Flower making module

A technology of pattern pattern and pattern claw, which is applied in the field of pattern grasping modules, can solve the problems of low efficiency and inability to adapt to large-scale assembly line production, etc., and achieve the effect of strong applicability and improved pattern grasping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

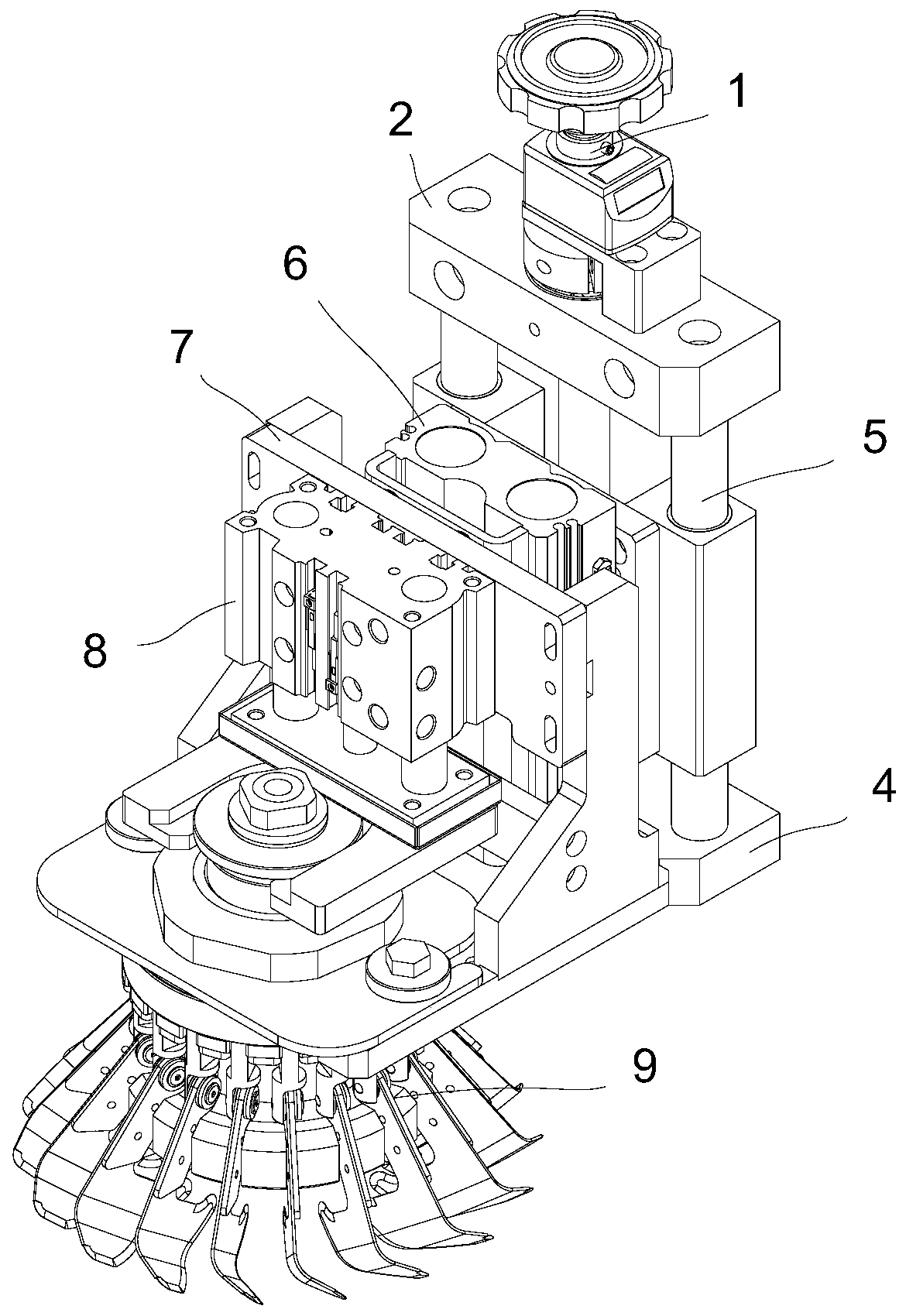

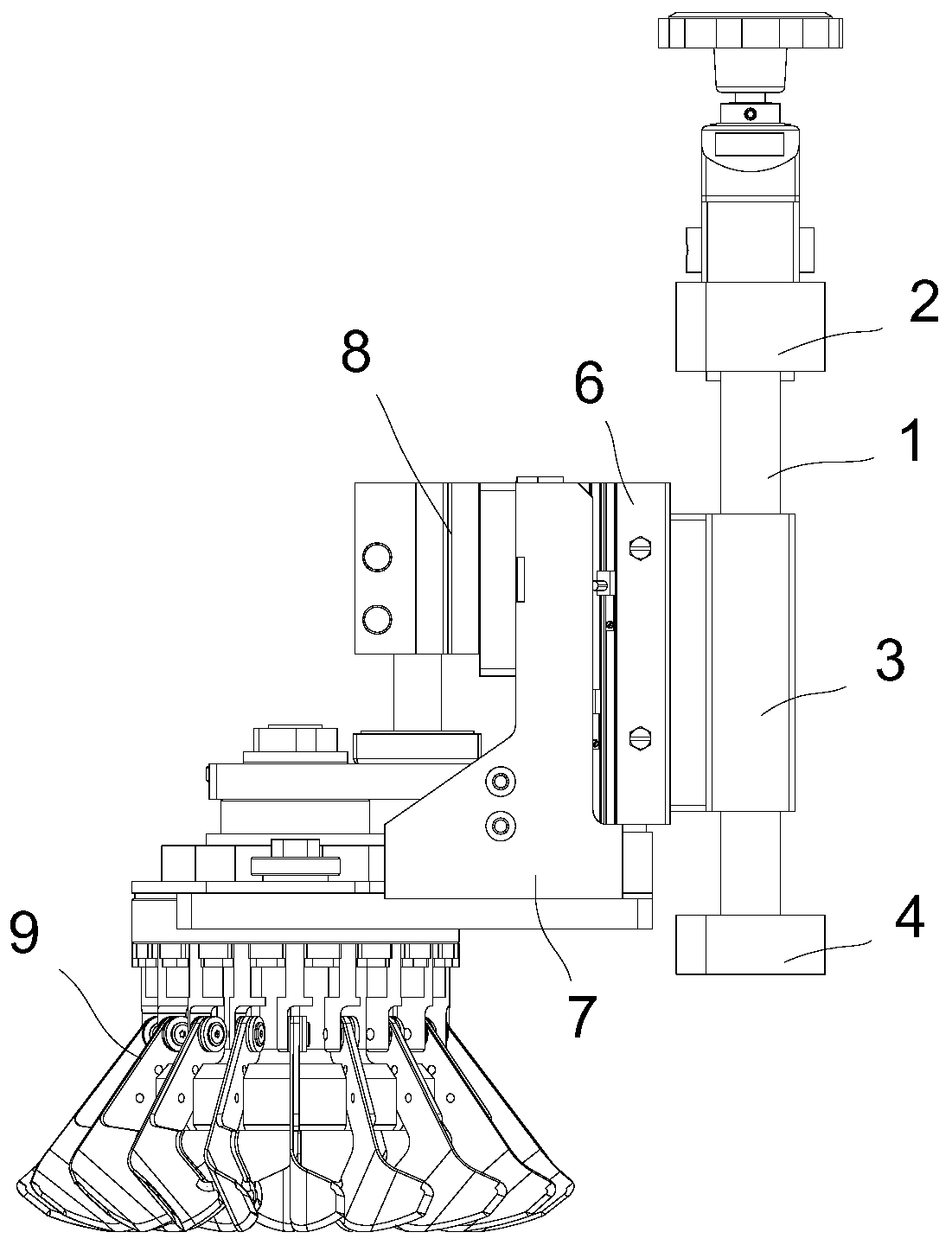

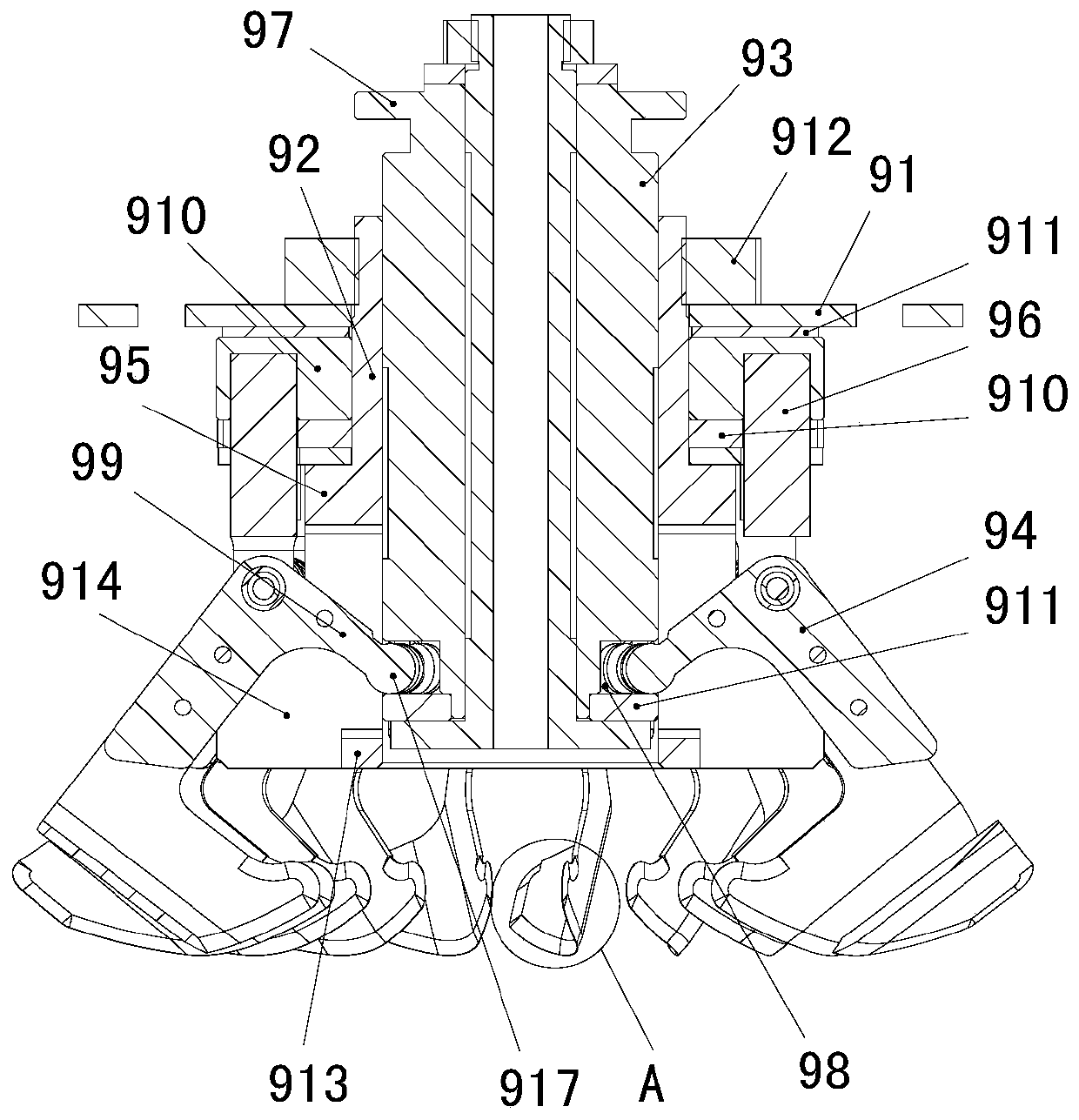

[0027] Such as figure 1 , figure 2 As shown, a scratch module includes an adjusting screw 1, a fixed seat 2, a lifting seat 3, a limit seat 4, a guide rod 5, a lifting cylinder 6, a mounting frame 7, a scratch cylinder 8 and a scratch mechanism 9, The adjusting screw 1 passes through the fixed seat 2 and is fixed to rotate with it. The upper end of the adjusting screw 1 is fixed with a hand wheel. There are two guide rods 5. The upper end of the limit seat 4 is fixed, the lifting seat 3 has a guide hole matched with the guide rod 5, the lifting seat 3 is set on the guide rod 5 and the lifting seat 3 is screwed with the adjusting screw 1, and the lifting cylinder 6 Be fixed on the lifting seat 3, the mounting frame 7 is fixed on the piston rod of the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com