Automobile subframe crossbeam positioning and welding device

A positioning device and positioning welding technology, used in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of inaccurate cavity size of parts, difficulty in manual retrieval, affecting product quality, etc., to prolong service life and connect quickly. , the effect of reducing the burden on workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

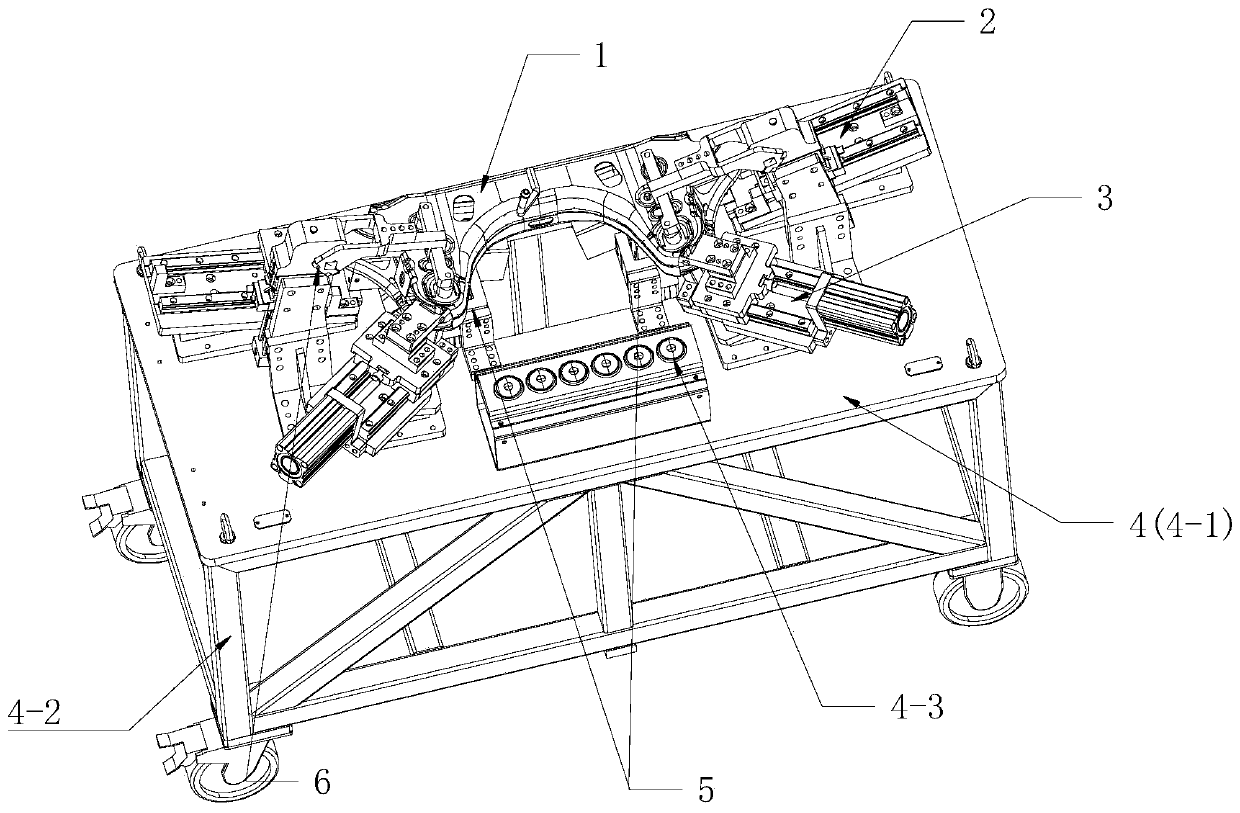

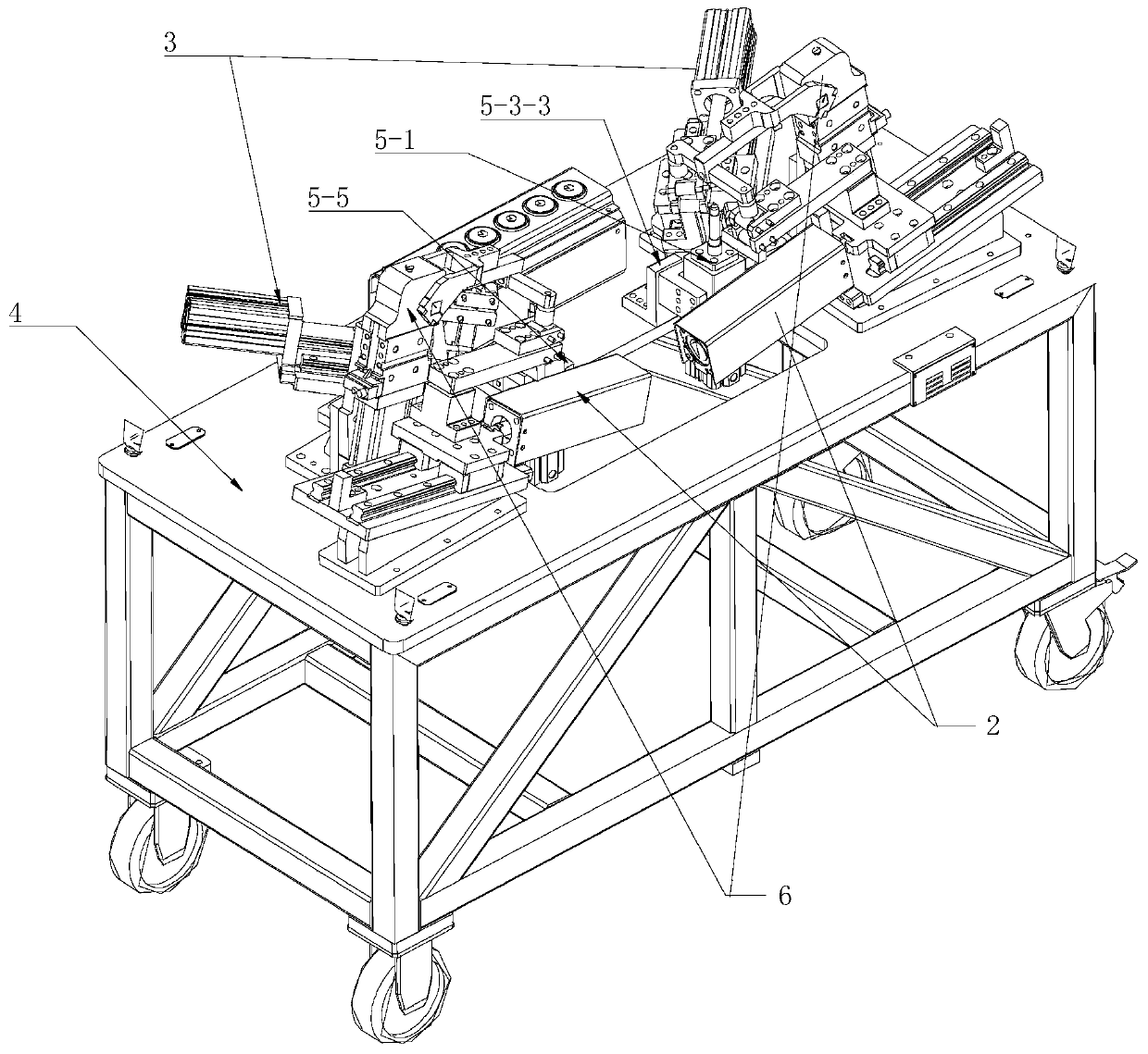

[0047] See figure 1 with figure 2 , a positioning welding device for an automobile sub-frame beam, comprising a base device 4, a first positioning device 5, a second positioning device 2, a third positioning device 3 and a clamping device 6, the first positioning device 5, the second positioning device The positioning device 2 , the third positioning device 3 and the clamping device 6 are all mounted on the base device 4 . The automobile subframe 1 is positioned and fastened on the first positioning device 5 through the first positioning device 5 , the second positioning device 2 , the third positioning device 3 and the clamping device 6 .

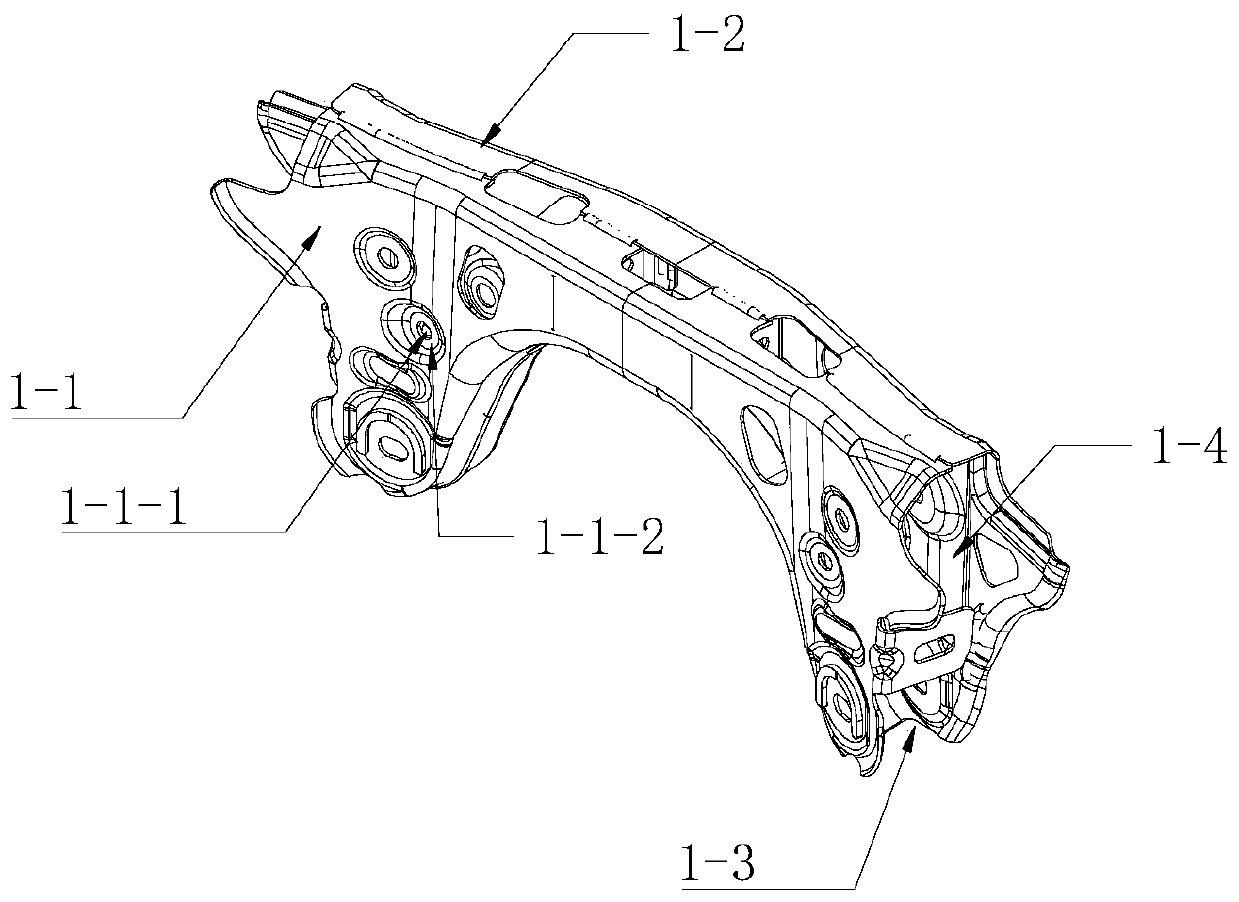

[0048] Such as image 3 , the automobile subframe 1 includes a subframe upper plate 1-1 and a subframe lower plate 1-2, wherein the subframe upper plate 1-1 is provided with an upper plate positioning hole 1-1-1, and the upper plate is positioned The surrounding plane of the hole 1-1-1 is the upper plate positioning surface 1-1-2 (inne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap