Production line of absorbable core

A production line and absorbent core technology, applied in absorbent pads, clothing, underwear, etc., can solve problems such as unfavorable product promotion, increased production process, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now, the present invention will be further described in detail in conjunction with the accompanying drawings and preferred embodiments.

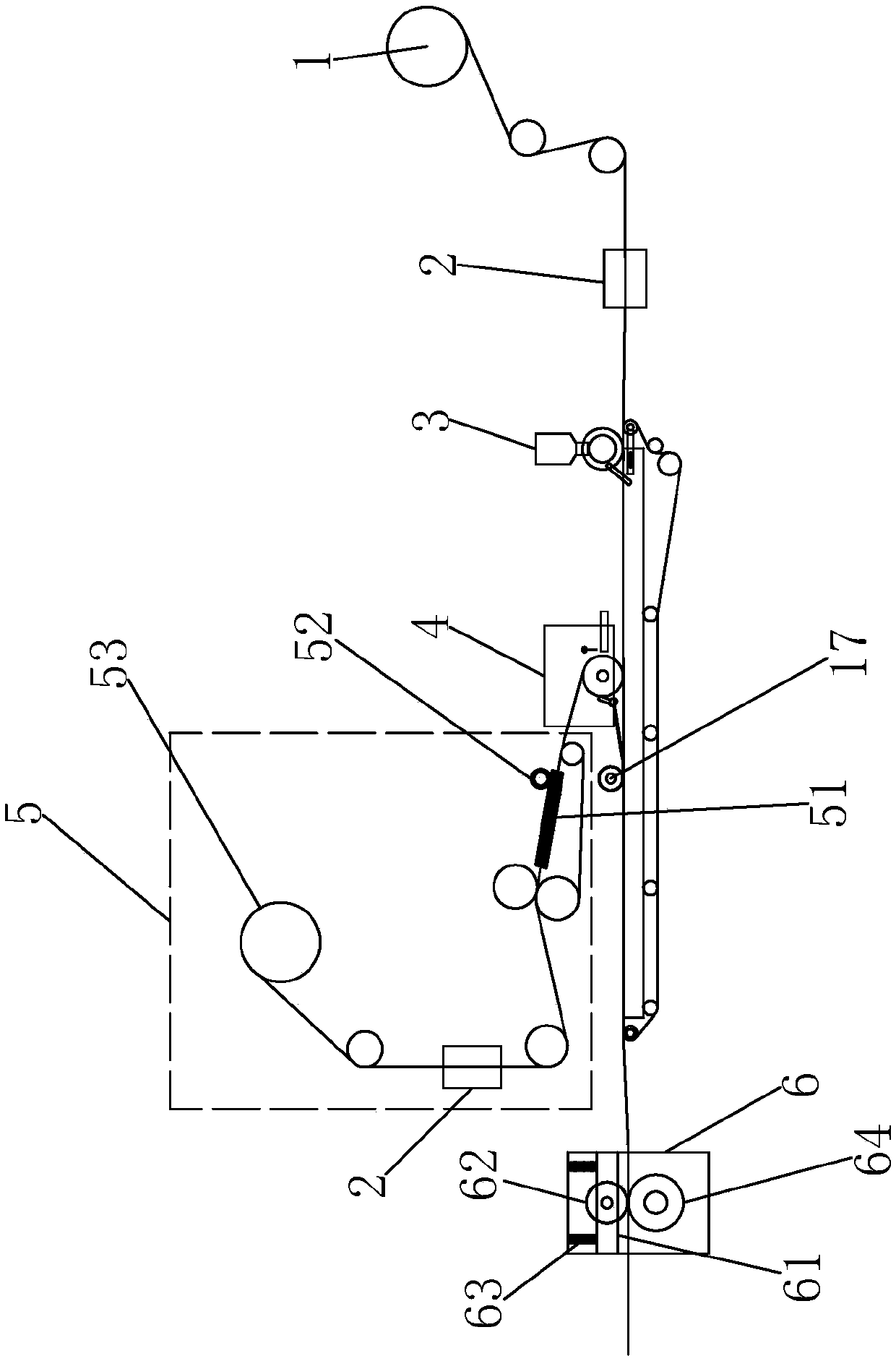

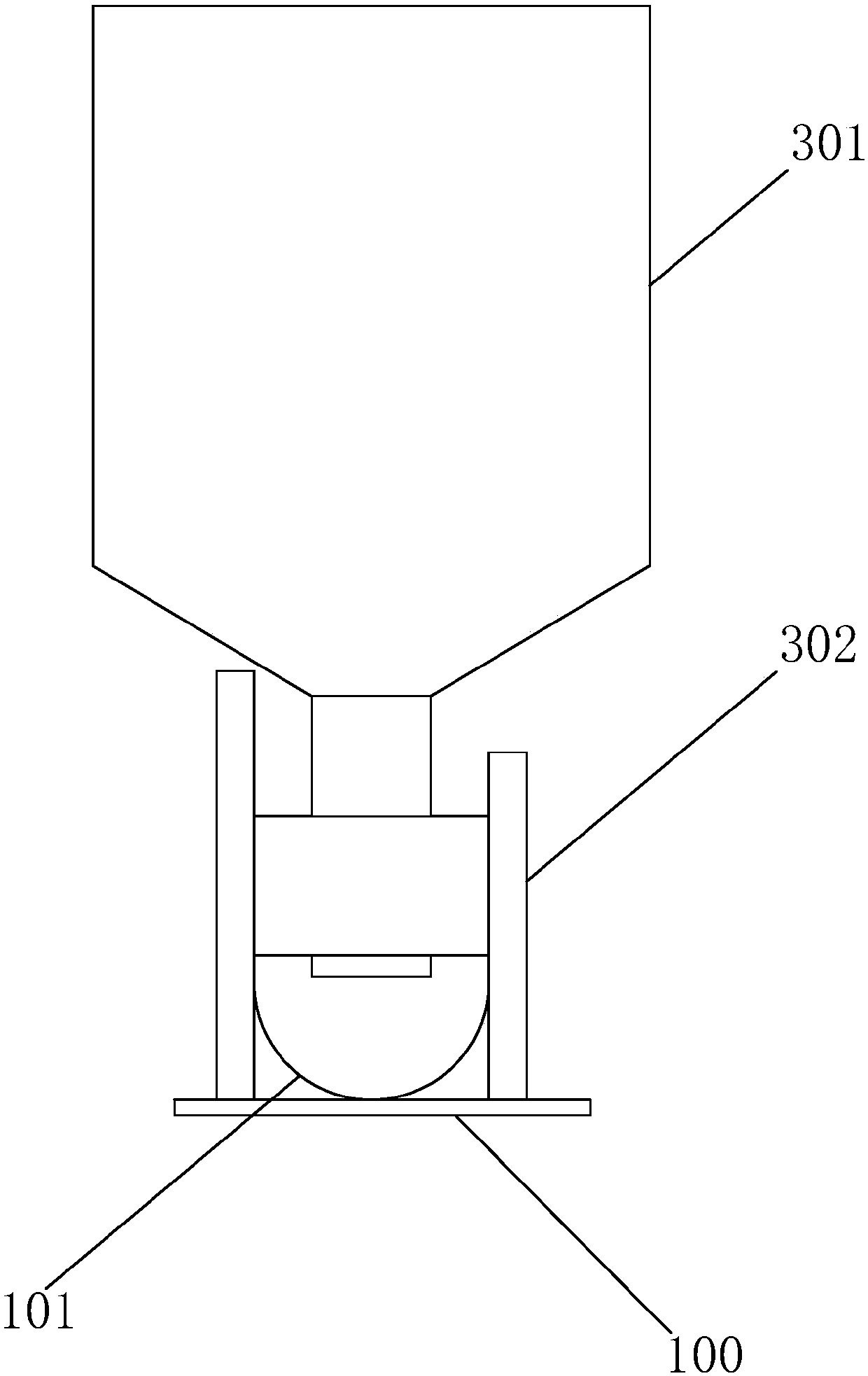

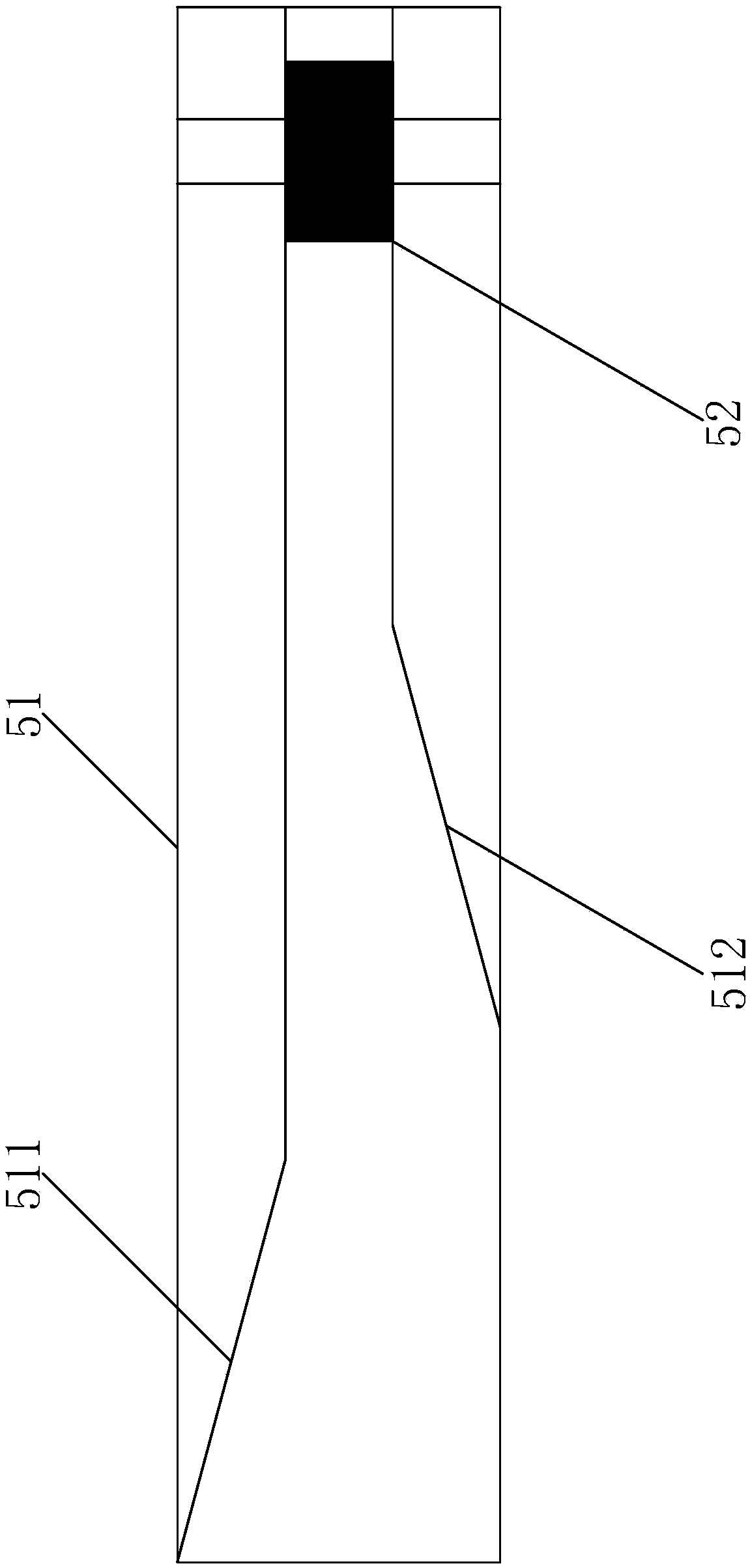

[0020] A production line for absorbent cores such as figure 1 As shown, including the conveying line 100, the first material roller 1, the flattening mechanism 2, the fluff pulp injection mechanism 3, the cutting mechanism 4, the first pressing roller 17, the blanking The mechanism 6 also includes a narrow paper feeding device 5 arranged above the blanking mechanism 6 .

[0021] The first material roll 1: the wide paper 101 is stored on the first material roll 1, and the wide paper 101 is transported to the flattening mechanism 2 through the combined structure of the conveying roller and the guide roller.

[0022] Flattening mechanism 2: The flattening mechanism 2 is equipped with a sheet-shaped passing port, so that the wide paper 101 passes through the sheet-shaped passing port and then flattened, and then transported to the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com