T-shaped floating element capacitive shear stress microsensor chip

A micro-sensor, shear stress technology, applied in the field of sensors, can solve the problems of unfavorable micro-sensor structure optimization design, large amount of calculation, blockage of comb structure, etc., to reduce the probability of blockage or adhesion, improve reliability and continuous, The effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

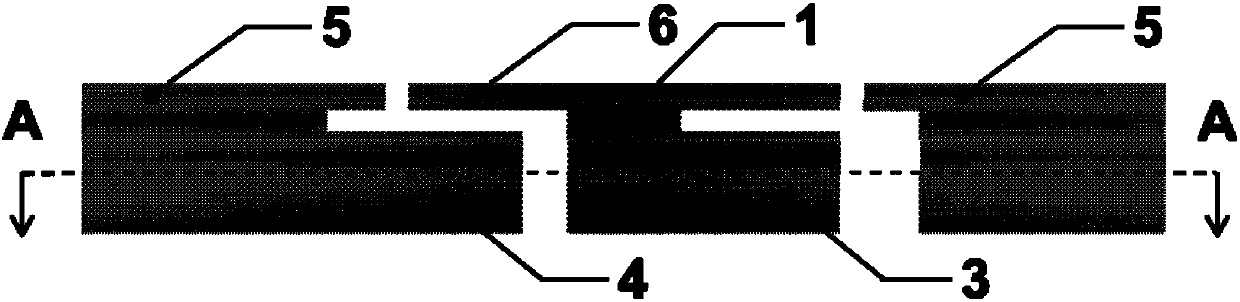

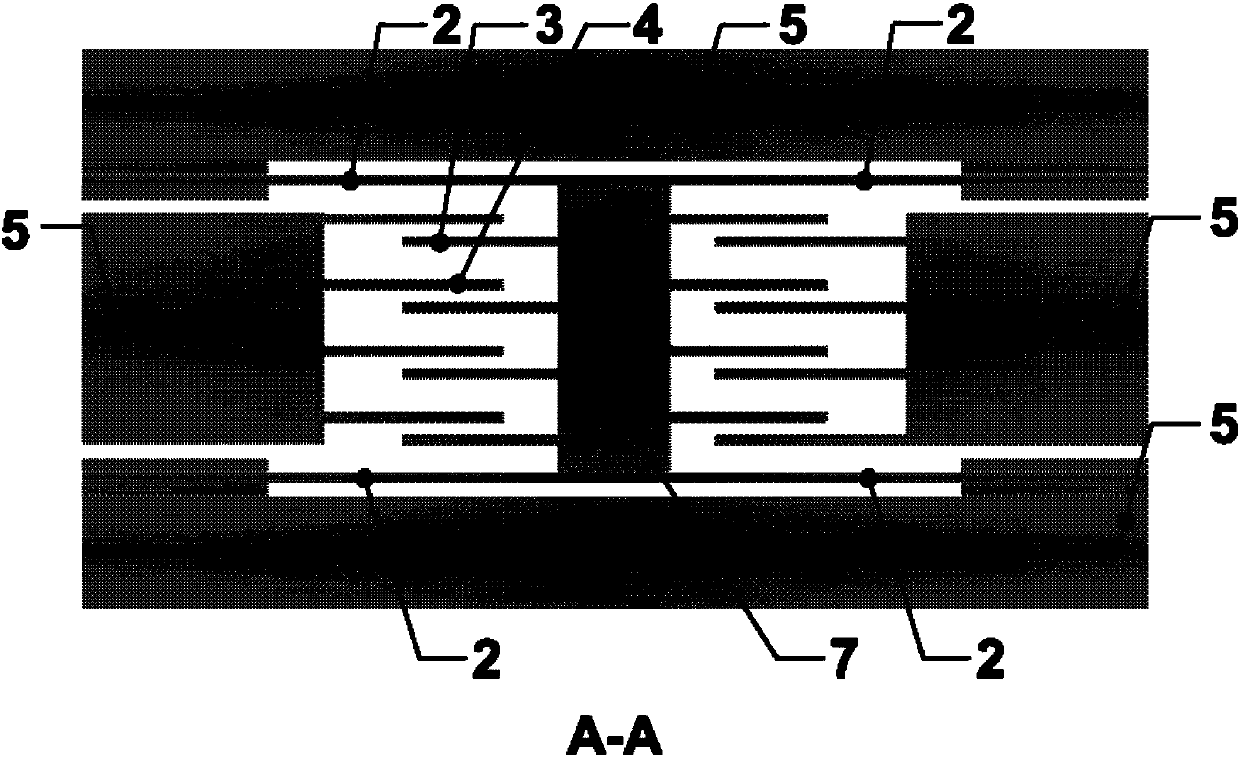

[0017] A kind of T-shaped floating element capacitive shear stress microsensor chip of the present invention comprises: T-shaped floating element (1), elastic beam (2), movable comb (3), fixed comb (4) and base ( 5); if figure 1 -3 shown.

[0018] The T-shaped floating element (1) has an upper surface (6) and a lower central axis (7). During detection, the upper surface (6) is flush with the surface of the fluid wall surface measured by the microsensor, and the upper surface of the T-shaped floating element (1) ( 6) Covering the elastic beam (2), the movable comb (3) and the fixed comb (4) at the same time, the T-shaped floating element (1) is surrounded by four bases (5), and the elastic beam (2) There are four, located at the front and rear ends of the T-shaped floating element (1), and the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com