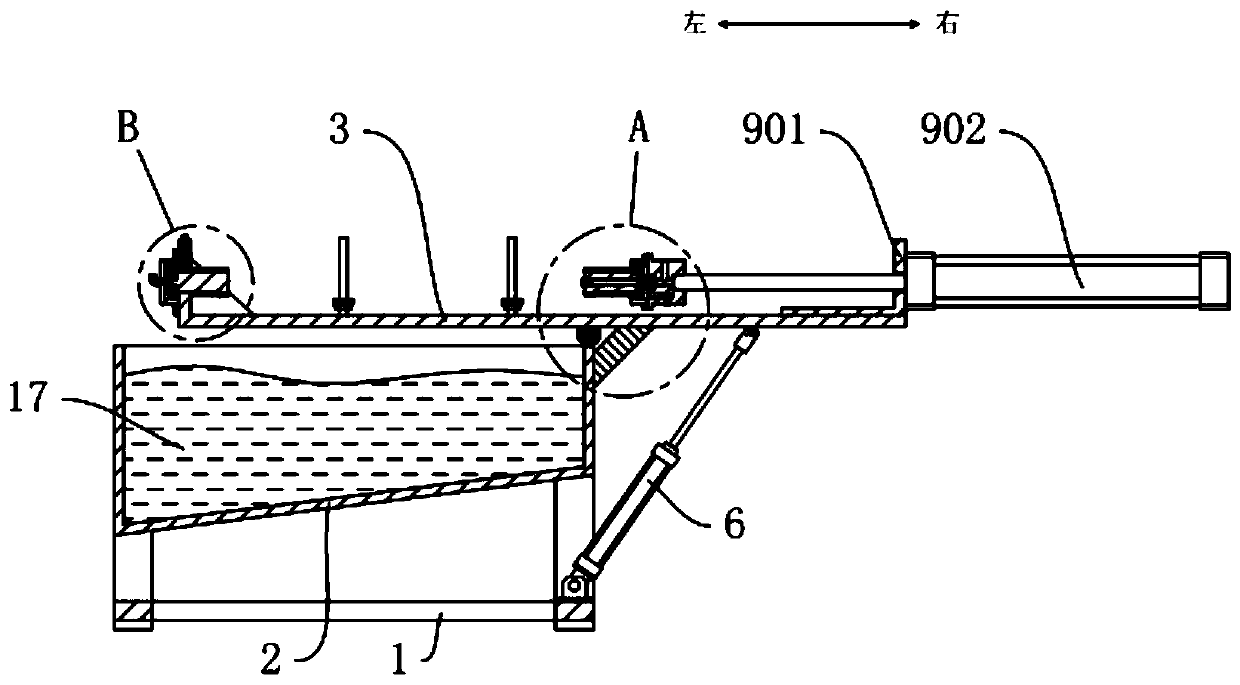

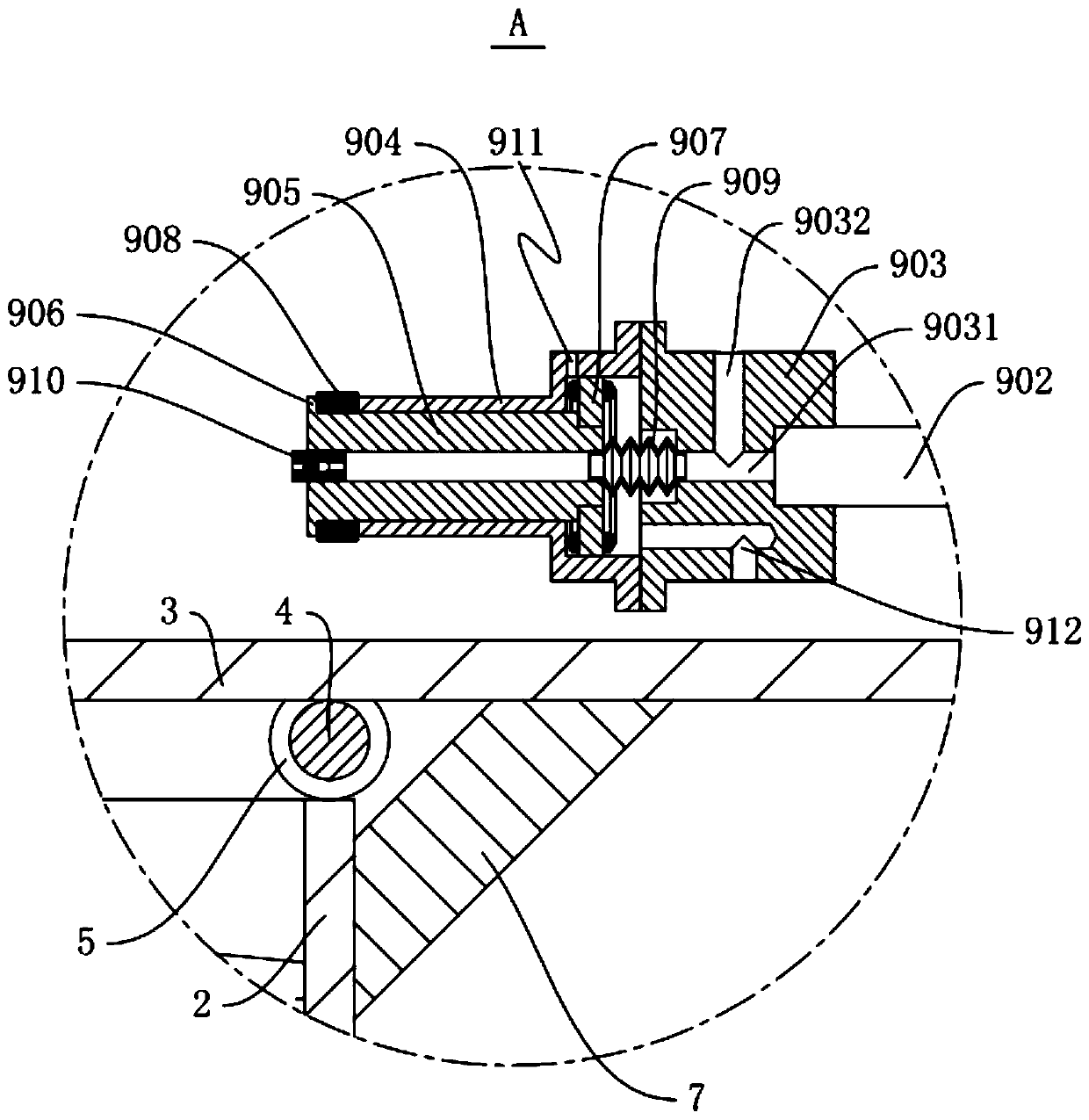

[0037] see figure 1 , figure 2 with image 3 , a composite type steel-plastic pipe fittings airtightness testing device, comprising a frame 1, a rectangular water tank 2 is welded on the frame 1, and the water tank 2 is filled with water 13 for testing the tightness of the steel-plastic conversion joint. A rectangular rotating plate 3 is pivotally connected to the short side on the right side of the opening end of the water tank 2. The lower end surface of the rotating plate 3 is welded with a pivot shaft 4, and the corresponding short side of the opening end of the water tank 2 is welded with a sleeve matching the pivot shaft 4. 5. The width of the rotating plate 3 is smaller than the width of the opening of the water tank 2, the axis of the pivot shaft 4 is parallel to the width direction of the rotating plate 3, the left short side of the rotating plate 3 is located inside the opening of the water tank 2, and the right side of the rotating plate 3 The short side is locat...

Embodiment 2

[0046] see Figure 5 , a composite airtightness detection device for steel-plastic pipe fittings. The difference between this embodiment and Embodiment 1 is that a V-shaped groove is provided on the upper end surface of the pallet 11, which is convenient for the automatic centering of the steel-plastic pipe fittings placed on the pallet 11. ; On the cylinder mounting plate 901, a linear bearing is also installed, and the piston rod of the cylinder two 902 is slidably connected in the linear bearing, which can ensure that the cylinder seat 904 driven by the piston rod of the cylinder two 902 runs more smoothly and can be inserted more accurately The steel-plastic pipe fittings are sealed inside.

Embodiment 3

[0048] A composite type steel-plastic pipe fitting airtightness detection device, the difference between this embodiment and embodiment 1 or embodiment 2 is that, see Image 6 , the expansion sealing ring 1 806 is hollow, and the middle part of the outer wall and the middle part of the inner wall of the expansion sealing ring 806 protrude radially outward to form an arc surface. When the expansion sealing ring 1 806 is squeezed by the pressure block 804, it is easy to expand The middle part of sealing ring one 806 expands radially outward to realize sealing, and the middle part of the inner wall of expansion sealing ring one 806 also protrudes to form a circle of reinforcement ring 8061, which is used to improve the structural strength of expansion sealing ring one 806 and prolong its service life. see Figure 7 , the structure of the second expansion sealing ring 908 is the same as that of the first expansion sealing ring 806 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com