A method for preparing a transparent conductive nanowire grid film on a three-dimensional microstructure surface

A transparent conductive, conductive nanotechnology, applied in the field of photoelectric detection, can solve the problems of reduced light transmittance, increased resistance, difficulty in taking into account light transmittance and reliable electrical path, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0027] A high-efficiency visible light detection structure and manufacturing method of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

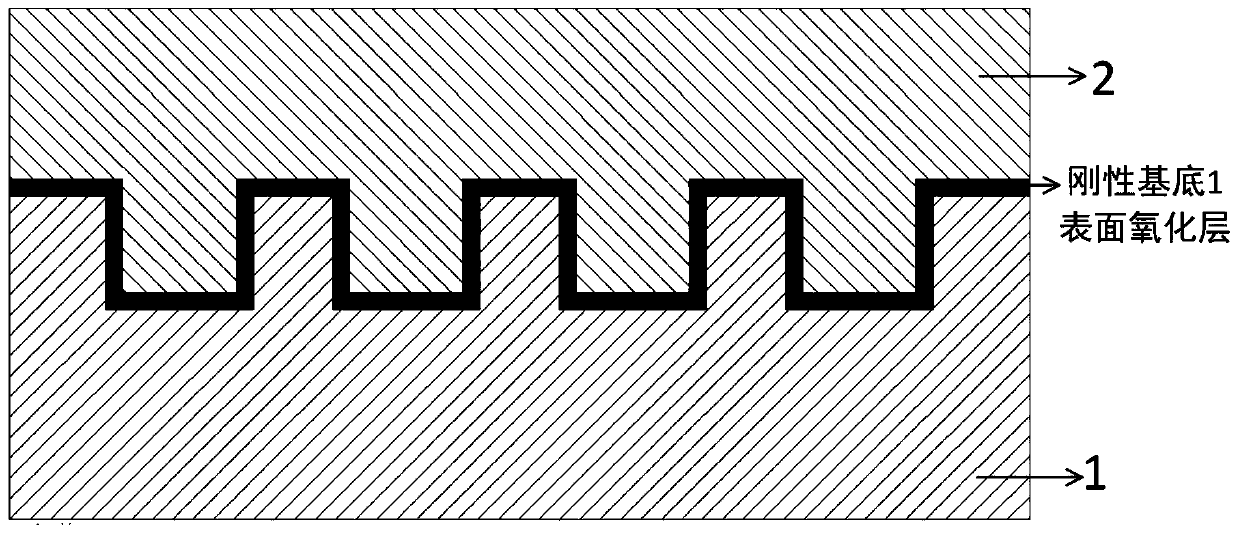

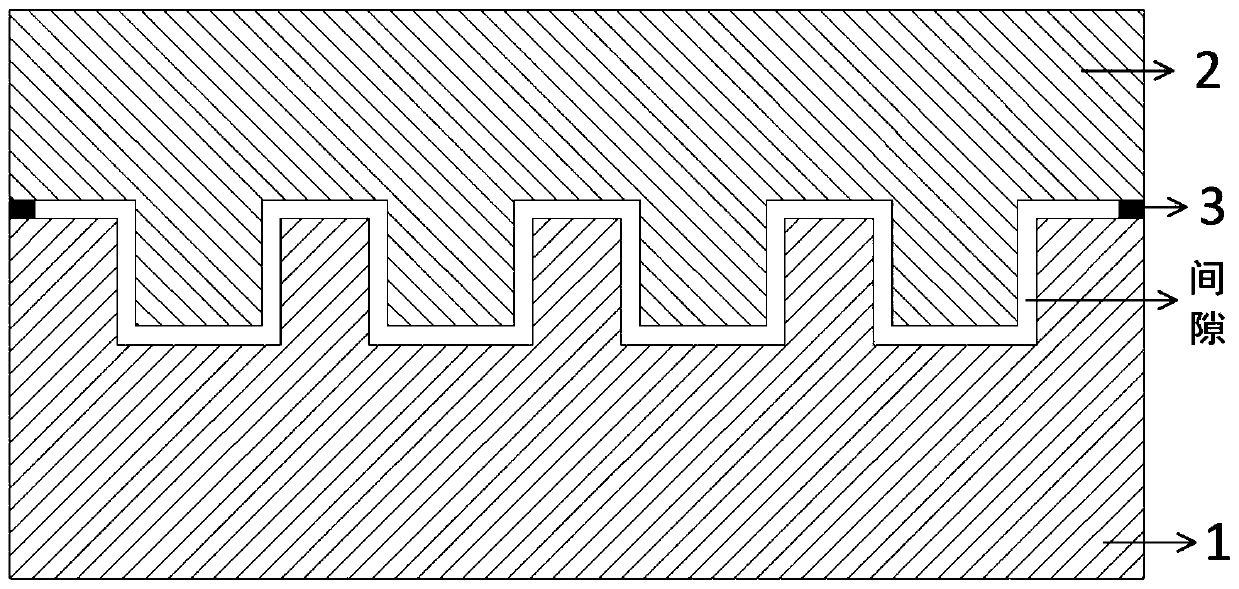

[0028] The present invention is a method for preparing a transparent conductive nanowire grid film on the surface of a three-dimensional microstructure, specifically as follows: the material of the rigid substrate 1 is a material that can be oxidized at high temperature and the oxide layer can be removed by etching. In this embodiment, it is preferably monocrystalline silicon. The material of the flexible press plate 2 is a material that can be embossed, and in this embodiment it is preferably PDMS.

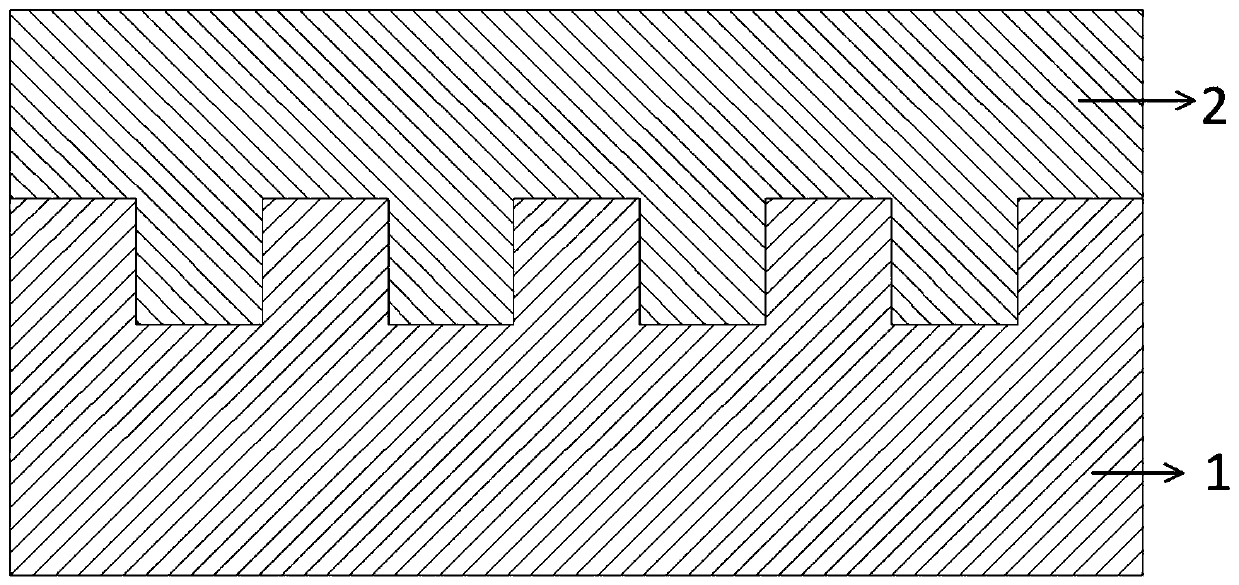

[0029] Such as figure 1 As shown, first a three-dimensional microstructure is fabricated on the upper surface of a single crystal silicon wafer, and the single crystal silicon wafer with a three-dimensional microstructure on the surface is a rigid substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com