Fuel assembly and spacer

A technology for positioning grids and fuel assemblies, applied in the field of nuclear power, can solve problems such as scratches, affecting the structural integrity of fuel rods, and prone to abrasion in the contact area, so as to avoid scratches, reduce the risk of abrasion, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

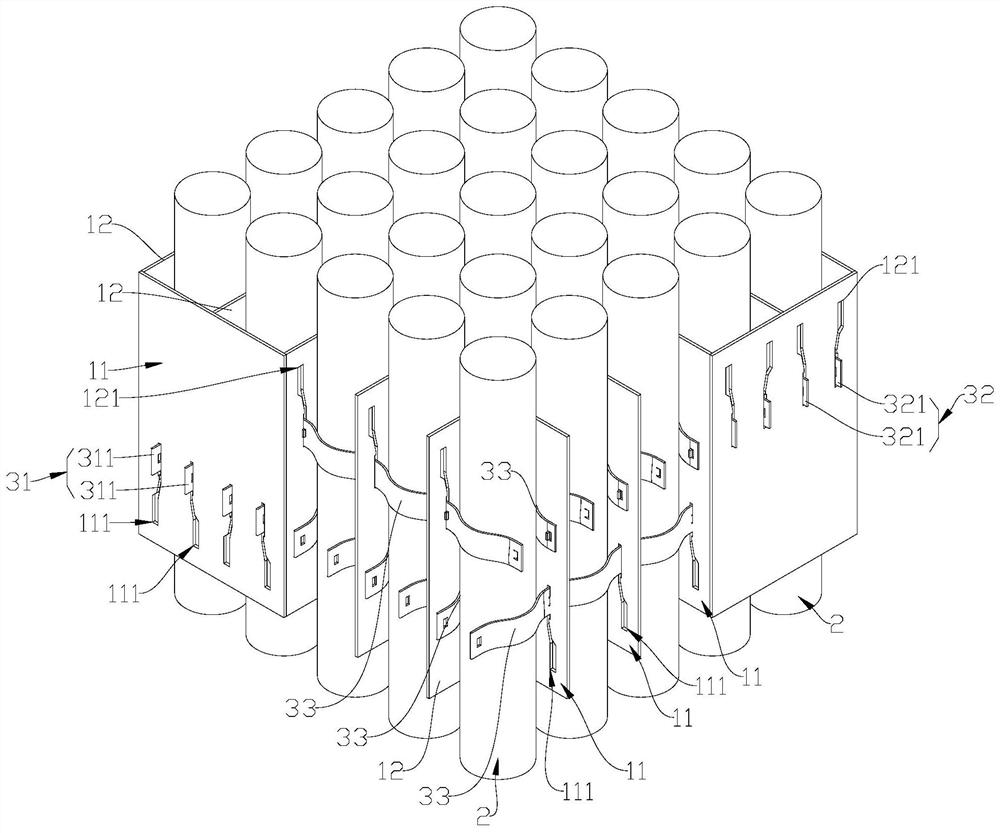

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

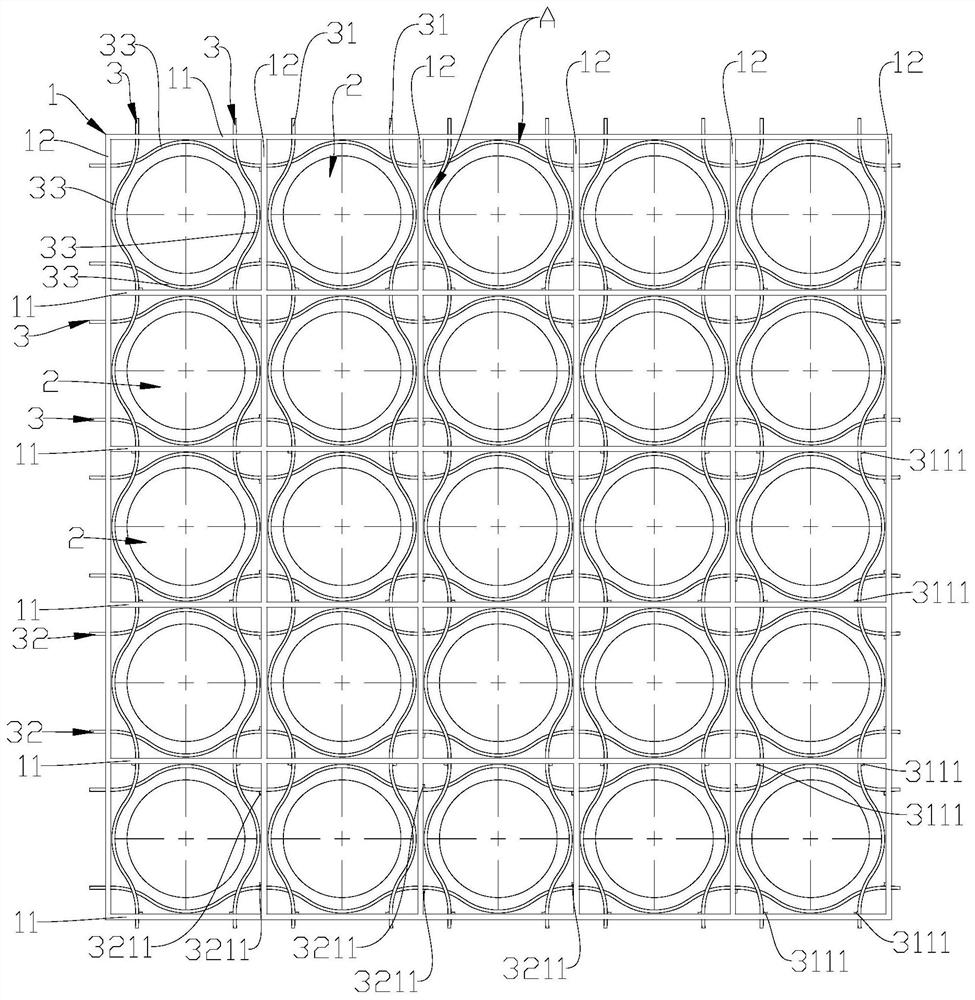

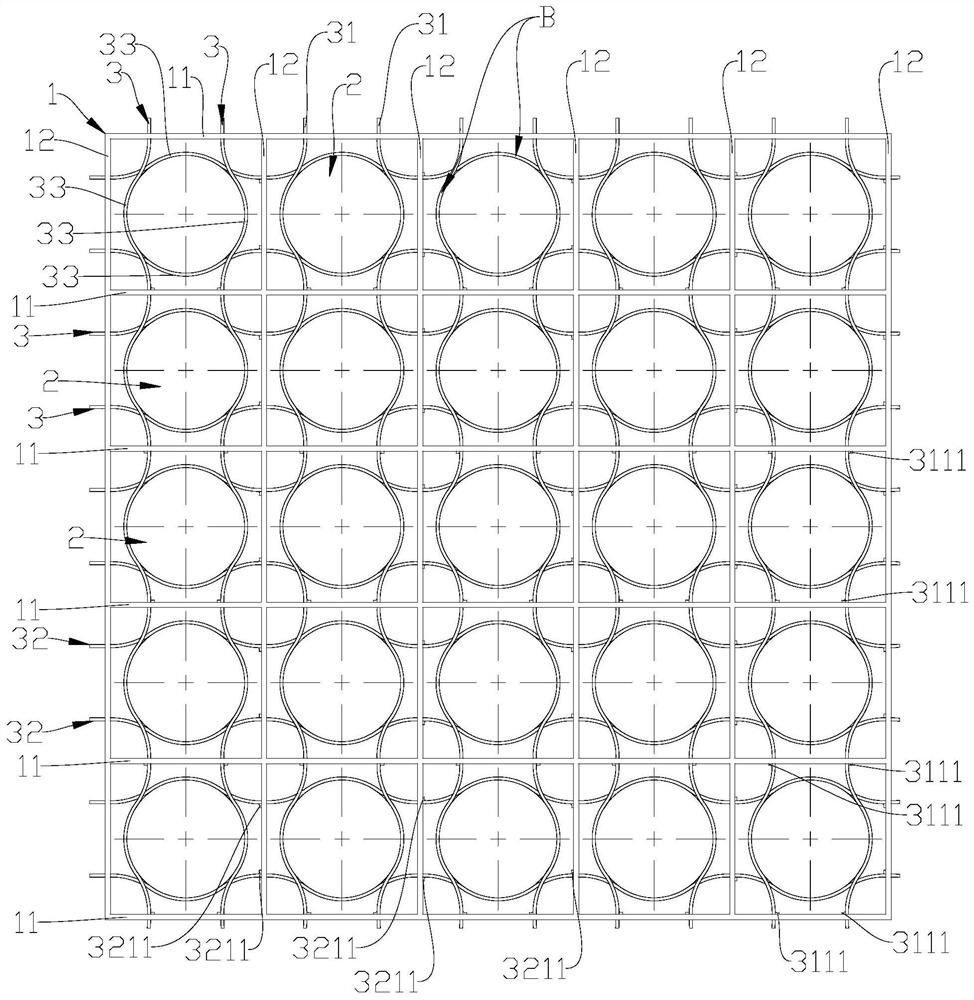

[0046] Such as Figure 1 to Figure 3 As shown, the fuel assembly in a preferred embodiment of the present invention includes a spacer grid 1 and a fuel rod 2, and the spacer grid 1 includes a plurality of first strips 11 arranged side by side at intervals and a plurality of second strips 12 arranged at intervals side by side, The first strip 11 and the second strip 12 cross each other to form a plurality of grids for the fuel rods 2 to pass through.

[0047] Further, the positioning grid 1 further includes an elastic clamping mechanism 3, and the elastic clamping mechanism 3 includes clamping portions 33 located in each grid.

[0048] The clamping portion 33 of the elastic clamping mechanism 3 can be switched between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com