A double-layer plasma generator and its application

A plasma and generator technology, applied in the field of plasma, can solve the problems that the generation of gas cannot be effectively adjusted, it is not conducive to the uniform ignition and combustion of propellants, and the ablation area of the capillary wall is small, so as to achieve controllable and uniform pressure Jet, plasma ablation large wall, the effect of solving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

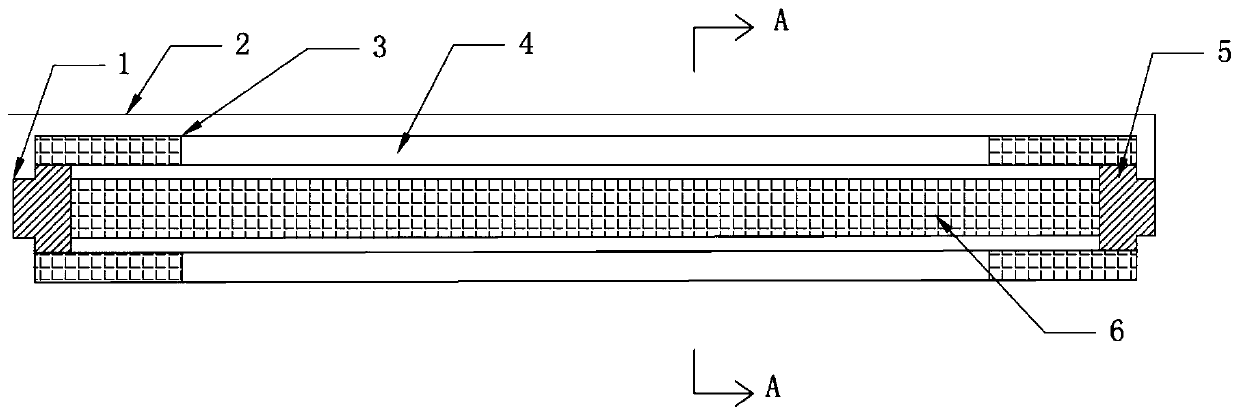

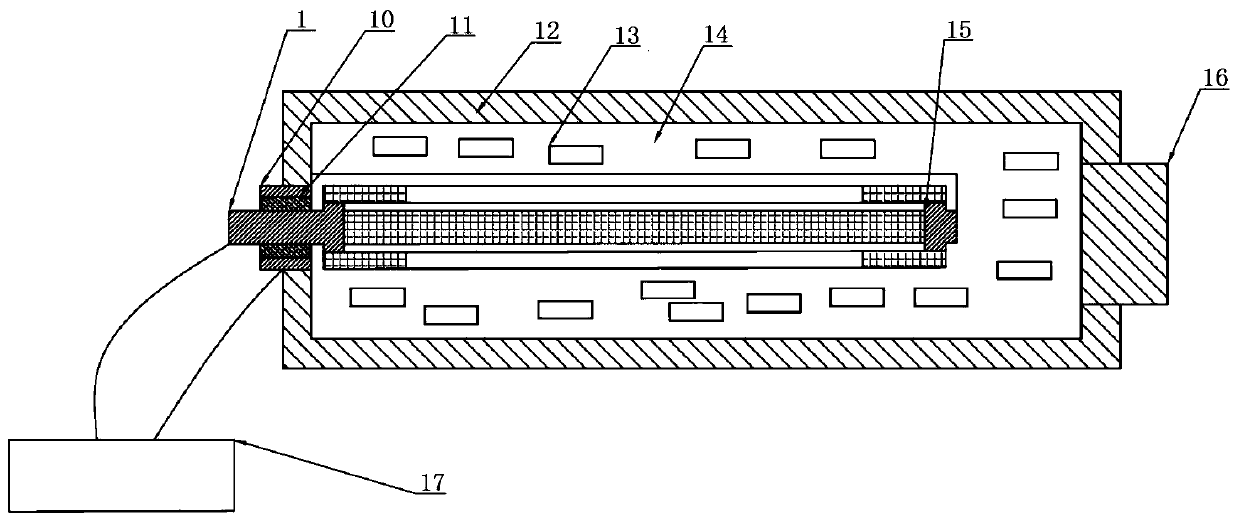

[0044] A double-layer plasma generator, the bottom of the positive plug 1 is Φ10mm×5mm in size, the raised part is Φ5mm×5mm in size, the raised part is connected to the airtight erupter body 12, and the bottom external thread is connected to the outer ablation layer 3 connection, the bottom of the boss is connected to the inner ablation layer 6;

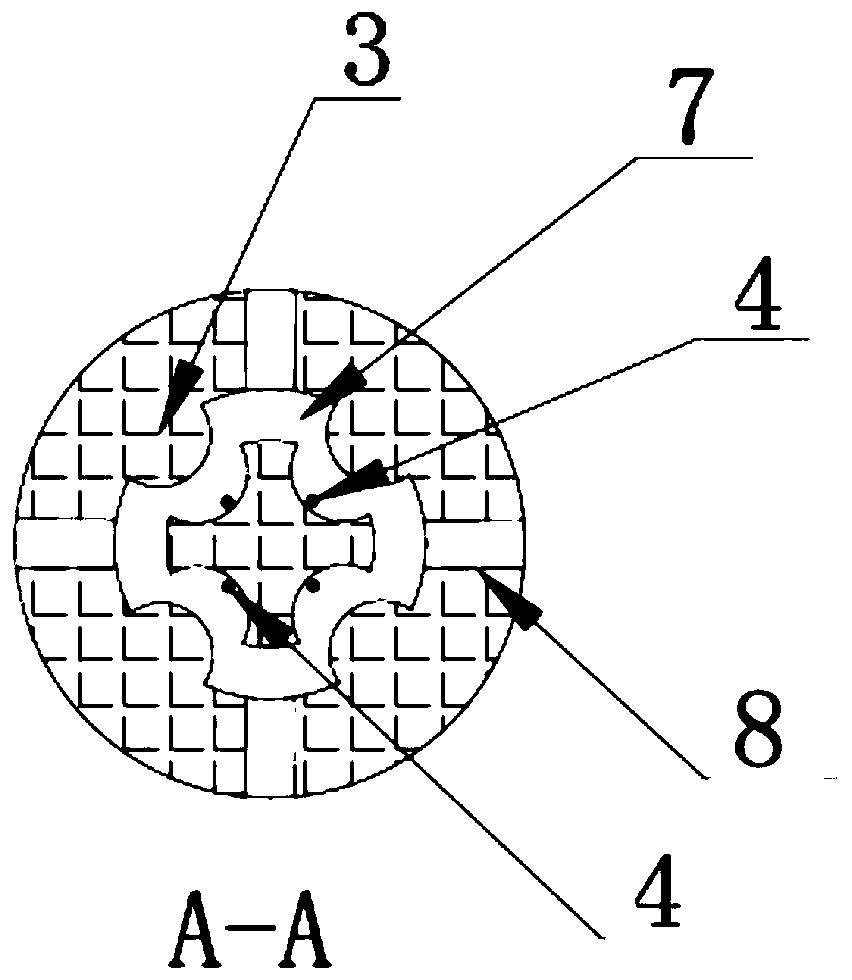

[0045] The outer ablation layer 3 is made of polytetrafluoroethylene, the inner diameter is Φ10mm×150mm, the outer diameter is Φ15mm×150mm, and four slots 8 are evenly distributed on the cylinder, and the length of the slots 8 is 100mm. The width is 2mm, and four convex structures with a radius of 2-4mm are distributed inside the cylinder, corresponding to the concave structure of the inner ablation layer 6, and the two ends are respectively connected with the positive plug 1 and the negative plug 5.

[0046] The inner ablation layer 6 is made of polytetrafluoroethylene, with a diameter of Φ8mm×150mm, and four concave structures with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com