Squeeze-expansion type steel pipe pile

A technology of steel pipe piles and pipe piles, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of unfavorable pile sides and soil bearing performance at pile ends, and achieve overall function improvement, improve lateral resistance, and pile The effect of strong body carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0021] see Figures 1 to 4 As shown, an extruded and expanded steel pipe pile involved in this embodiment includes:

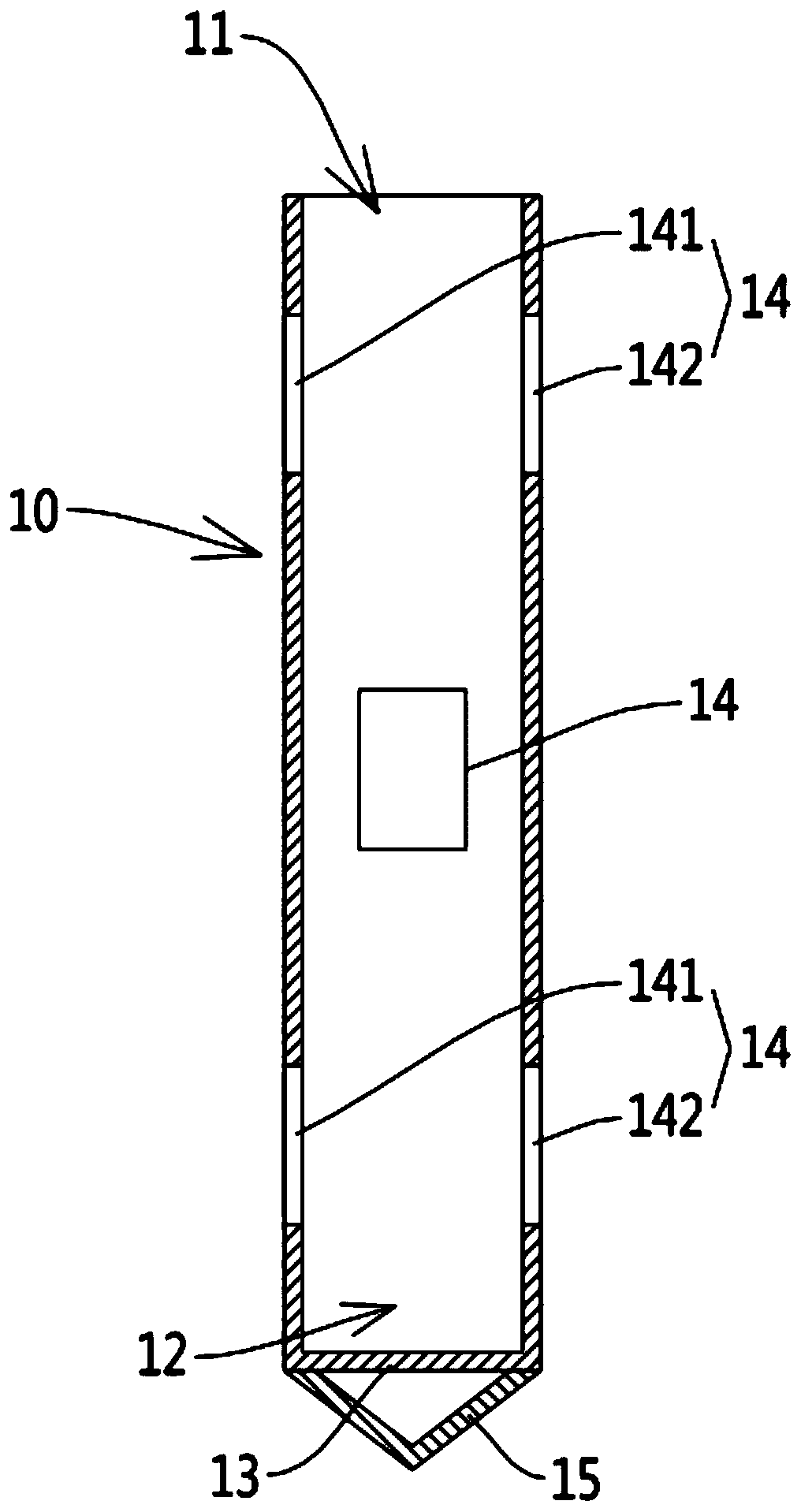

[0022] Pipe pile main body 10, the pipe pile main body 10 is a tubular structure extending from bottom to top. Sealing plate 13, the side wall of the pipe pile main body 10 is provided with a number of extrusion and expansion hole groups 14 from bottom to top, the extrusion and expansion hole groups 14 are arranged in sequence along the height direction of the pipe pile main body 10, and the extrusion and expansion holes Group 14 includes an extruded expansion hole 1 141 opened on the side wall of the pipe pile main body 10 and an extruded expansion hole 2 142 opposite to the extruded expansion hole 1 141;

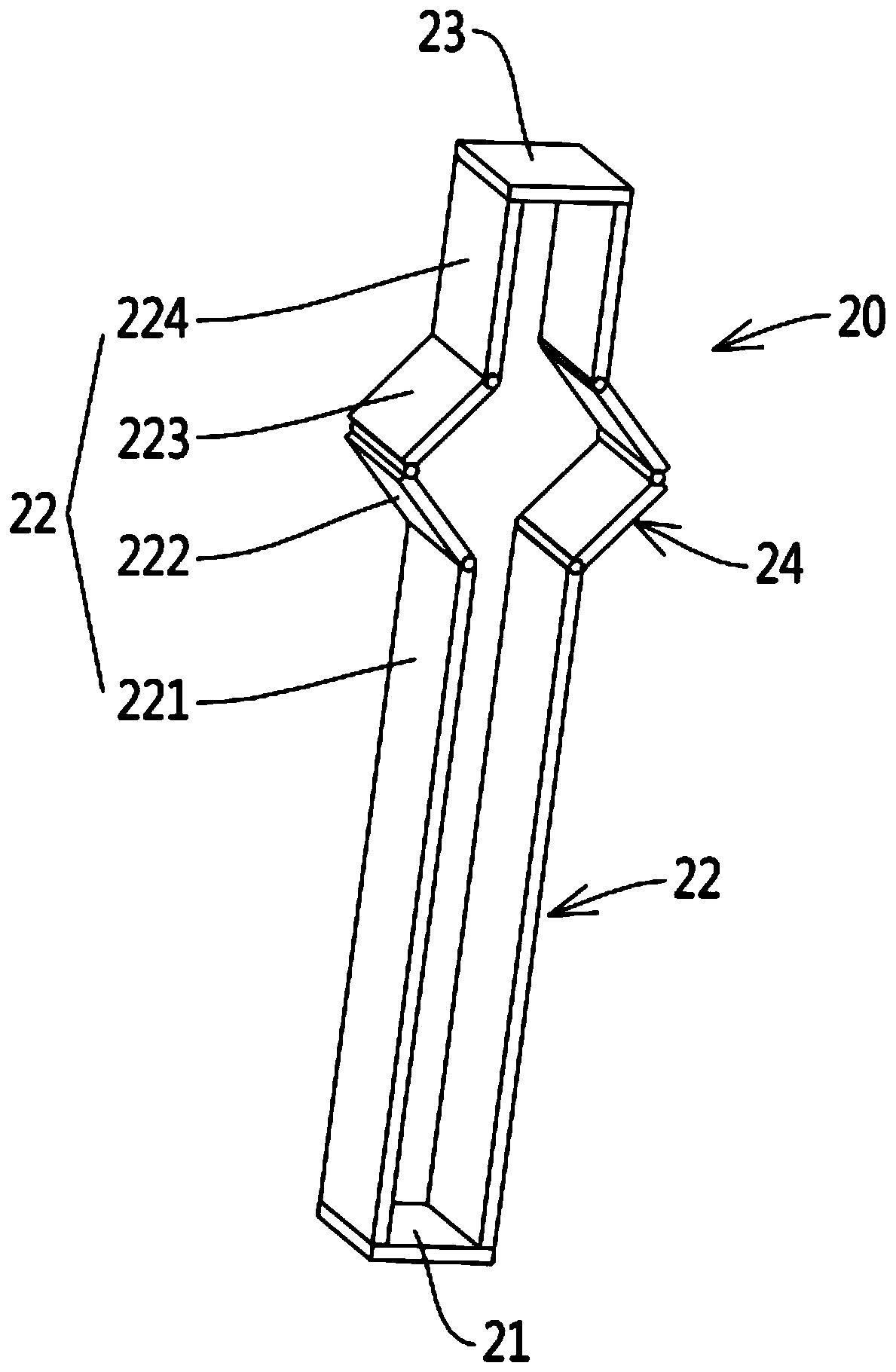

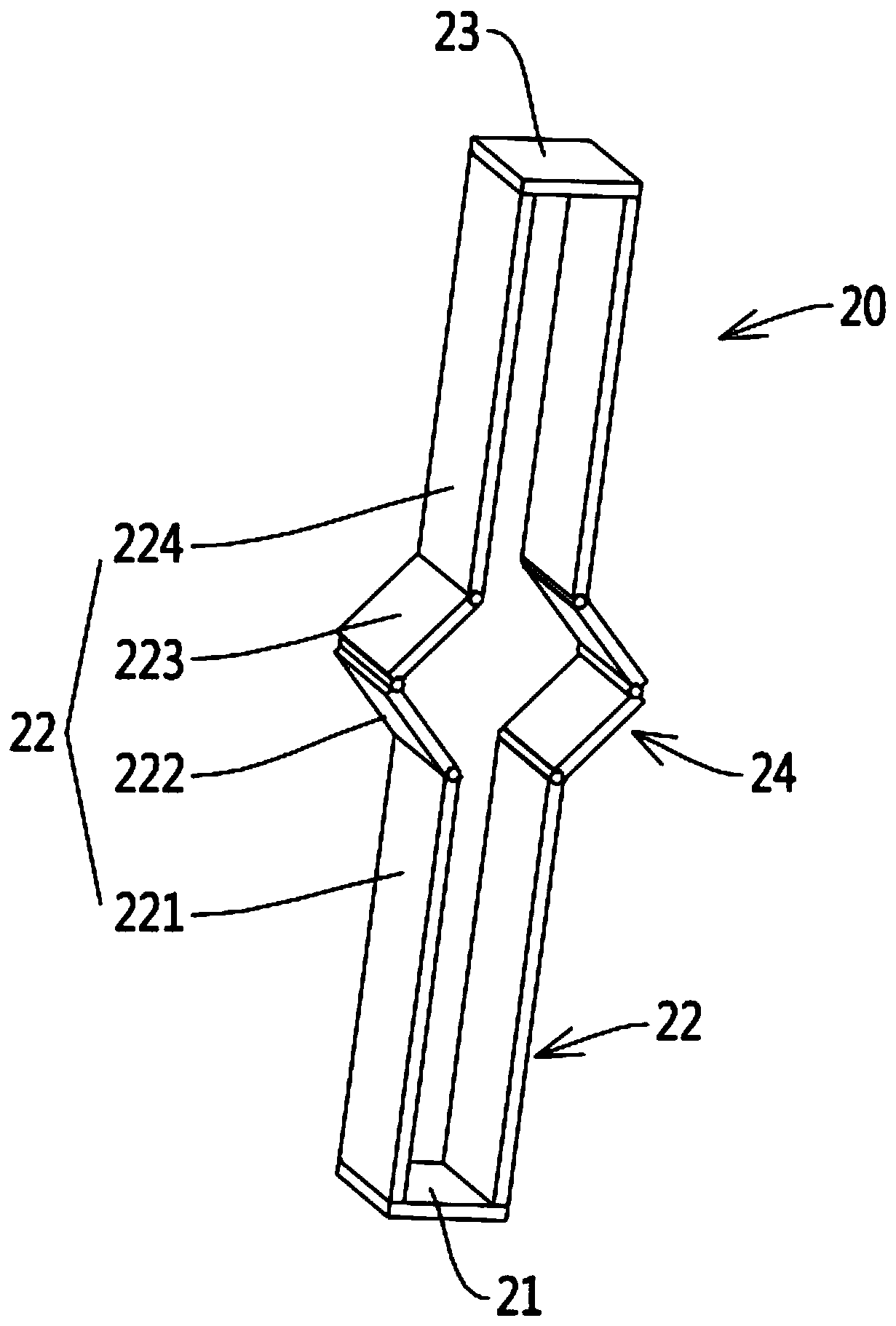

[0023] The extrusion assembly 20 has the same number as the group number of the extrusion hole group 14. The extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com