Plastic woven bag with BOPP film for food packaging

A technology of food packaging and woven bags, which is applied in the field of woven bags, can solve the problems of reduced height and inconvenient operation of woven bags, and achieve the effect of reducing the difficulty of access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

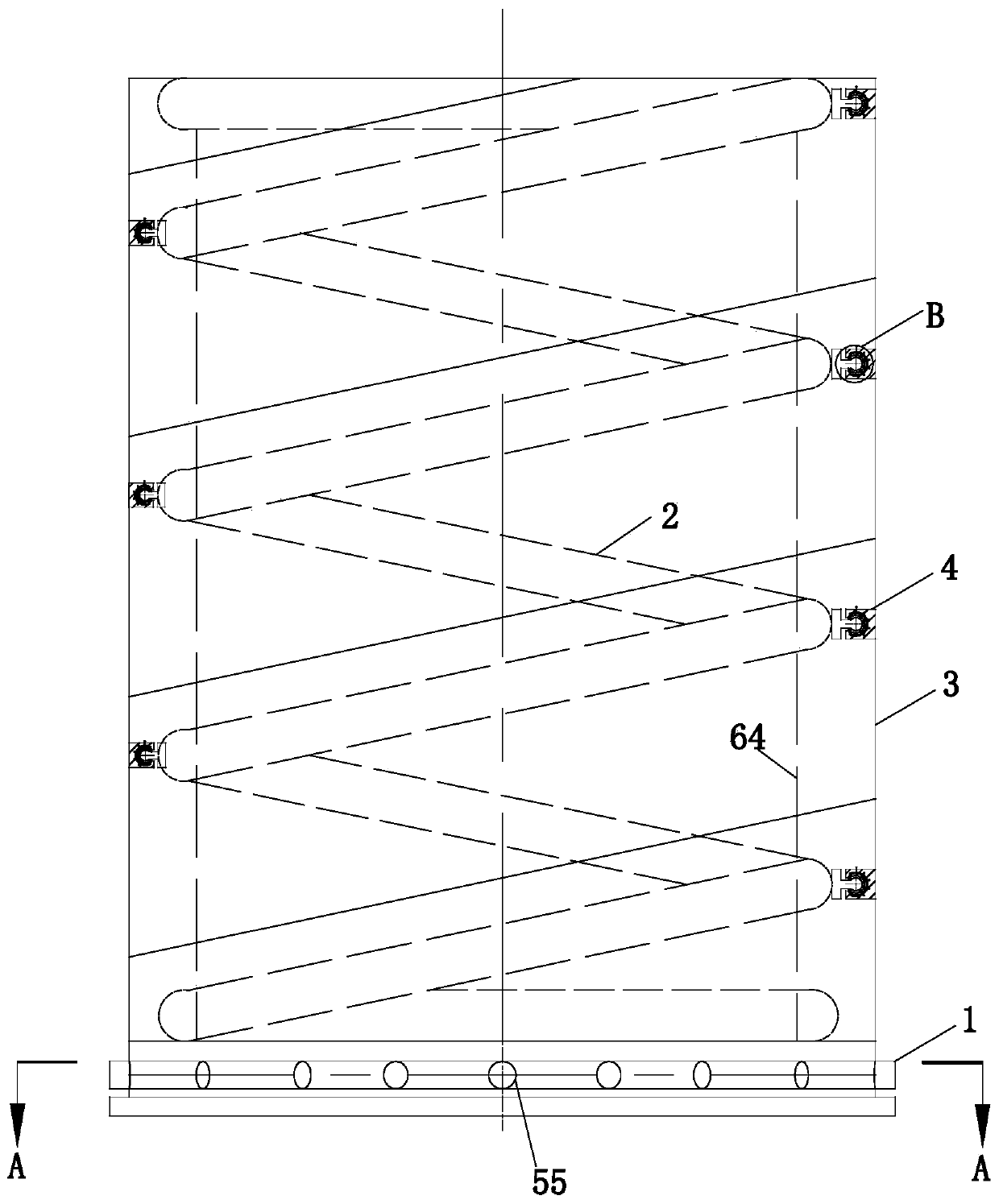

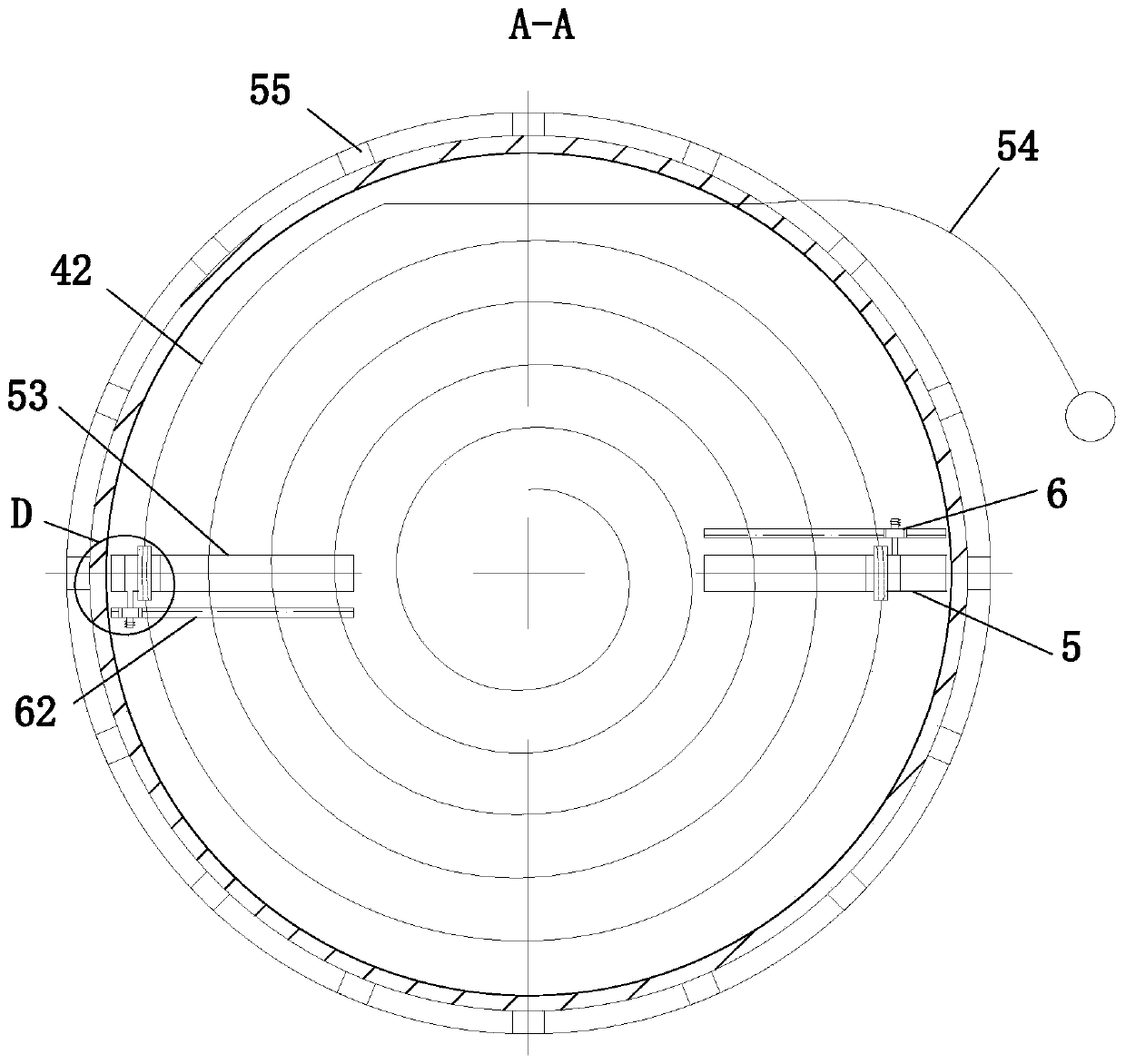

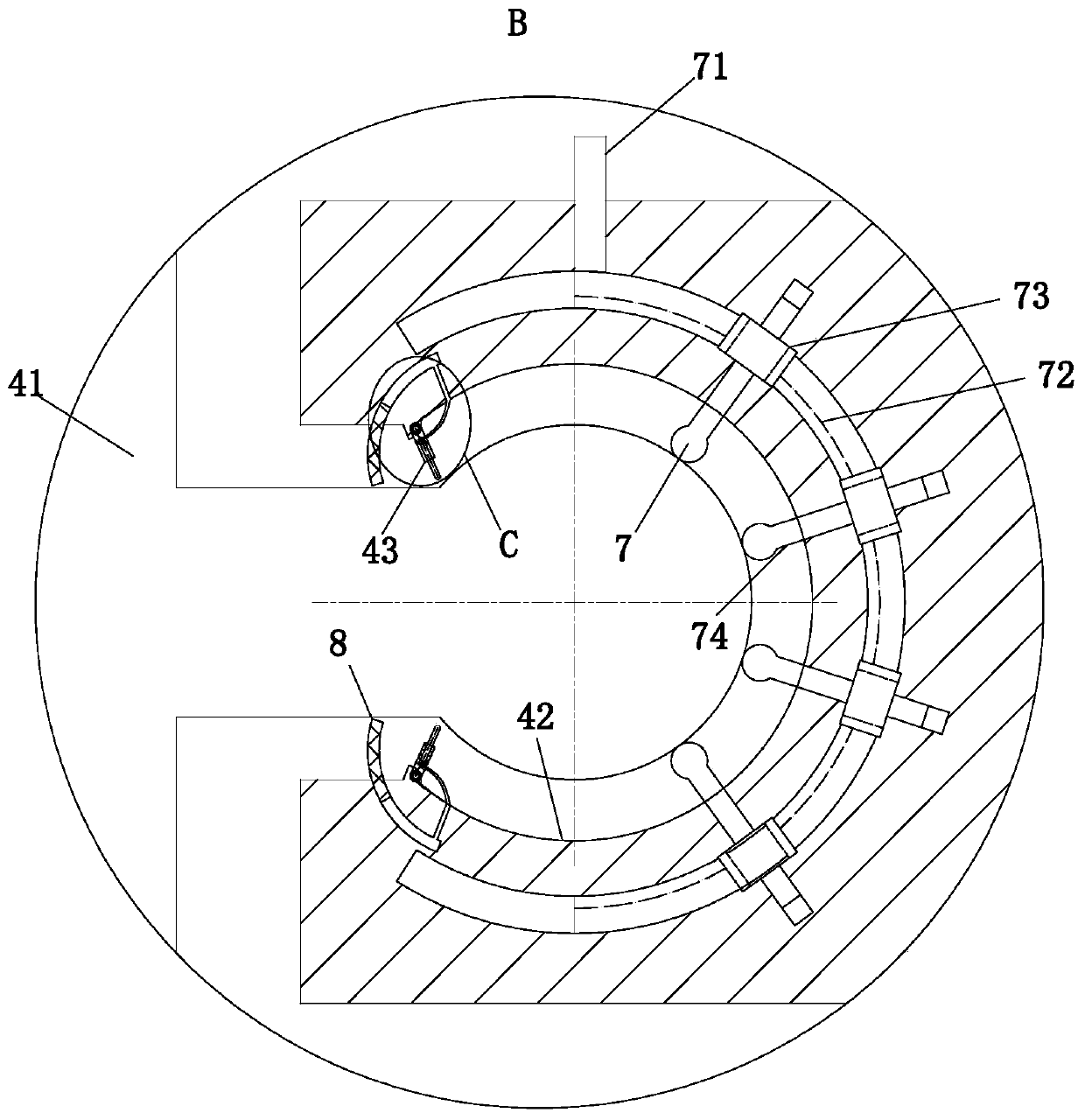

[0025] As an embodiment of the present invention, the clamping unit 4 includes a clamping block 41, a clamping slot 42, a rotating rod 43 and a support assembly 7; the clamping slot 42 is provided with a clamping block 41, and the clamping block 41 is inserted into the clamping slot 42 snapped in; the slot 42 is symmetrically provided with a pair of rotating rods 43 near the opening, the rotating rod 43 is hinged with the slot 42, and a torsion spring is arranged between the rotating rod 43 and the slot 42; the slot 42 The inner side is provided with a support assembly 7; the front end of the block 41 slowly approaches the slot 42 through the protrusion of the front end of the block 41, and the front end of the block 41 protrudes against the rotating rod 43, and the block 41 continues to be inserted into the slot 42 until it is fixed on the support assembly 7. When the front end of the locking block 41 protrudes over the rotating rod 43, the rotating rod 43 returns to its origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com