A plasma processing device and method for balancing etching rate

An etching rate and plasma technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problems of reduced surface height of the focus ring, uneven etching rate, and influence of wafer etching process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] based on the following Figure 2 to Figure 5 , specifically explain the preferred embodiment of the present invention.

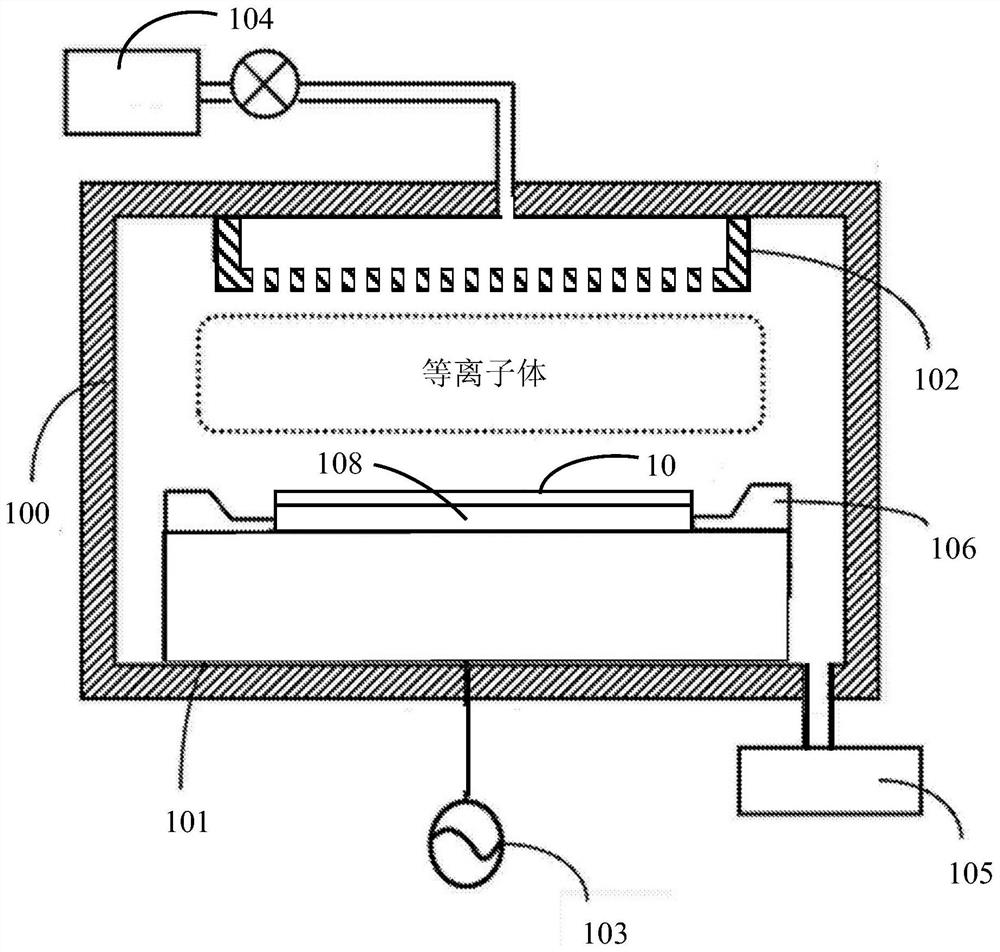

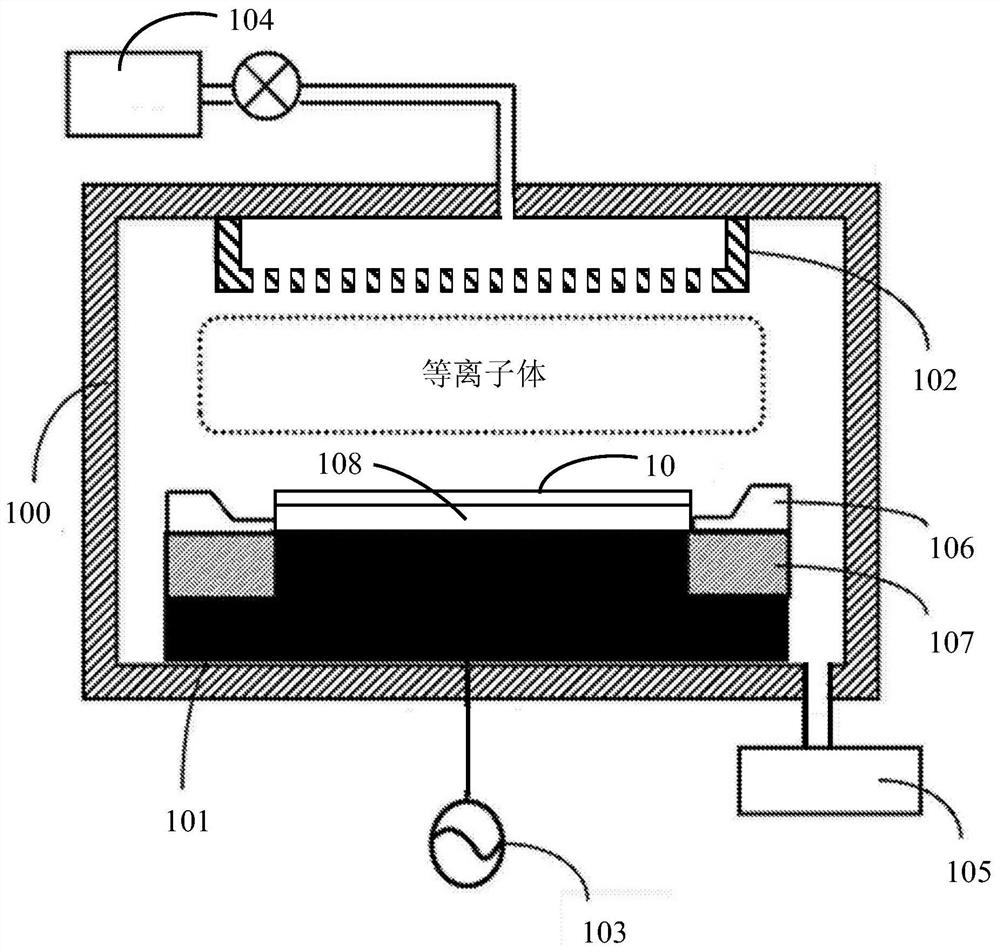

[0025] like figure 2 As shown, the plasma processing device includes a reaction chamber 100, and the reaction chamber 100 is provided with an upper electrode 102 and a lower electrode 101 arranged parallel to each other, and the upper electrode 102 is connected to a reaction gas source 104, and the gas in the reaction gas source 104 passes through the upper electrode 102 is uniformly injected into the interior of the reaction chamber 100. A radio frequency power source 103 is applied on the lower electrode 101, and the radio frequency power source 103 forms a high radio frequency energy field between the upper electrode 102 and the lower electrode 101, and dissociates the reaction gas injected into the reaction chamber 100 into the plasma required for the process , etch the wafer 10 . The lower electrode 101 is also used as a base for supporting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com