Fluffy and crisp puff shell and making method thereof

A puff and crisp technology, which is applied in the field of puff shell preparation, can solve the problems of poor fluffiness and brittleness of puff shells, and achieve the effects of delaying moisture absorption, prolonging brittleness and straightening appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for fluffy and crispy puff shells, comprising the following steps:

[0039] Melting fat: Put water, fat, salt, and isomaltulose into a container and heat until the fat is completely melted to form a mixture of oil and water, then stop heating;

[0040] Hot noodles: Pour flour into the oil-water mixture and stir it, heat it again for hot noodles, and form the flour into a hot dough;

[0041] Stir the batter: cool the hot dough, then add eggs to the cooled dough, and mix the eggs and dough thoroughly to form puff batter;

[0042] Extrusion molding: put the puff batter into the piping bag, extrude the puff batter through the piping bag, and form the batter body on the baking tray;

[0043] Baking: put the batter body into an oven, the oven baking temperature is 160-220°C, and the baking time is 20-35min.

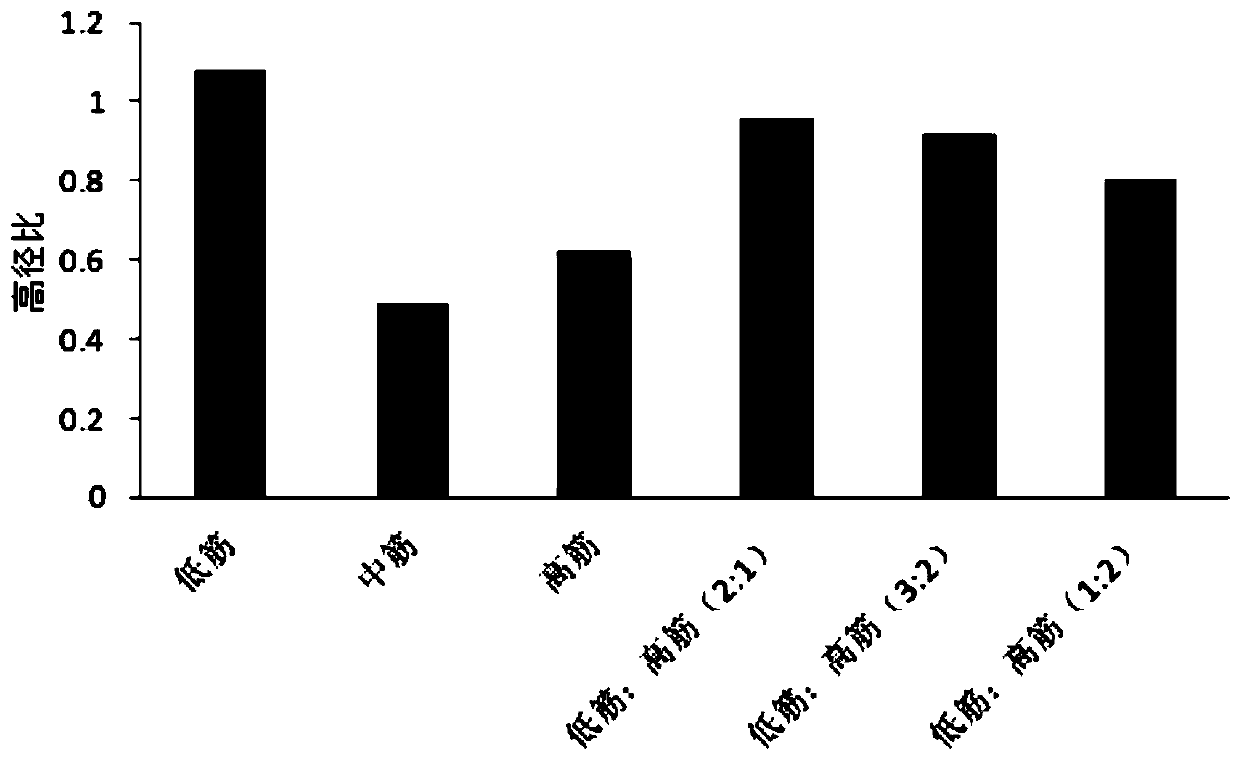

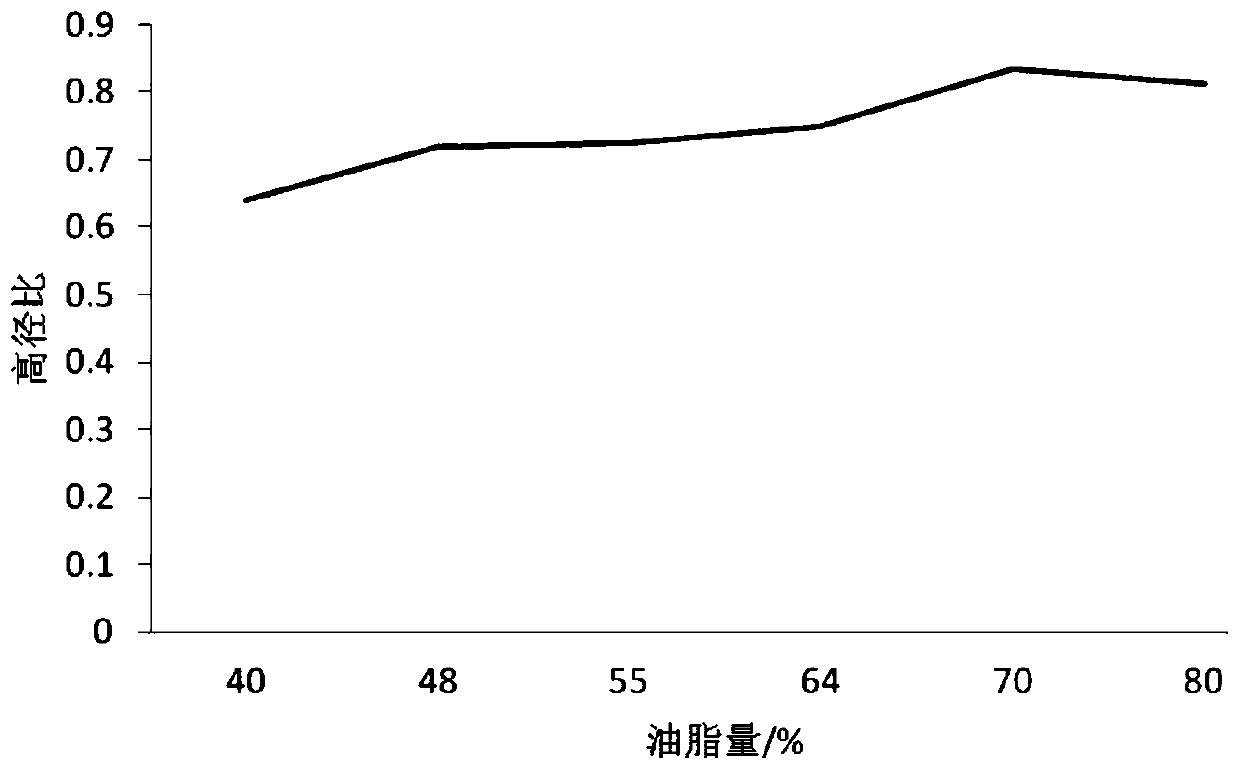

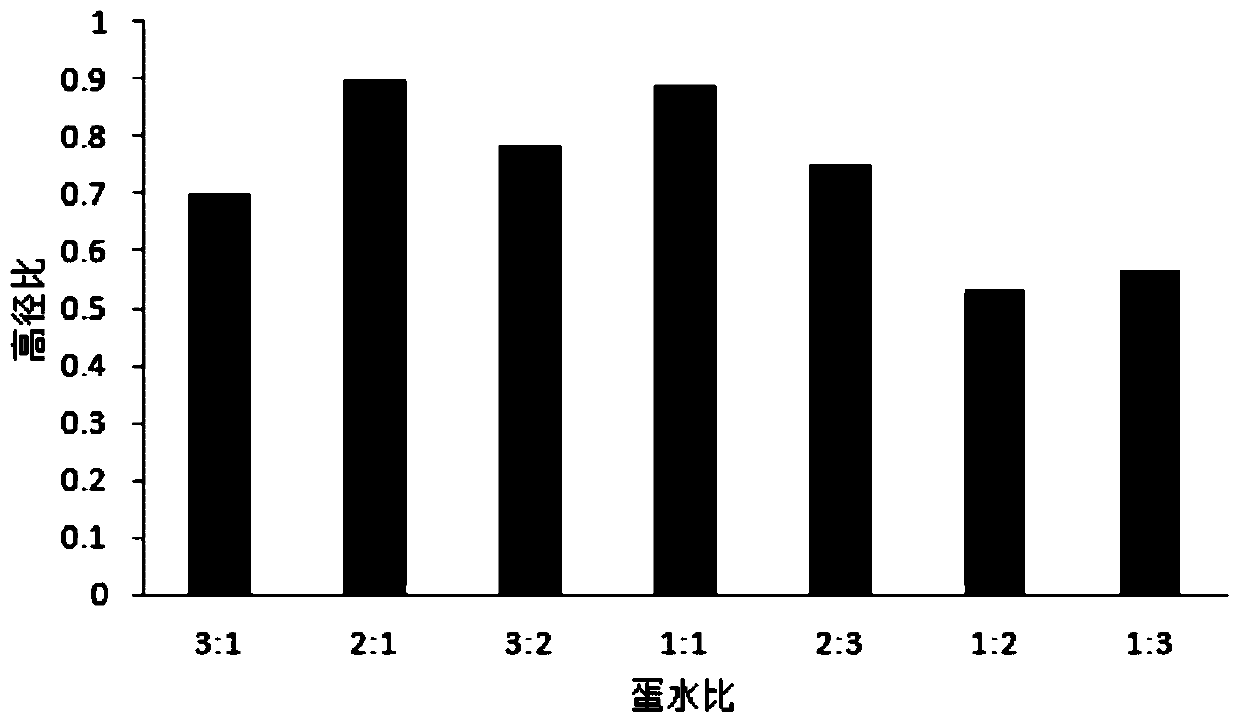

[0044] During the preparation of puff shells, the process conditions will also affect the fluffy and crisp properties of puff shells. In the prep...

Embodiment 11

[0056] A kind of fluffy, crispy puff shell, puff shell comprises following raw material components and parts by weight,

[0057]

[0058] A preparation method for fluffy and crispy puff shells, comprising the following steps:

[0059] Fat melting: Add water, vegetable butter, salt, and isomaltulose into the stainless steel basin according to the above weight ratio, then place the steel basin on the induction cooker and heat until the fat is completely melted to form an oil-water mixture, then stop heating;

[0060] Hot noodles: Pour low-gluten flour into the oil-water mixture and stir evenly with a wooden spoon, then heat again for hot noodles. The heating time is 4 minutes, and the flour will form a hot dough;

[0061] Stir the batter: cool the scalded dough to 60°C, then add eggs to the cooled dough. Eggs are added several times, so that the eggs and dough are fully mixed to form a puff batter; adding eggs in stages can effectively ensure that the eggs and other material...

Embodiment 12

[0064] Embodiment 12: Different from Embodiment 11, low-gluten flour is replaced by medium-gluten flour in Embodiment 12, and the others are the same as Embodiment 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com