Environmental-friendly edible straw and preparation method thereof

A straw and environmental protection technology, applied in the field of environmentally friendly edible straws, can solve the problems of inability to use edible taste, unenvironmental straws, and high production costs, and achieve the effects of improving taste and using experience, low cost, and reducing production costs and use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

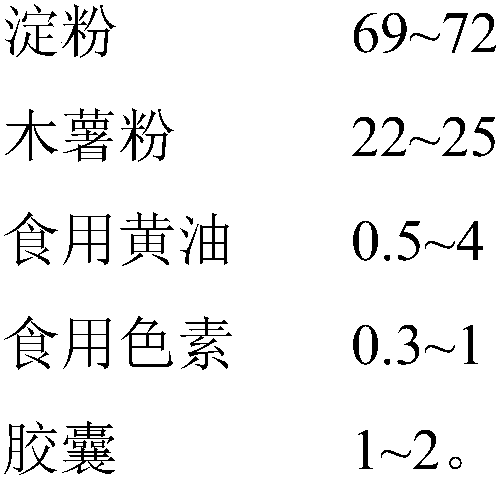

[0021] Embodiment 1: This embodiment provides an environmentally friendly edible straw, which is prepared from the following parts by weight:

[0022]

[0023] The starch is corn starch, rice starch or flour.

[0024] The capsule is edible gelatin.

[0025] It is a hollow tubular structure with a circular or oval interface.

[0026] The thickness of the tube wall is 0.4mm-2mm.

[0027] A preparation method of the environment-friendly edible straw, which comprises the following steps:

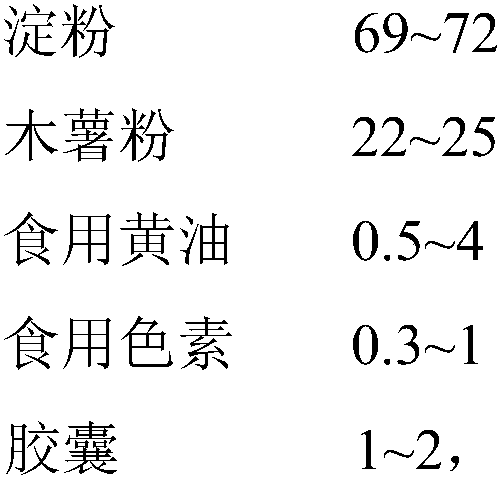

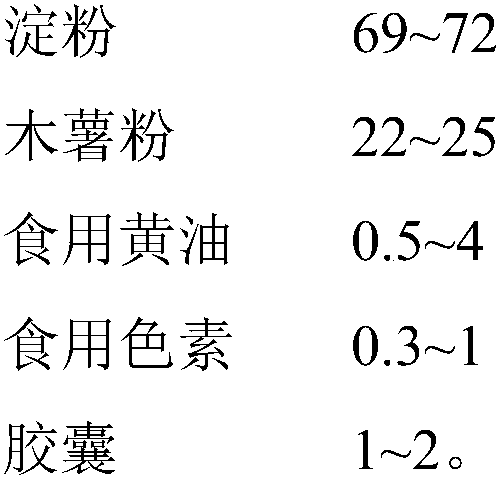

[0028] (1) Prepare each component according to the following parts by weight:

[0029]

[0030] (2) Mix and stir prepared starch, tapioca flour, edible butter, food coloring and capsules evenly;

[0031] (3) Prepare straw extrusion molding equipment;

[0032] (4) Place the mixture mixed in step (2) in the straw extrusion molding equipment, and carry out extrusion molding at a temperature of 80°C to 140°C and an extrusion pressure of 4MPa to 10MPa to obtain a pipe wall Finished produc...

Embodiment 2

[0035] Embodiment 2: This embodiment provides an environmentally friendly edible straw and its preparation method. Its components and steps are basically the same as those in Embodiment 1, except that:

[0036] An environmentally friendly edible straw is prepared from the following parts by weight:

[0037]

[0038] A preparation method of the environment-friendly edible straw, which comprises the following steps:

[0039] (1) Prepare each component according to the following parts by weight:

[0040]

[0041] (2) Mix and stir prepared cornstarch, tapioca flour, edible butter, food coloring and capsules evenly;

[0042] (3) Prepare straw extrusion molding equipment;

[0043] (4) Place the mixture mixed in step (2) in the straw extrusion molding equipment, and carry out extrusion molding at a temperature of 80°C and an extrusion pressure of 4MPa to obtain a pipe wall thickness of 0.4mm- 2mm finished product;

[0044] (5) after the semi-finished product in the step (4)...

Embodiment 3

[0046] Embodiment 3: This embodiment provides an environmentally friendly edible straw and its preparation method. Its components and steps are basically the same as those in Embodiments 1 and 2, except that:

[0047] An environmentally friendly edible straw is prepared from the following parts by weight:

[0048]

[0049] A preparation method of the environment-friendly edible straw, which comprises the following steps:

[0050] (1) Prepare each component according to the following parts by weight:

[0051]

[0052] (2) Mix and stir the prepared rice starch, tapioca flour, edible butter, food coloring and capsules evenly;

[0053] (3) Prepare straw extrusion molding equipment;

[0054] (4) Place the mixture mixed in step (2) in the straw extrusion molding equipment, and carry out extrusion molding at a temperature of 100°C and an extrusion pressure of 7MPa to obtain a pipe wall thickness of 0.4mm- 2mm finished product;

[0055] (5) after the semi-finished product in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com