Method for dividing dynamic flowing units of extra-high-water-cut stage oil reservoir

A technology of ultra-high water cut period and flow unit, which is applied in the fields of production fluid, earthwork drilling and production, and special data processing applications, etc. It can solve problems such as inability to describe and solve invalid drives, and no combination of geology and reservoirs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further describe the present invention, examples are used for detailed description.

[0041] Considering the heterogeneity of the reservoir, a five-point numerical simulation model is established according to the required conditions, and the flow units are divided for the ultra-high water-cut period. The model parameters are set as follows:

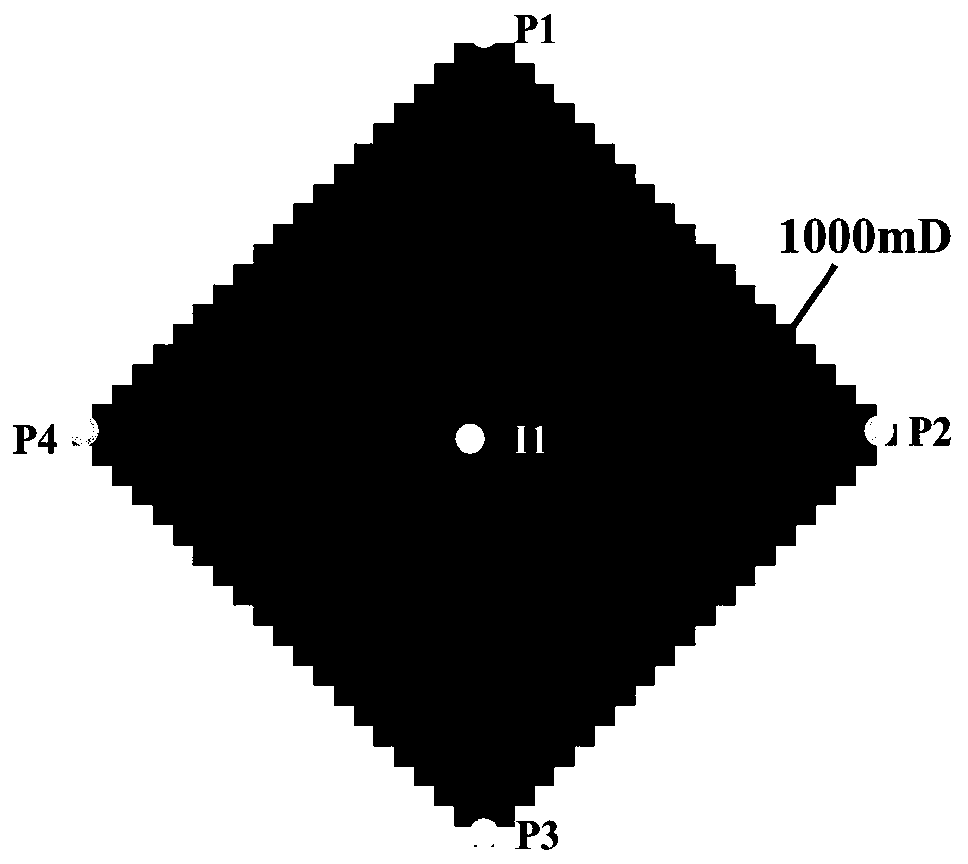

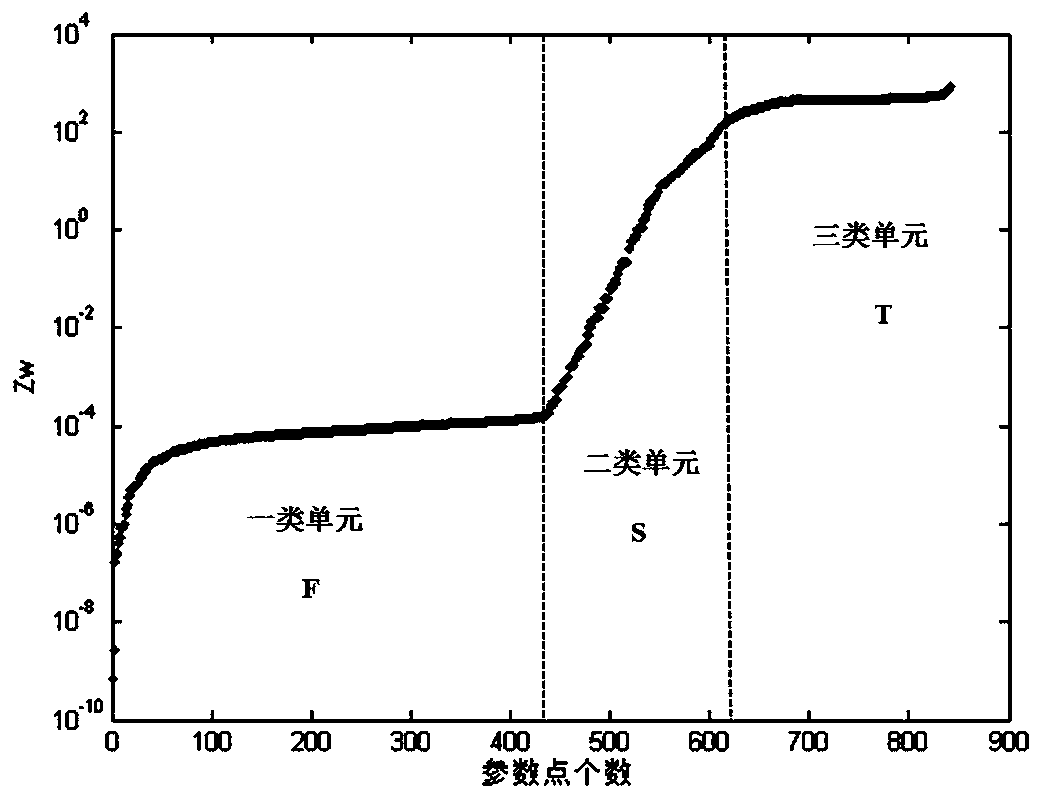

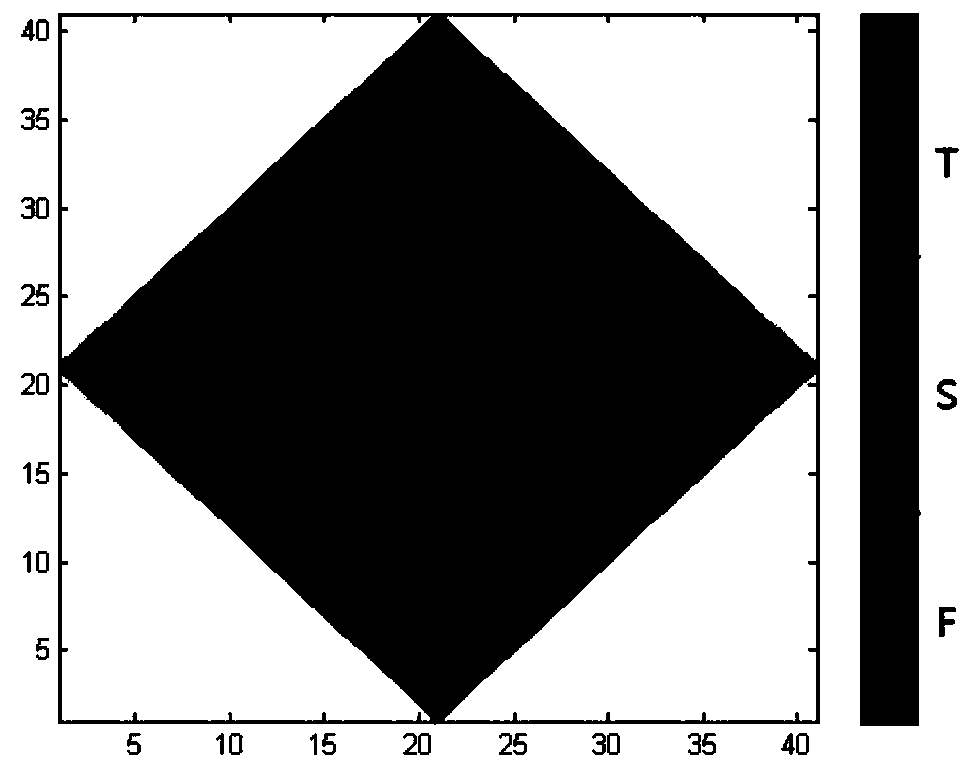

[0042] The distance between injection and production wells in the model is 300m; the model has a high permeability zone with a permeability of 1000mD, and the permeability on both sides of the high permeability zone is 500mD; the permeability at the boundary is low, the lowest is 50mD, and the permeability gradually changes to both sides; The injection wells (P1, P2, P3, P4) are distributed around the model, and the production well (I1) is in the center of the model. The schematic diagram of the model is as figure 1 shown.

[0043] Step 1: Regression and arrangement of 100 relative permeability curves in Shengli Oilf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com