Electric spindle unbalance fault diagnosis method

A technology of fault diagnosis and electric spindle, which is applied in the direction of instruments, computer control, simulators, etc., can solve the problems of high dependence on human level, difficult fault identification, and difficult conclusions, so as to improve the degree of intelligence and accuracy , Efficient judgment, simple and intuitive judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

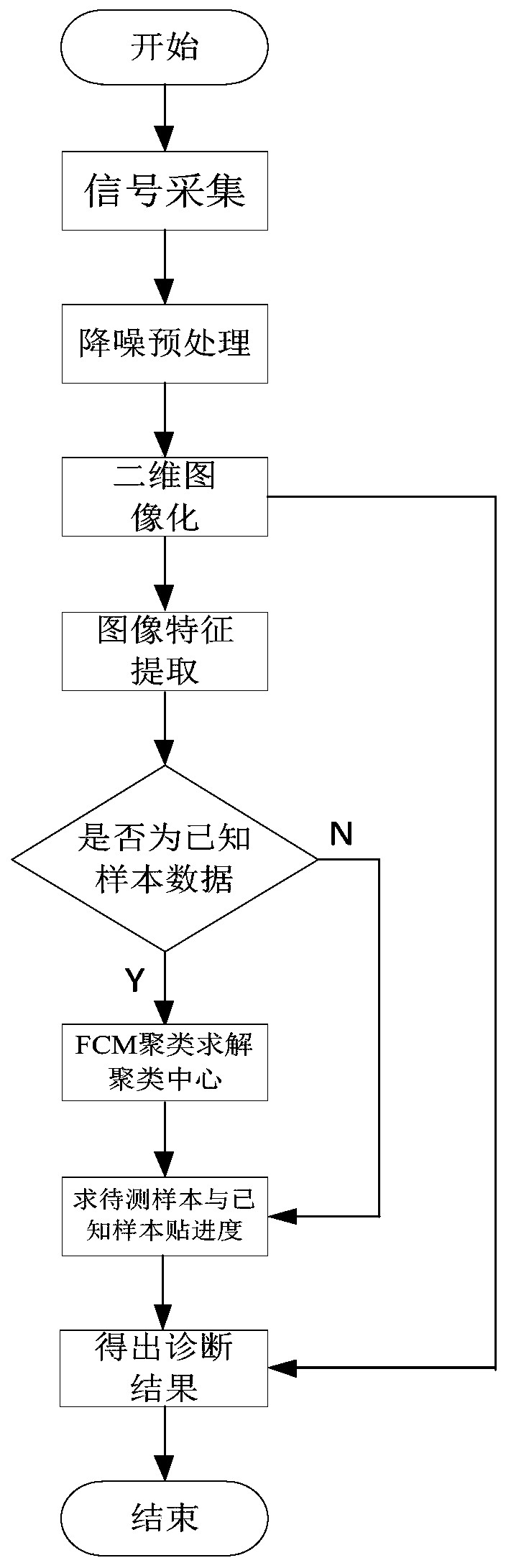

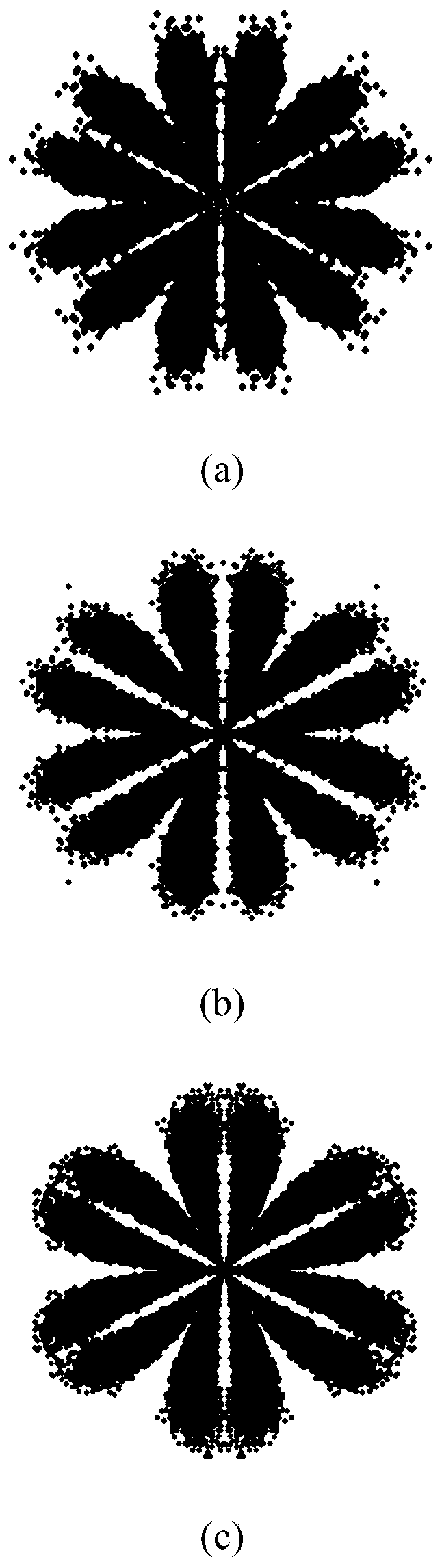

[0034] see figure 1 , a method for diagnosing the unbalanced faults of the electric spindle. After measuring the time-domain vibration signals of the electric spindle under different unbalanced states, it is transformed into a hexagonal snowflake-like mirror-symmetric image by using the symmetric polar coordinate image method after noise reduction processing. Through the snowflake image to judge the severity of the unbalanced fault of the electric spindle; extract the characteristic parameter matrix of the snowflake image through the gray level co-occurrence matrix and use it as the input of the FCM clustering to obtain the cluster center, and judge the fault sample according to the calculation of the progress of the Haiming paste Fault category. The specific steps of the diagnostic method are:

[0035] 1) Measure the vibration data of the electric spindle in differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com