Method for manufacturing high-loading electrode

A high-load, electrode technology, used in electrode manufacturing, battery electrodes, final product manufacturing, etc., can solve problems such as uneven dispersion, floating on the surface, and de-embedding, and achieve the effect of preventing floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

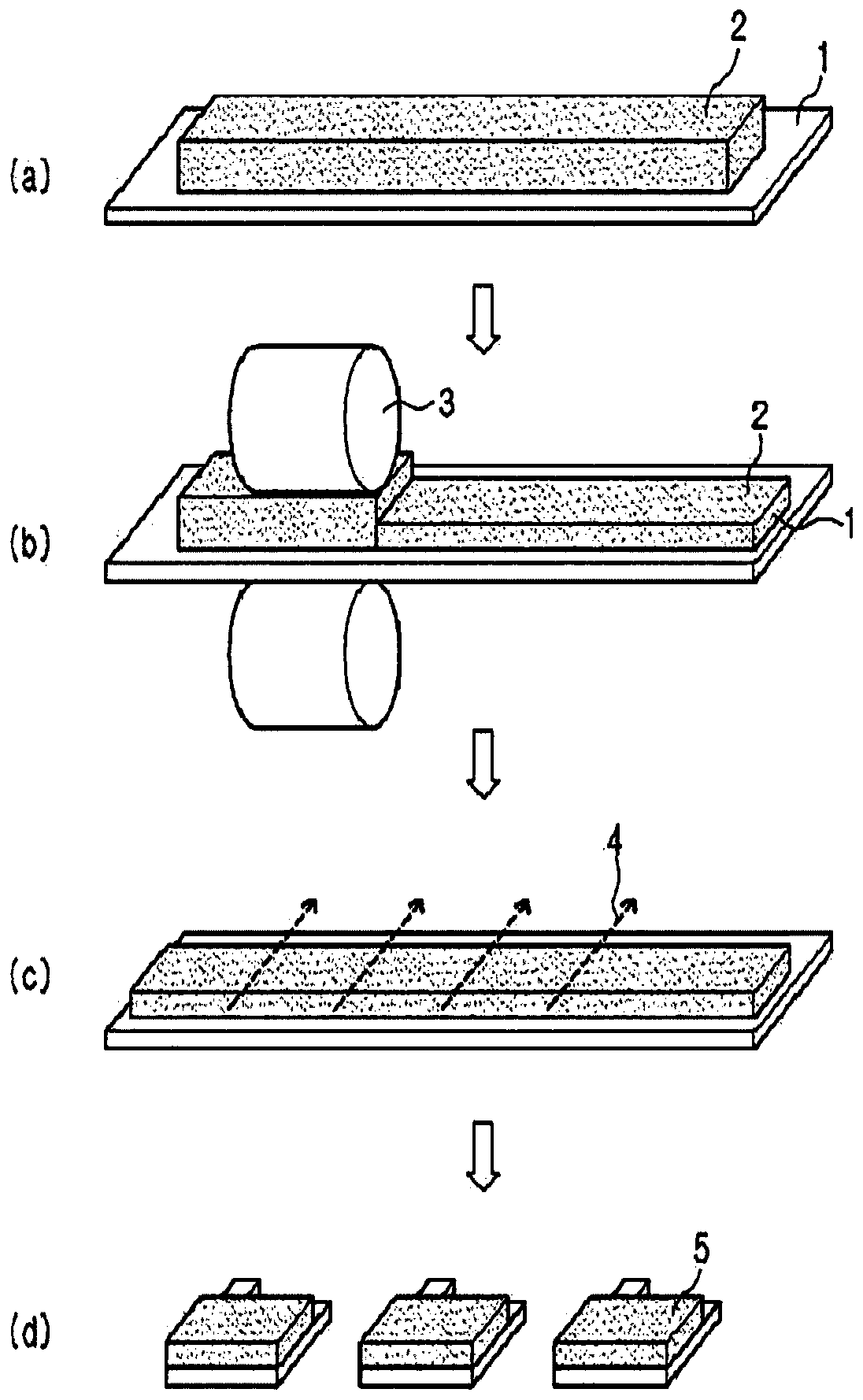

Embodiment 1

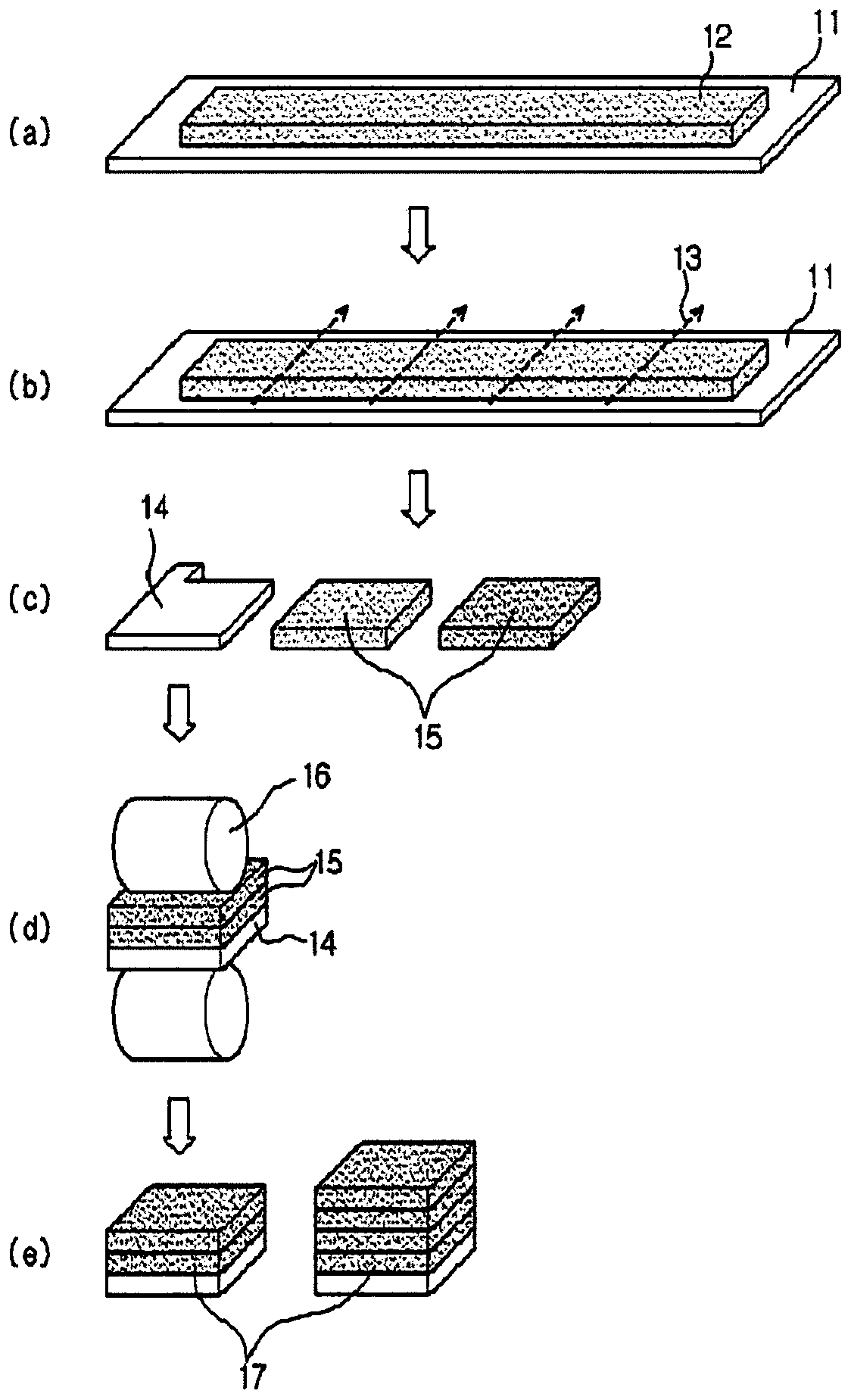

[0063] Will LiNi 0.55 mn 0.30 co 0.15 o 2 (positive electrode active material), Danka black (denka black, conductive agent) and polyvinylidene fluoride (PVDF) (binder) were mixed in a weight ratio of 96:2:2, and then NMP (N-methylpyrrolidone ) to make slurry. The slurry was applied on a PET film to make an electrode layer. The thickness of the electrode layer was set to 120 μm. The electrode layer was punched out in a unit electrode size and the release film was removed, which was then placed in 2 layers on an aluminum foil current collector and rolled to produce a positive electrode.

[0064] An electrode assembly was fabricated using the fabricated positive electrode, and then the electrode assembly was placed in an aluminum pouch and connected to an electrode lead. Thereafter, will contain 1M LiPF 6 The carbonate-based composite solution is injected into the electrolyte, and then sealed to assemble a lithium secondary battery.

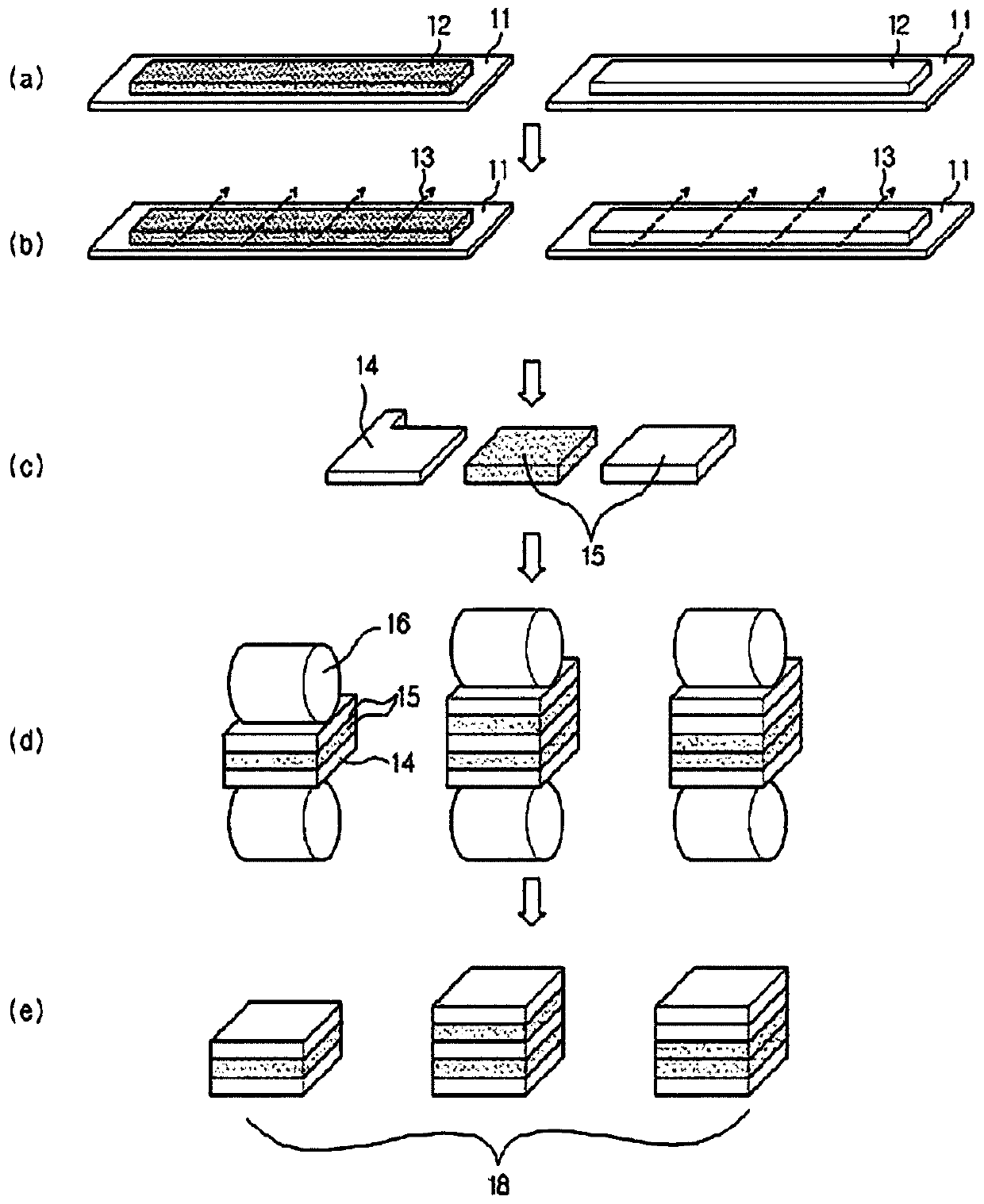

Embodiment 2 to 8

[0066] A positive electrode and a lithium secondary battery were manufactured in the same manner as in Example 1 except having the thicknesses and the number of layers shown in Table 1 below.

Embodiment 9

[0068] Will LiNi 0.55 mn 0.30 co 0.15 o 2 (cathode active material), Danka black (conductive agent) and polyvinylidene fluoride (PVDF) (binder) are mixed in a weight ratio of 96:2:2, and then NMP (N-methylpyrrolidone) is added to manufacture slurry. The slurry was applied on the PET film to make the first electrode layer. The thickness of the first electrode layer was set to 120 μm.

[0069] LiCoO 2 (positive electrode active material), Danka black (conductive agent) and polyvinylidene fluoride (PVDF) (binder) are mixed in a weight ratio of 80:5:15, and then NMP (N-methylpyrrolidone) is added to manufacture slurry. The slurry was applied on a PET film to make a second electrode layer. The thickness of the second electrode layer was set to 120 μm.

[0070] The first electrode layer and the second electrode layer were punched out in a unit electrode size and the release film was removed, and were alternately placed on an aluminum foil current collector to form a total o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com