Intelligent remote debugging system

A remote debugging and intelligent technology, applied in transmission systems, using remote testing to detect faulty hardware, TVs, etc., can solve problems such as inability to achieve real-time and continuous recording, failure to be dealt with in the first place, and high requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

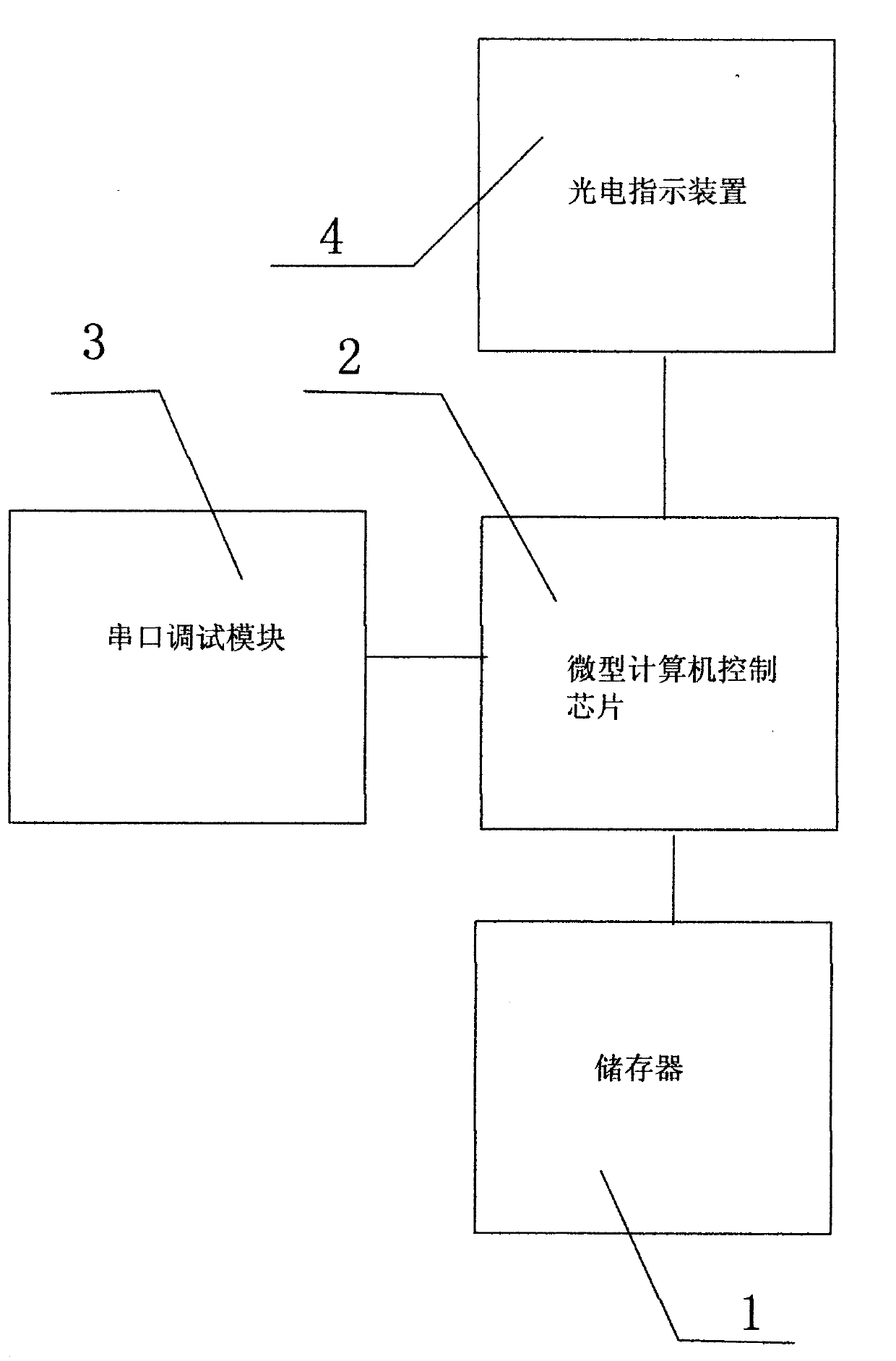

[0009] figure 1 is a structural diagram of an embodiment of the present invention, such as figure 1 As shown, the intelligent remote debugging system of the present invention is electrically connected with the object to be debugged, a hard disk 1 for storing data information, a microcomputer 2 for controlling and processing the acquired data information, and a monitor for connecting to the object to be debugged 3 and a status indicator light 4, the microcomputer 2 is electrically connected to the hard disk 1, and the microcomputer 2 is electrically connected to the monitor 3.

[0010] The microcomputer 2 and the hard disk 1 are bidirectionally electrically connected to obtain the data information in the hard disk 1, the microcomputer 2 is bidirectionally electrically connected to the monitor 3, the monitor 3 is connected to the object to be debugged, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com