An intelligent lock production test method

A technology for production testing and smart locks, which is used in functional inspection and detection of faulty computer hardware and instruments. It can solve the difficulty of saving test information, the inability to display test results intuitively, and the difficulty in collecting and sorting for quality retrospective and process improvement. and other problems to achieve the effect of improving test coverage, saving labor costs and time costs, and increasing the probability of finding defects

Inactive Publication Date: 2019-06-21

广州技象科技有限公司

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] b) Limited by the hardware resources of the electronic lock itself, the test results cannot be displayed intuitively;

[0010] c) It is difficult to save the test information, and it is difficult to collect and organize it for quality traceability and process improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

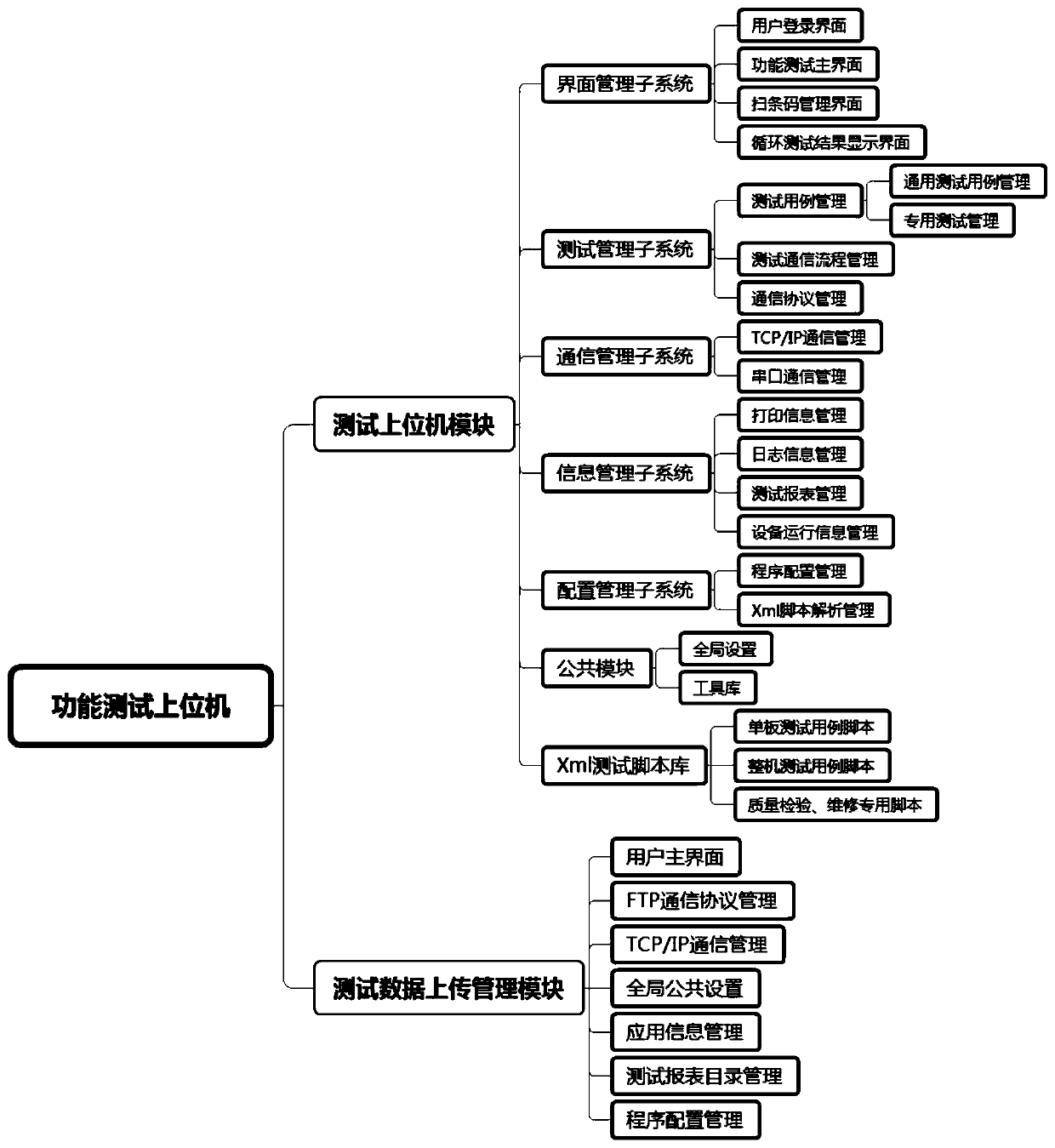

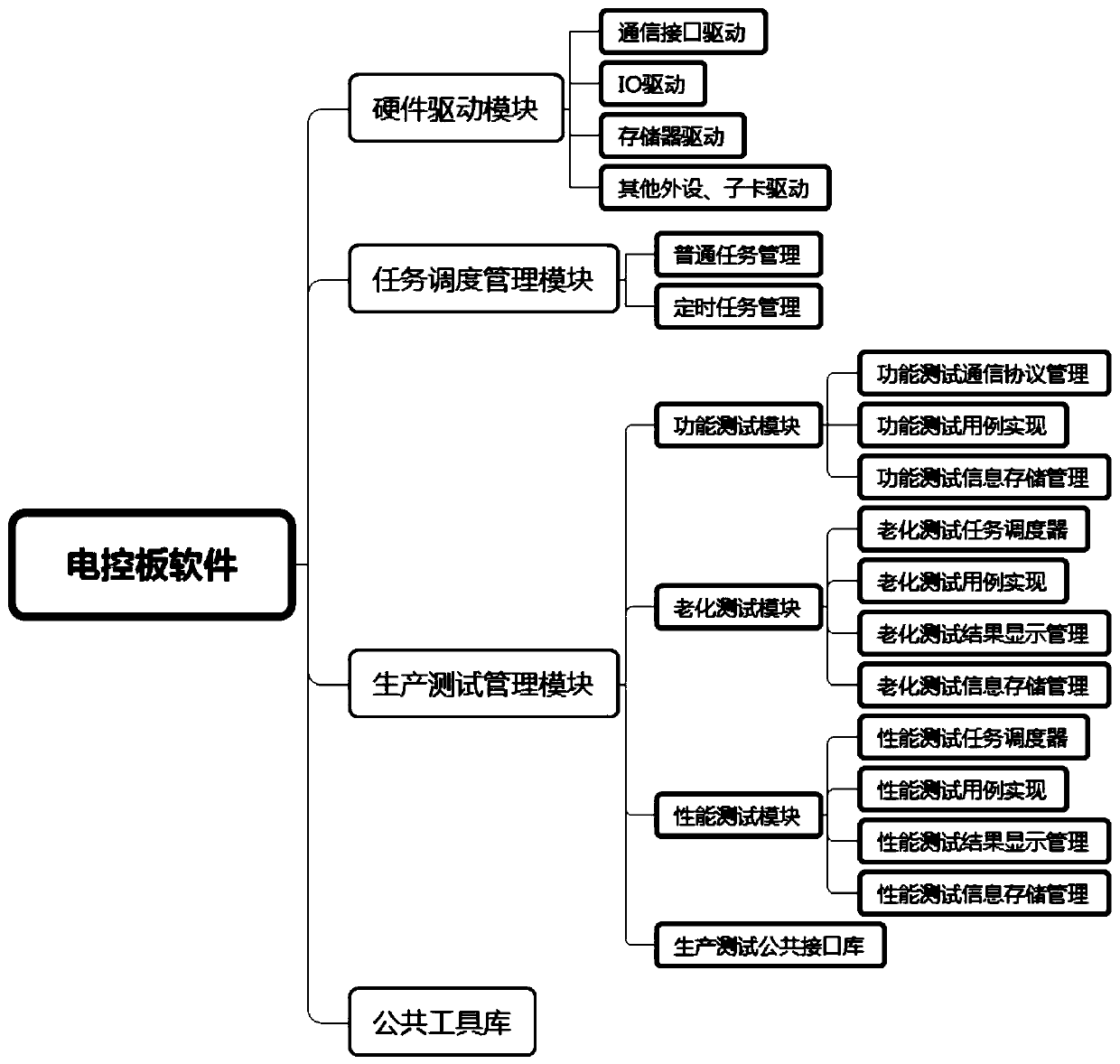

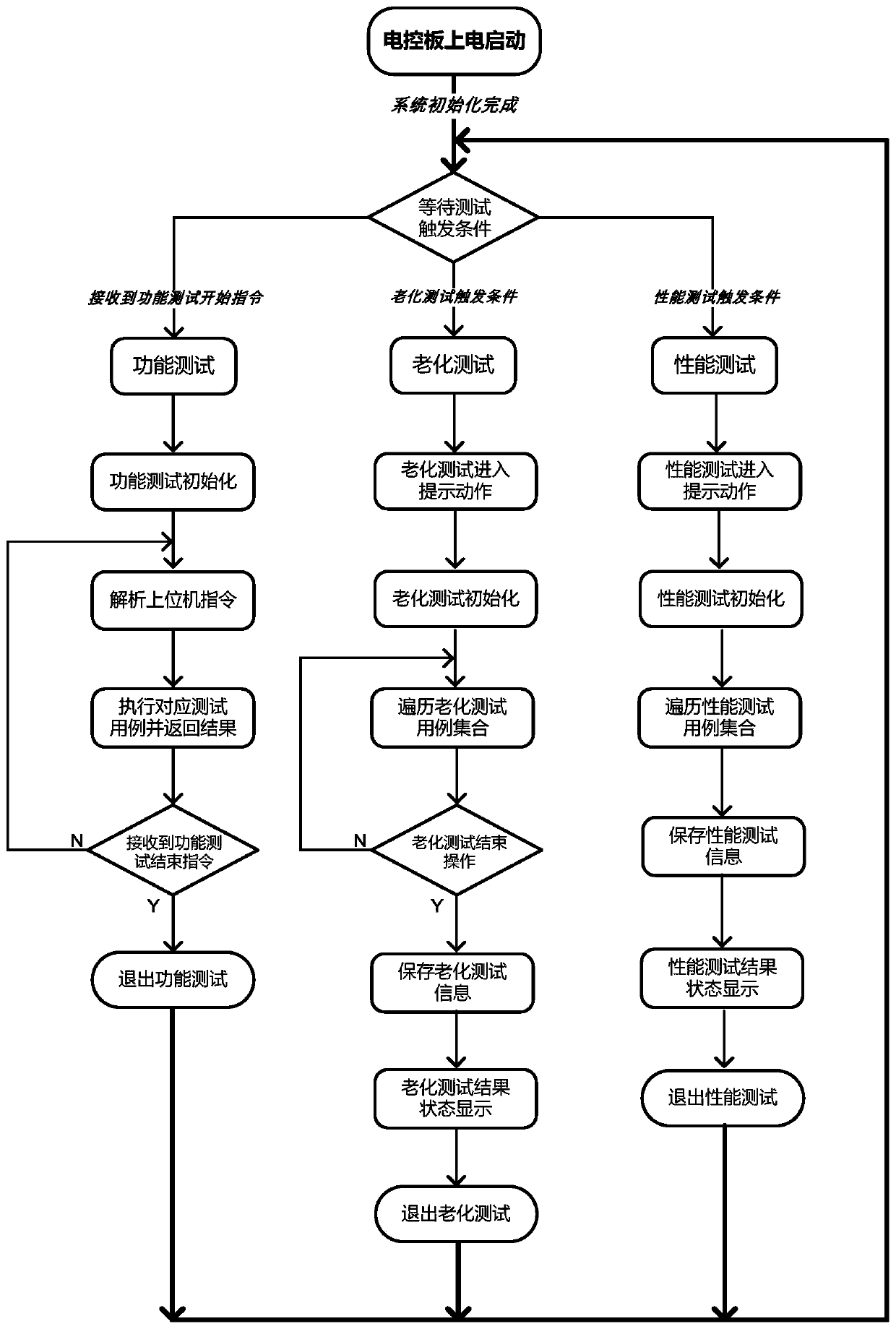

[0079] Such as Figure 1-14 As shown, a kind of smart lock production testing method of the present embodiment comprises the following steps:

[0080] S1. In the PCBA stage of the smart lock electric control board, the online test method is used for functional testing;

[0081] S2. After the function test is performed, the aging test is carried out in an offline test mode;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an intelligent lock production test method. The method comprises the following steps: S1, carrying out function test in an on-line test mode in a PCBA stage of an intelligent lock electric control board; S2, after the function test is carried out, carrying out an aging test in an offline test mode; And S3, carrying out performance test on the assembled intelligent lock in an offline test mode. The test efficiency is greatly improved; A more precise test can be realized by using special test software, so that the test coverage rate is improved, and the probability of finding defects is increased; The test standardization degree is very high, and the condition of test leakage or false test caused by negligence of testers or misoperation is greatly reduced; The operation is simple, and the requirement on the professionality of testers is reduced; The requirement for high efficiency of mass testing is met, and the requirement for test data refinement is also met; And a three-in-one electric control board test software scheme is adopted, so that the procedure of burning for multiple times is avoided, and the production cost is saved.

Description

technical field [0001] The invention belongs to the field of electronic testing equipment, and in particular relates to a production and testing method for an intelligent lock. Background technique [0002] Existing smart lock production testing mainly relies on manual testing or testing using the embedded software program of the lock itself. [0003] Among them, manual testing has the following disadvantages: [0004] a) Manual operation is inefficient and requires a lot of time and manpower; [0005] b) The error rate of manual operation is high, and it is easy to introduce missed detection and misjudgment of human operation; [0006] c) It is difficult to unify the test standards, and different testers may get different results when testing. [0007] There are the following disadvantages in the embedded software program testing of the smart lock itself: [0008] a) Adding a test module to the embedded software program of the smart lock will occupy the scarce hardware ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F11/22G06F11/26G07C9/00

Inventor 刘毅

Owner 广州技象科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com