Cassette Rotation Mechanism and Loading Chamber

A technology of rotating mechanism and loading chamber, which is applied in the direction of transportation and packaging, conveyor objects, electrical components, etc. It can solve the problems of unergonomic operation, different friction coefficients, and failure to return the film box, so as to improve the process The effect of making yield, reducing process cost, and improving chip yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

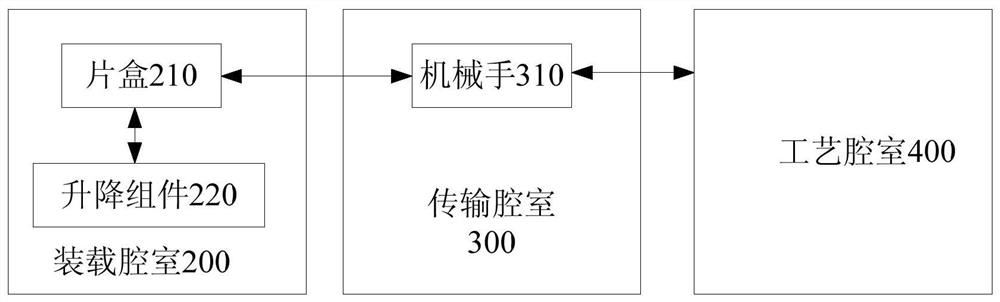

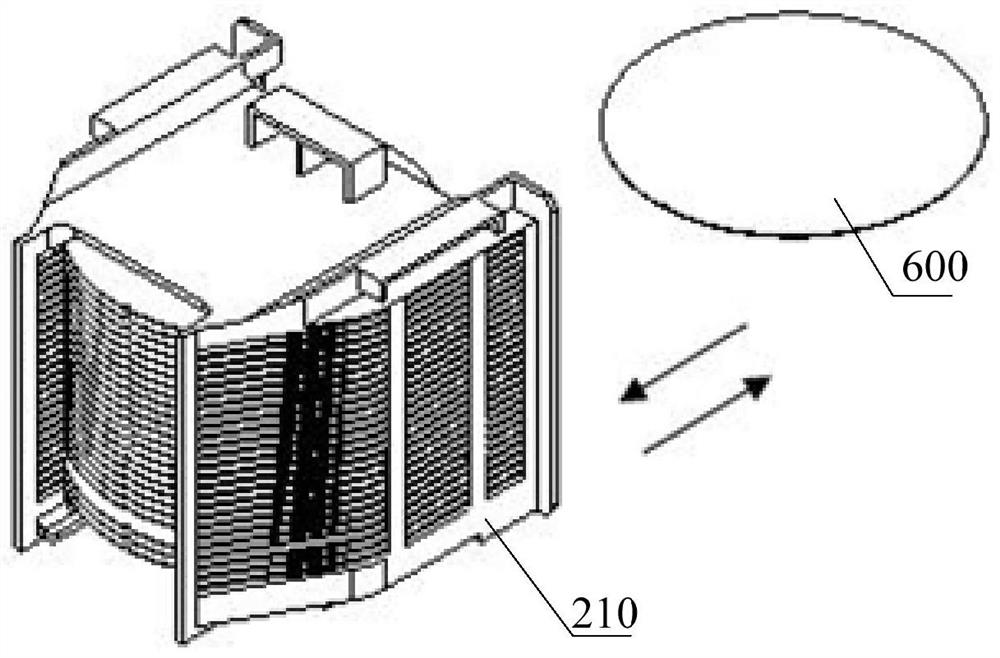

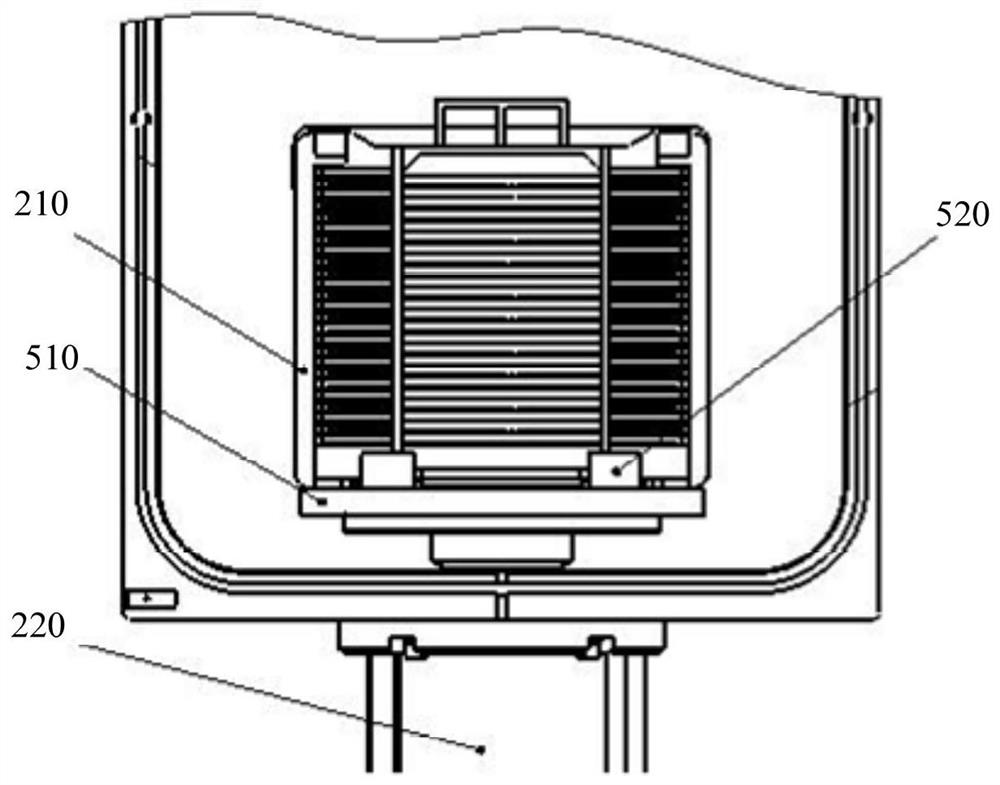

[0075] Such as Figure 6 to Figure 11 As shown, the first aspect of the present invention relates to a cassette rotating mechanism 100 . Wherein, the cassette rotating mechanism 100 includes a supporting base 110 , a rotating supporting base 120 and a moving assembly 130 .

[0076] The support base 110 mentioned above can move linearly in the vertical direction under the action of the driving force. For example, the support base 110 can be connected with the lifting assembly 220 described below, which provides the driving force for the support base 110 . That is to say, driven by the lifting assembly 220 , the support base 110 can move linearly in the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com