Improved method for manufacturing a hybrid structural part of a motor vehicle and corresponding hybrid structural part

A technology of hybrid structure and manufacturing method, applied in the direction of vehicle components, superstructure, superstructure sub-assembly, etc., can solve problems such as lack of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

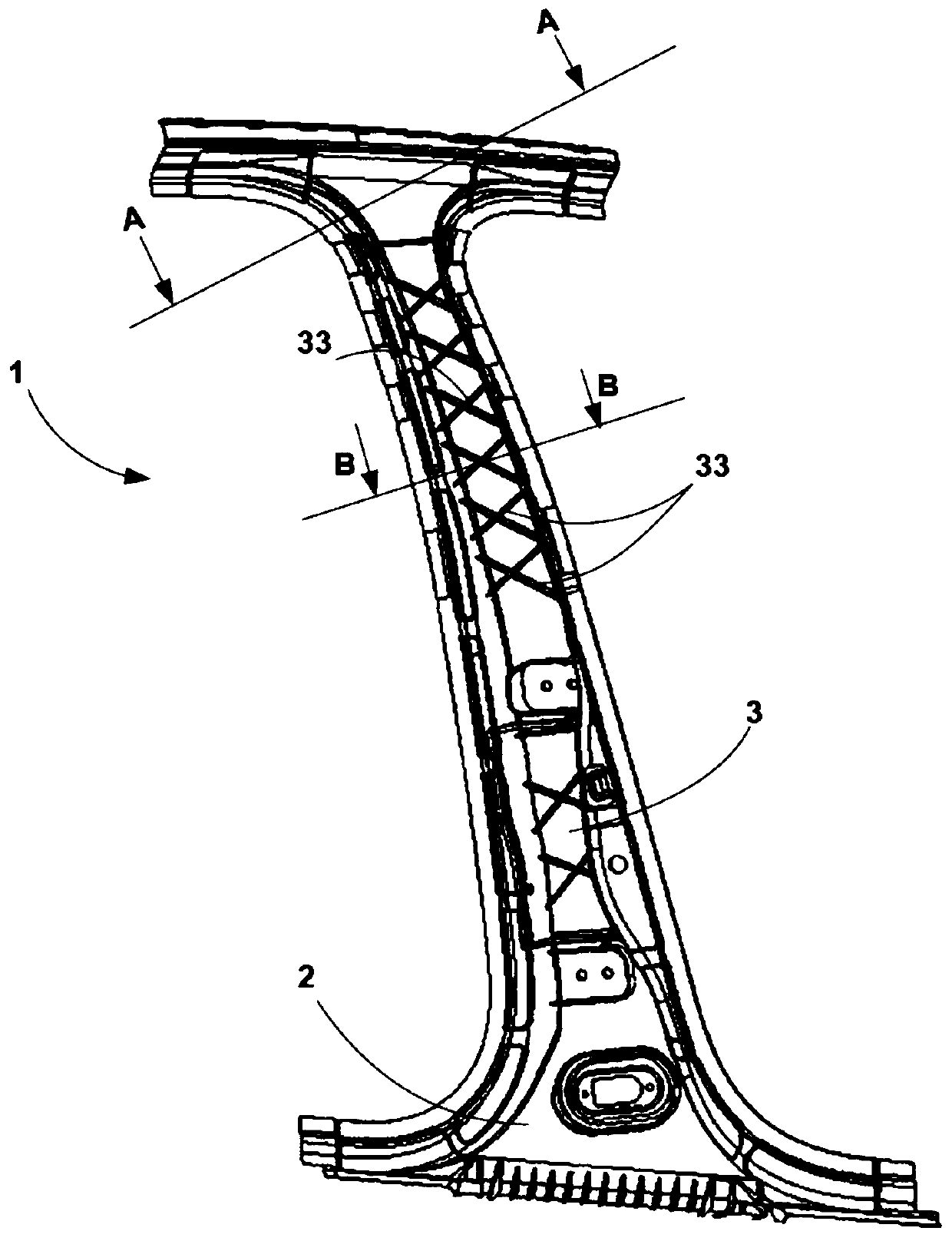

[0044] exist figure 1 The center pillar 1 shown in includes a profiled metal part 2 on which a layer 3 of thermoplastic or thermosetting material is molded. Ribs 33 made of thermoplastic or thermosetting material are locally arranged to reinforce the structure of the metal part 2 by increasing the overall inertia of the hybrid structure, wherein said ribs result from the same molding operation and are of the same material as the molded layers. continuously. When the metal part 2 has a recess, ribs made of thermoplastic or thermosetting material are advantageously arranged in the recess in order to limit the opening or closing of the recess to a large extent under the effect of impact. The ribs 33 can have a longitudinal or transverse orientation, or be formed as figure 1 The cruciform shown.

[0045] The forming of the sheet metal for producing the metal part 2 in step a is preferably carried out by cold stamping or hot stamping. The sheet metal is in the form of a plate h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com