Non-woven fabric structure and its manufacturing method

A production method and non-woven technology, which can be used in non-woven fabrics, textiles and papermaking, etc., can solve the problems of insufficient tensile strength and affecting the bulkiness of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly illustrate the spirit of the present invention with the accompanying drawings and detailed descriptions. After any person with ordinary knowledge in the art understands the preferred embodiments of the present invention, he can change and modify it by the technology taught in the present invention. without departing from the spirit and scope of the present invention.

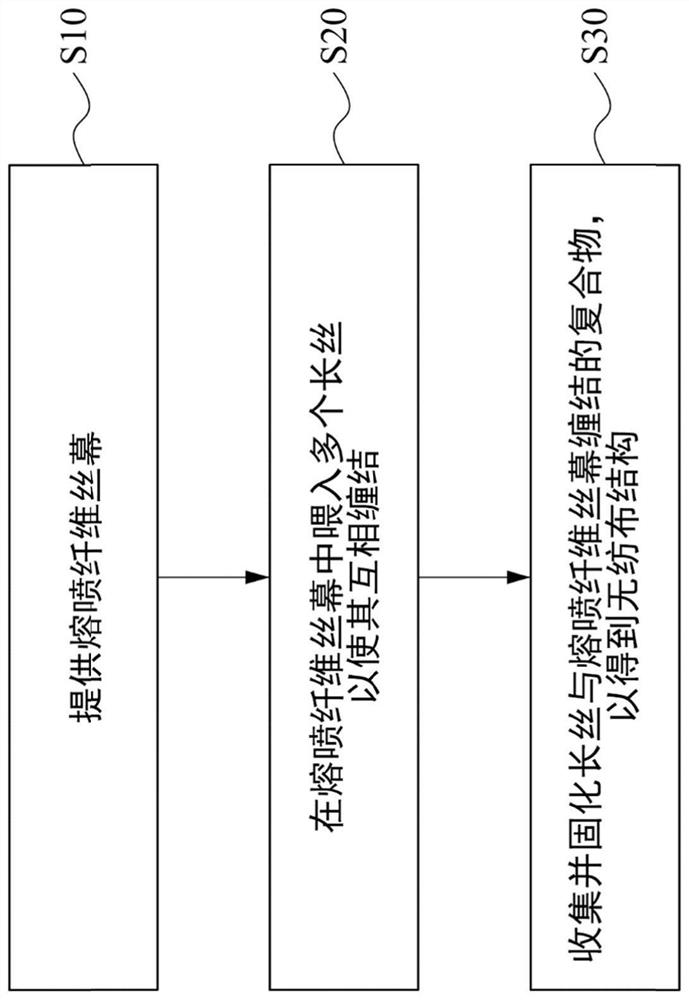

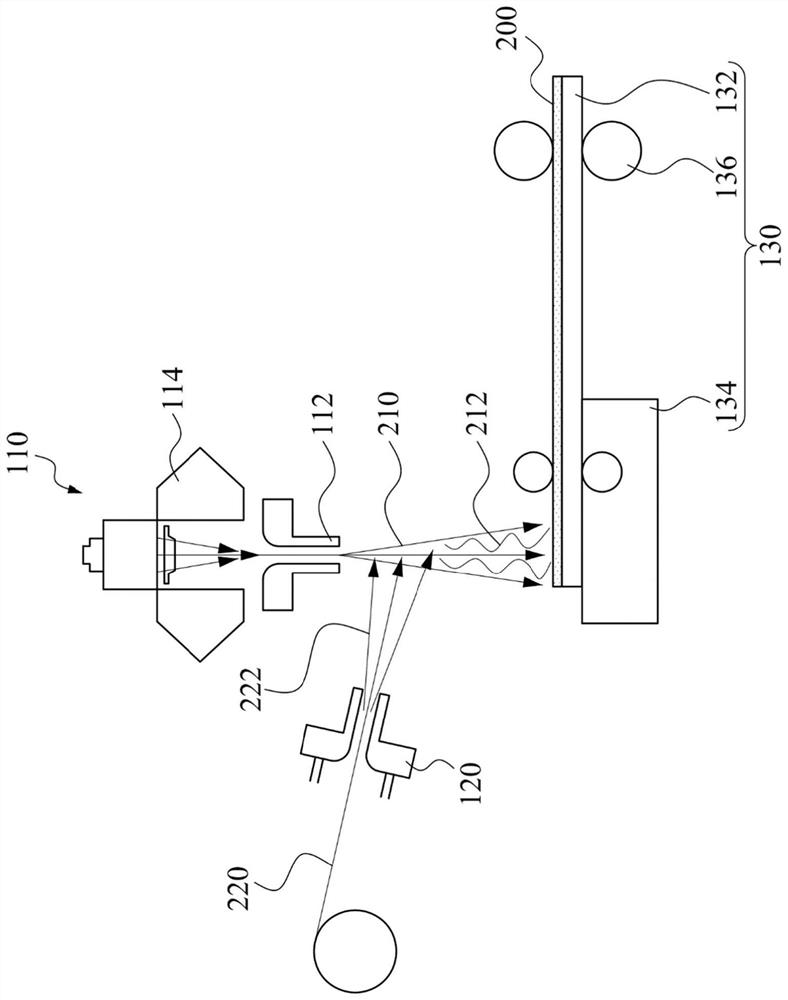

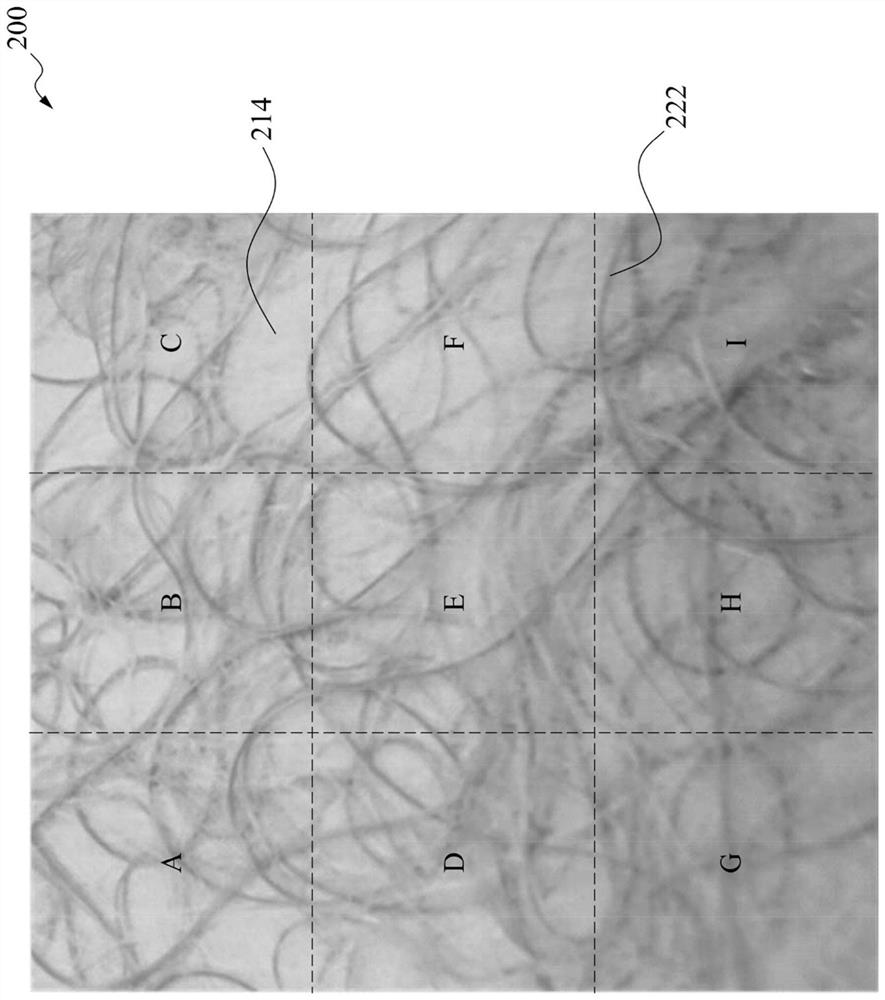

[0023] Please also refer to figure 1 and figure 2 , which are respectively a flow chart and a schematic diagram of an embodiment of the method for fabricating a nonwoven fabric structure of the present invention. The manufacturing method of the non-woven fabric structure begins with step S10 . The step S10 is to provide a melt-blown fiber curtain 210 , and the melt-blown fiber curtain 210 is composed of a plurality of melt-blown fibers 212 . The meltblown fiber curtain 210 may be provided by the meltblown mechanism 110 .

[0024] In one embodiment, the melt blowing mechanism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com