Automatic riveting and pressing mechanism applied to toy connecting piece

A technology for connecting parts and automatic assembly machines, which is applied in applications, household components, household appliances, etc., can solve the problems of poor environmental protection effect, low work efficiency and high labor cost, and achieves strong adaptability, high degree of automation, and novel structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described below in conjunction with specific embodiments.

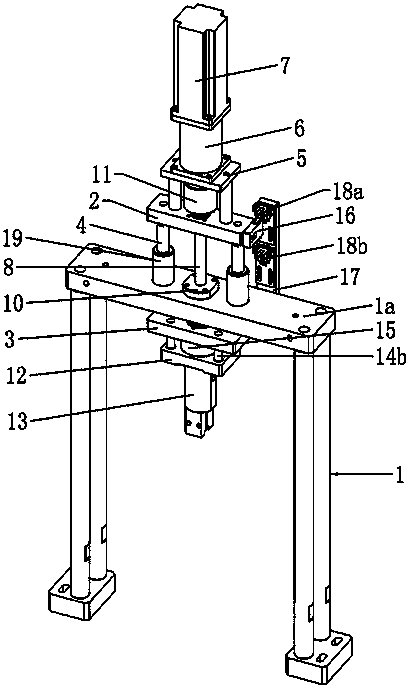

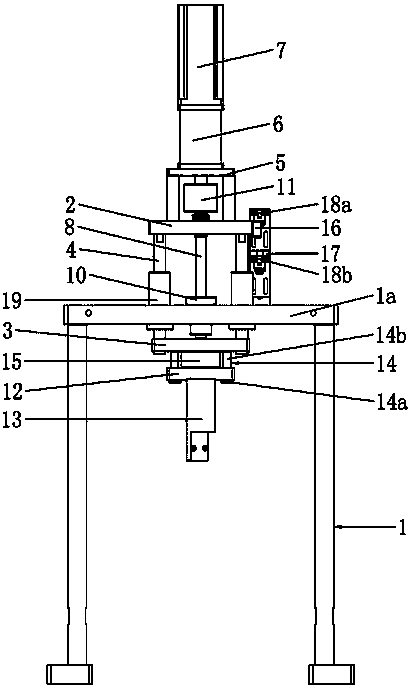

[0035] Such as Figure 2 to Figure 4 As shown, an automatic riveting mechanism applied to toy connectors includes a fixed support frame 1 installed on the upper end of the frame of the toy automatic assembly machine, and the upper end of the fixed support frame 1 is provided with a horizontally extending The support plate 1a, the upper end side of the fixed support plate 1a can be equipped with an upper movable plate 2 relatively movable up and down, and the lower end side of the fixed support plate 1a can be relatively movable up and down with a lower movable plate that moves synchronously with the upper movable plate 2 3. A connecting guide post 4 is installed between the upper movable plate 2 and the lower movable plate 3, the upper end of the connecting guide post 4 is screwed to the upper movable plate 2, and the lower end of the connecting guide post 4 penetrates the fixed su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com