Remote determination method and system of faults of industrial flow instrument

A flow meter and fault technology, which is applied to the remote judgment method of industrial flow meter faults and its system field, can solve problems such as untimely troubleshooting of industrial meter faults and impact on energy consumption statistics, and achieve accurate instrument fault analysis, accurate energy settlement, and Effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

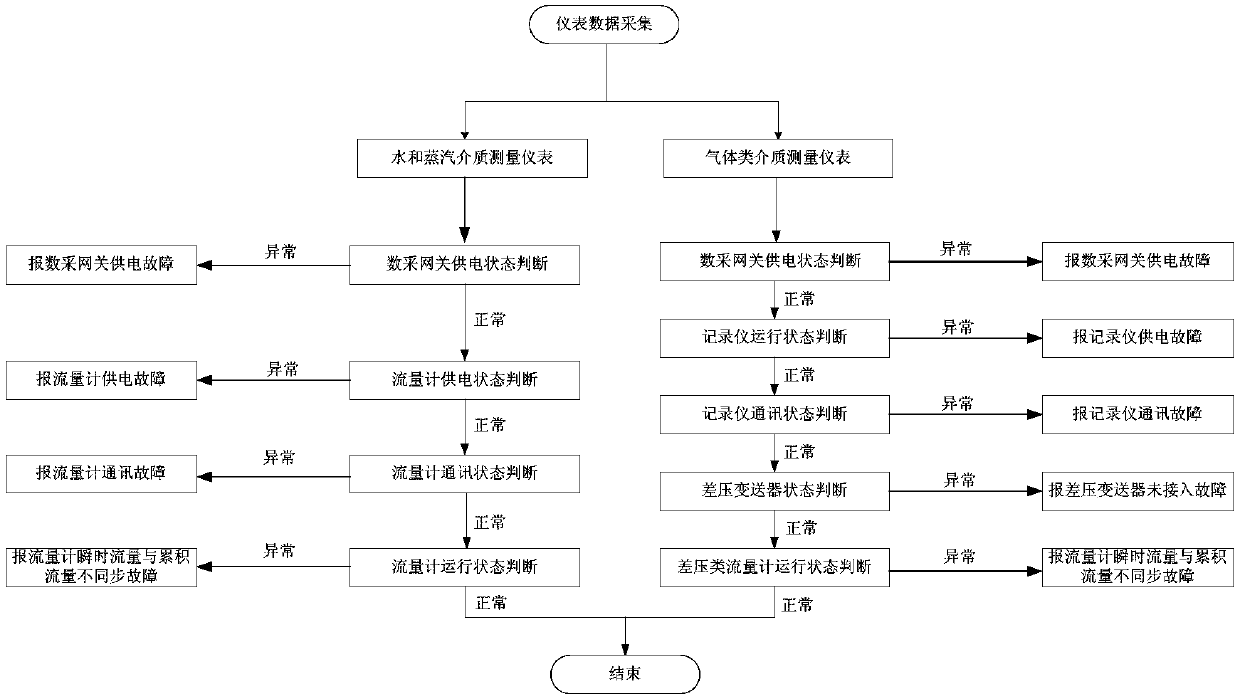

[0019] see figure 1 and figure 2 , the present invention provides a method and system for remote fault diagnosis of industrial flow meters, which can be used for remote fault diagnosis of industrial flow meters. When the meter fails, an alarm prompt will be given in the monitoring platform software in time, so that the maintenance personnel of the enterprise meter can find the faulty meter in time , so that maintenance personnel can check and repair the faulty instrument in time, reduce the time of instrument operation failure, and make the energy settlement in the factory more accurate. Realize the flow chart as figure 1 As shown, the method includes the following steps:

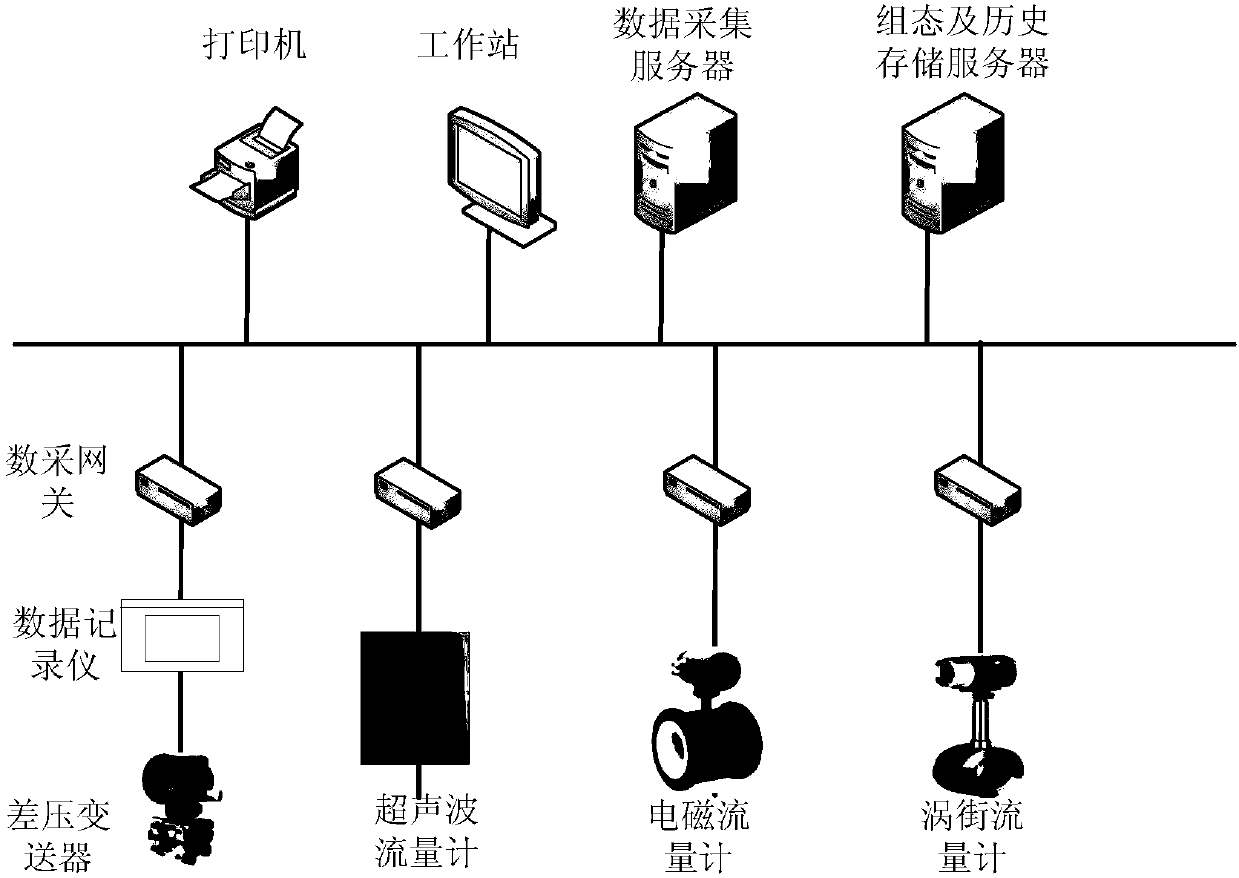

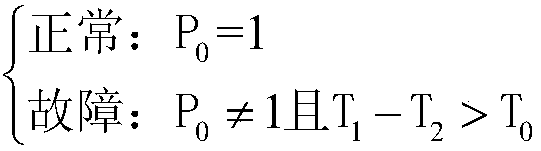

[0020] Step 1, collect real-time data of industrial enterprise instruments, such as figure 2 As shown in the figure, the data acquisition gateway uses the specifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com