Non-woven fabric looped pile planting process and equipment thereof

A non-woven and terry technology, applied in textiles and papermaking, knitting, crocheting and other directions, can solve the problems of parallel knitting, inability to clean up, weak adsorption force, etc., and achieves good wiping effect, simple structure, The effect of improving the lateral tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

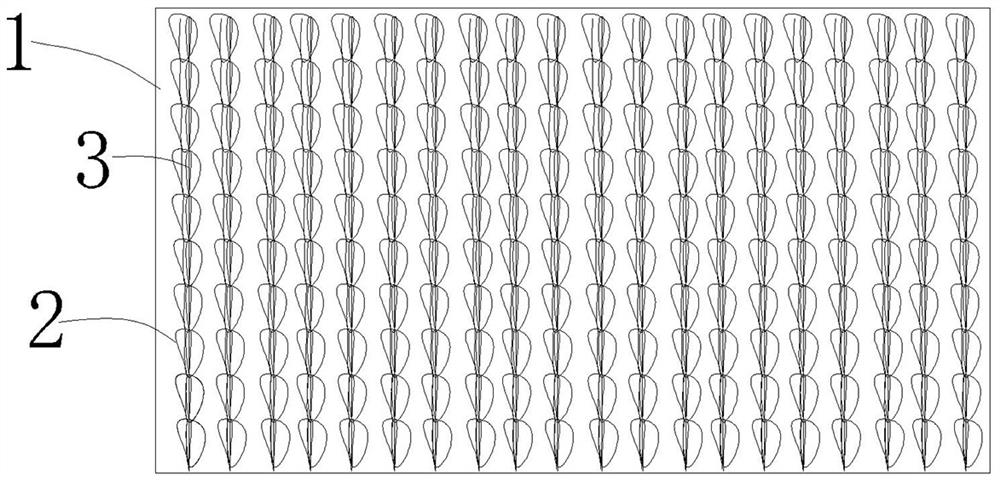

[0024] like figure 1 As shown, a non-woven fabric loop planting process is characterized in that it includes the following steps: plant loops 3 on the non-woven fabric 1 and reserve the loops. Puncture with a terry piercing needle with a terry thread, then bring the loop out and reserve it with a pin; then the terry piercing needle exits.

[0025] In this embodiment, the existing structure is used to make the pile fall down: the needle with the pile piercing needle is inserted into the non-woven fabric, and then the needle is inserted into the pile thread, and then the needle with the pile piercing exits and pulls the pile thread, and then the nonwoven When the cloth feeds or the needle moves backward, the loop thread falls backwards along the trend.

[0026] Secure the loops to the non-woven fabric with chain stitch 3. It specifically includes: using a puncture array poured with fixed thread needles to puncture the non-woven fabric with loops; using a crochet needle array p...

Embodiment 2

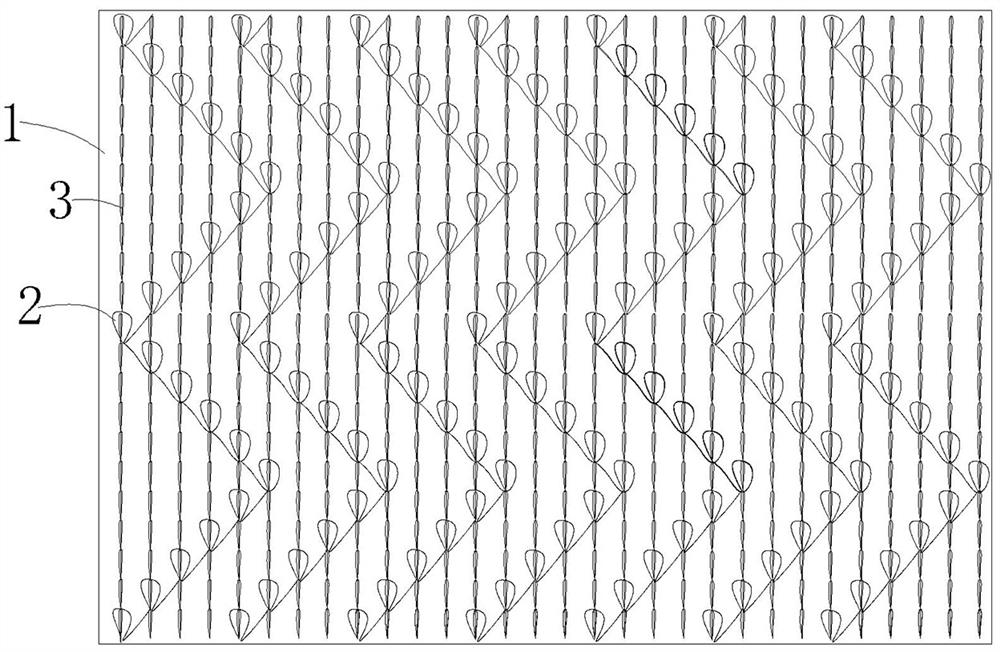

[0030] like figure 2 Shown: This embodiment is an improvement of Embodiment 1. In this embodiment, in order to increase the lateral stretch resistance of the product, it also includes that the loop puncture needle moves laterally by one needle position after the loop puncture needle penetrates into the non-woven fabric for the second piercing.

Embodiment 3

[0031] Embodiment 3: This embodiment is an improvement of Embodiment 1. A pressing roller is used to set between the loop piercing needle and the fixed thread piercing needle, and the pressing roller is used to overwhelm the pile to form an overturned pile.

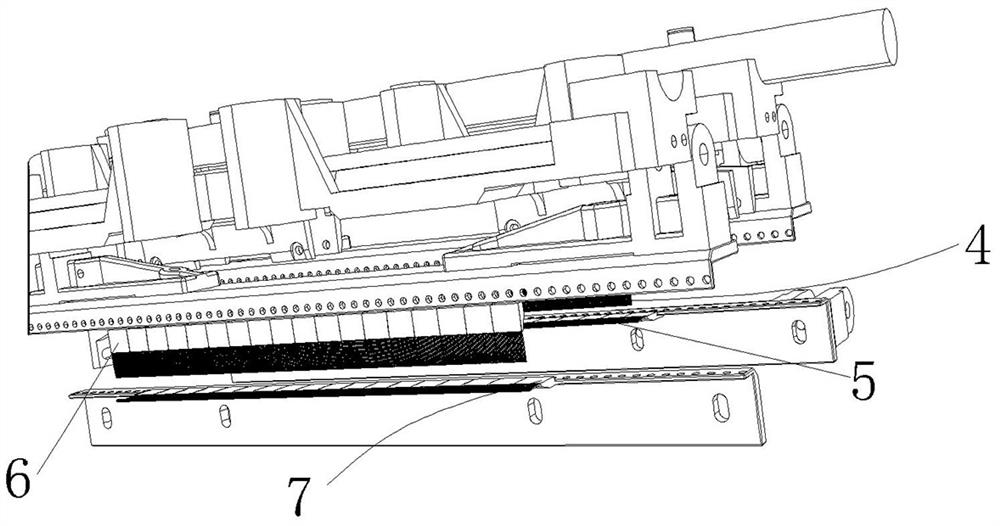

[0032] like image 3 Shown: a non-woven fabric terry planting process equipment, including a terry puncture needle 4, and a needle 5 that cooperates with the terry puncture needle to realize terry reservation; it also includes a fixed line puncture needle array cast in one 6, and the crochet needle array which is located below the puncture needle array and cooperates with the puncture needle to realize the hook and loop, and complete the chain stitch. The fixed line needle spacing is 14 needles within 1 inch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com