Biological experiment test tube batch detoxification device

A biological experiment and generating device technology, which is applied in the field of biological experimental test tube batch disinfection devices, to achieve good cleaning effect, good cleaning and sterilization effect, and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below by means of drawings and embodiments.

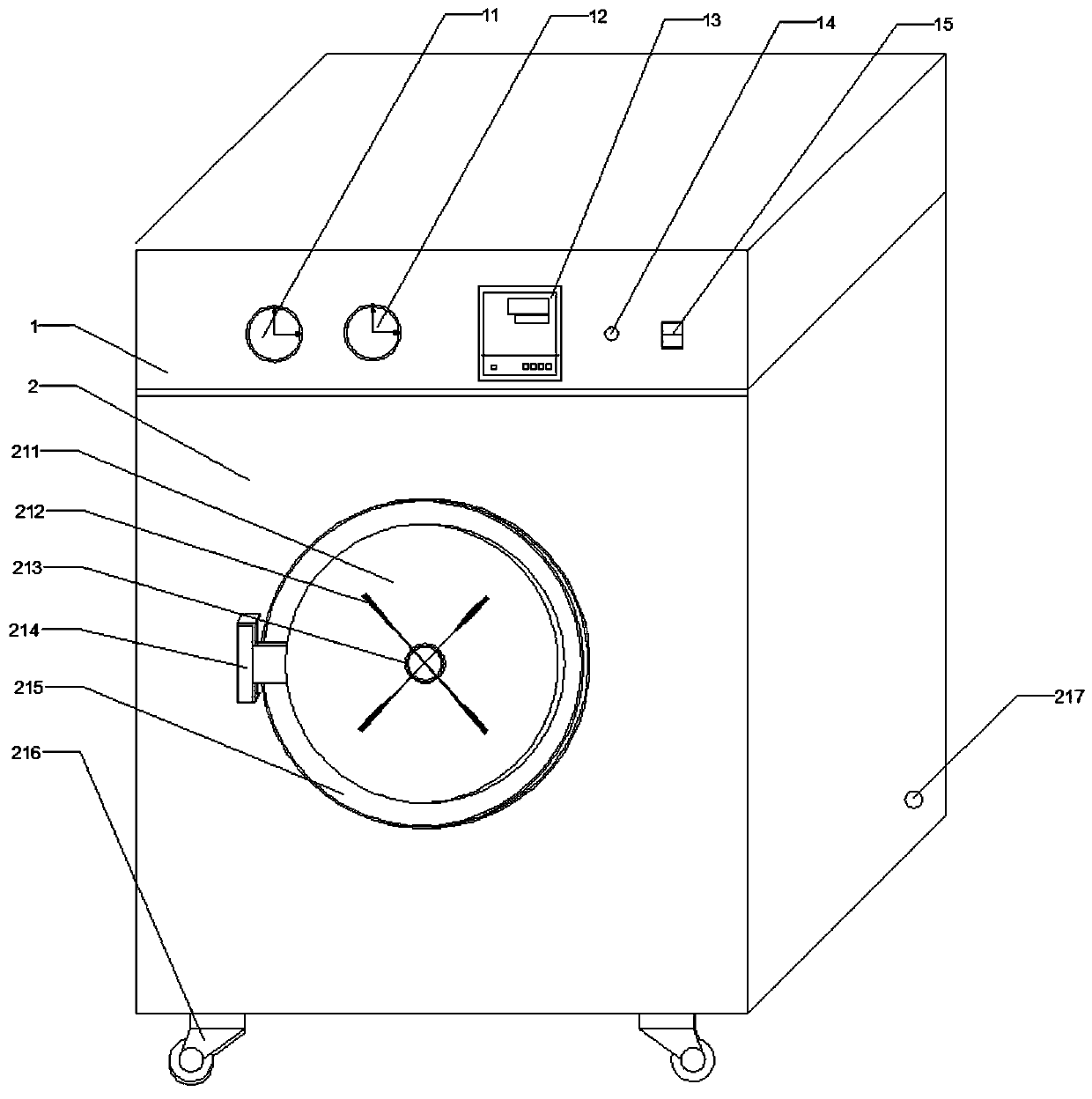

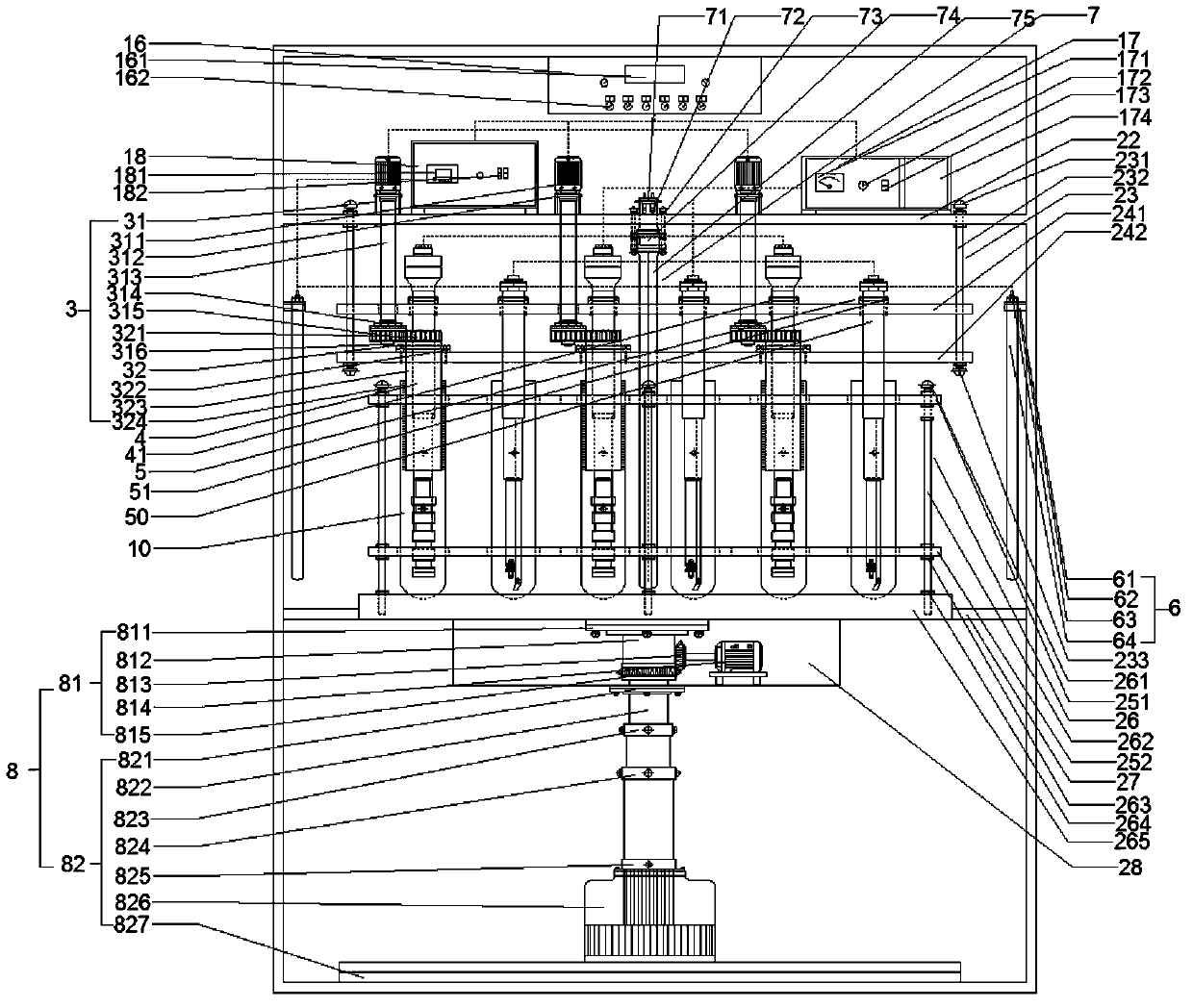

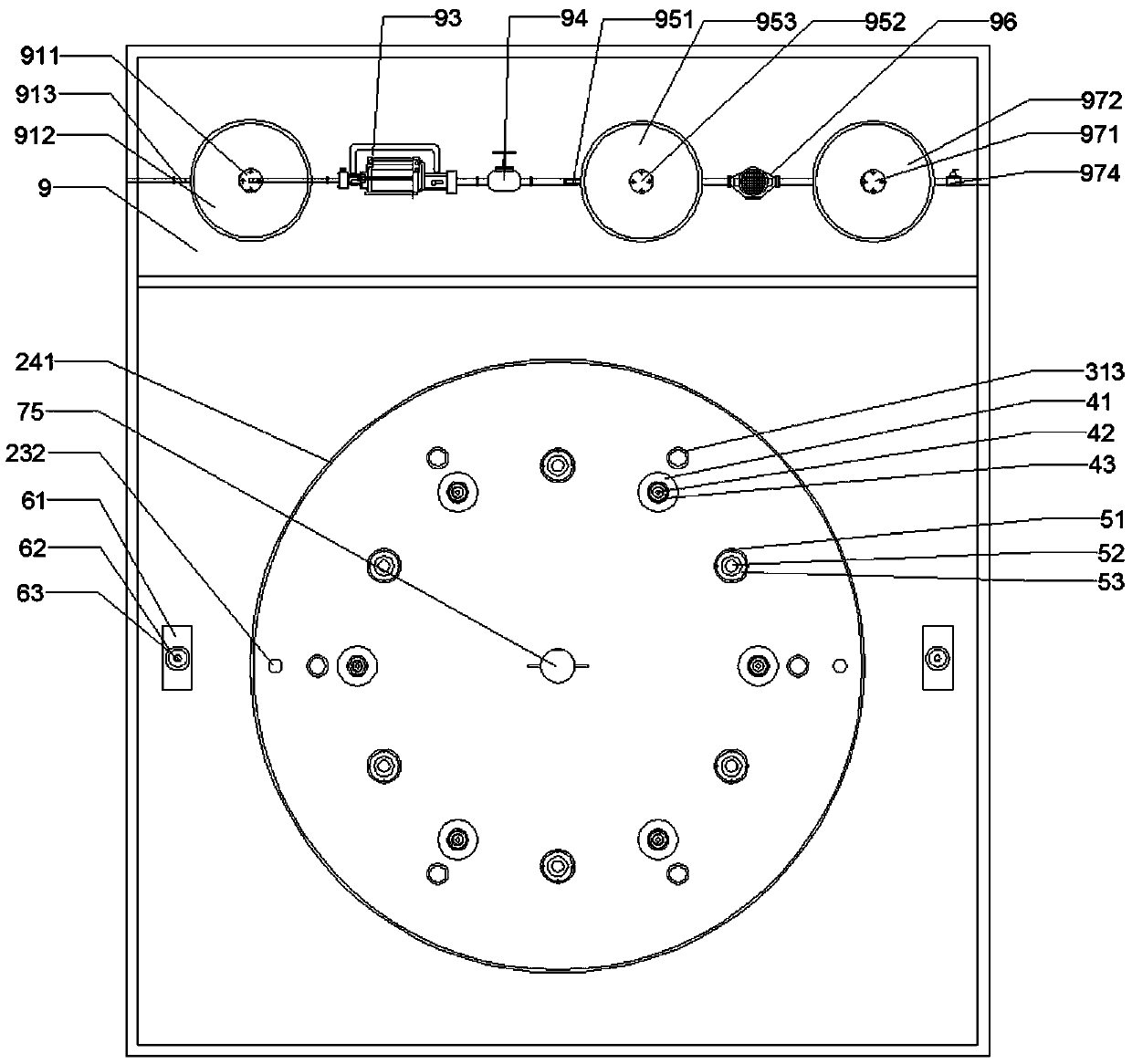

[0036] Such as figure 1 As shown, the biological experiment test tube batch disinfection device of the present invention comprises an upper casing 1 and a lower casing 2, and a rotating scrubbing device 3, an ultrasonic processing device 4, a high-pressure steam processing device 5, a support table adjusting device 8, Ultraviolet generating device 7, preheating device 6. The exterior of the upper box 1 is equipped with a temperature gauge 11, a pressure gauge 12, an operation controller 13, a display lamp 14, and a switch button 15. The switch button 15 can control the device to be turned on or off. When the device is turned on, according to different processing stages, the display The lamp 14 will have different color changes, and the operation controller 13 controls the high-pressure steam treatment time, ultrasonic and rotary scrubbing treatment time, ultraviolet switch, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com