Gourd-type anti-yarn-falling winding cylinder for spinning process of textile industry and using method thereof

A winding bobbin and gourd-type technology, which is applied in the field of gourd-type anti-off-thread winding bobbins used in the spinning process of the textile industry. It can solve the problems of easy loose threads, unfixable thread ends, and inconvenient use of pulling threads, etc., so as to facilitate finding and fixing , prevent the overall off-line, easy to pull the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

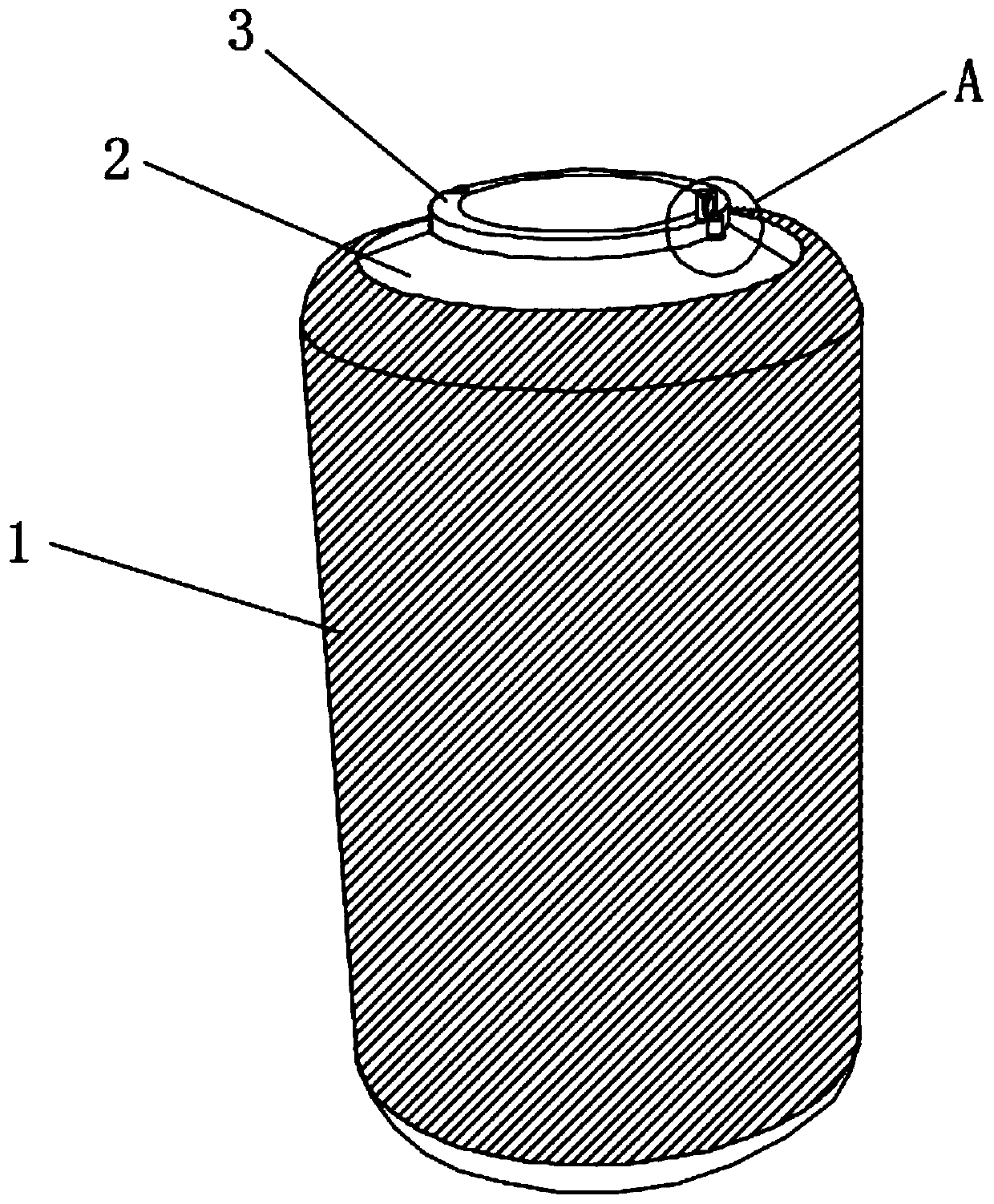

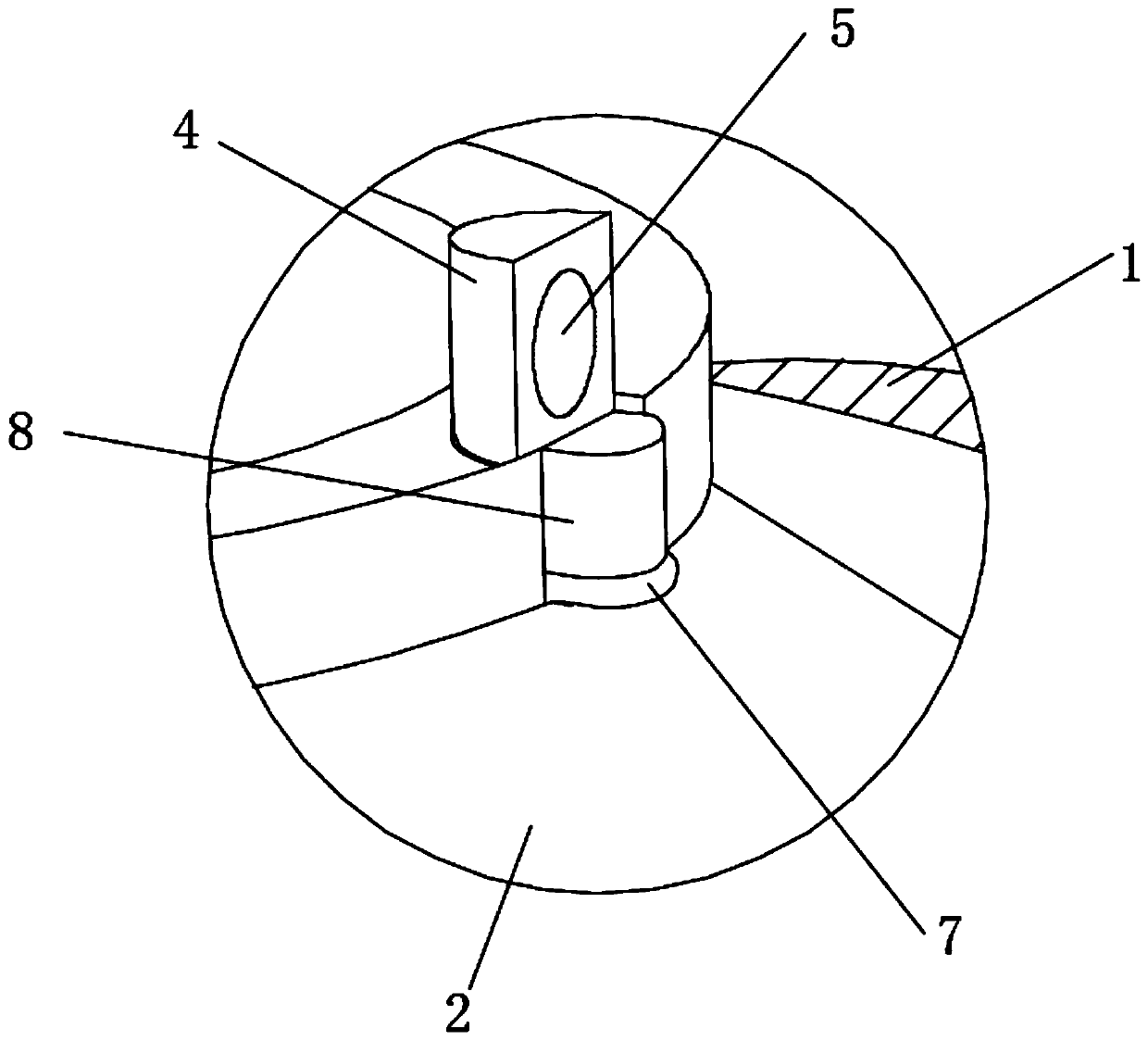

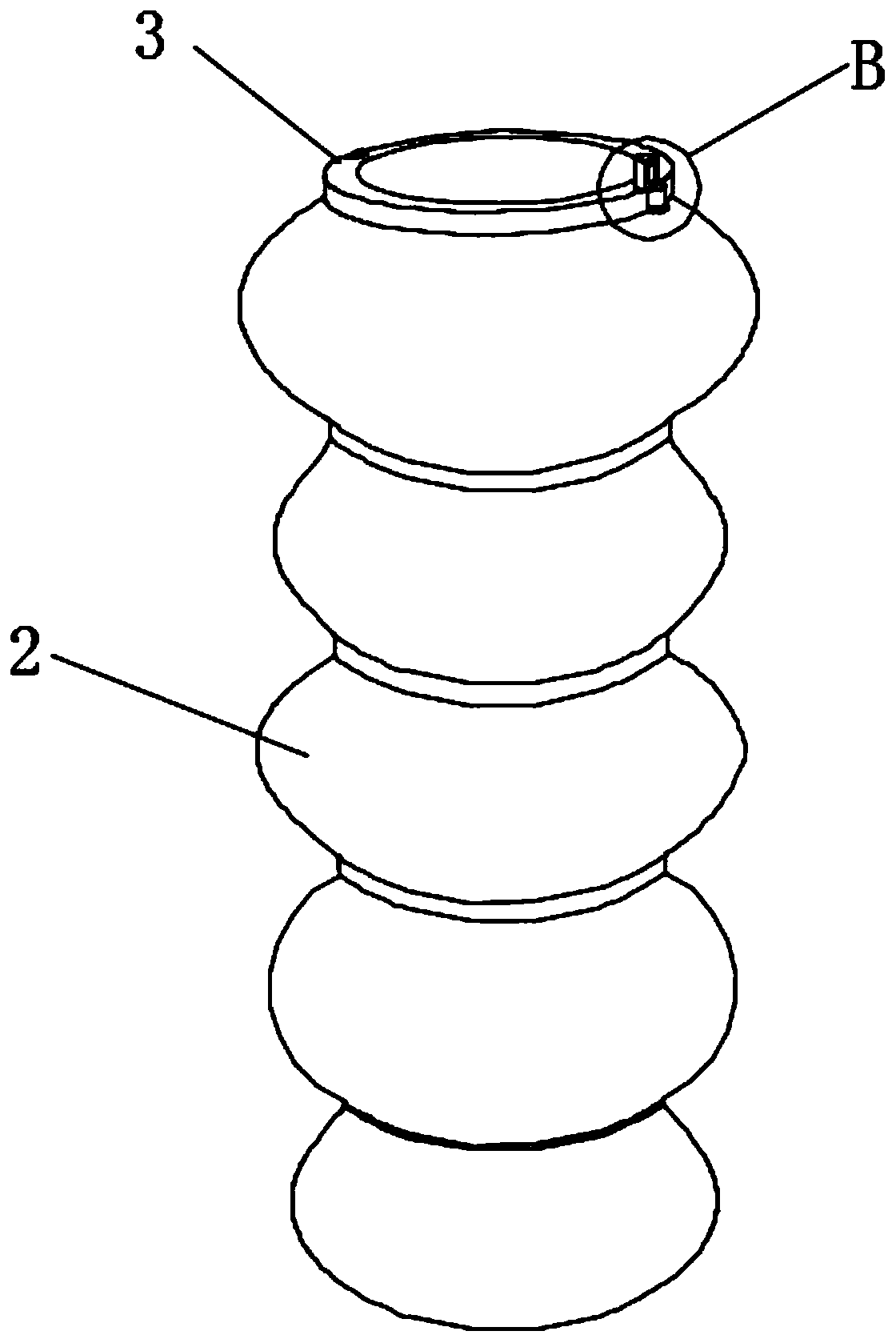

[0058] see figure 1 , a gourd-type thread-off-preventing bobbin for the spinning process of the textile industry, including a bobbin body with a finished thread 1 wound on the outer end, the bobbin body includes a movable bobbin 2 and a fixed bobbin 3, and the fixed bobbin 3 Located inside the movable spool 2, and the movable spool 2 is rotatably connected with the fixed spool 3, please refer to figure 2 , image 3 and Figure 4 A first chute 6 is dug at the top of the side of the fixed bobbin 3, a second chute 7 is dug at the top of the side of the movable bobbin 2, and the cylindrical area formed by the second chute 7 and the first chute 6 is provided with a fixing piece , set the winding bobbin into two layers, and set the outer layer into a gourd-shaped irregular bobbin, which is convenient for smooth winding and prevents the overall off-line; it is fixed and rotated with the cylindrical bobbin of the inner layer , to achieve the fixation of the thread ends, not easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com