Processing device for hardware tool pliers cutting edge

A technology for processing devices and hardware tools, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems that the cutting edge cannot meet the requirements of high precision, consume a large labor cost, and have a long processing process, and save on The effect of cutting tool time, reducing production and processing costs, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

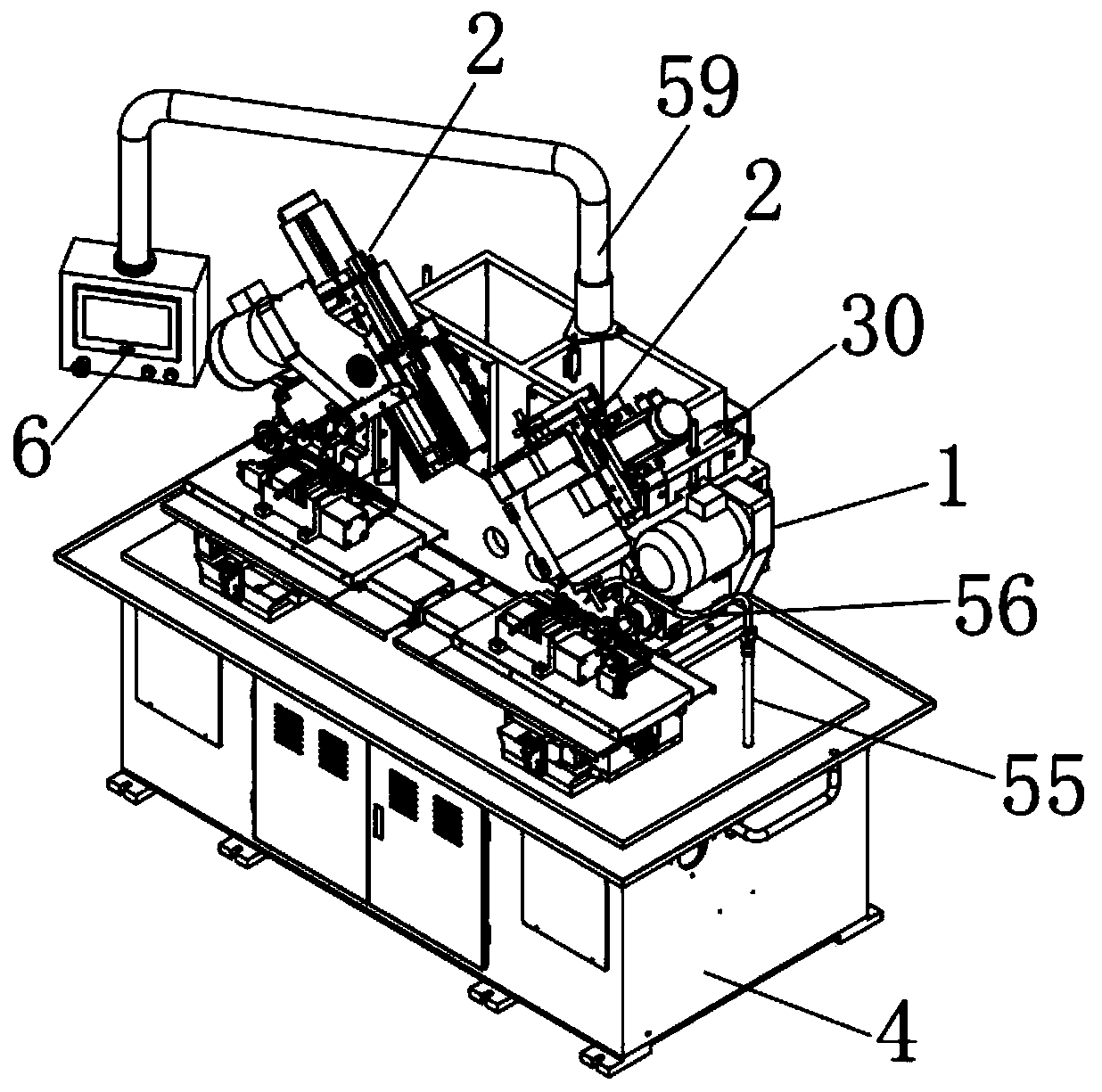

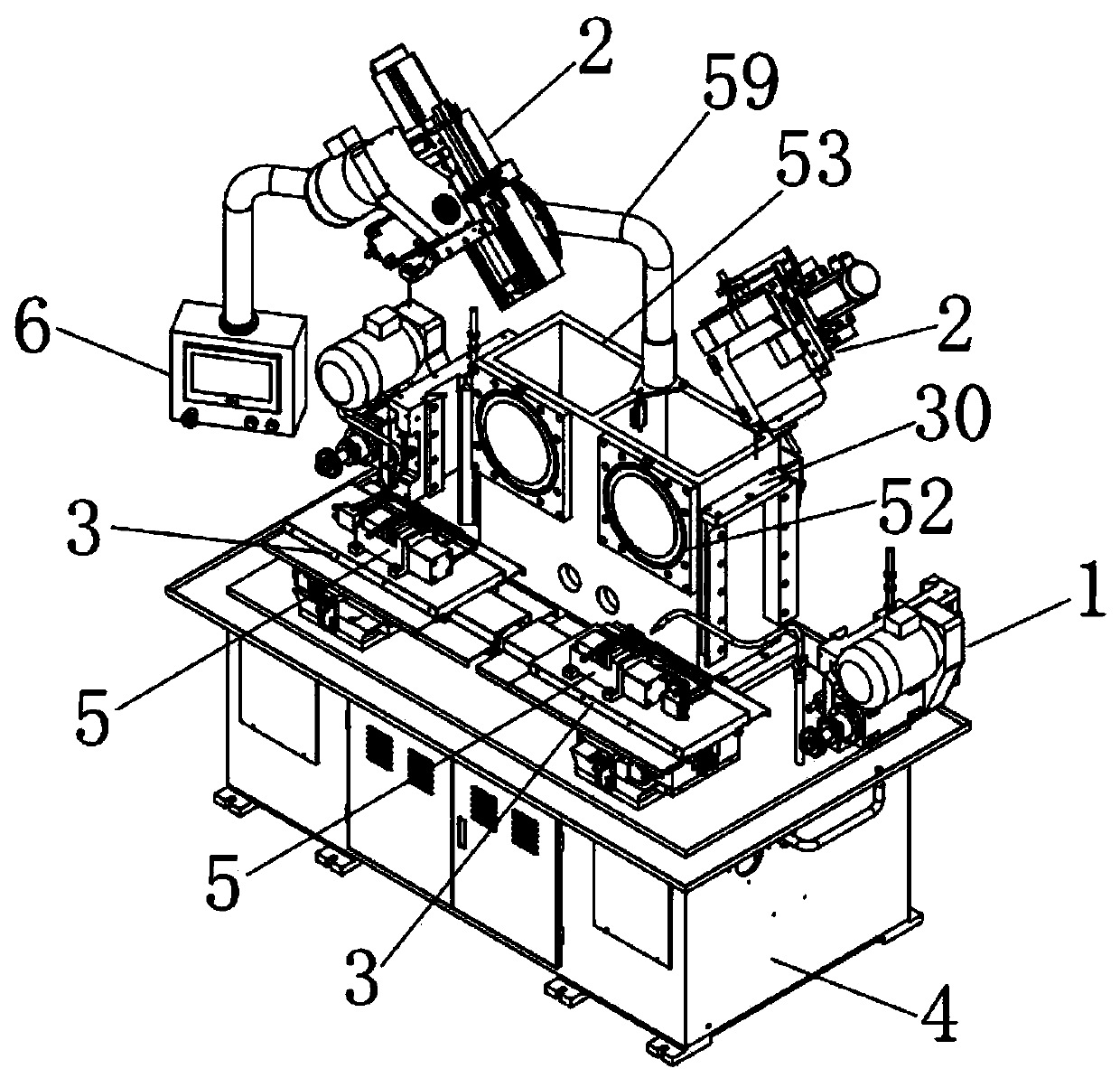

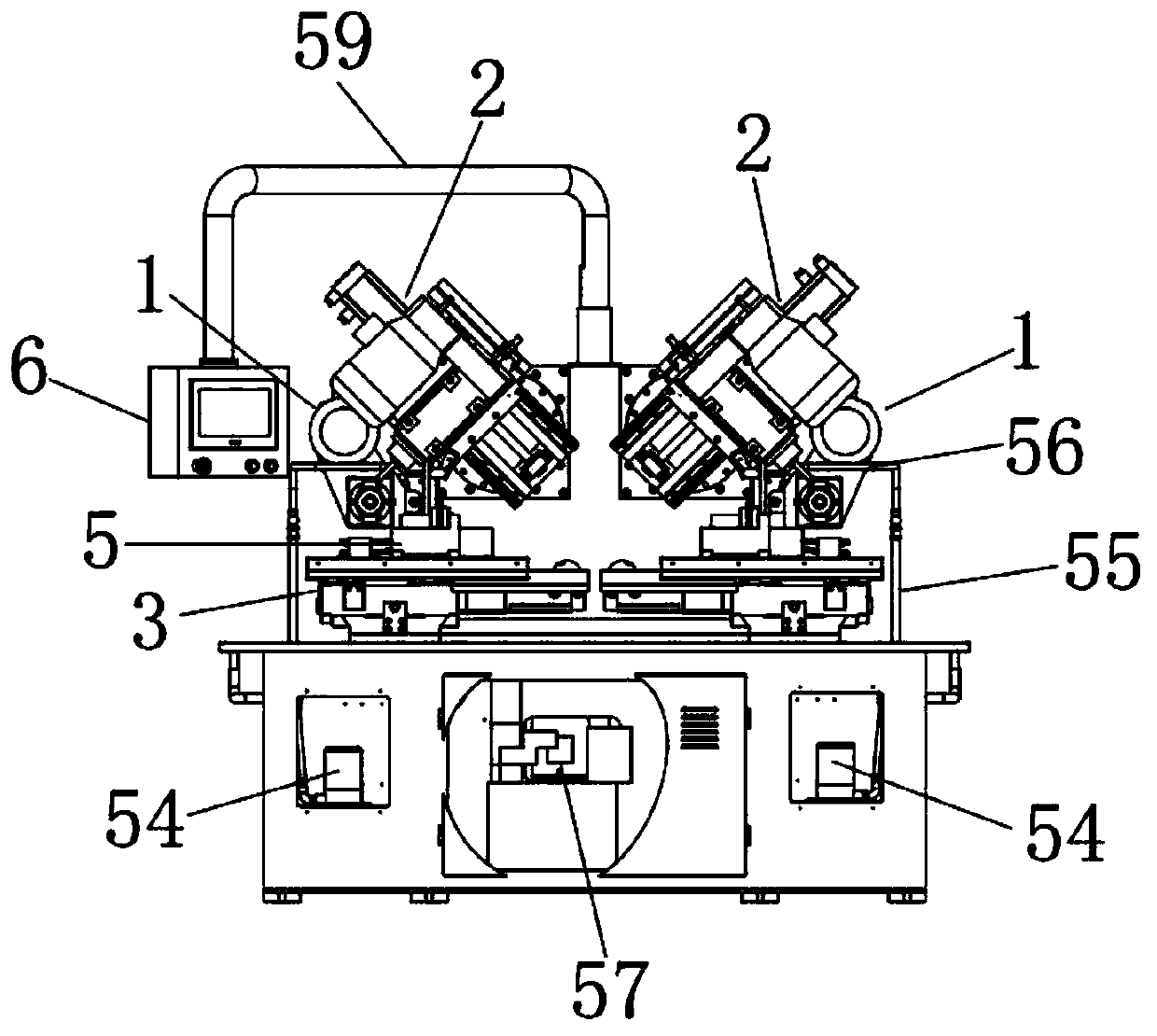

[0031] This embodiment provides a processing device for the cutting edge of hardware tool pliers, such as figure 1 , 2 , shown in 3, including machine tool table 4, frame 53, outer blade surface processing mechanism 1, inner blade surface processing mechanism 2, translation mechanism 3, clamping mechanism 5, console 6 and hydraulic cylinder 57, the left and right sides of frame 53 An outer blade surface processing mechanism 1 is installed on both sides, two inner blade surface processing mechanisms 2 are installed on the frame 53, two translation mechanisms 3 are distributed on the machine table 4, and a clamping mechanism is installed on each translation mechanism 3 5.

[0032] Such as Figure 4As shown, the inner blade surface processing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap