Patents

Literature

71results about How to "Save pickup time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

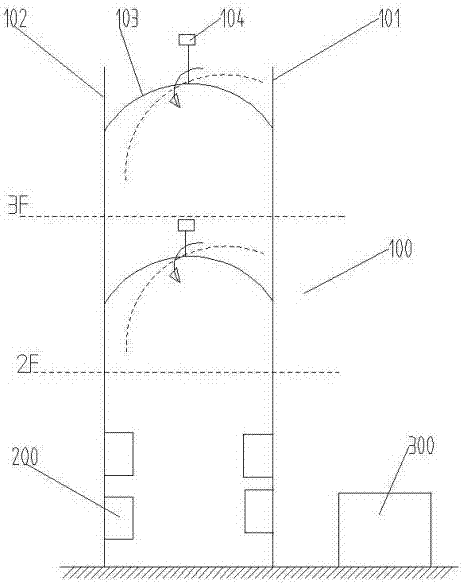

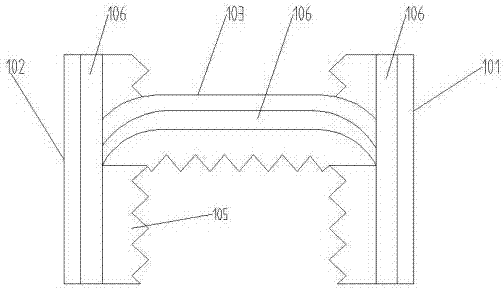

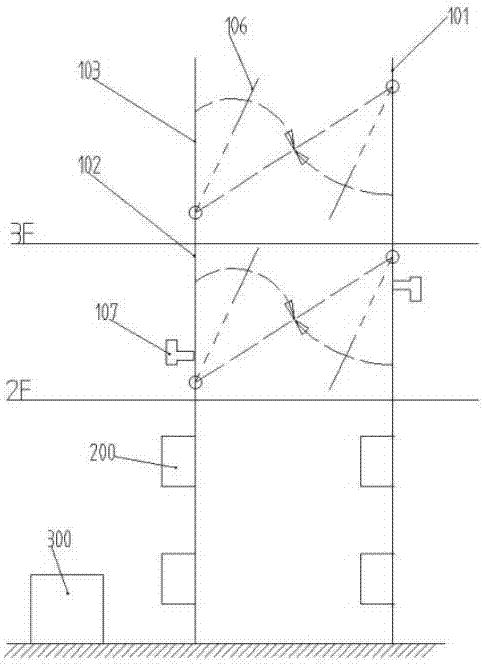

Automatic goods delivery system for high-rise building

InactiveCN107651532ASimple structureReduce productionElevatorsBuilding liftsTransceiverControl system

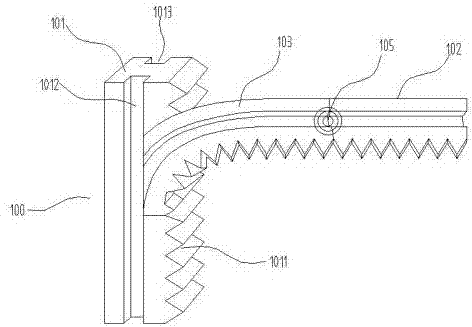

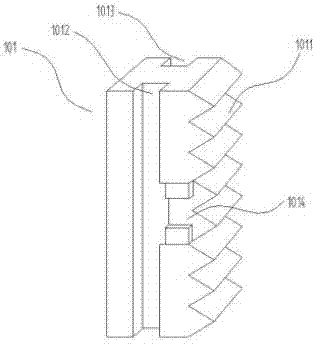

The invention discloses an automatic delivery system for high-rise buildings, which includes a delivery track, a delivery trolley, a delivery box and a control system; the delivery track includes a main rail and an auxiliary rail; the main rail is installed vertically along the wall of the building, There are corresponding attached rails on each floor; there is also a transition rail between the main rail and the attached rail, which is connected by a rail changing device. The rail changing device enables the two ends of the transition rail to be connected / detached from the main rail and the attached rail respectively; The delivery trolley is connected to the delivery track and walks on the delivery track under the action of the driving device; the delivery box is connected to one end of the main track for the courier or the delivery robot to store and pick up the pieces; the control system includes control The center and the main rail part, accessory rail part, track changing part and delivery part connected to it; solve the problem of the last "100 meters" of logistics; facilitate the receiving and dispatching of the receiving personnel and delivery personnel; the high-rise building automatically delivers goods The system has a simple structure and convenient operation, which improves the delivery efficiency of the automatic delivery system for high-rise buildings.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

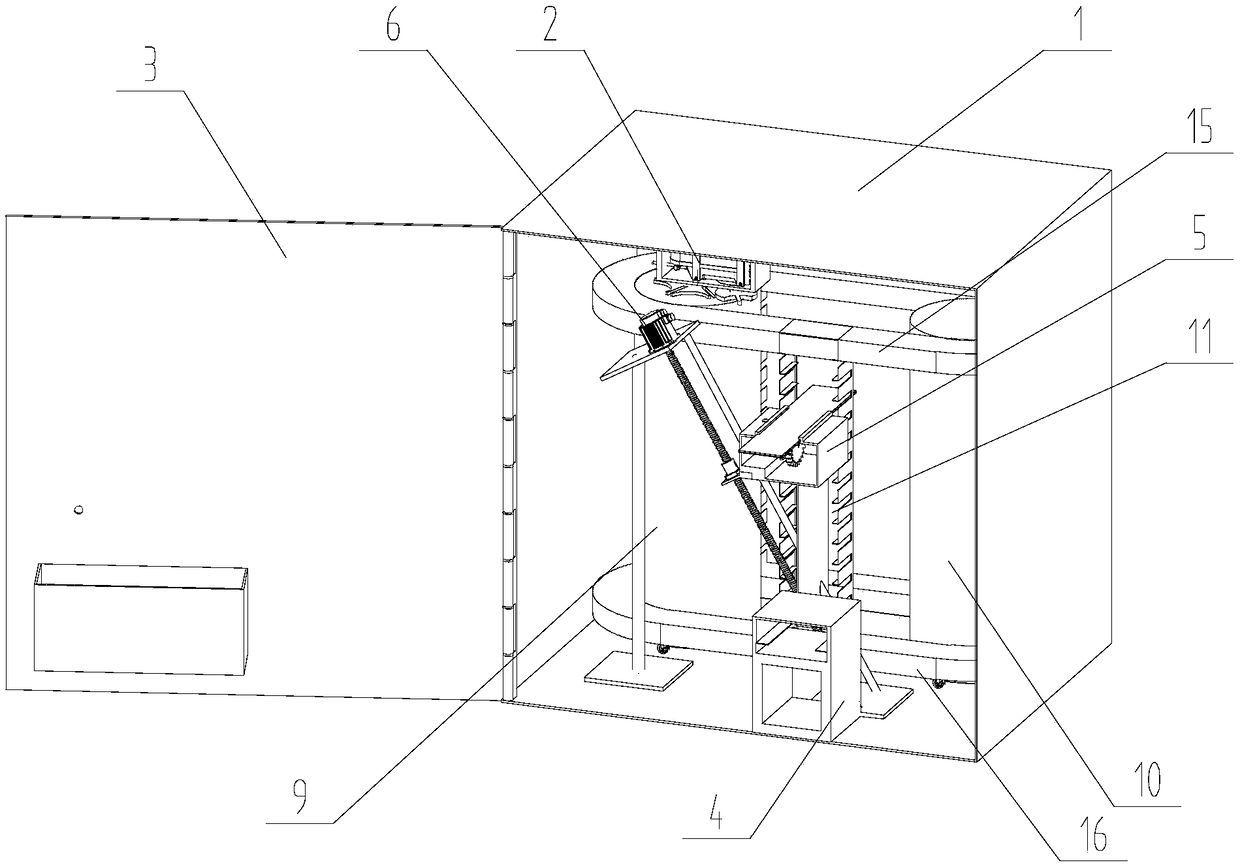

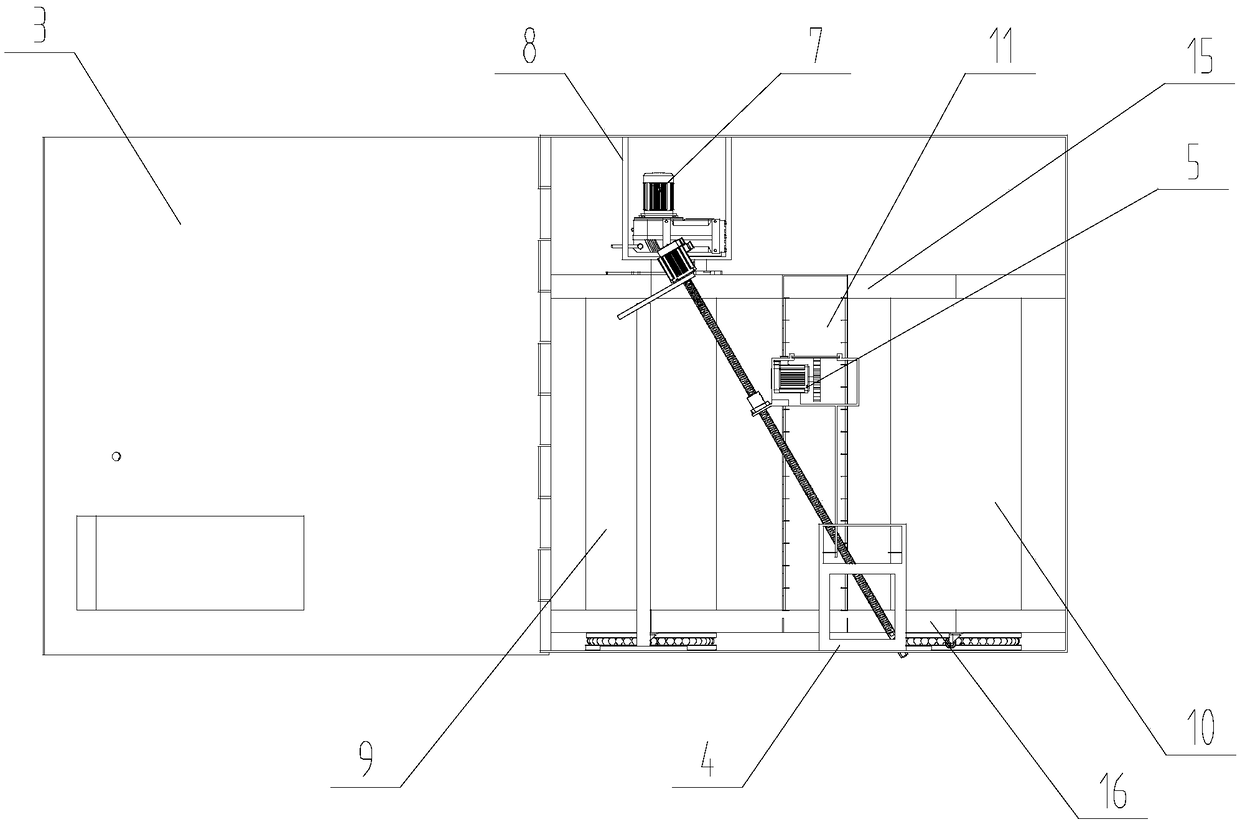

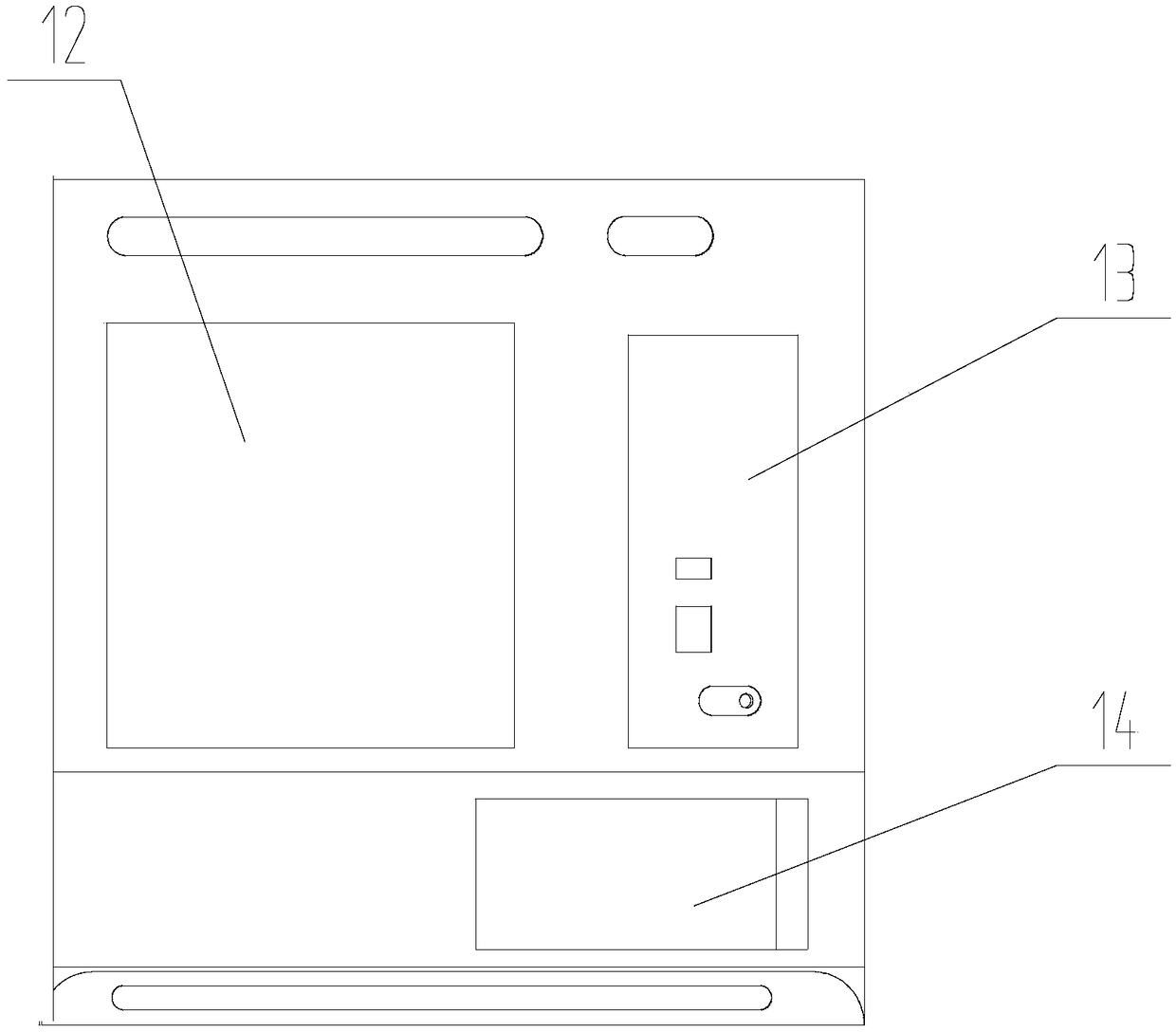

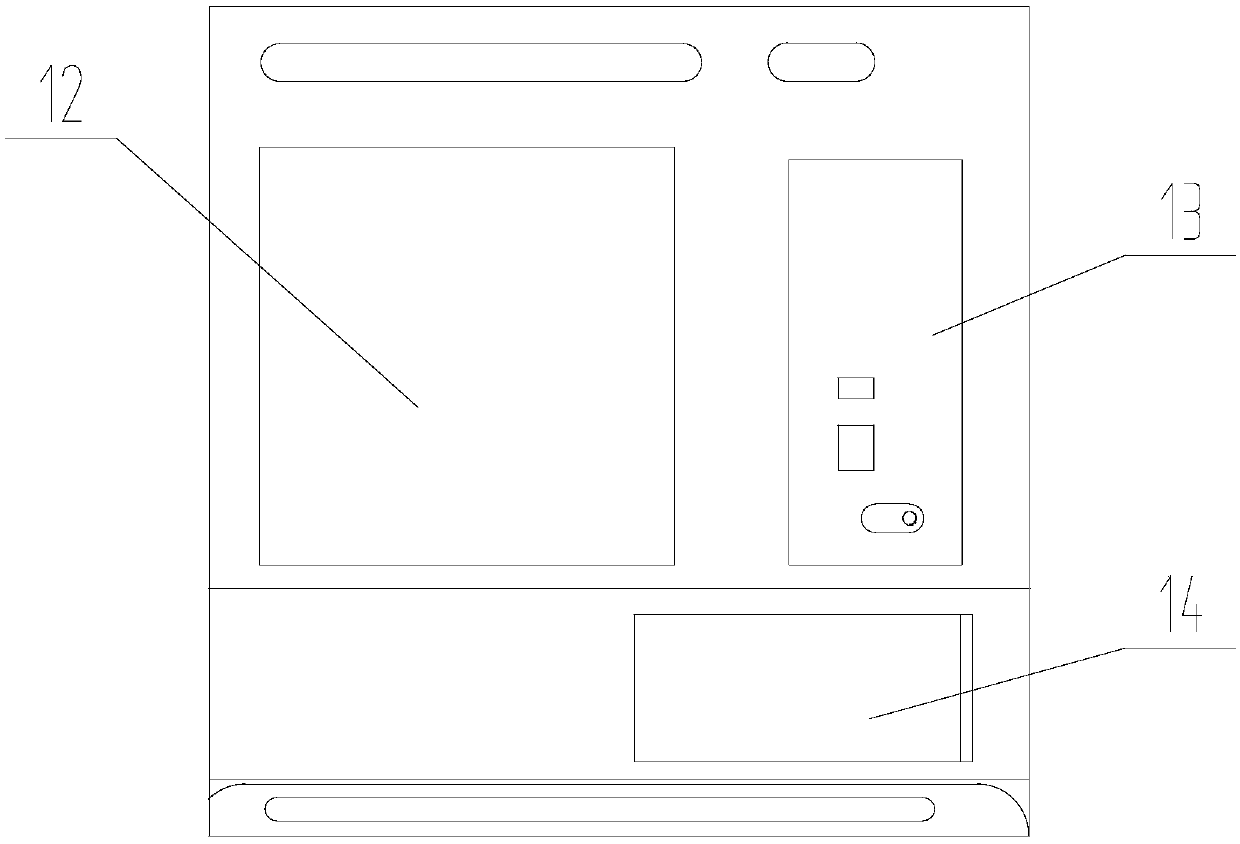

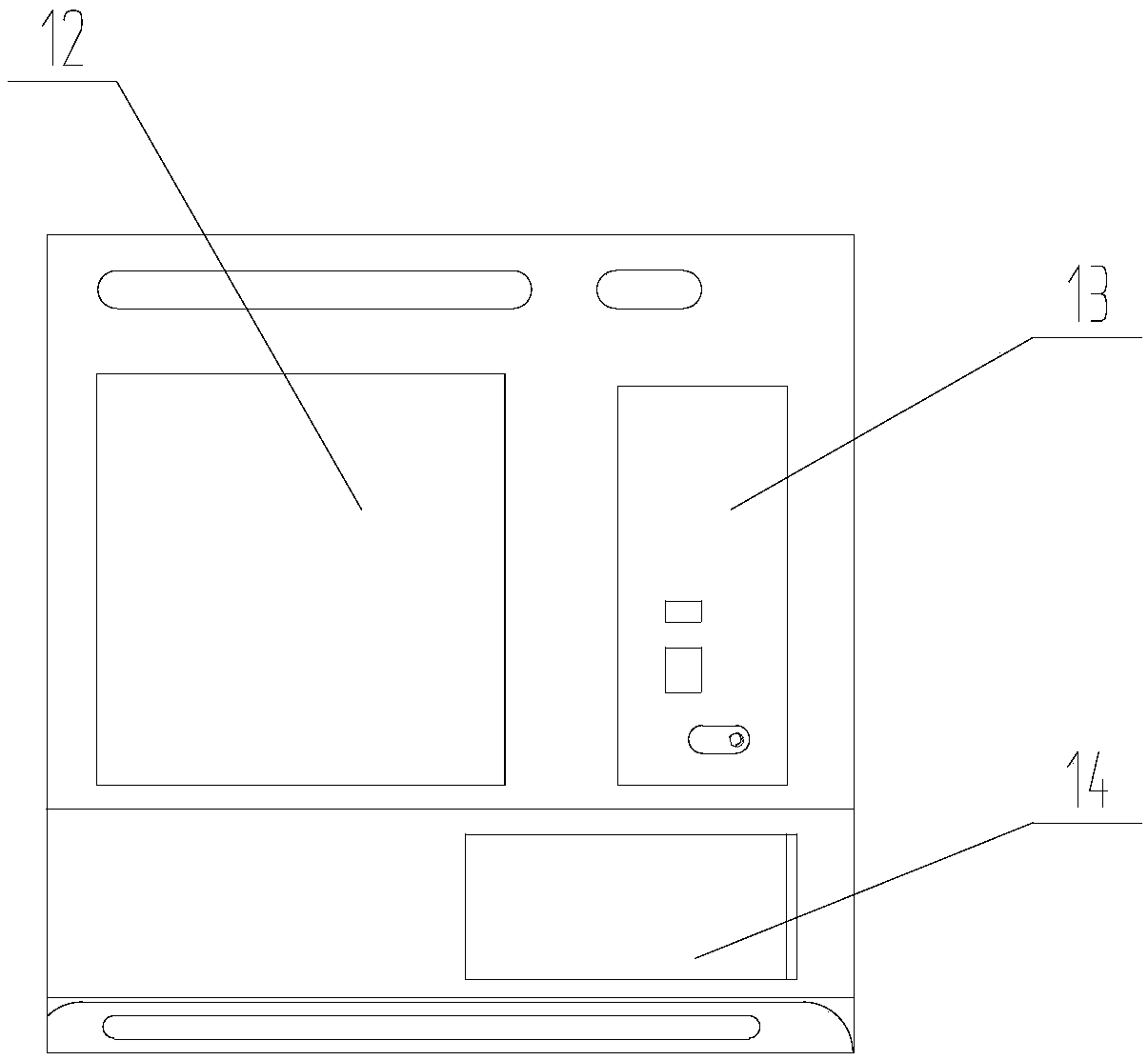

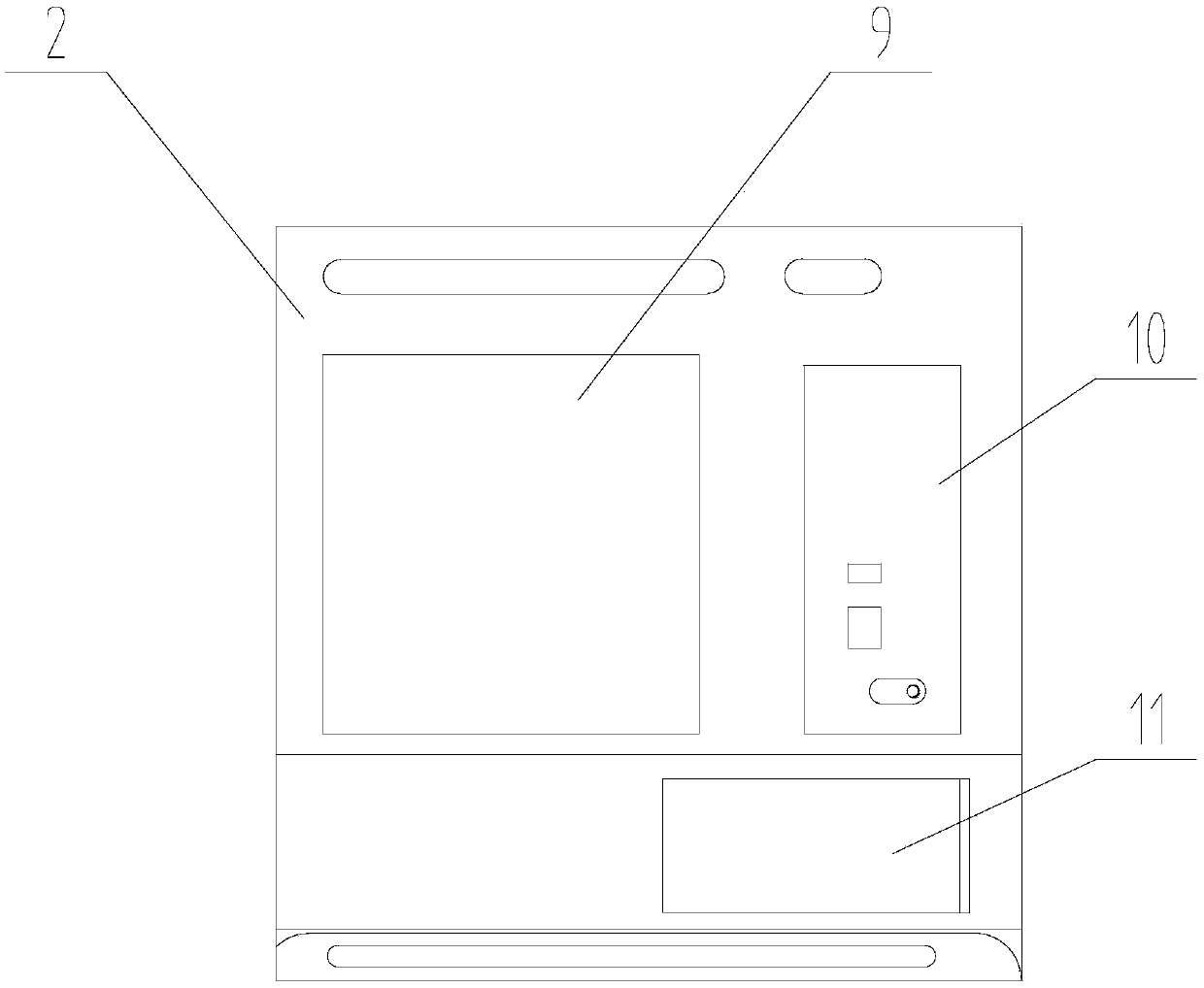

Vending system with overdue reminding rotary material-taking type storage type bento

ActiveCN109493512AEasy to take outTake out accuratelyCoin-freed apparatus detailsApparatus for meter-controlled dispensingHeating timeComputer terminal

The invention discloses a vending system with overdue reminding rotary material-taking type storage type bento, which comprises a user handheld terminal, a vending machine and a cloud server, whereinthe user handheld terminal is provided with a bento selling APP, the vending machine is provided with a code scanning mechanism, the user handheld terminal is connected with the cloud server through anetwork, and the vending machine is connected with the cloud server through GPRS. The vending machine comprises a shell, a door, a rotary driving device, an upright column, a storage bin, a material-taking device and a material-taking driving device, wherein the rotary driving device comprises a rotary motor and a grooved wheel mechanism, the material-taking device comprises an arc-shaped liftingtrack and the material-taking device. The vending system with overdue reminding rotary material-taking type storage type bento can make the user order the food in the vending machine on the APP. After the vending machine receives the order of the user, the food reserved by the user can be processed before the pick-up time reserved by the user. The user can directly take the processed food when taking the meal without waiting for heating time.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

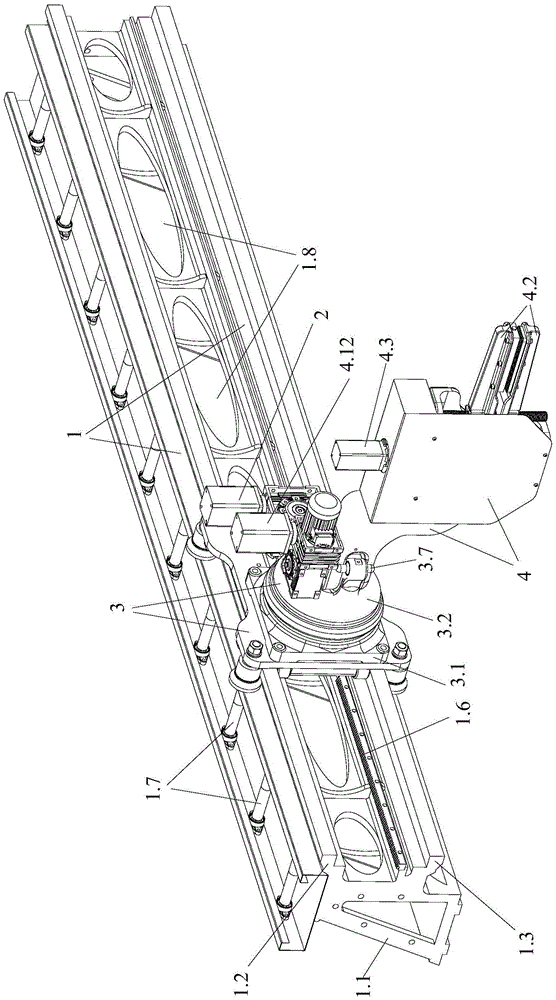

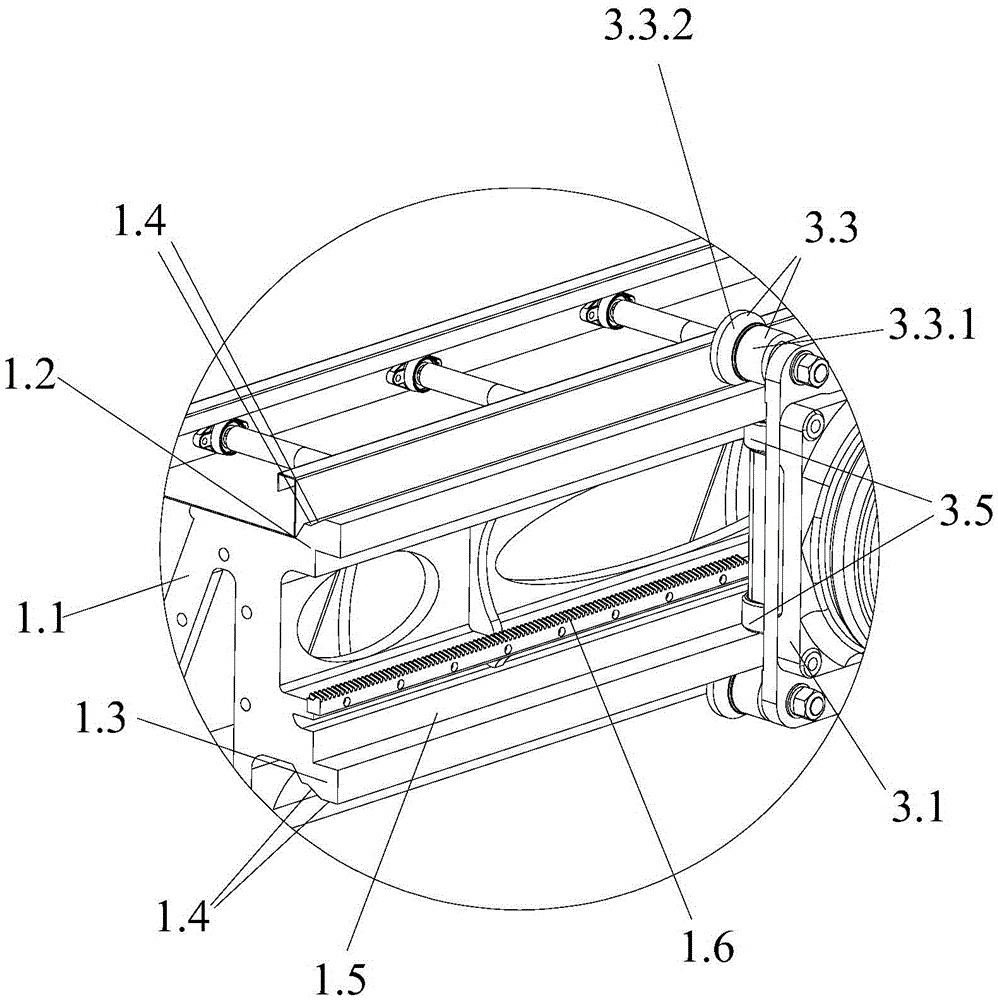

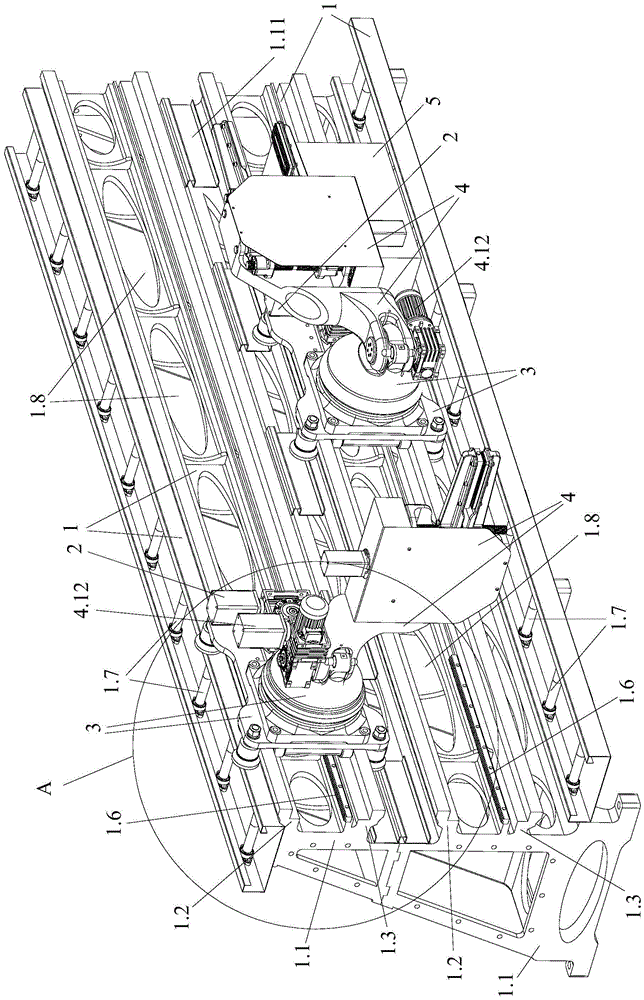

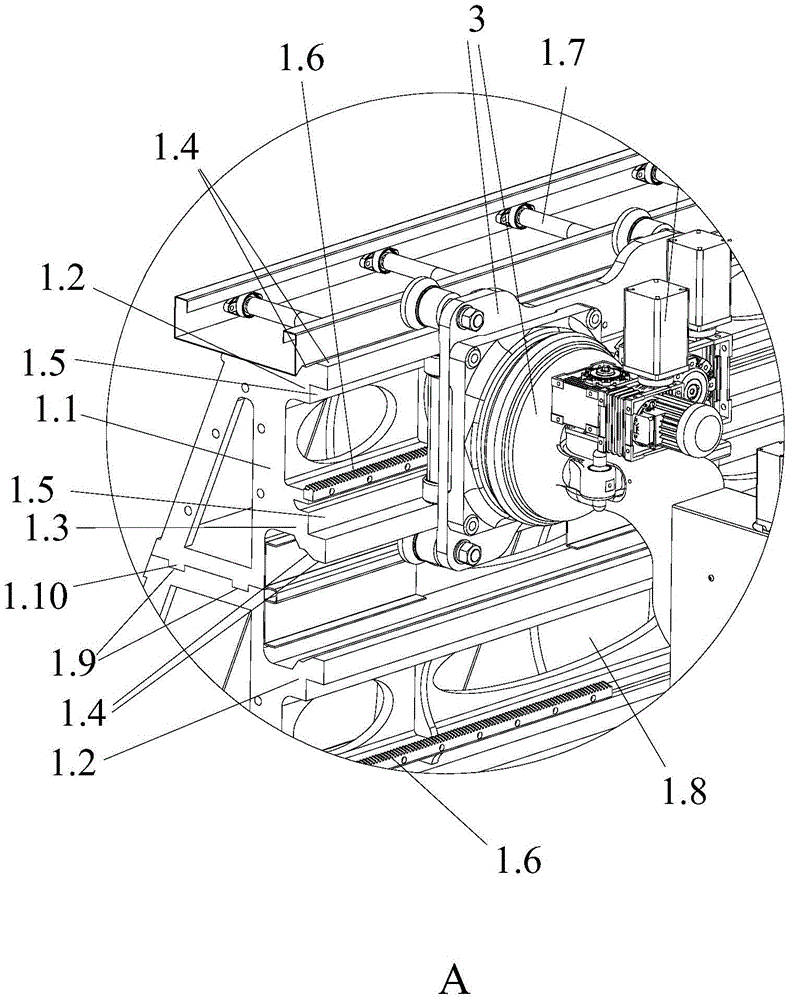

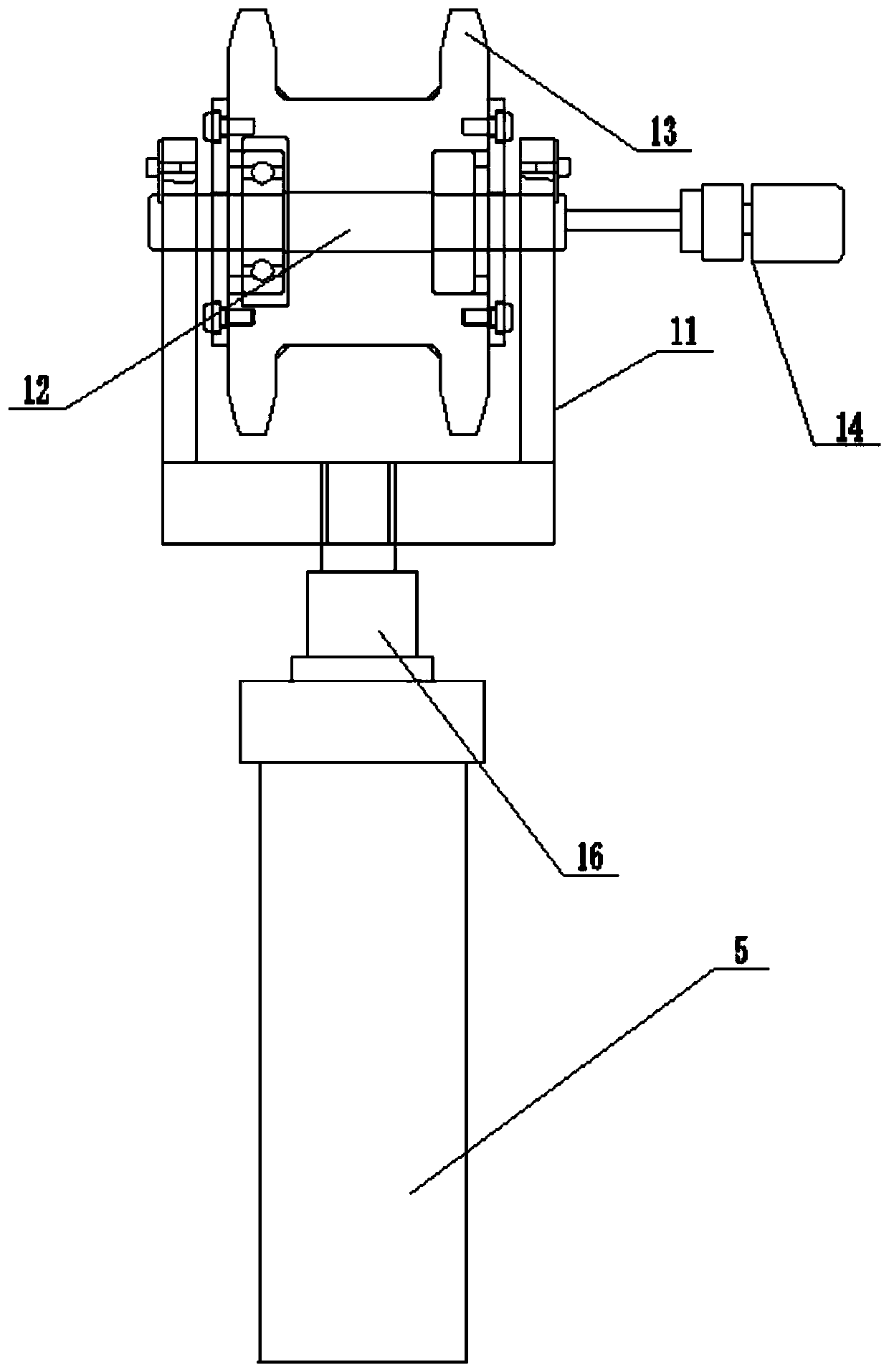

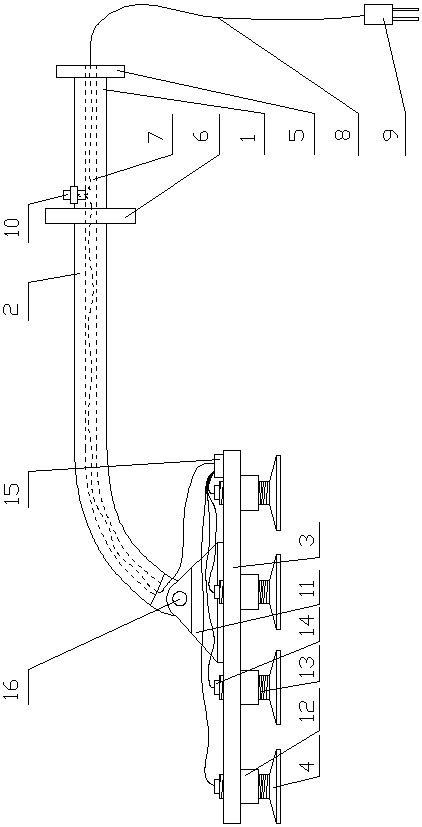

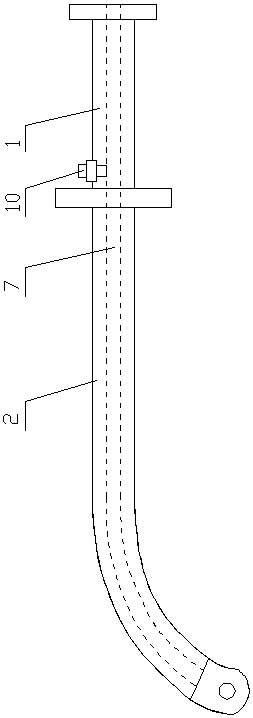

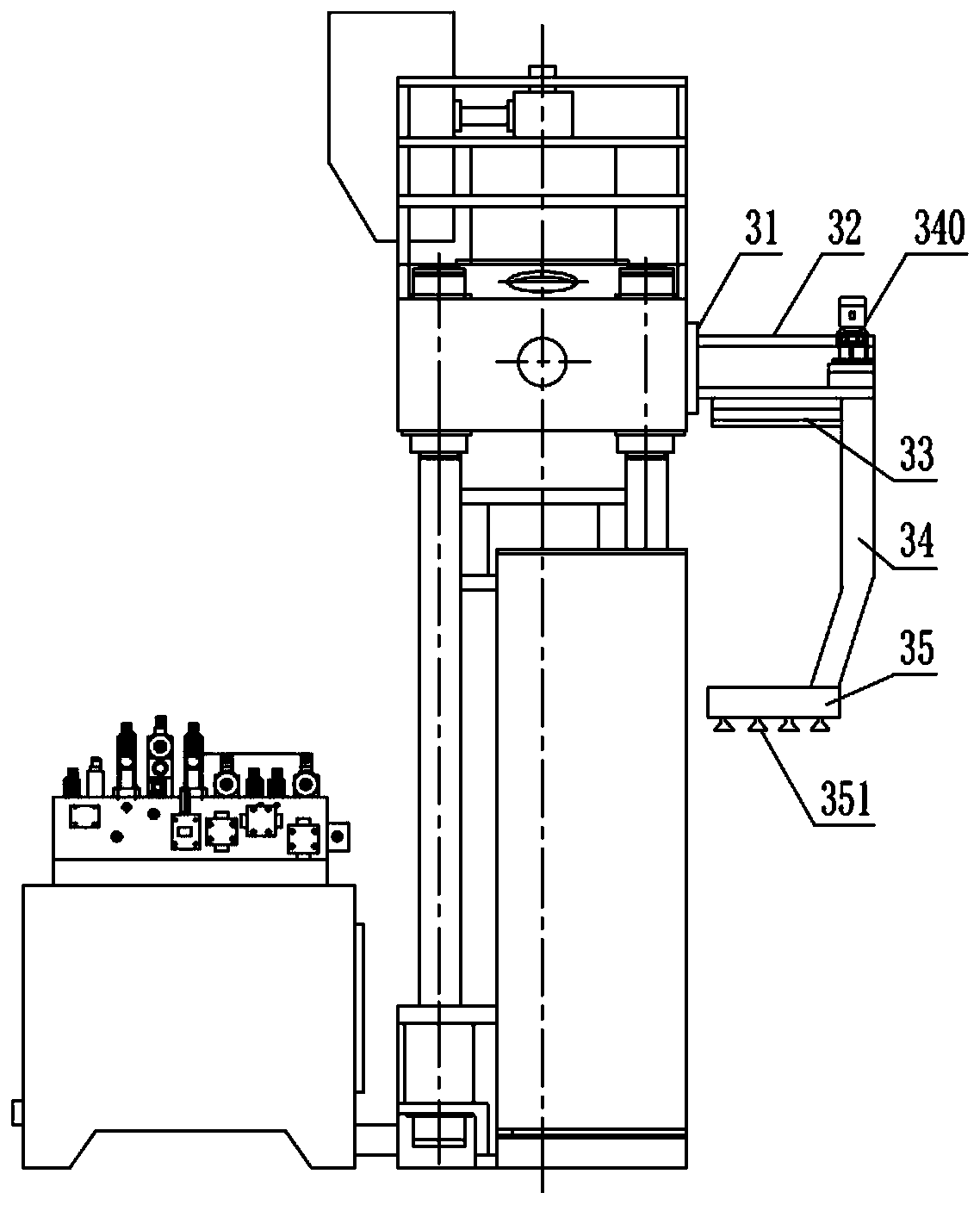

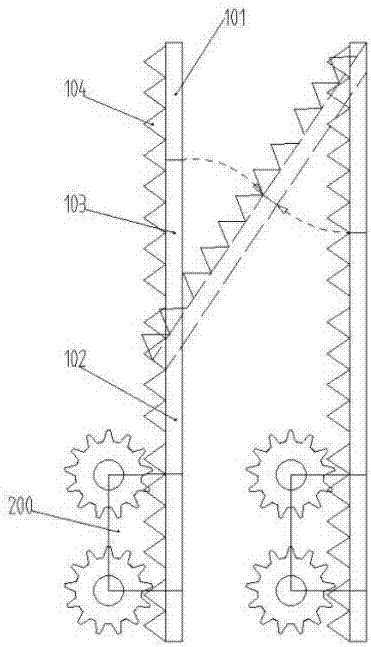

Vertical profile single-rail traction robot

The invention provides a vertical profile single-rail traction robot. The vertical profile single-rail traction robot comprises a vertical walking rail, a mechanical arm for clamping and towing a profile, a transmission mechanism, a driving mechanism for connecting with the transmission mechanism, and a control mechanism; the mechanical arm is buckled on the side surface of the vertical walking rail, and is slidingly connected with the side surface of the vertical walking rail to realize walking movement by hanging on the side surface of the vertical walking rail; the transmission mechanism consists of a transmission device 1 arranged on the mechanical arm and a transmission device 2 arranged on the vertical walking rail; and the control mechanism is respectively in signal connection with the driving mechanism and the mechanical arm. The vertical profile single-rail traction robot adopts the mechanical arm as an actuation mechanism for towing the profile, and is flexible in operation and convenient for control. Meanwhile, the vertical profile single-rail traction robot can shrink the floor area to reduce the production cost, and is not influenced by the ground condition to effectively solve the problem of incapability of guaranteeing the profile towing straightness caused by uneven ground so as to improve the profile towing processing quality.

Owner:广东泰格威机器人科技有限公司

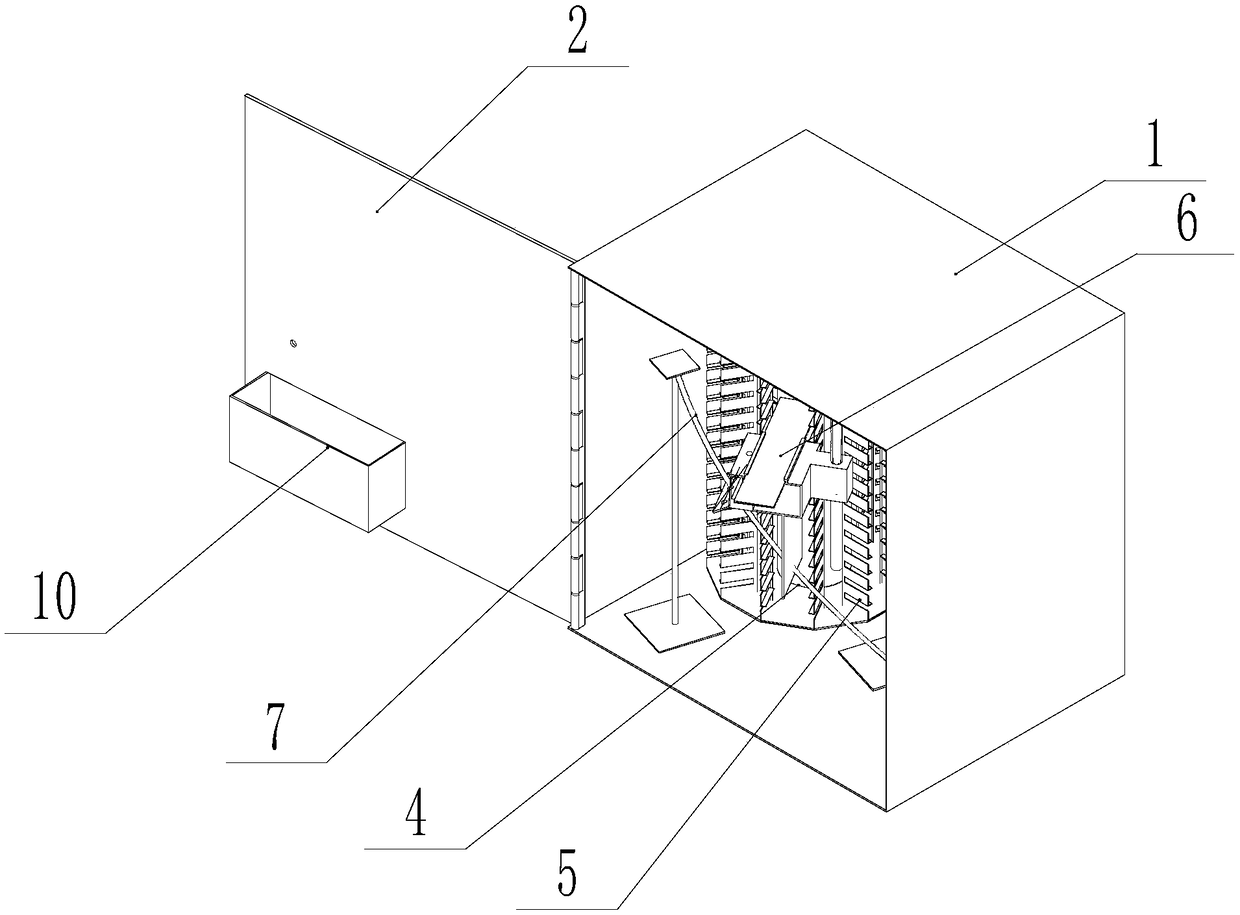

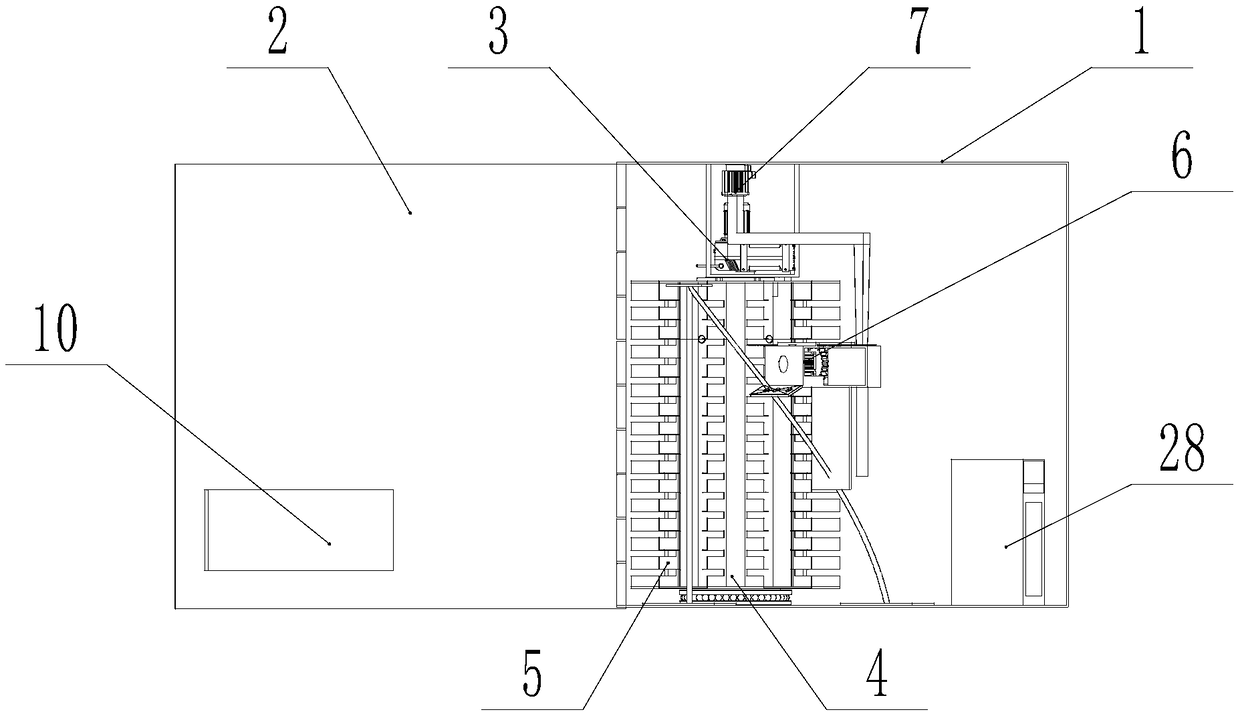

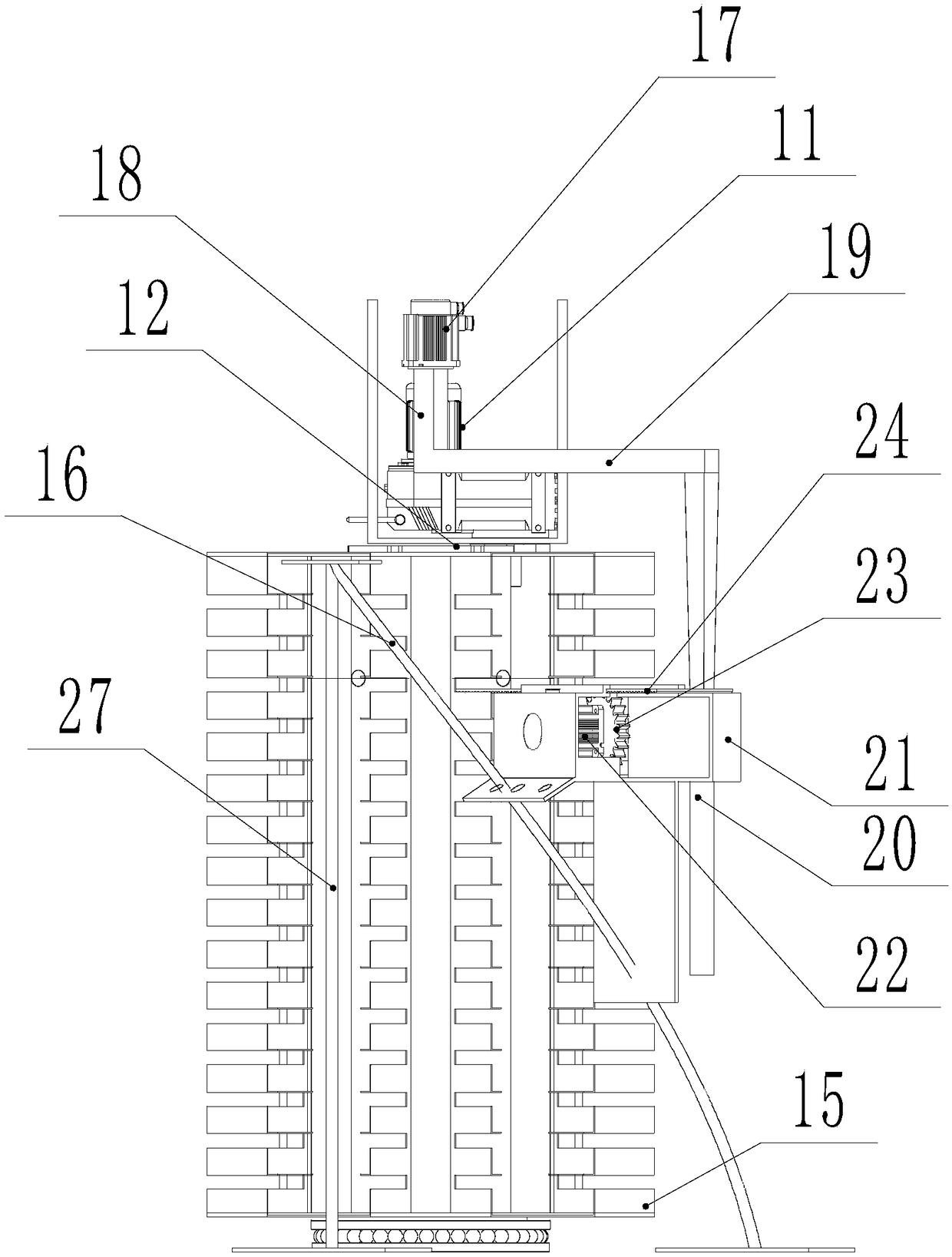

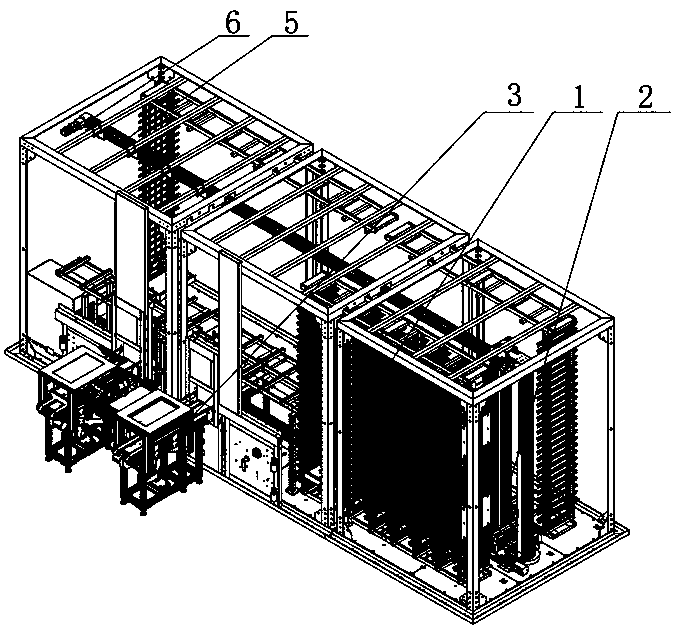

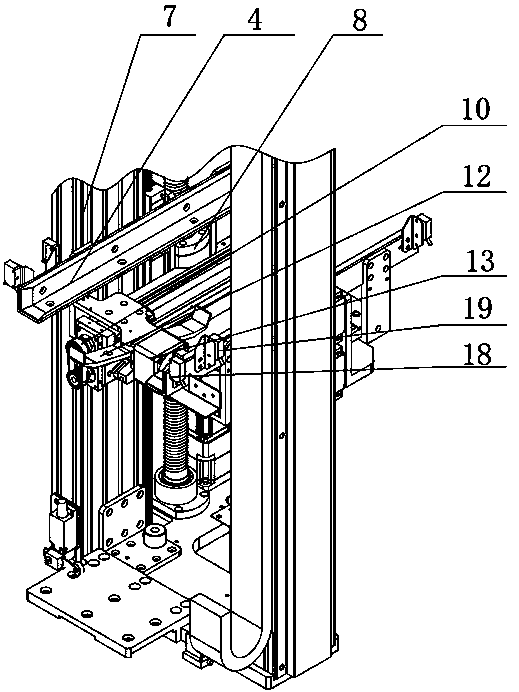

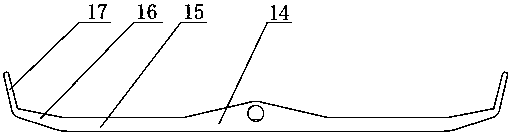

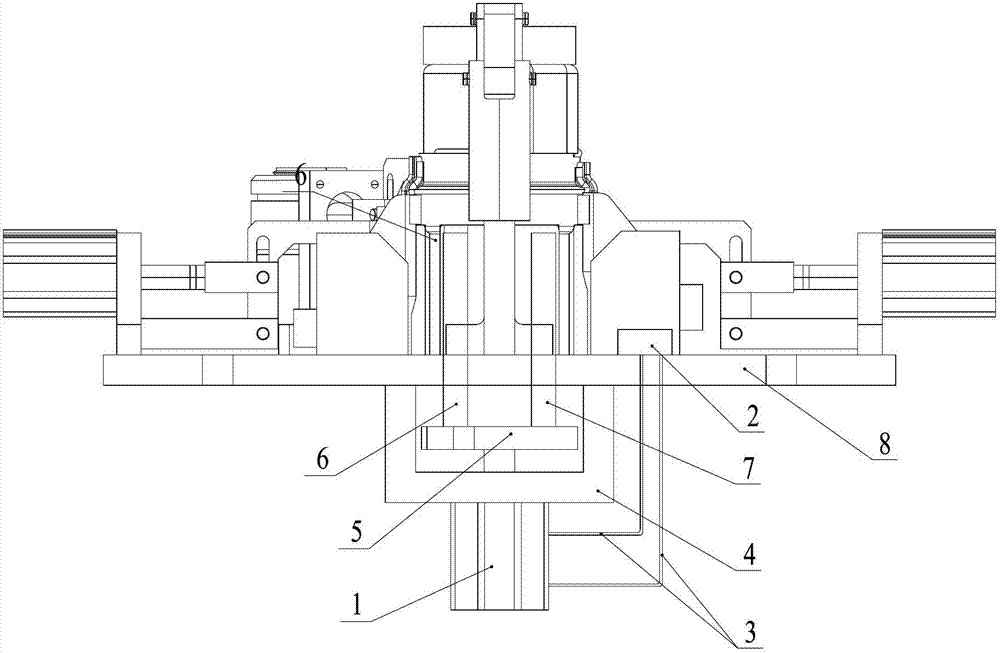

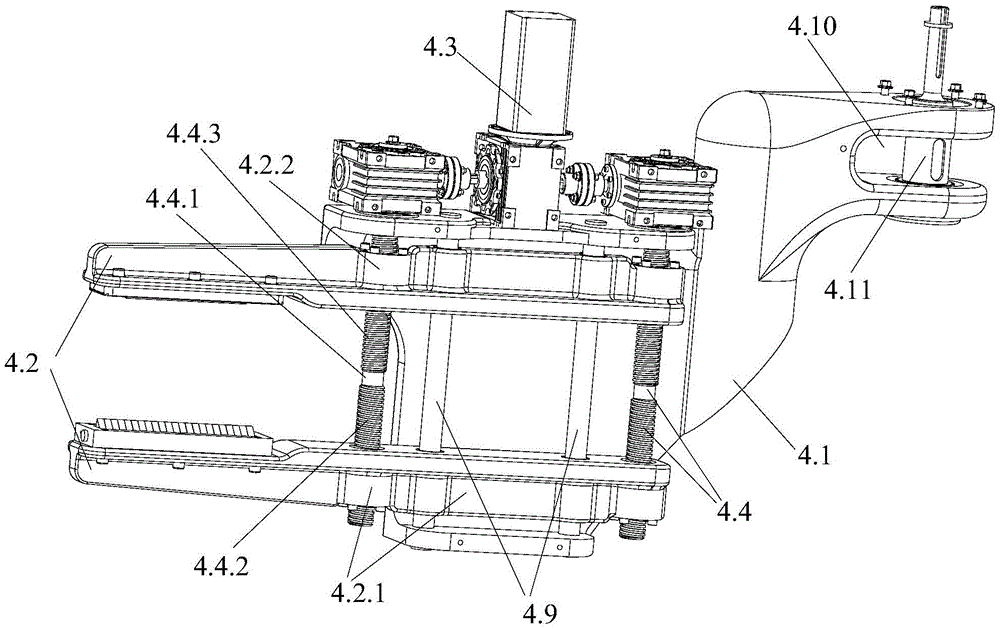

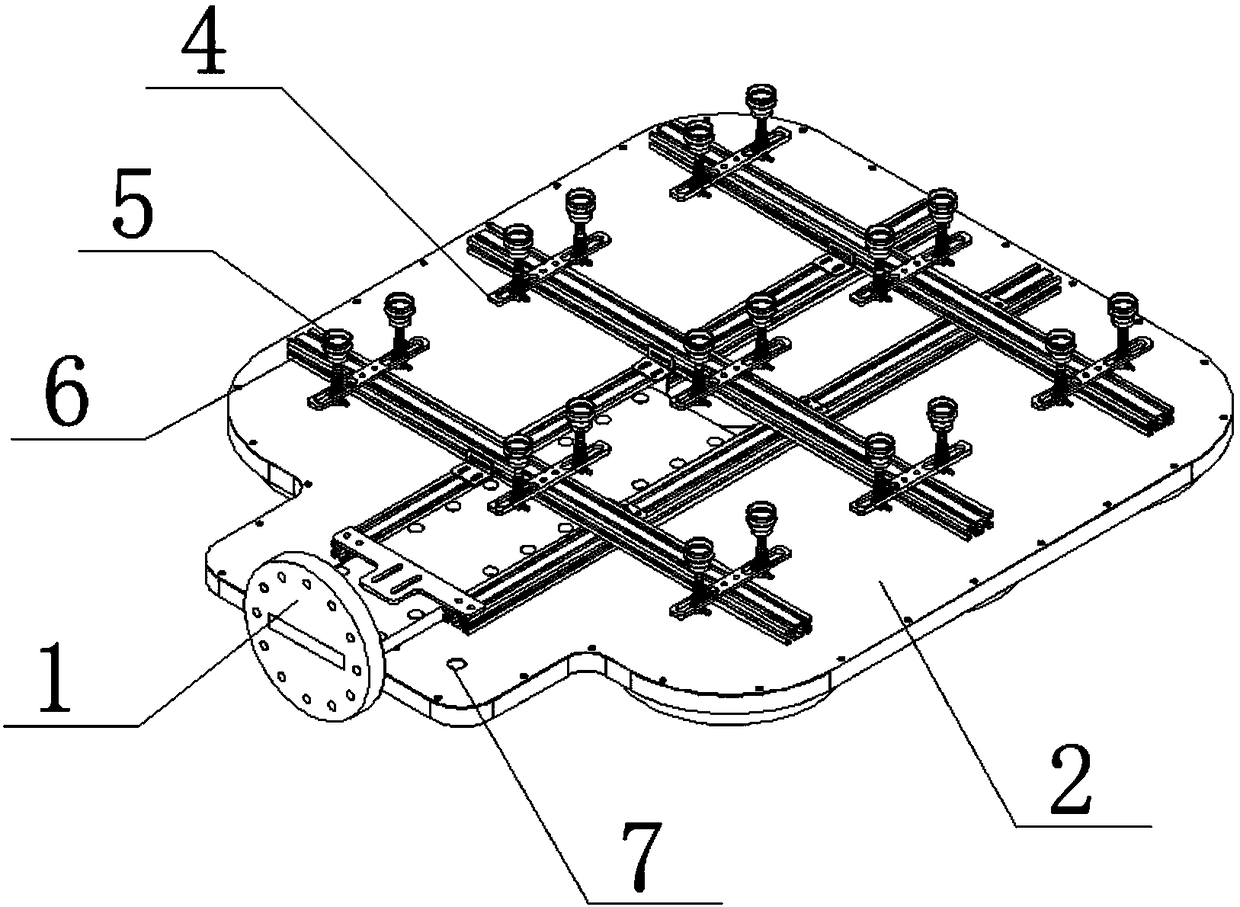

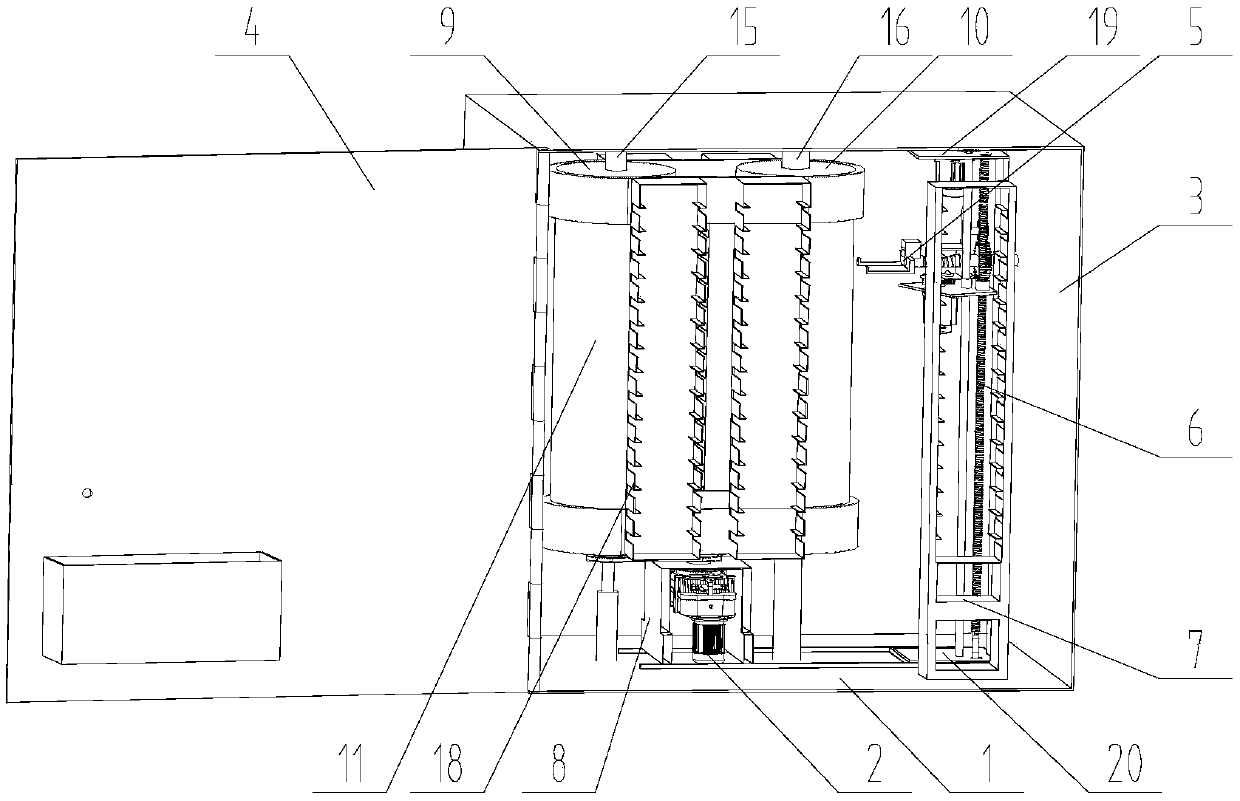

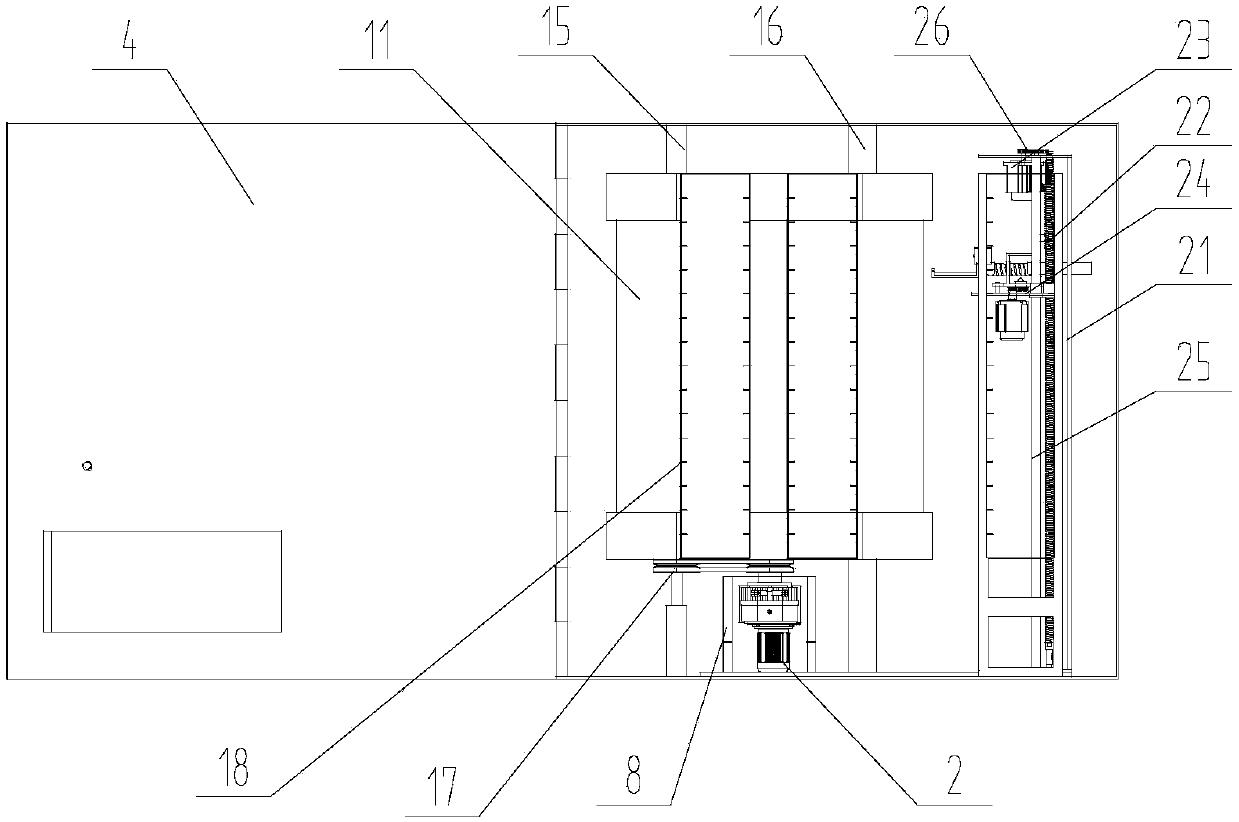

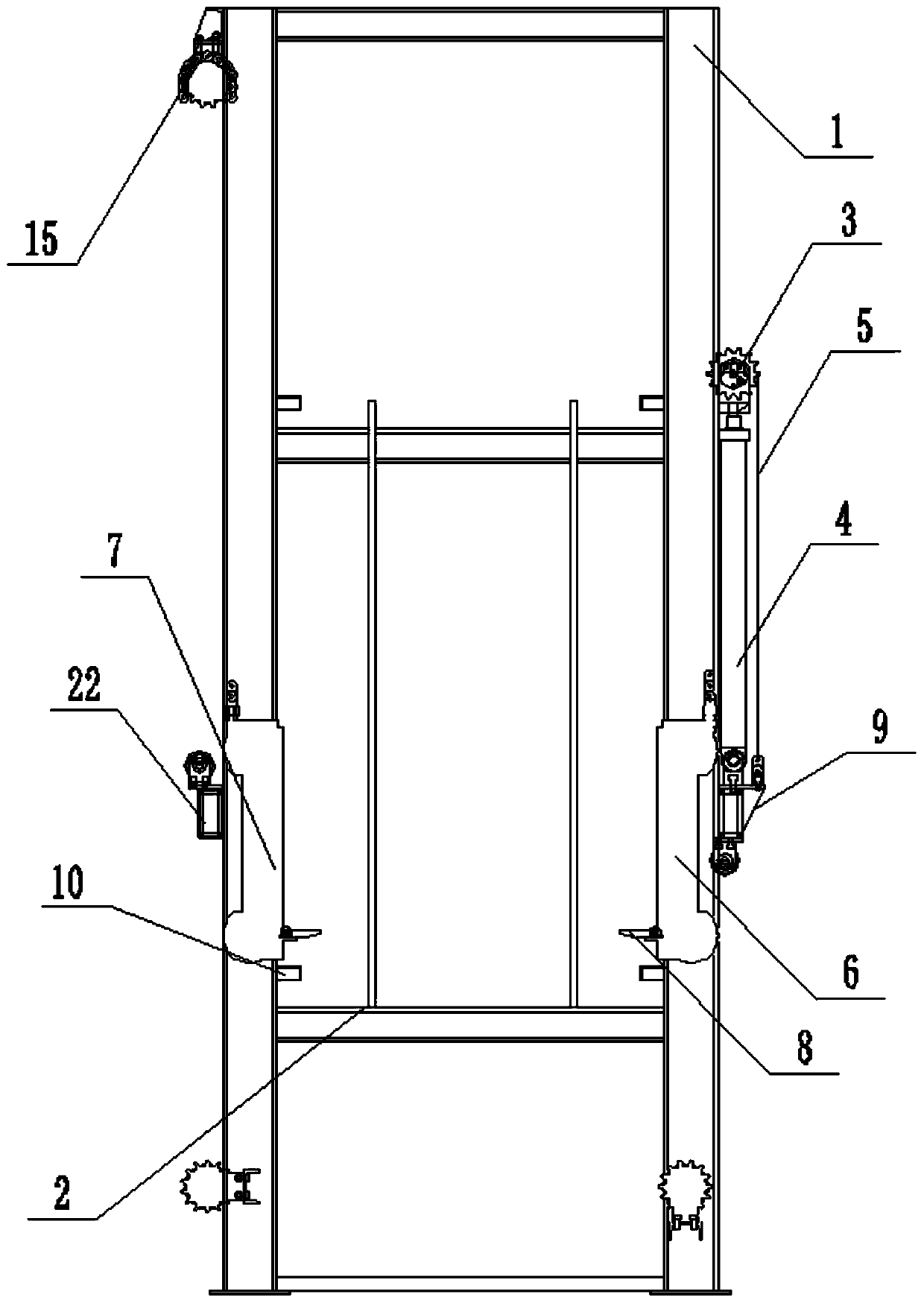

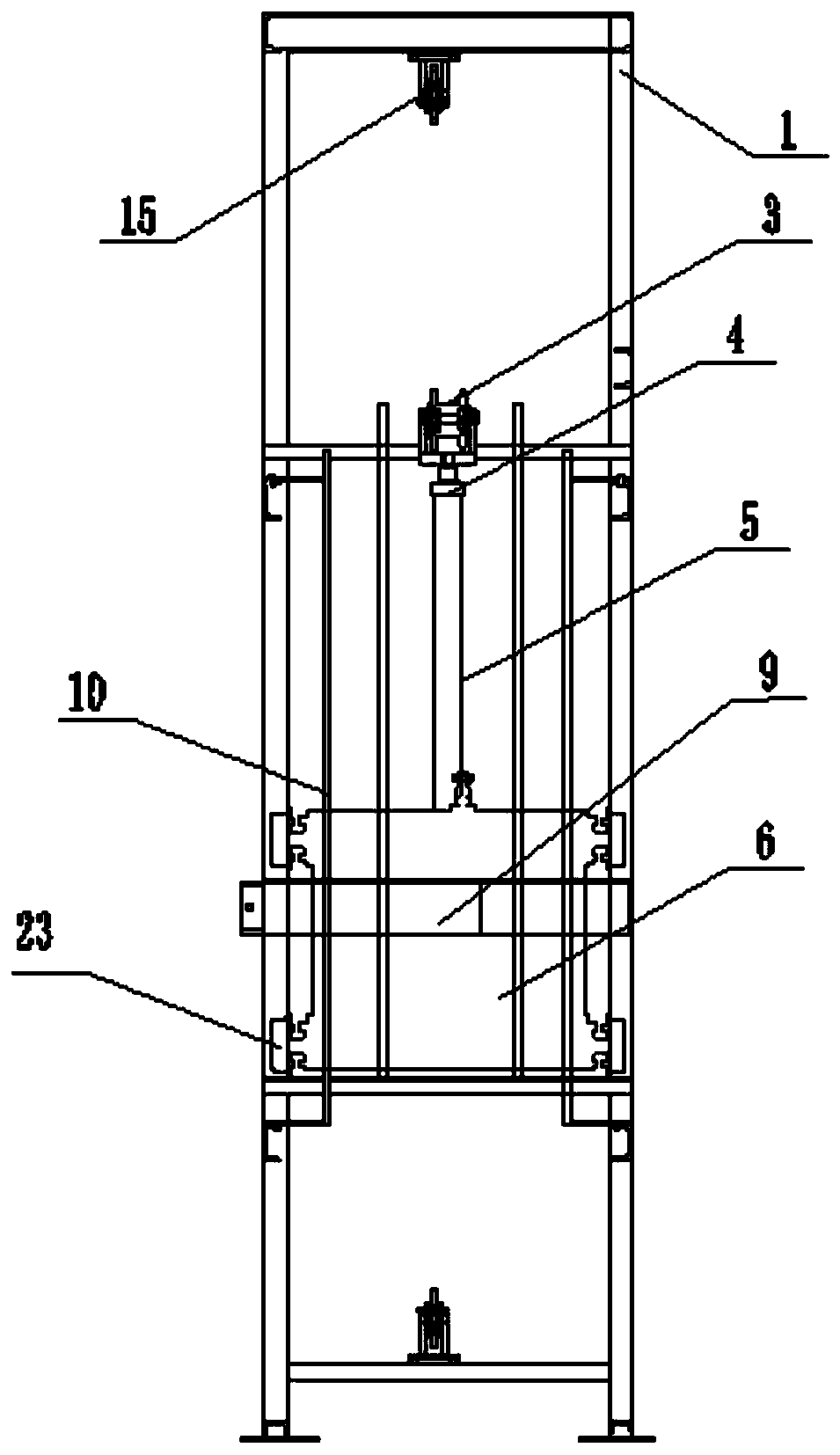

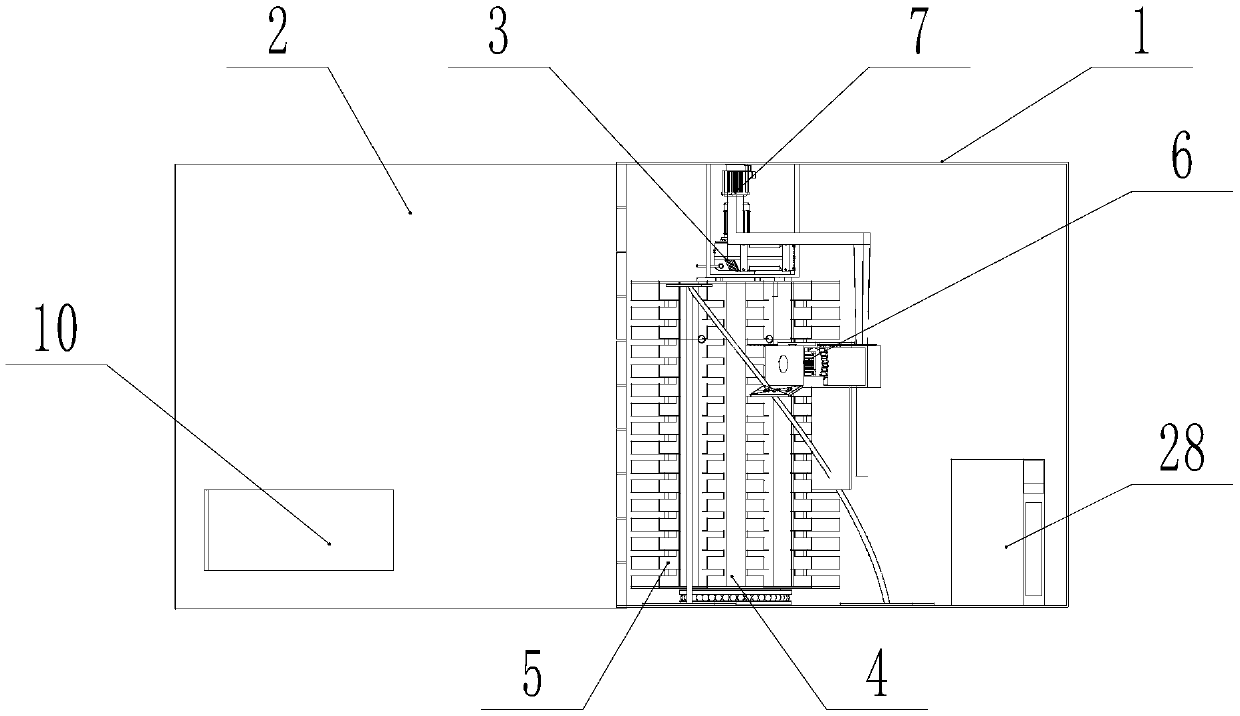

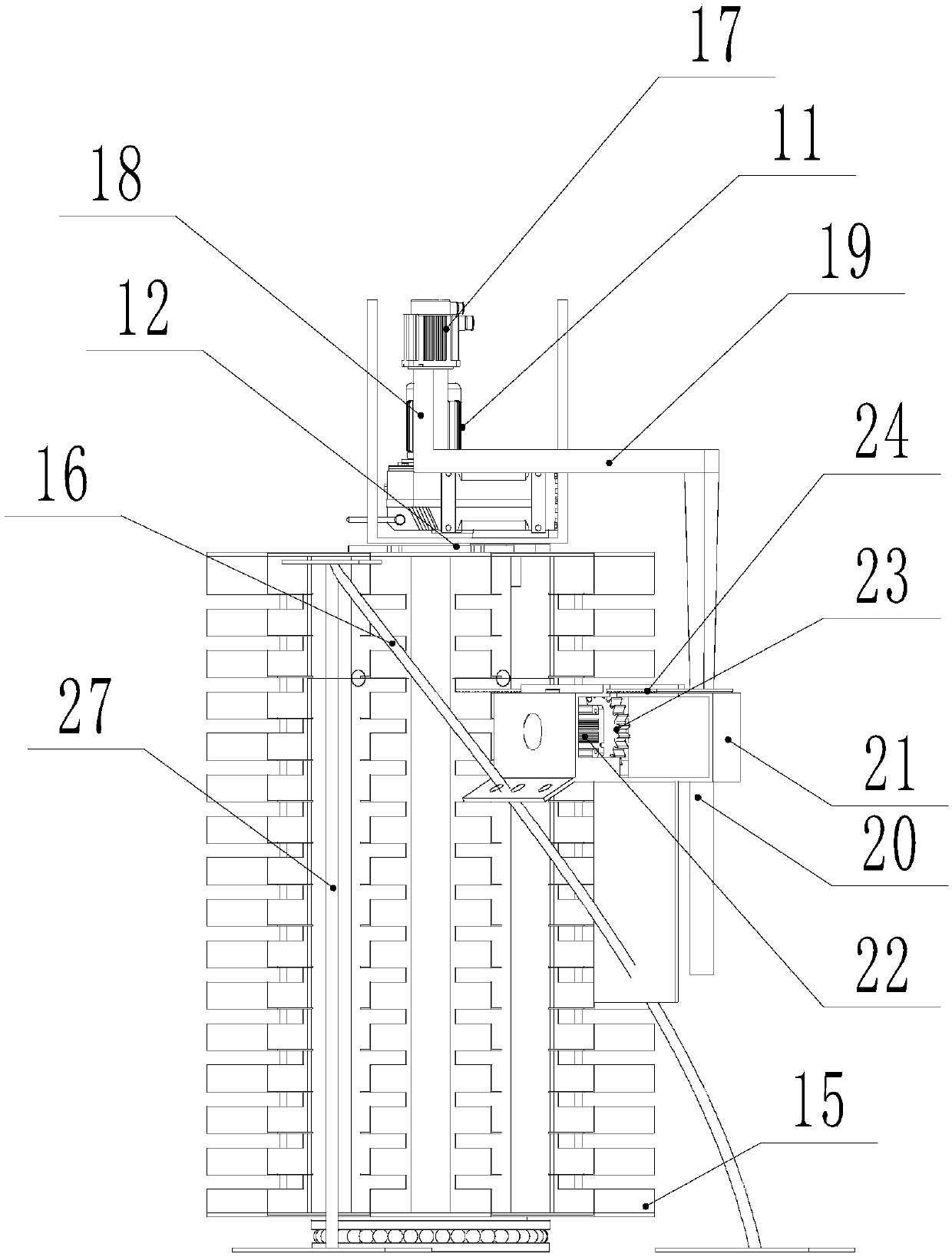

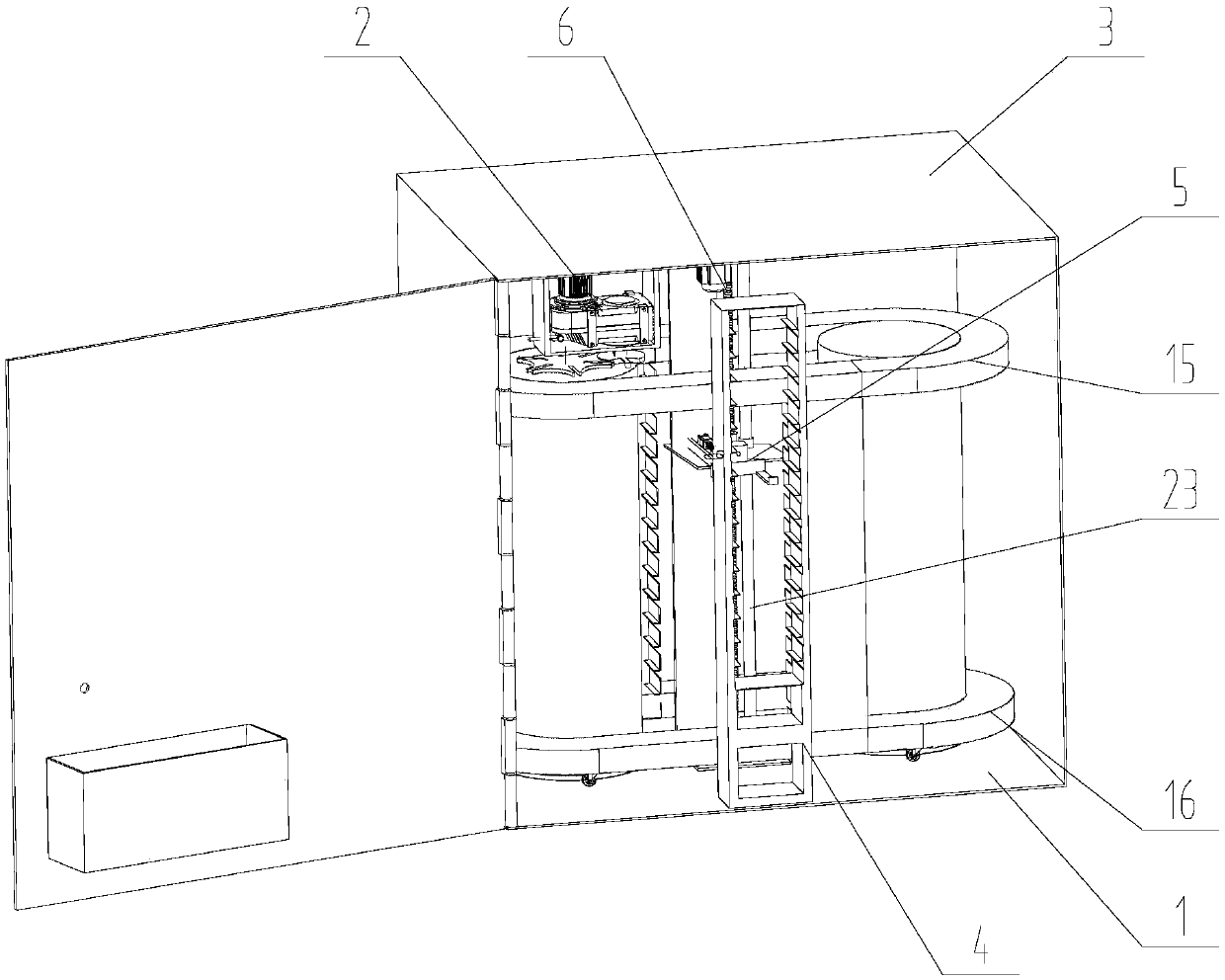

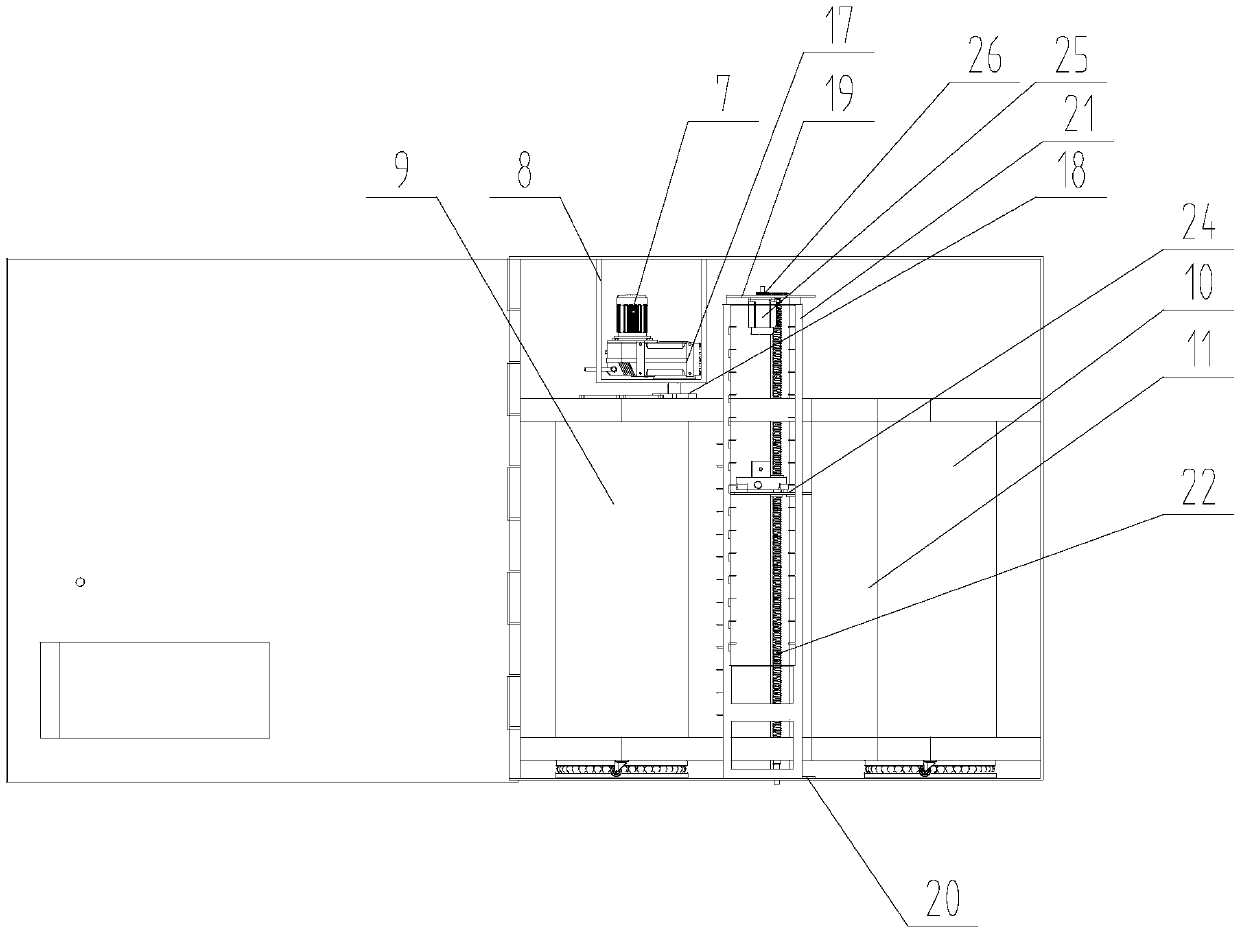

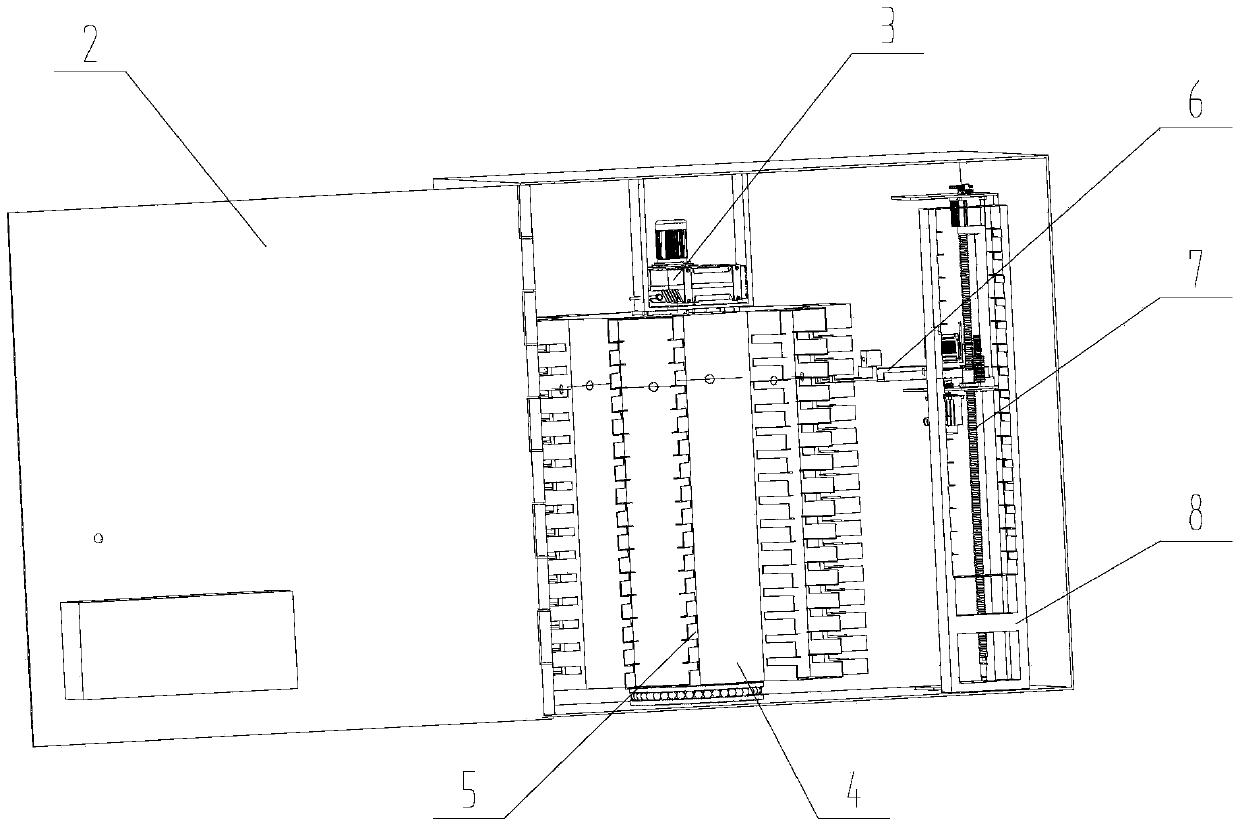

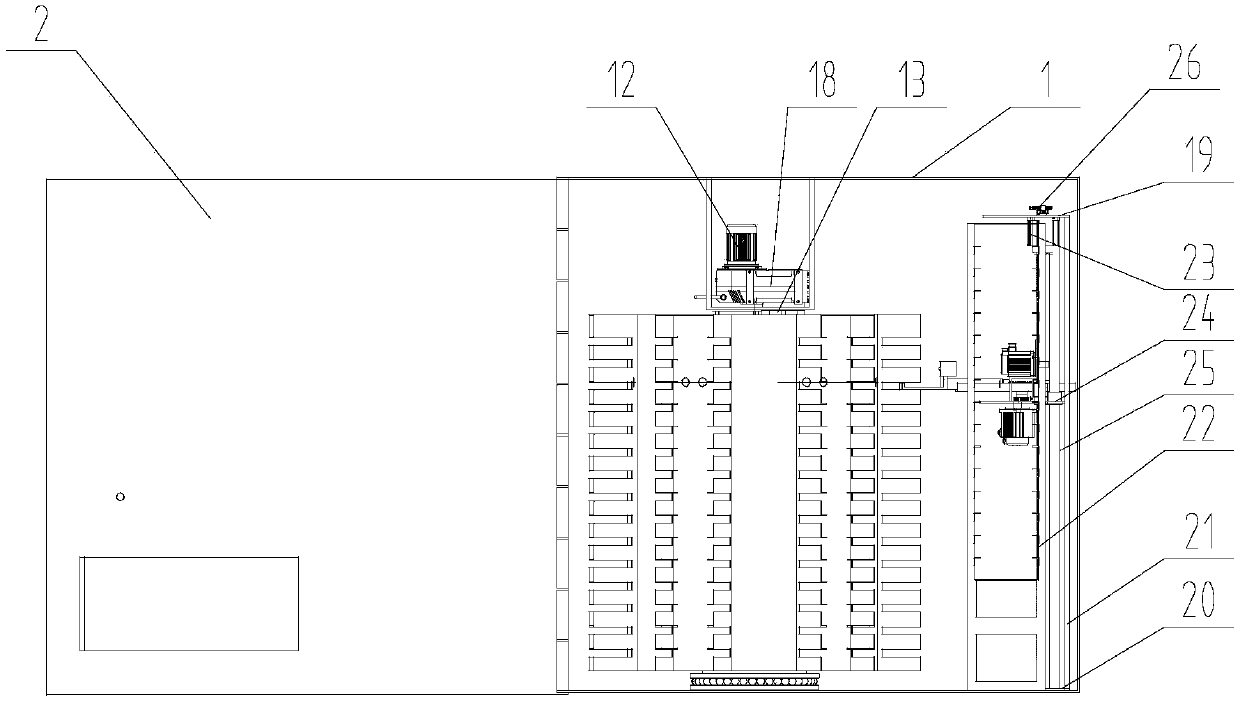

Full-automatic intelligent safe deposit box system and control method thereof

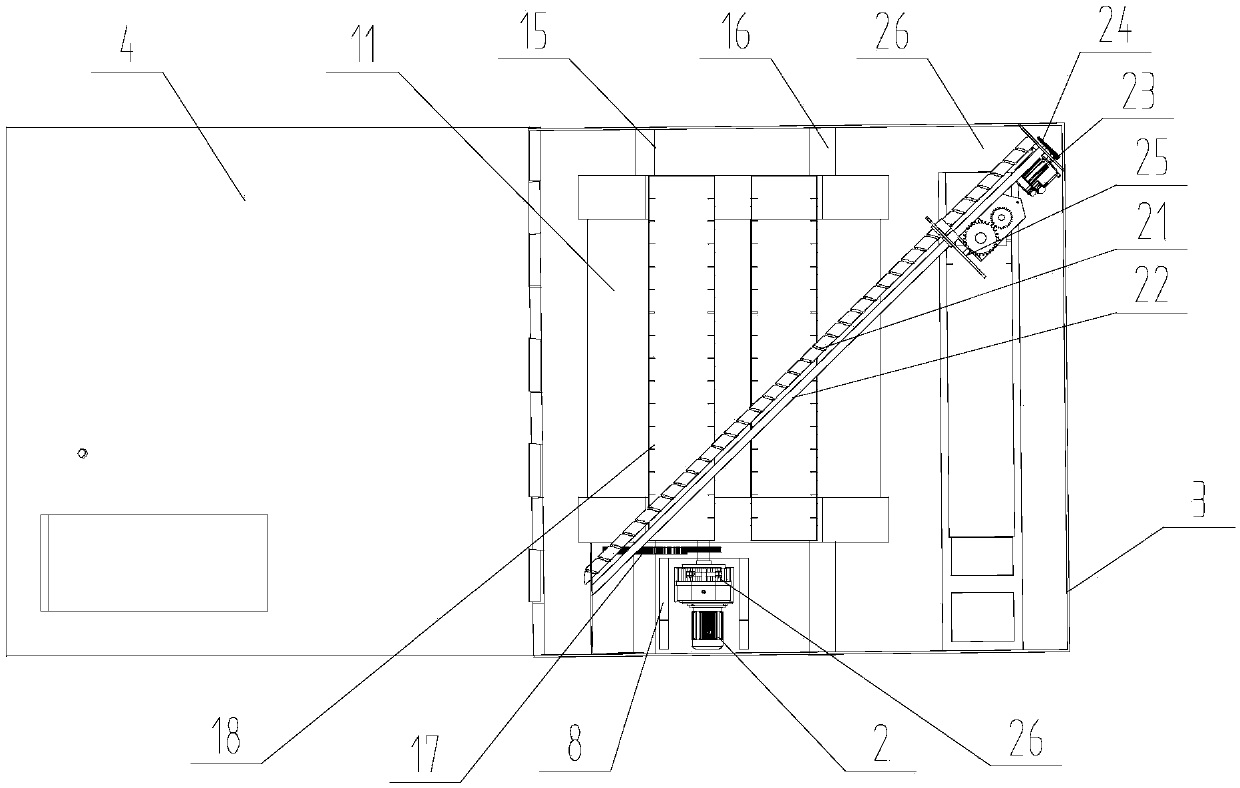

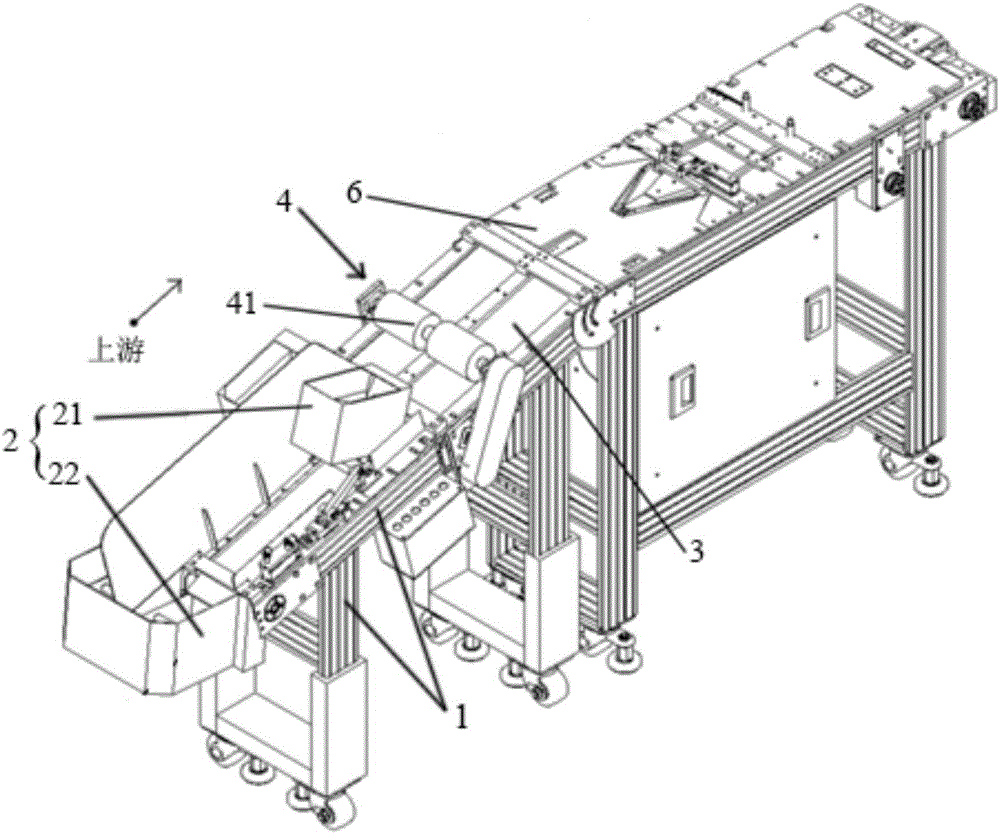

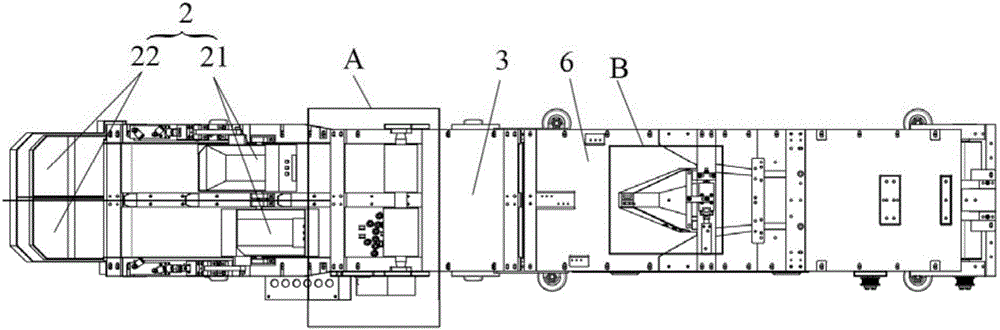

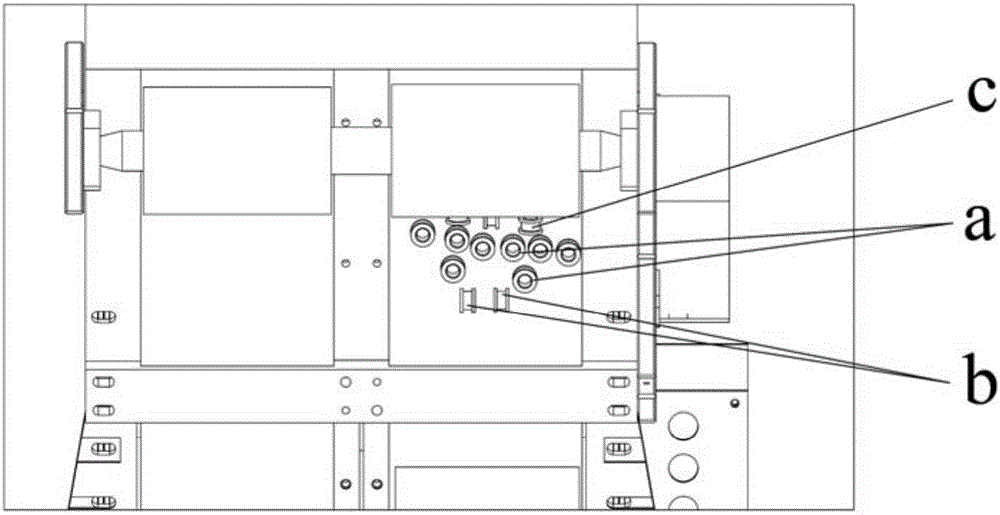

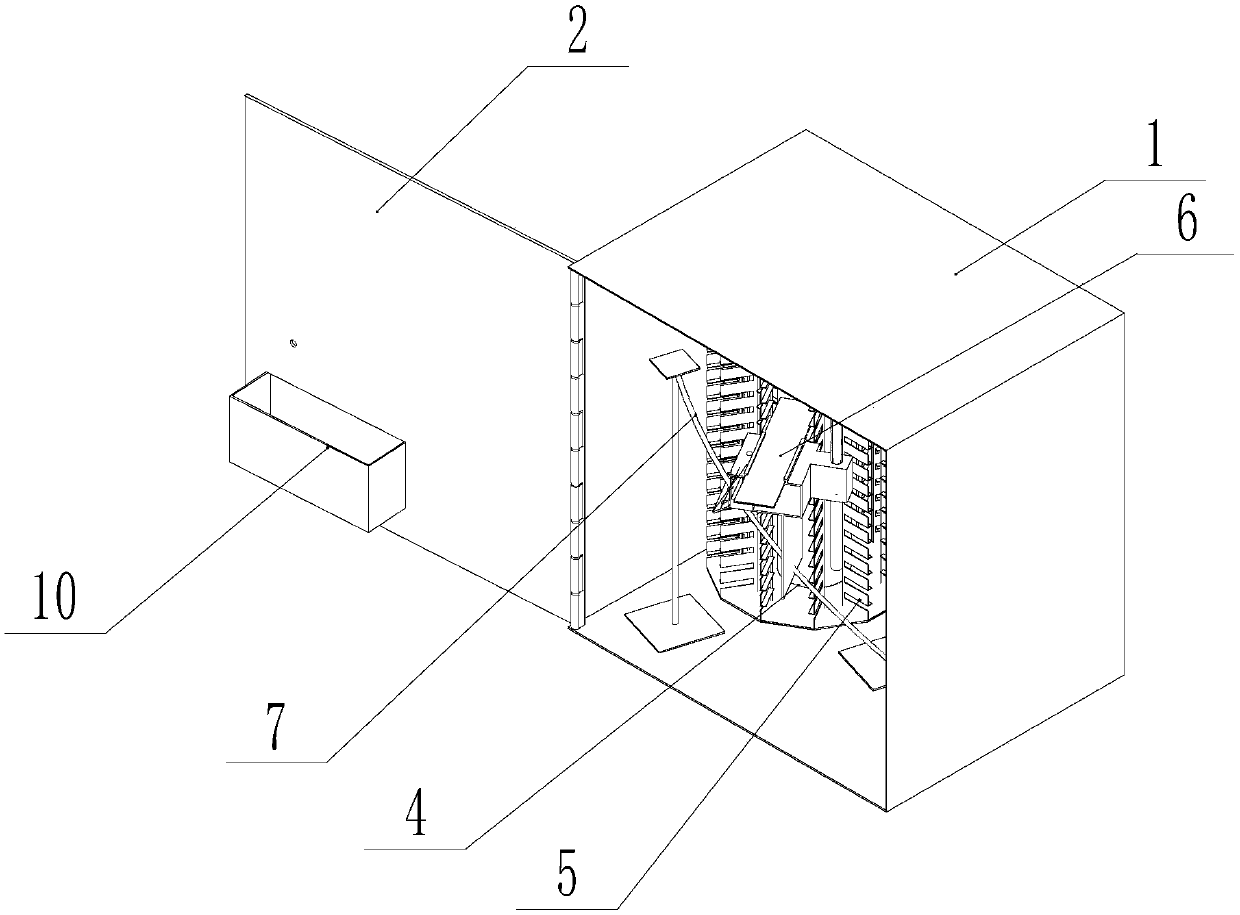

PendingCN108263796ASave pickup timeThe pickup effect is goodConveyorsStorage devicesElectricityEngineering

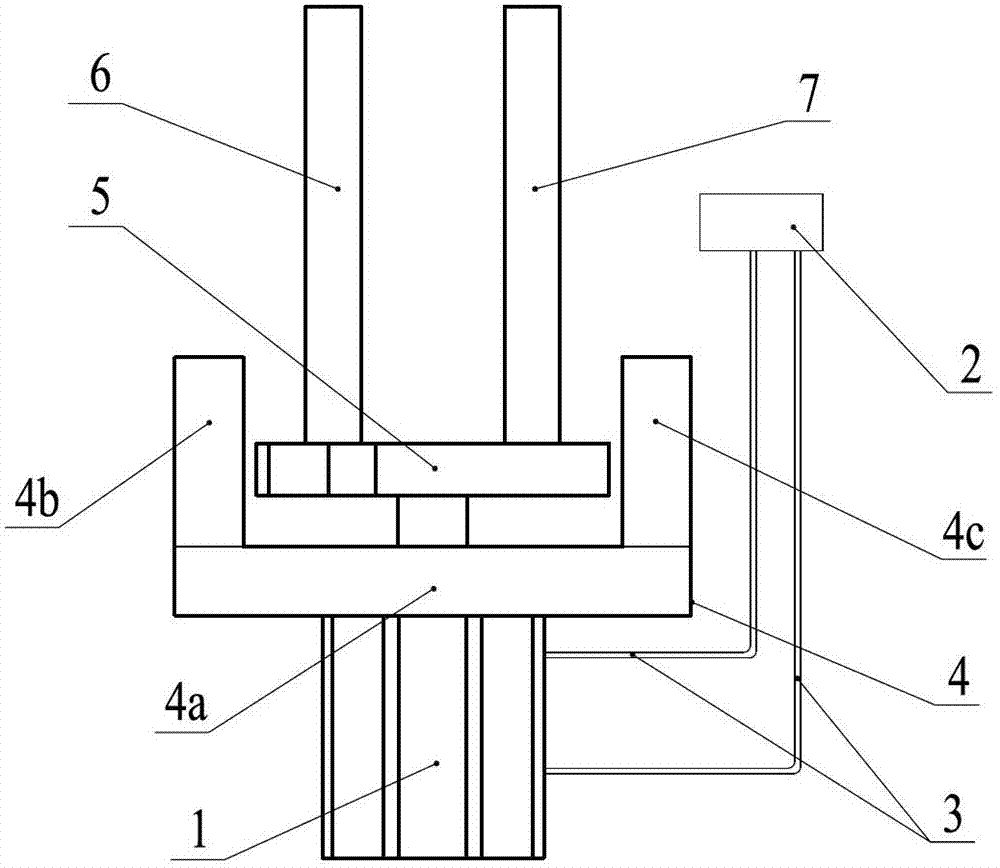

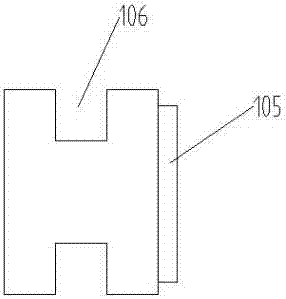

The invention relates to the technical field of safe deposit boxes, in particular to a full-automatic intelligent safe deposit box system and a control method thereof. The full-automatic intelligent safe deposit box system comprises a box body and an automatic storage device, wherein two chambers are arranged in the box body and comprise a storage chamber and an operation chamber; the automatic storage device comprises a controller, a box storage frame (1) and a box taking mechanism; the box taking mechanism comprises a first box taking mechanism (2) and a second box taking mechanism (3); thefirst box taking mechanism (2) comprises a placement frame (4), a first guide rail (5), a first power mechanism (6), a second guide rail (7), a second power mechanism (8), a fixing mechanism and a third power mechanism (10); and the first power mechanism (6), the second power mechanism (8), the fixing mechanism, the third power mechanism (10) and the second box taking mechanism (3) are electrically connected with the controller. The intelligent safe deposit box system is simple in structure, lower in cost and lower in error rate.

Owner:NINGBO XINWANBAO SAFE EQUIP

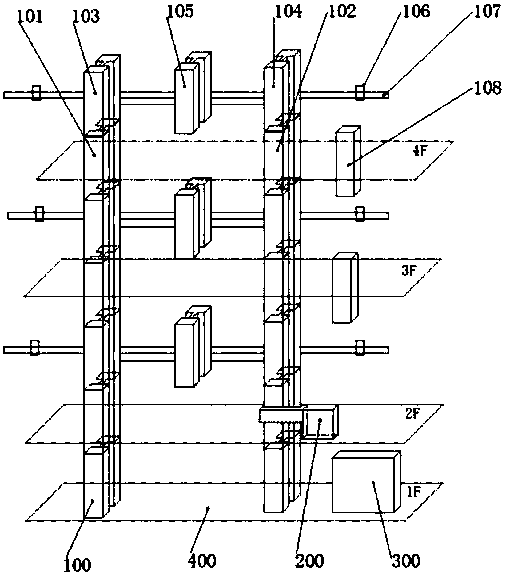

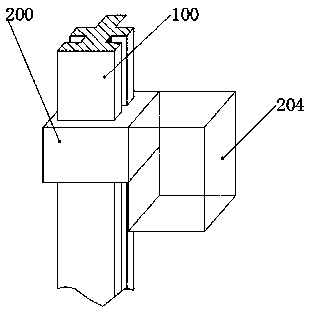

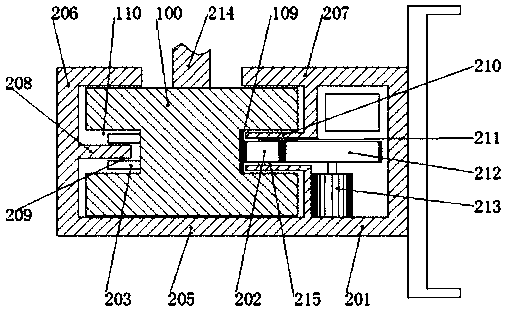

Building goods delivery system

InactiveCN107458836ASimple structureReduce manufacturing costControl devices for conveyorsMechanical conveyorsLogistics managementControl system

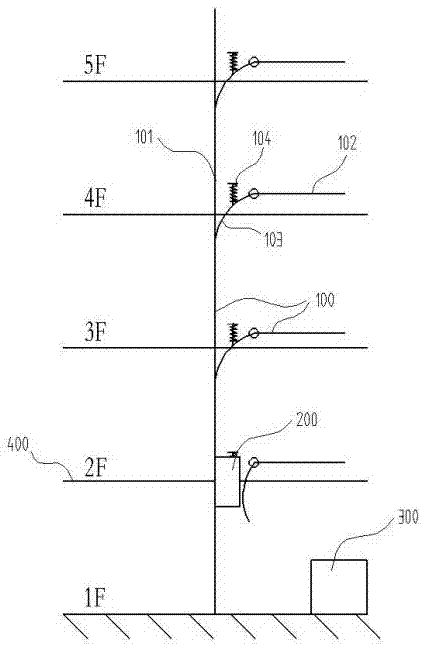

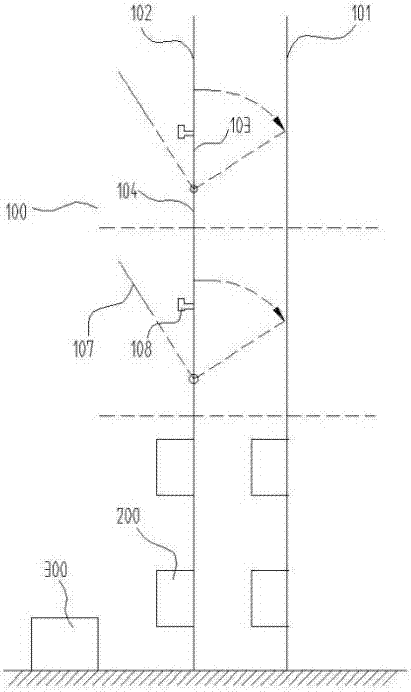

The invention discloses a building delivery system, which includes a delivery track, a delivery trolley, a delivery box and a control system; the delivery track includes a main rail and an auxiliary rail; the main rail is installed vertically along the wall of the building, and each floor of the building There are corresponding attached rails; there is also a transition rail between the main rail and the attached rail, which is connected by a rail changing device. The rail changing device enables the two ends of the transition rail to be connected / detached from the main rail and the attached rail respectively; delivery The trolley is connected to the delivery track and walks on the delivery track under the action of the driving device; the delivery box is connected to one end of the main track for the courier or delivery robot to deposit and pick up from the trolley; the control system includes the control center and The main rail part, the attached rail part, the track changing part and the delivery part connected to it; it solves the problem of the last "100 meters" of logistics; it is convenient for the receiving personnel and the delivery personnel to receive and receive; the building delivery system has a simple structure, The operation is convenient, and the delivery efficiency of the building delivery system is improved.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

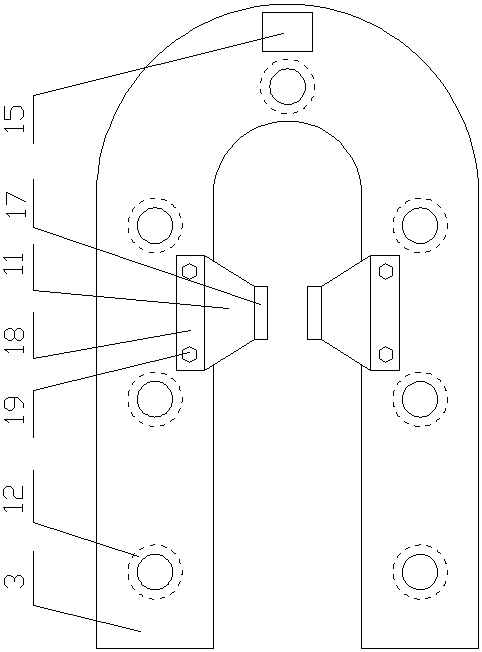

Pneumatic ejecting mechanism of welding jig

InactiveCN103203573AEliminate Pickup DifficultiesSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a pneumatic ejecting mechanism of a welding jig. The pneumatic ejecting mechanism is characterized by comprising a cylinder, a mechanical valve, an air tube, a stand, an ejector plate, a first ejector rod and a second ejector rod, wherein the stand is fixedly arranged on the welding jig, the cylinder is fixedly arranged on the stand, an air inlet and an air outlet of the cylinder are respectively connected with the mechanical valve by the air tube, a piston rod of the cylinder is controlled to stretch out and draw back by the mechanical valve, the piston rod end of the cylinder is connected with the ejector plate, the first ejector rod and the second ejector rod are arranged on the ejector plate, allowance holes through which the first ejector rod and the second ejector rod can penetrate are formed in a bottom plate of the welding jig, and the first ejector rod and the second ejector rod can freely move on the corresponding allowance holes. The pneumatic ejecting mechanism is simple, compact and reasonable in structure, welded parts in the welding jig can be ejected out in a pneumatic manner so as to be taken conveniently, the problem of difficulty in taking the welded parts can be eliminated, the time for taking the parts can be greatly shortened, and the welding work efficiency can be improved so as to win the benefits for enterprises.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

Boxed meal vending system with external chute from which materials are taken through direct pushing for goods acquisition based on time

ActiveCN109410462AEasy accessAccurate acquisitionCoin-freed apparatus detailsDigital data protectionNetwork connectionComputer terminal

The invention discloses a boxed meal vending system with external chute from which materials are taken through direct pushing for goods acquisition based on time. The vending system includes users' handheld terminals provided with a boxed meal vending mobile phone APP, an automatic vending machine and a cloud server. A code scanning mechanism is arranged on the automatic vending machine, the users' handheld terminals are linked with the cloud server through a network, and the automatic vending machine is linked with the cloud server through GPRS; the automatic vending machine consists of a boxbody, a box door, a roller driving device, a first roller arranged vertically, a second roller arranged vertically, a first synchronous belt sleeving the upper ends of the first and second rollers, asecond synchronous belt sleeving the lower ends of the first and second rollers, a material taking device, a heating device, a material taking drive device and a boxed meal storage cavity. A date judgment module is arranged in the automatic vending machine, the capacity of the automatic vending machine is large, boxed meals can be placed freely, and convenience is provided for operation of merchants.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

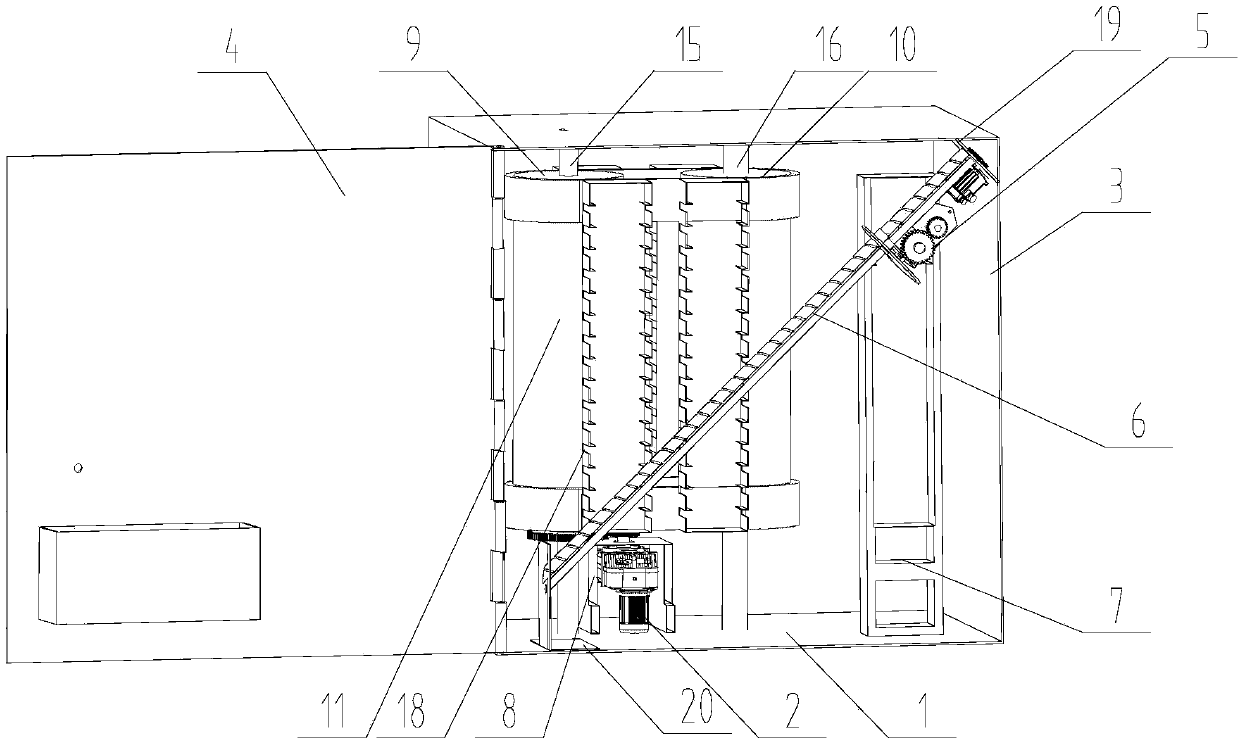

Vertical multi-track pulling robot for section bars

ActiveCN105598942AImprove the efficiency of automatic tractionExpand traction workspaceManipulatorEngineeringElectrical and Electronics engineering

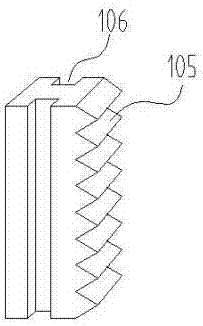

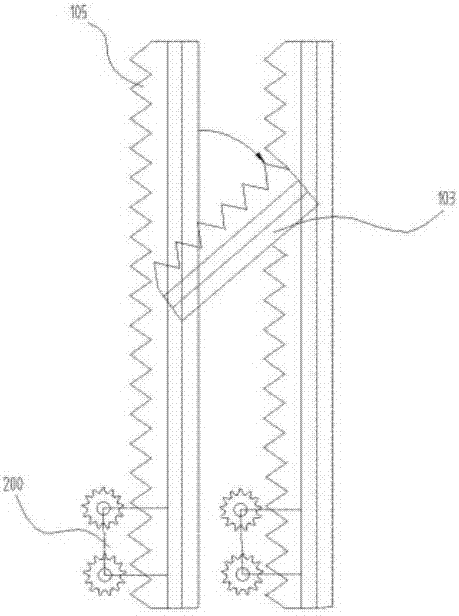

The invention provides a vertical multi-track pulling robot for section bars. The vertical multi-track pulling robot comprises M pulling units and a control mechanism. Each pulling unit comprises a vertical travel track, a mechanical arm, a transmission mechanism and a driving mechanism, the mechanical arms are used for clamping and pulling the section bars, the driving mechanisms are used for being connected with the transmission mechanisms, and the mechanical arms are clipped on the side surfaces of the vertical travel tracks and are slidably connected with the side surfaces of the vertical travel tracks, so that the mechanical arms can be suspended on the side surfaces of the vertical travel tracks and can travel and move; the transmission mechanisms comprise first transmission gears and second transmission gears, the first transmission gears are arranged on the mechanical arms, and the second transmission gears are arranged on the vertical travel tracks; the M pulling units are spliced with one another in an overlapped manner by the aid of the vertical travel tracks, and the mechanical arms of each two adjacent pulling units are suspended on the corresponding vertical travel tracks and can cooperatively alternately travel and move, so that the section bars can be pulled in a cooperative alternative manner. The vertical multi-track pulling robot has the advantages that the section bars can be fully automatically pulled in a multi-track mode according to production requirements, and accordingly the section bar pulling efficiency can be improved.

Owner:广东省智行机器人科技有限公司

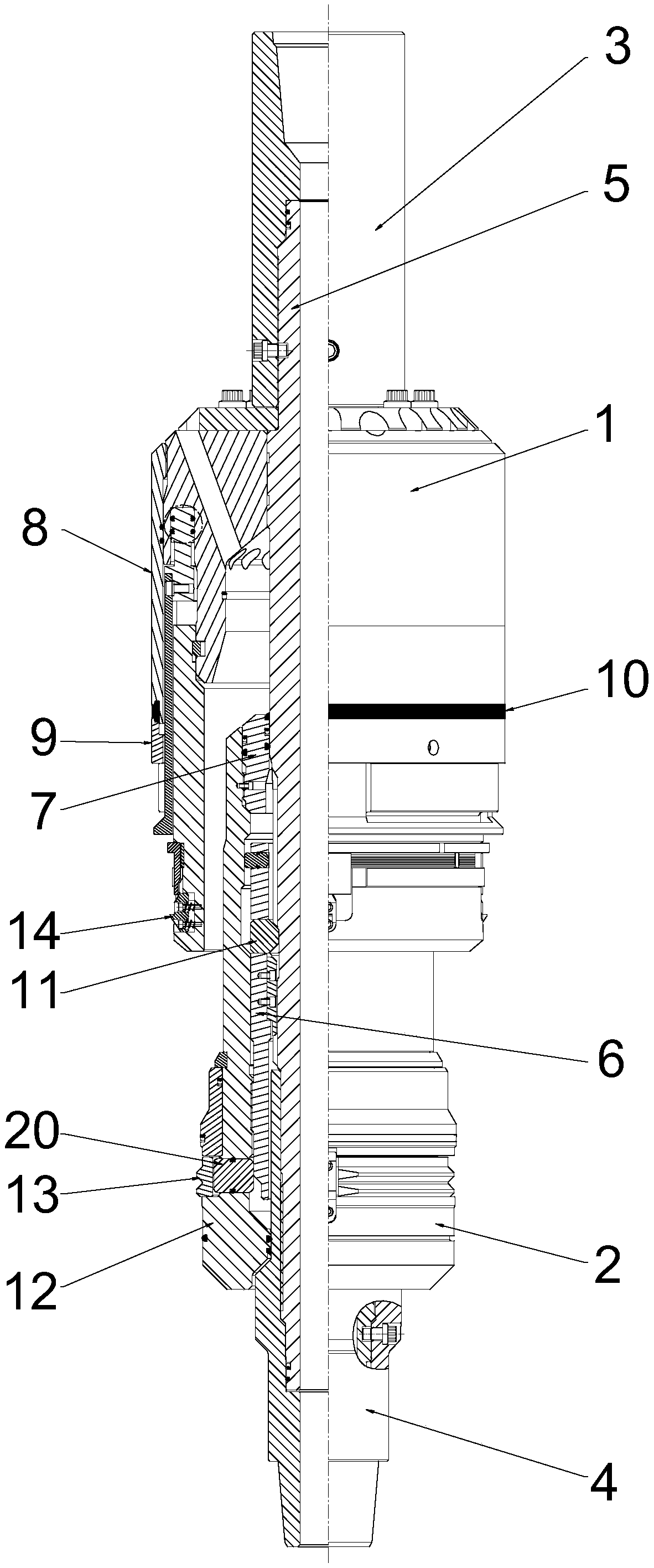

Single-pass running tool and method for casing hanger and sealing assembly for underwater wellhead

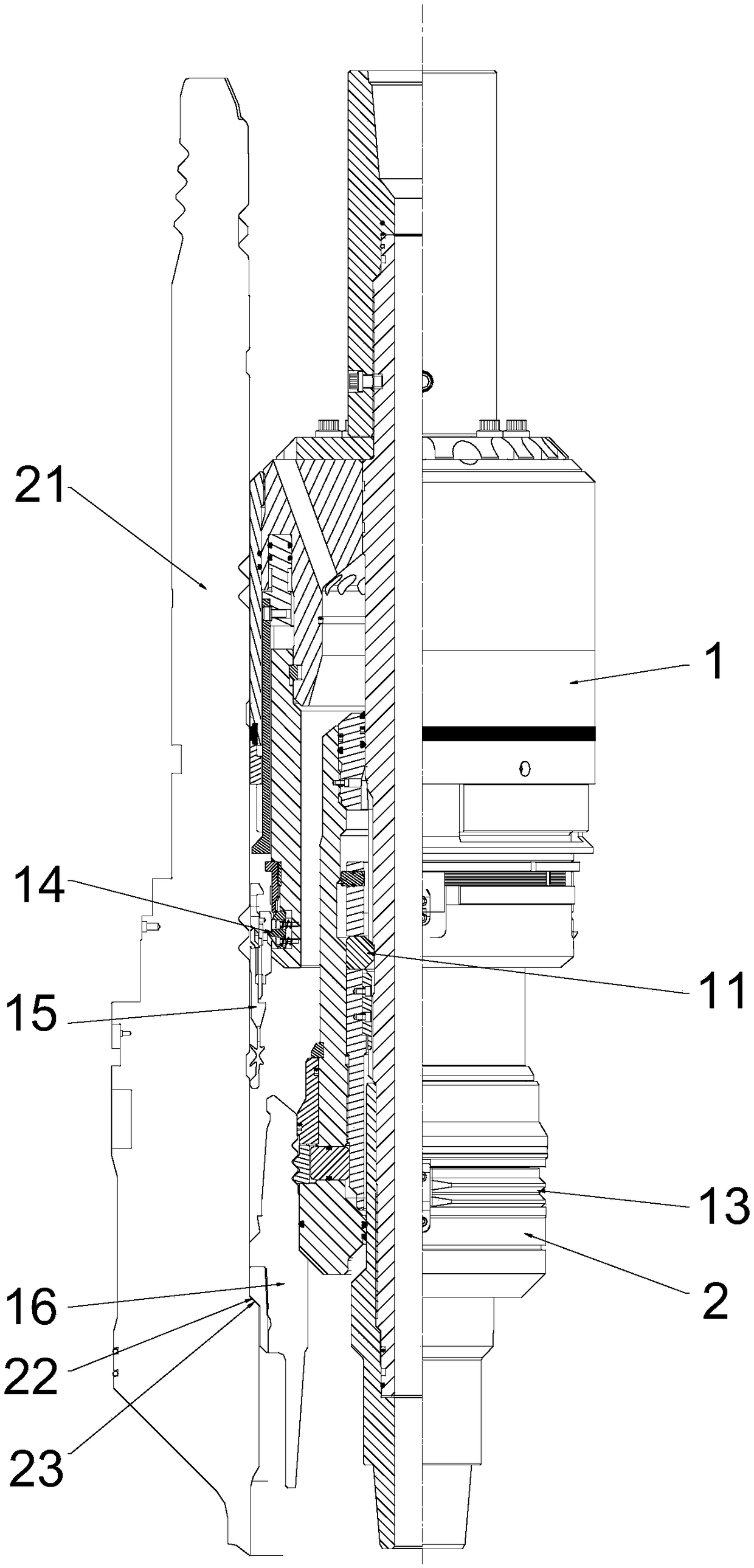

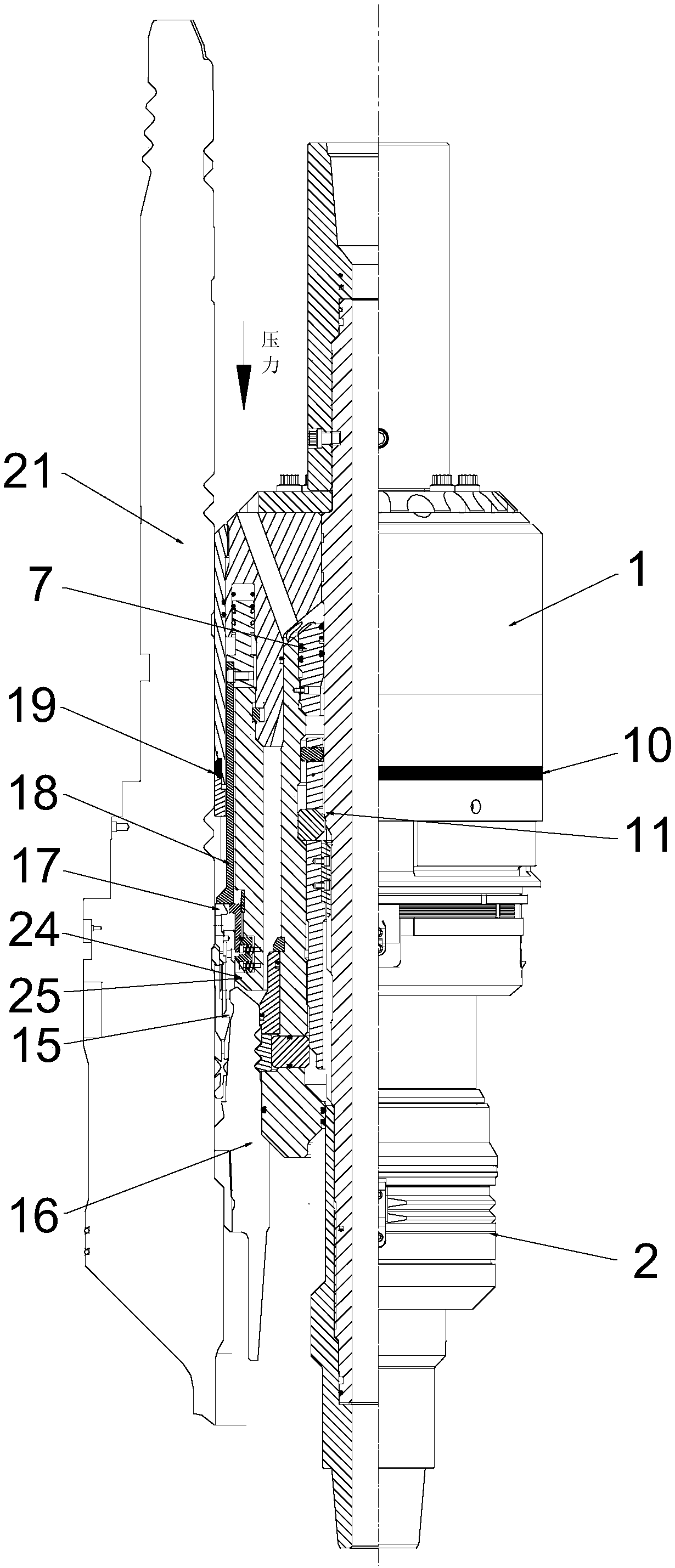

PendingCN109488239ASave pickup timeSimple and fast operationConstructionsBorehole/well accessoriesEngineeringMechanical engineering

The invention discloses a single-pass running tool and method for a casing hanger and a sealing assembly for an underwater wellhead. The tool comprises an upper body, a lower body, a core shaft, and adriving body, wherein the upper body and the lower body are connected with each other; the core shaft penetrates through the insides of the upper body and the lower body; a driving body is positionedbetween the upper body and the lower body; and a joint is arranged on the upper body. According to the technical scheme, the single-pass running tool of the casing hanger and the sealing assembly forthe underwater wellhead is manufactured with simple operation and reliable effect. The same tool has multiple functions, and can better meet the operation effect.

Owner:上海霞为石油设备技术服务有限公司

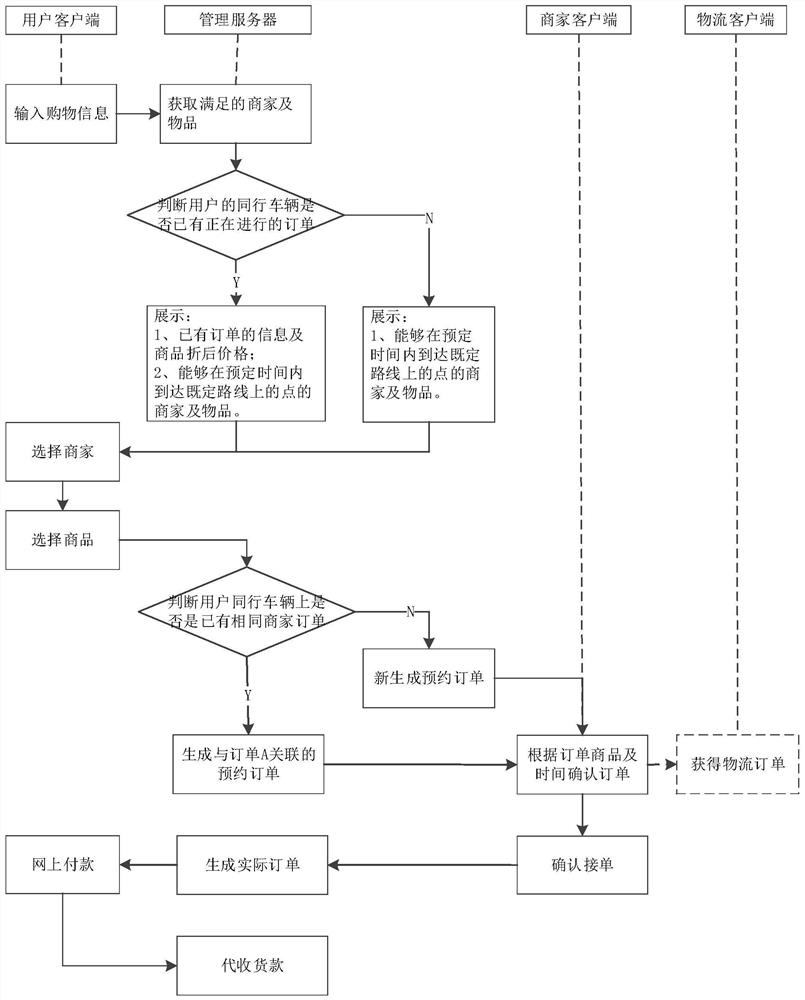

Method, device, equipment, and medium for shopping in journey

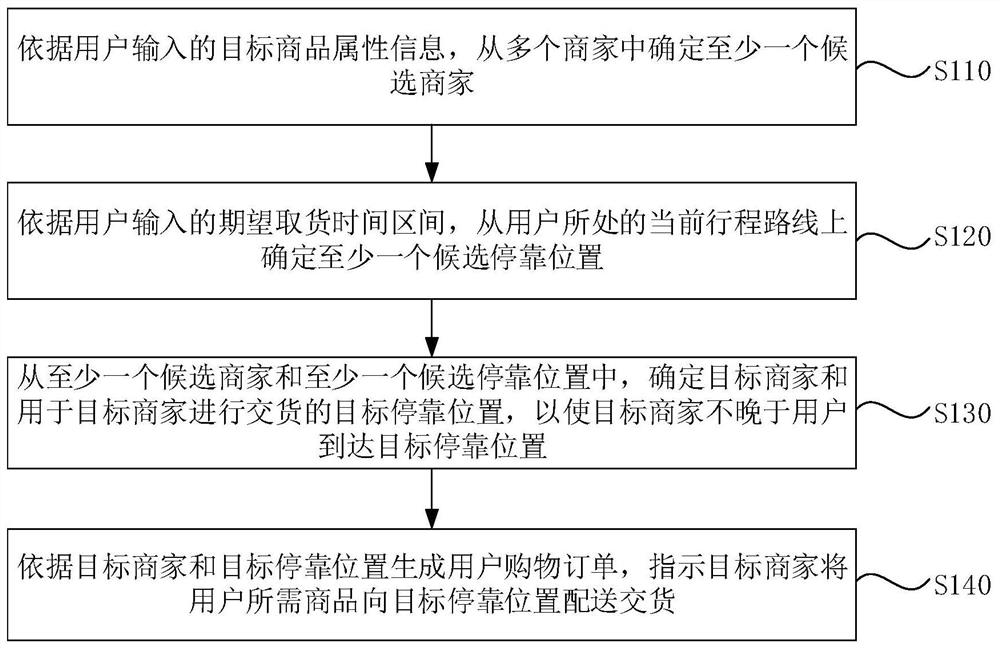

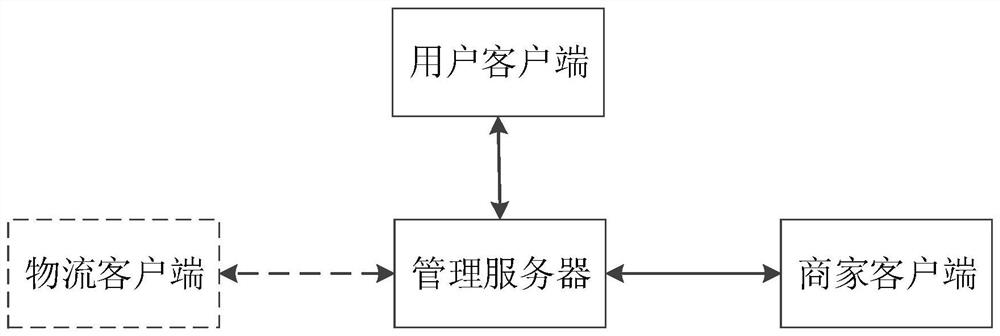

PendingCN111798011AAvoid wasting timeSave pickup timeReservationsBuying/selling/leasing transactionsData miningOperations research

The embodiment of the invention discloses a method, a device, equipment, and a medium for shopping in journey. The method comprises the steps of determining at least one candidate merchant from a plurality of merchants according to target commodity attribute information input by a user; determining at least one candidate parking position on the current travel route where the user is located according to an expected goods taking time interval input by the user; determining a target merchant and a target parking position for the target merchant to deliver goods from the at least one candidate merchant and the at least one candidate parking position, so that the target merchant arrives at the target parking position not later than the user; and generating a user shopping order according to the target merchant and the target parking position, and indicating the target merchant to deliver and deliver the commodity required by the user to the target parking position. By the adoption of the scheme, the user can obtain the commodity needing to be purchased without changing the current travel, the commodity taking distance is shortened, and the commodity taking time is prevented from beingovertime as much as possible.

Owner:CHINA FIRST AUTOMOBILE

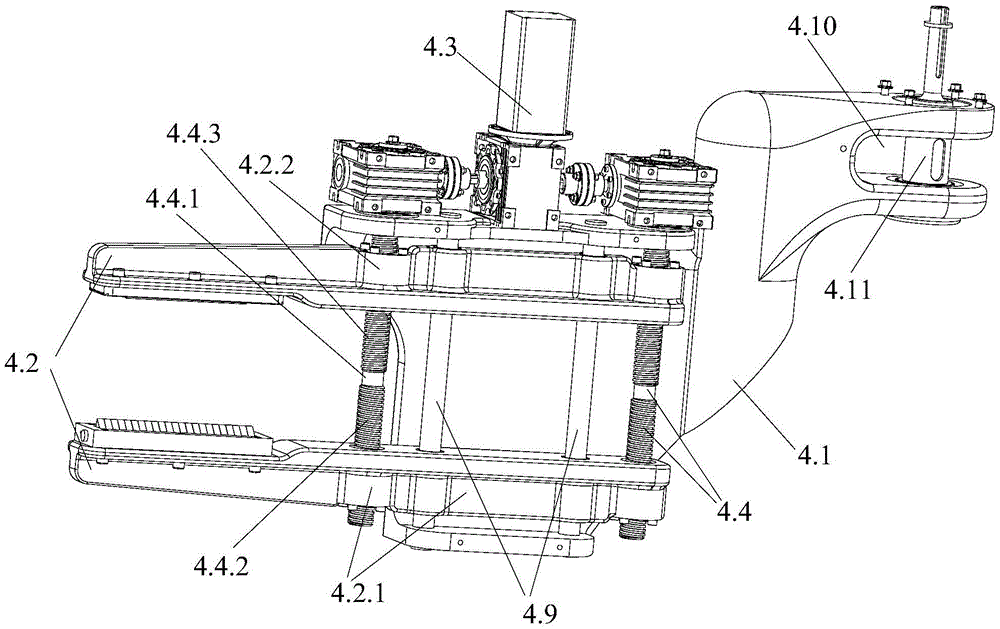

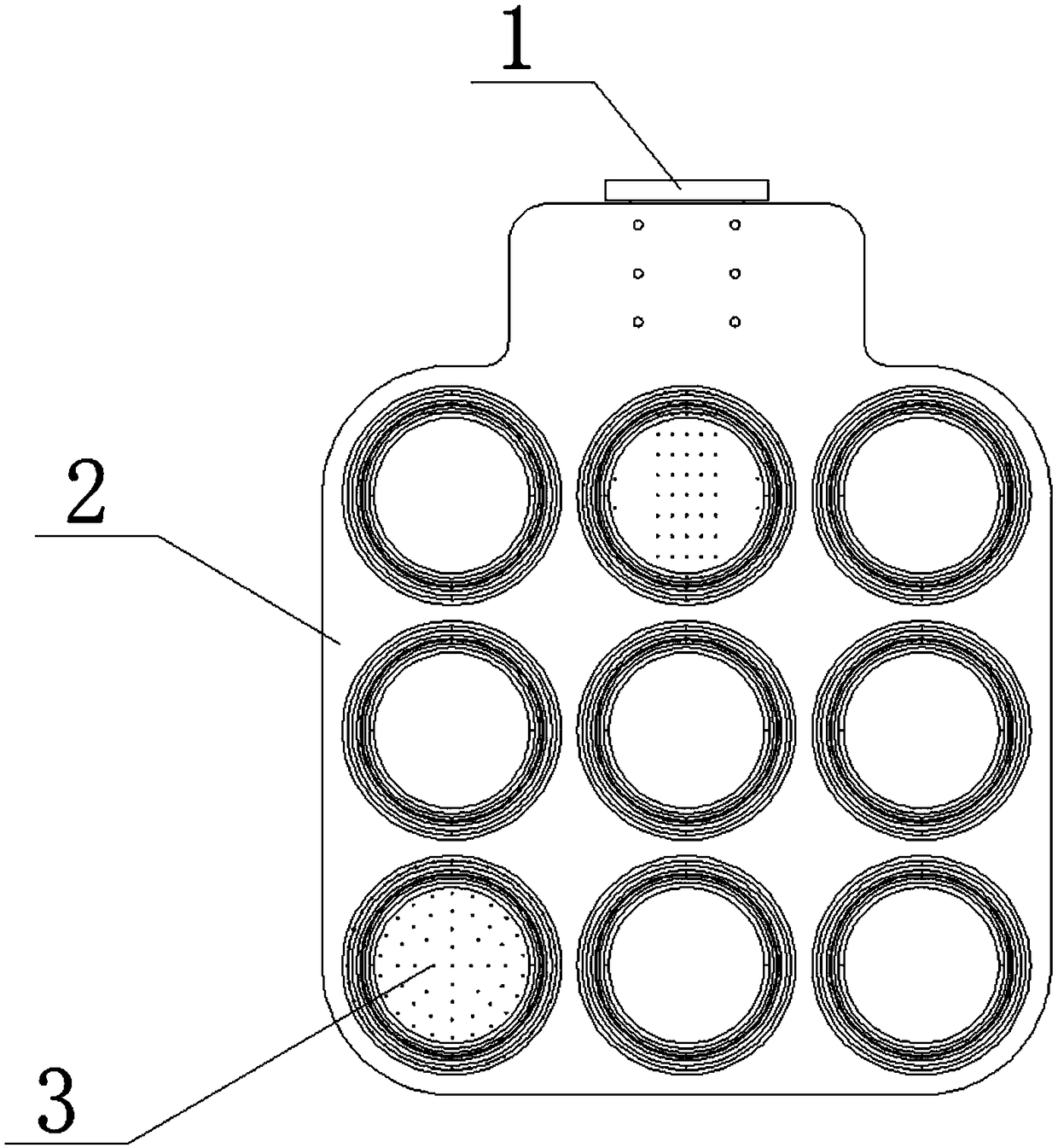

Paper pulp mould robot material taking jig

PendingCN108262759ASave pickup timeMeet the needs of pick and placeGripping headsTextiles and paperPulp and paper industryNozzle

The invention discloses a paper pulp mould robot material taking jig which comprises an air inlet plate; a robot connecting plate is arranged on one side of the air inlet plate; a plurality of suctionnozzle fixing brackets are arranged at the bottom of the air inlet plate; suction disc seats are erected on the suction nozzle fixing brackets, and are fixed to the bottom of the air inlet plate through screws; vacuum suction nozzles are formed in the suction disc seats; air inlets are formed in the positions, close to the robot connecting plate, of the lower surface of the air inlet plate; and aplurality of vacuum chucks are arranged on the upper surface of the air inlet plate. The paper pulp mould robot material taking jig is equipped with the vacuum suction nozzles and the vacuum chucks,so that products are sucked and fixed more firmly, the piece taking and releasing requirements before and after paper pulp moulds are formed are met; and a robot is not required changing the verticaldirection to suck the products, so that the time for the robot to go to a moulding machine for piece releasing and taking is saved, and the working efficiency is improved.

Owner:东莞市隆盛智能装备有限公司

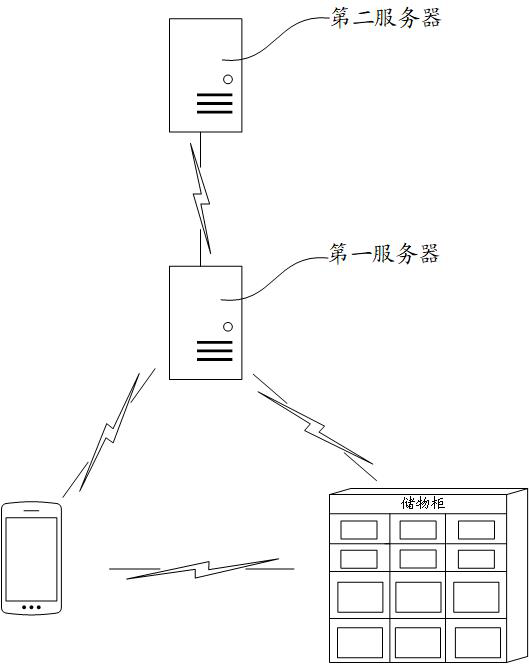

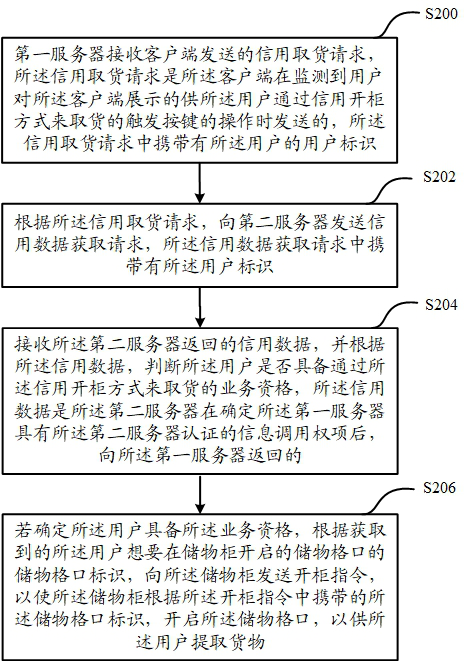

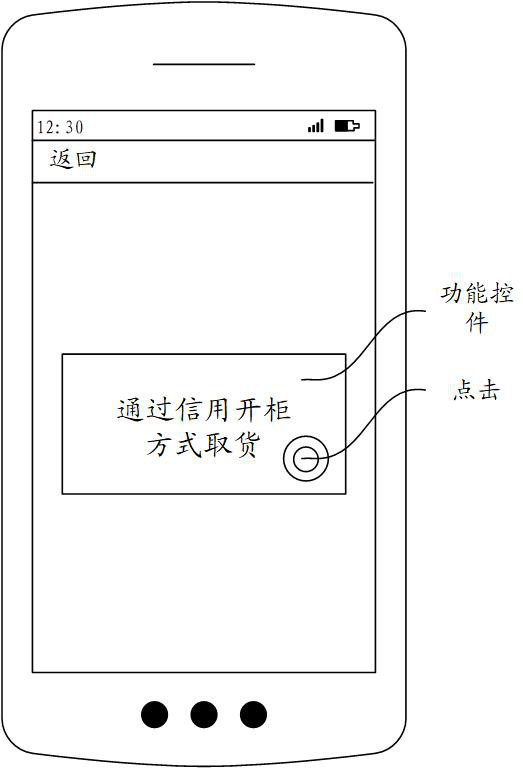

Method, device and system for extracting goods

PendingCN114387735ASave pickup timeImprove experienceApparatus for meter-controlled dispensingIndividual entry/exit registersEngineeringDatabase

The invention discloses a method, a device and a system for picking up goods, and particularly discloses a method for sending a credit data acquisition request to a second server according to a credit goods picking request after a first server receives the credit goods picking request sent when a user requests to pick up goods in a credit cabinet opening mode. And then, the second server returns credit data after determining that the first server has the information calling authority authenticated by the second server. And then, after the first server determines that the user has the business qualification of taking goods through a credit cabinet opening mode according to the credit data, a cabinet opening instruction is sent to the storage cabinet according to a storage grid opening identifier of a storage grid opening which the user wants to open in the storage cabinet, so that the storage grid opening of the storage cabinet is opened for the user to take goods. Therefore, when the user cannot normally take the goods, the goods can be taken in a credit cabinet opening mode, and if the goods are successfully taken, the user does not need to contact a manual customer service to remotely open the cabinet, so that the service execution efficiency is improved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Object delivery system based on high-rise building

InactiveCN107472841AImprove work efficiencyShorten the timeControl devices for conveyorsMechanical conveyorsHigh riseSystem structure

The invention discloses an object delivery system based on a high-rise building, which includes a delivery track, a delivery trolley and a delivery box; the delivery track is arranged vertically from bottom to top along the wall of the building; the delivery trolley is connected to the delivery track and One end of the main rail of the delivery box is connected; the delivery track includes two vertical tracks, which are arranged and fixed along the vertical direction of the building, and the two vertical tracks are arranged in parallel. The cargo trolley can run along its track direction; there is also a transition track between the two vertical tracks, the transition track is set corresponding to each floor, and the transition track can be connected / detached from one end to a vertical track under the action of a track changing device , the other end is connected / disconnected with another vertical track; it is convenient for the recipients and delivery personnel to send and receive items; the object delivery system has a simple structure, which improves the delivery efficiency of the object delivery system based on high-rise buildings; solves the logistics final " 100 meters" problem.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Goods delivery system for high-rise building object delivery

InactiveCN107539736AEnsure safetyShorten the timeCoin-freed apparatus detailsApparatus for meter-controlled dispensingEngineeringHigh rise

The invention discloses a goods delivery system for high-rise building object delivery. The system comprises goods delivery tracks, goods delivery trolleys and a drop-in box; the goods delivery tracksare vertically arranged along the walls of a building and connected with the goods delivery trolleys; the goods delivery trolleys travel on the goods delivery tracks under the action of drive devices; the drop-in box is connected with the tracks; the goods delivery tracks comprise the two vertical tracks arranged in the vertical direction of the building and fixed; the goods delivery trolleys arematched with the tracks and run in the track direction; the two vertical tracks are the movable track and the fixed track separately; the fixed track is fixedly installed in the vertical direction ofthe building; the movable track comprises main track bodies and movable track bodies which are matched; one main track body is arranged between any two floors of the building; one movable track bodyarranged in the vertical direction is arranged between any two main track bodies in a matched mode and can rotate relative to the main track bodies; and by rotation of the movable track bodies, one ends of the movable track bodies are matched with the main track bodies or the fixed track, so that the problem about last one hundred meters of logistics is solved.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

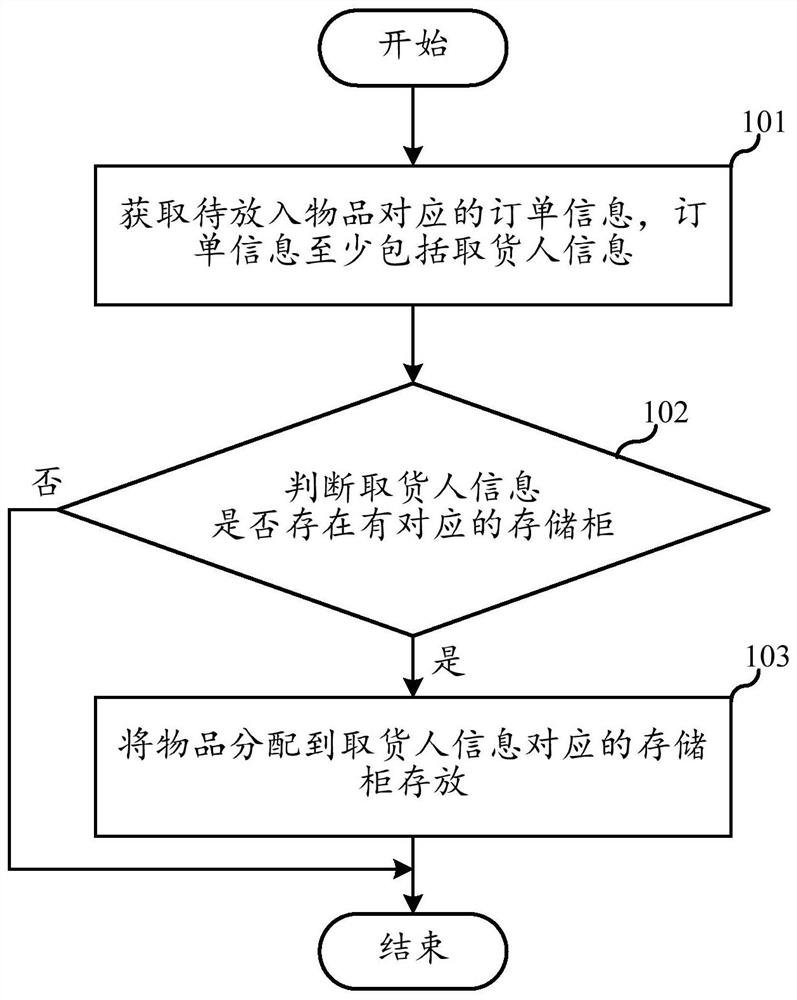

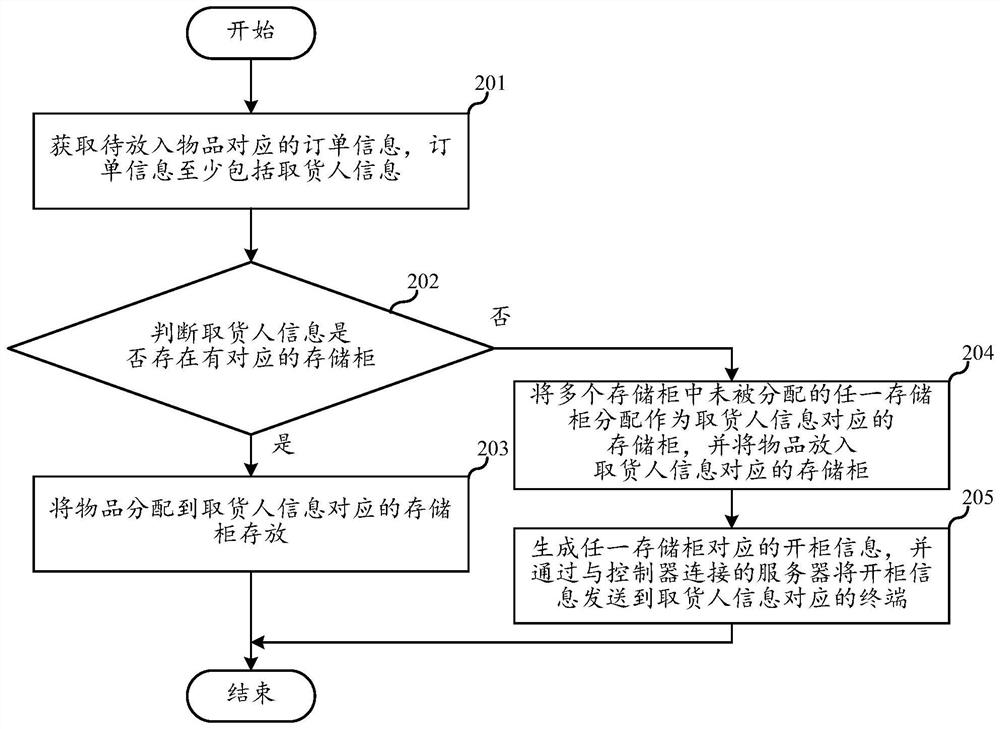

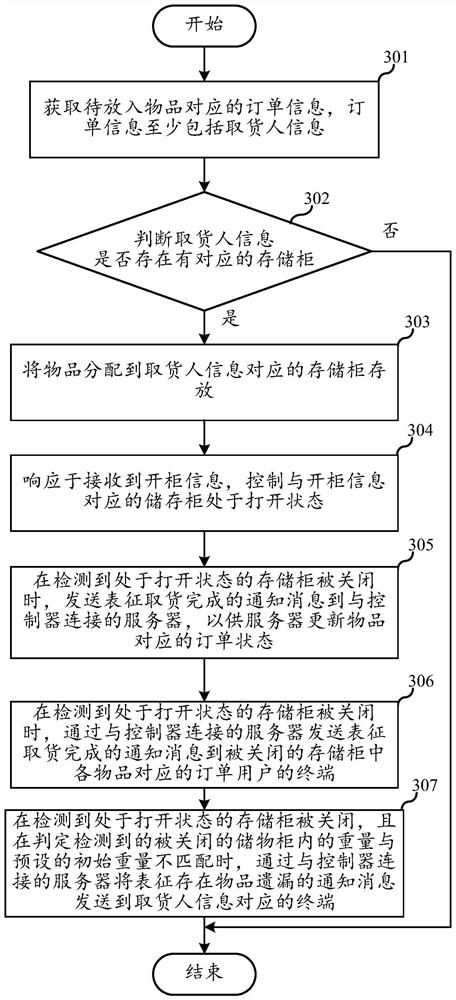

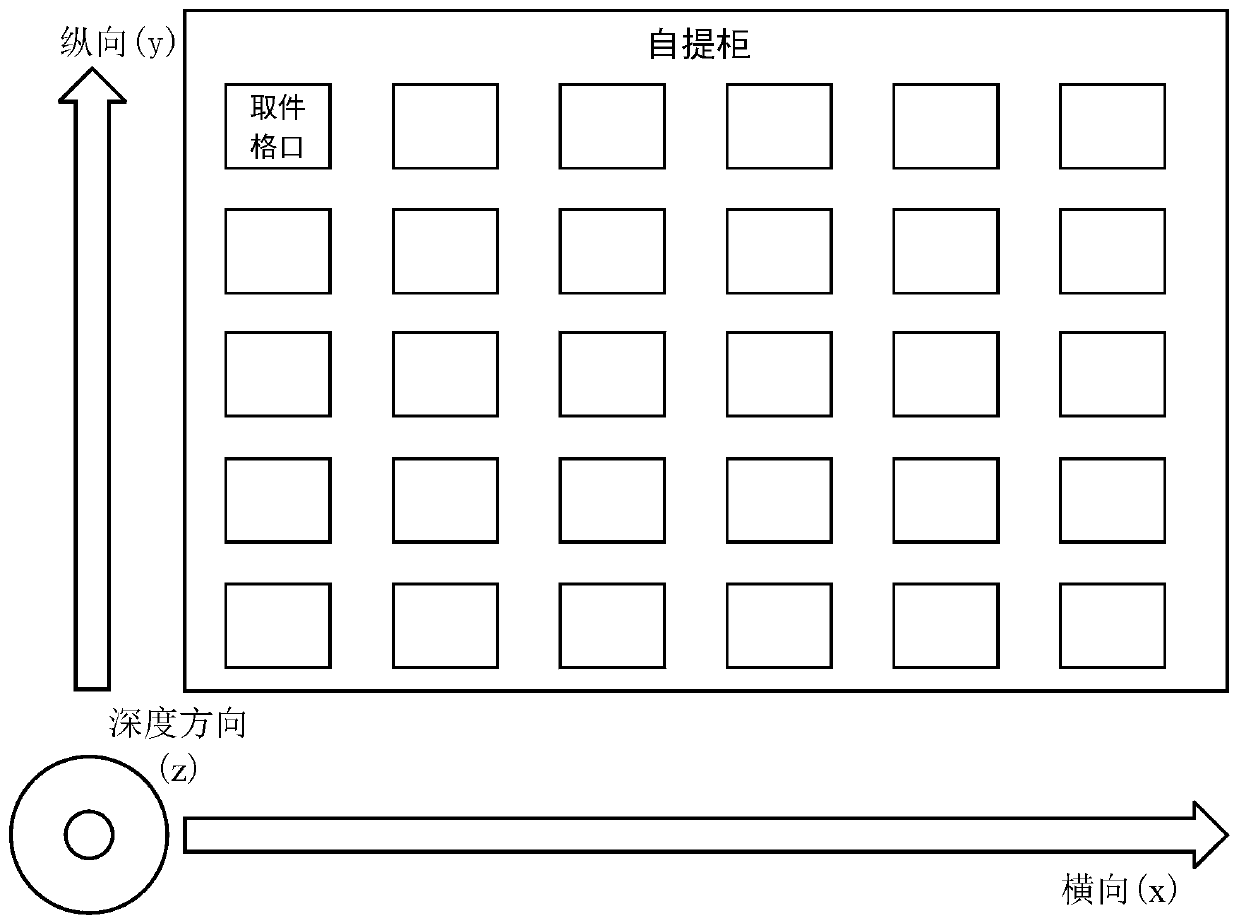

Article distribution method and device, controller and cabinet

PendingCN112446573AEasy to take outSave pickup timeApparatus for meter-controlled dispensingResourcesDistribution methodThe Internet

The embodiment of the invention relates to the technical field of the Internet, and discloses an article distribution method and device, a controller and a cabinet. The article distribution method comprises the steps of obtaining order information corresponding to a to-be-placed article, wherein the order information at least comprises goods taker information; judging whether the information of the consignee has a corresponding storage cabinet or not; and if it is judged that the corresponding storage cabinet exists in the information of the consignee, distributing the articles to the storagecabinet corresponding to the information of the consignee for storage. According to the article distribution method and device, multiple goods corresponding to the same consignee can be placed in thesame storage cabinet, the consignee can conveniently take out all the goods from the single storage cabinet at a time, the goods taking time is shortened, and the goods taking efficiency is improved.

Owner:RAJAX NETWORK &TECHNOLOGY (SHANGHAI) CO LTD

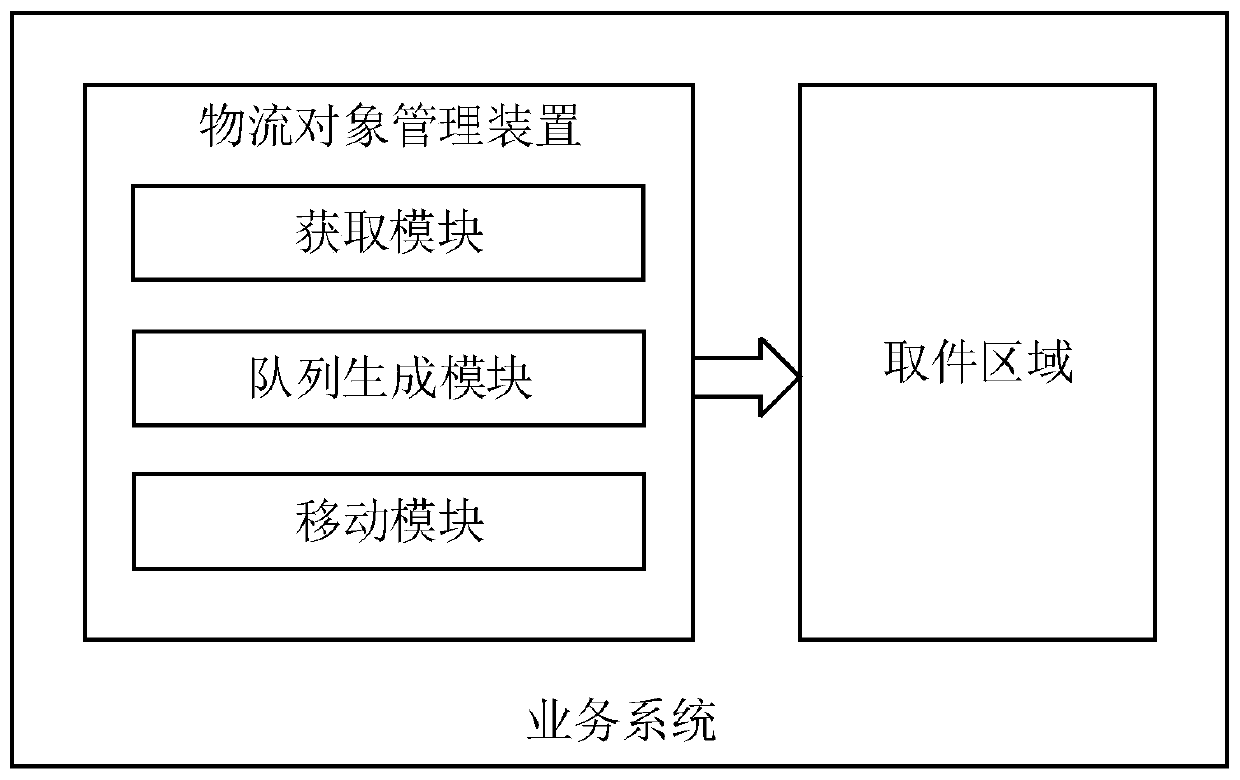

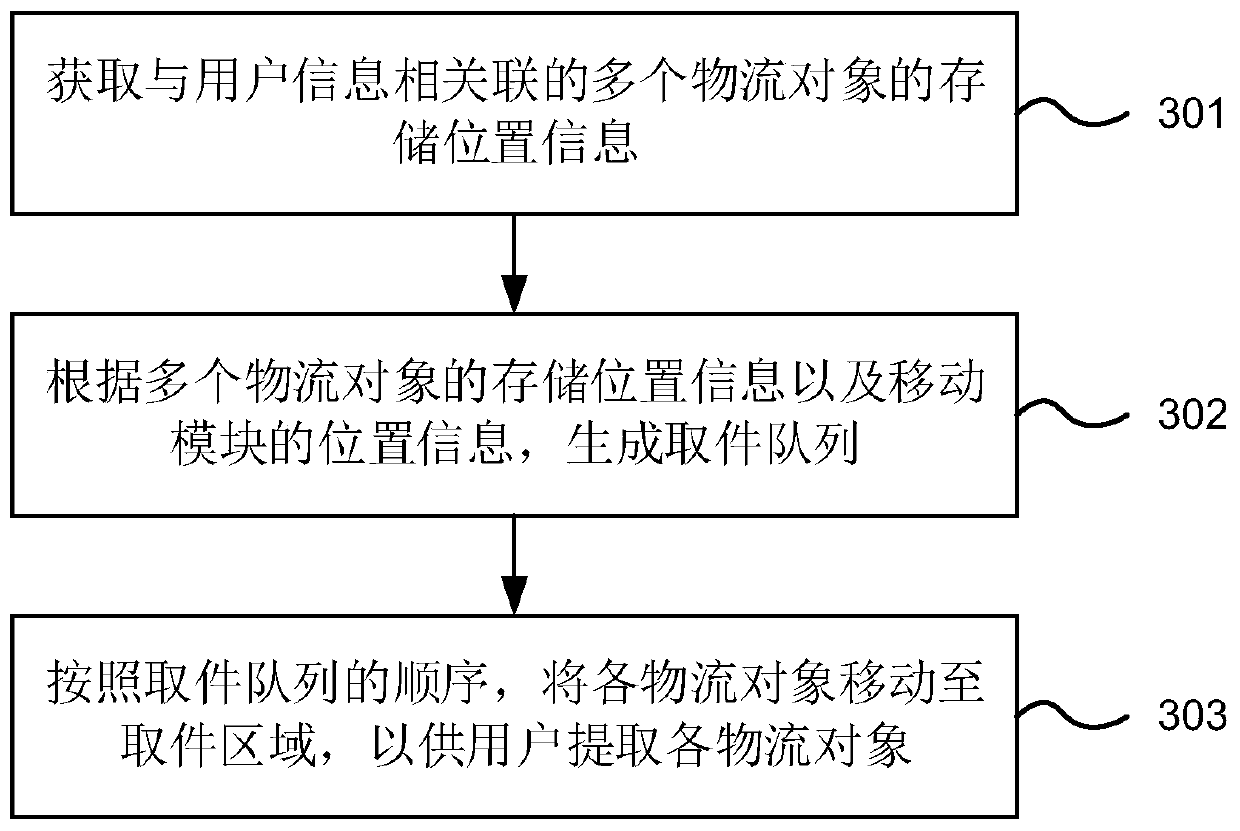

Logistics object management device, logistics object extraction method thereof and electronic equipment

ActiveCN111489111ASave pickup timeReduce waiting timeLogisticsManufacturing computing systemsLogistics managementDatabase

The embodiment of the invention provides a logistics object management device, a logistics object extraction method thereof and electronic equipment. The method comprises the steps of obtaining storage position information of a plurality of logistics objects associated with user information; generating a pickup queue according to the storage position information of the plurality of logistics objects and the position information of the mobile module; and according to the order of the pickup queue, moving each logistics object to a pickup area for a user to extract the logistics object. According to the embodiment of the invention, the moving module and the pickup area are arranged; a plurality of logistics objects related to the user are sequentially moved to a pickup area according to a certain pickup queue sequence; therefore, the situation that the user goes back and forth between different pickup grids for multiple times when picking up multiple logistics objects is avoided, the pickup action of the user is limited to a fixed area, the pickup time and waiting time of the user are greatly saved, the logistics object picking-up efficiency of the user is improved, and the user experience is improved.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

Runway type storage type boxed meal automatic selling system with expired date reminding function

InactiveCN109615770AEasy to take outTake out accuratelyCoin-freed apparatus detailsApparatus for dispensing discrete articlesFood reserveComputer terminal

The invention discloses a runway type storage type boxed meal automatic selling system with an expired date reminding function. The runway type storage type boxed meal automatic selling system comprises a user hand-held terminal equipped with boxed meal selling mobile phone APP, an automatic selling machine and a cloud server, the automatic selling machine is provided with a code scanning mechanism, the user hand-held terminal is connected with the cloud server through a network, and the automatic selling machine and the cloud server are connected through the GPRS; a user logs into the cloud server through the mode that the user hand-held terminal is connected with the cloud server in a wireless connection manner, the automatic selling machine is selected according to the address of the automatic selling machine, and foods capable of being purchased in the automatic selling machine are selected, ordered and reserved; and the automatic selling machine is internally provided with an expired date reminding module. By means of the automatic selling machine, the user can reserve the foods in the automatic selling machine in a manner of meal ordering on the mobile phone APP. After the automatic selling machine receives the order of the user, the foods reserved by the user can be processed before the meal taking time reserved by the user.

Owner:ZHEJIANG UNIV OF TECH

Logistics object management equipment control method, device and system

PendingCN111191972ASave pickup timeShorten the timeApparatus for meter-controlled dispensingLogisticsLogistics managementIndustrial engineering

The embodiment of the invention provides a logistics object management equipment control method, device and system, and the method comprises the steps that a first server determines the correspondinglogistics object information in the corresponding logistics object management equipment according to the user information and logistics object management equipment identification information obtainedfrom a first terminal; according to the logistics object information obtained from the first server, the second server determines cargo space identification information of a cargo space where a corresponding logistics object is located in the corresponding logistics object management equipment, and sends the cargo space identification information to the corresponding logistics object management equipment, so the corresponding logistics object management equipment opens the corresponding cargo grids according to the cargo grid identification information. A user does not need extra operation during pickup, so that the pickup time of the user is shortened.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

Supporting plate lifting device for mold shell chain injection machine

The invention relates to a supporting plate lifting device and particularly relates to a supporting plate lifting device for a mold shell chain injection machine, and belongs to the technical field ofproduction of building materials by utilizing a modified cement polystyrene particle material. The supporting plate lifting device comprises a hoisting frame and a supporting plate stack, wherein thesupporting plate stack is located at the bottom of the hoisting frame; two sides of the hoisting frame are connected with a double-chain-wheel assembly and a driven chain wheel assembly; a hydrauliccylinder is mounted on a side face of the hoisting frame; the hydraulic cylinder is connected with the double-chain-wheel assembly; the double-chain-wheel assembly is connected with a sleeve roller chain; the sleeve roller chain is in transmission connection with the double-chain-wheel assembly through the sleeve roller chain and a hoisting trolley I; the sleeve roller chain penetrates through thedriven chain wheel assembly to be in transmission connection with a hoisting trolley II; and the hoisting trolley I and the hoisting trolley II are located on the same horizontal plane of the hoisting frame. The supporting plate lifting device provided by the invention has the beneficial effects that the hoisting trolleys are operated synchronously and horizontally and stable operation of a supporting plate is ensured; one supporting plate is picked through a picking device after the picking device reaches a supporting plate picking position; and then the supporting plate is jacked through the hydraulic cylinder and the other supporting plate is picked.

Owner:烟台政通节能建材设备制造有限公司

Storage type box lunch automatic selling system with reminding function based on inclined material taking

ActiveCN109658608AFast heatingImprove efficiencyEncryption apparatus with shift registers/memoriesCoin-freed apparatus detailsMobile phoneStorage type

The invention discloses a storage type box lunch automatic selling system with a reminding function based on inclined material taking. The system comprises a user handheld terminal provided with a boxlunch selling mobile phone APP, a vending machine and a cloud server. A code scanning mechanism is arranged on the vending machine, the user handheld terminal is connected with the cloud server through a network, and the vending machine is connected with the cloud server through a GPRS. The vending machine comprises a base, a carriage body, a box door, a rotary motor, a bottom motor base, a material taking device, a material taking driving device, a heating mechanism, a vertically-arranged first roller, a vertically-arranged second roller, and a vertical follow-up rolling platform arranged onthe first roller and the second roller. An expiration reminding module is arranged in the vending machine, and the vending machine can enable a user to reserve food in the vending machine in a food ordering mode on a mobile phone app.

Owner:ZHEJIANG UNIV OF TECH

Steel sheet pickup device utilizing electromagnets

The invention discloses a steel sheet pickup device utilizing electromagnets. The steel sheet pickup device utilizing the electromagnets comprises a handle, a hollow bend arm, a horseshoe-shaped plateframe and the electromagnets. A pipeline is arranged in the middle of the handle and the hollow bend arm; a lead wire is arranged in the pipeline in a penetrating way; a pressing switch matched withthe lead wire is arranged at a position, close to the front end, of the handle; the front end of the hollow bend arm is detachably connected with the horseshoe-shaped plate frame through an engaging lug; a plurality of internal thread sleeves re arranged on the horseshoe-shaped plate frame; external thread shells are arranged on the upper parts of the electromagnets and are in threaded connectionwith the internal thread sleeves; electric contacts are arranged on the top part of the external thread sleeves; a wire connecting pedestal is further arranged on the horseshoe-shaped plate frame; andthe electric contacts are electrically connected with the wire connecting pedestal through the lead wire. The steel sheet pickup device utilizing the electromagnets is simple in structure, easy to replace parts, low in maintenance cost, easy to operate, and capable of quickly picking up steel sheets, so that the steel sheet pickup time is saved, and the production efficiency is effectively improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

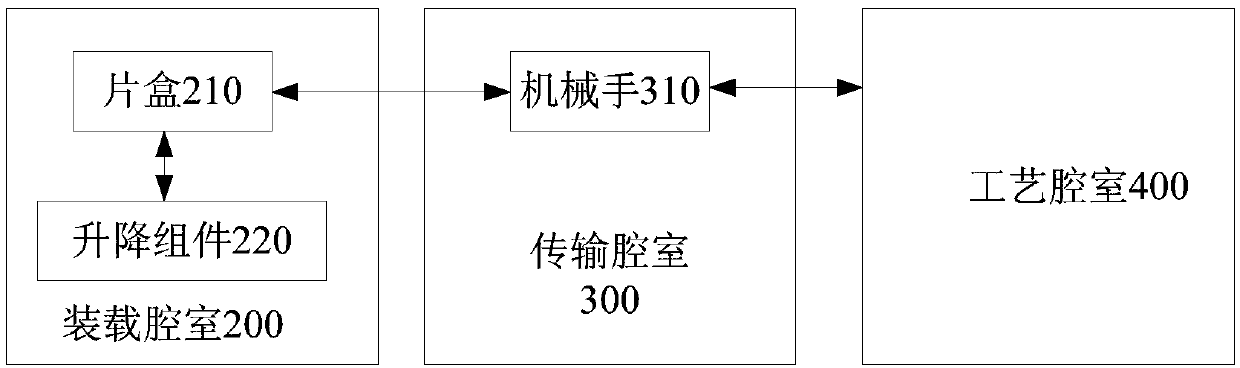

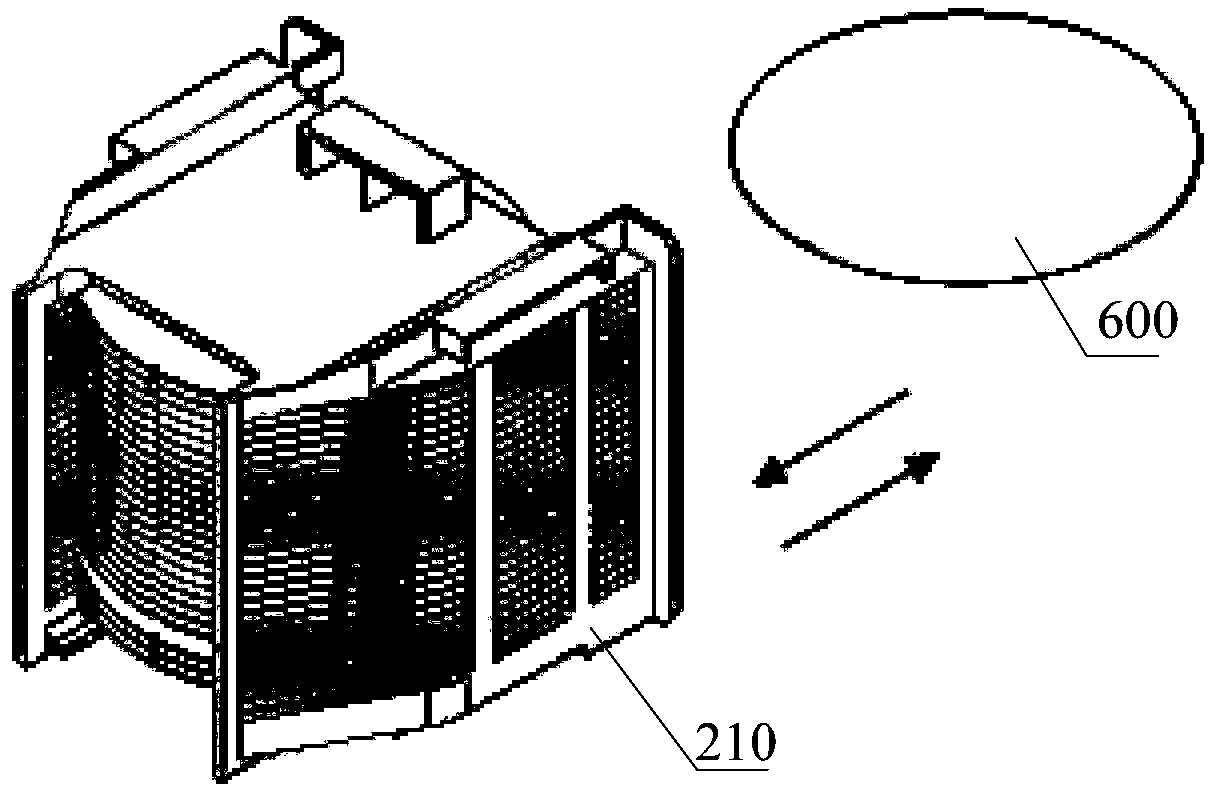

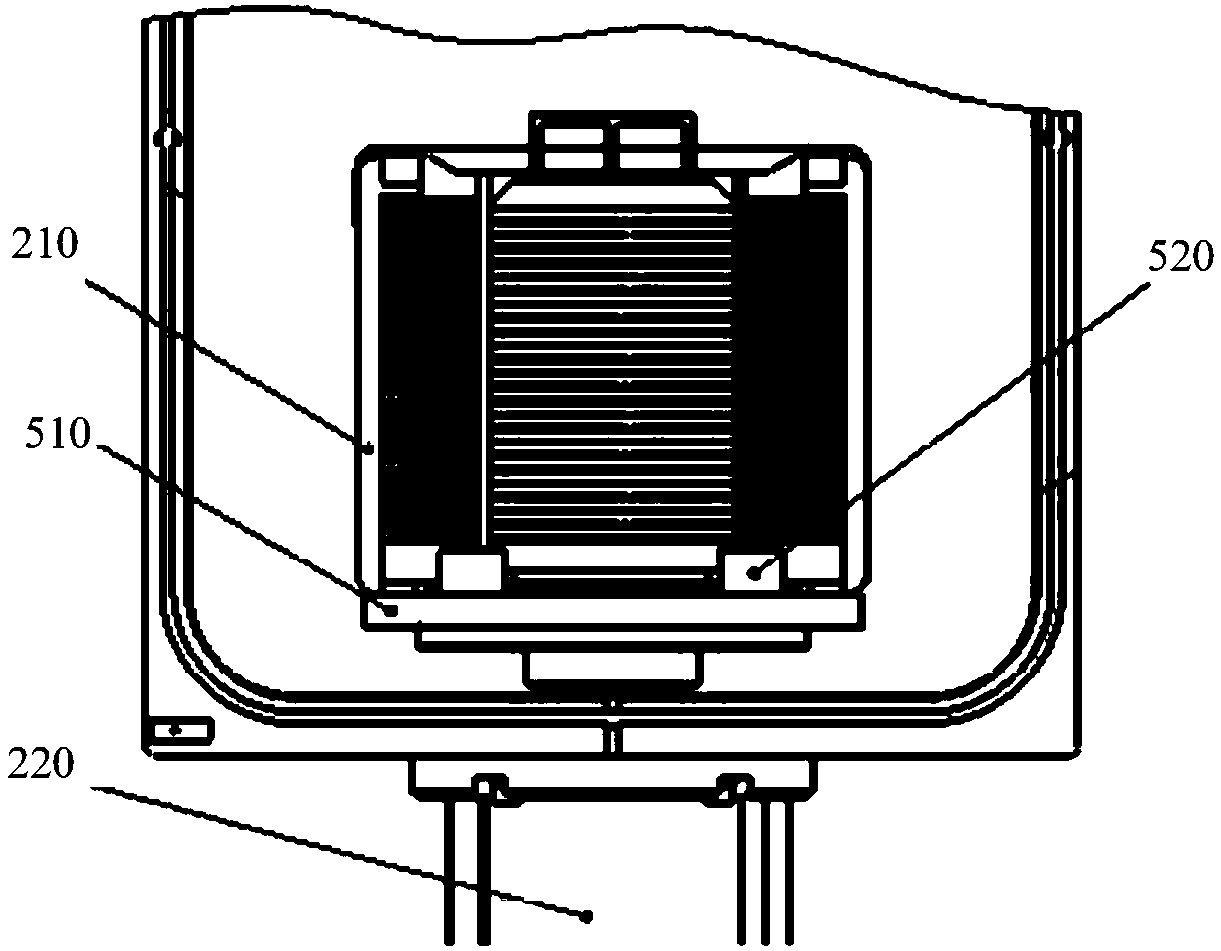

Wafer box rotating mechanism and loading chamber

ActiveCN109962029AAccurate pick-up positionGuaranteed coincidenceSemiconductor/solid-state device manufacturingConveyor partsEngineeringRestoring force

The invention discloses a wafer box rotating mechanism and a loading chamber. The wafer box rotating mechanism comprises a supporting base, a rotating support seat and a moving assembly. The supporting base can move linearly in the vertical direction under the action of a driving force. The rotating support seat is located on the supporting base, and one end of the rotating support seat is rotationally connected with one end of the supporting base. The rotating support seat is used for loading a wafer box. The moving assembly comprises a guide rail, a moving part and an elastic part. The moving part is connected to the side of the rotating support seat. The guide rail is fixedly arranged on the side wall of a loading chamber. During downward movement of the supporting base, the guide railcan contact the moving part and prevent the moving part from moving downward, so that the rotating support seat rotates from a vertical position to a horizontal inverted position. The elastic part isused for exerting a restoring force on the rotating support base so that the rotating support base rotates from the horizontal inverted position to the vertical position. A wafer can be accurately located in a wafer box, the yield of wafer taking can be improved, and the time for wafer taking can be saved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Automatic screening feeding mechanism for columnar parts

ActiveCN106241303AReduce friction lossImprove screening efficiencyConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to an automatic screening feeding mechanism for columnar parts. The mechanism comprises a base, a feeding device which is arranged on the base and a transfer track which transfers parts. The mechanism further comprises at least one screening device for screening the parts of the feeding device. Each of the screening devices comprises rollers which are arranged on the base through a shaft, wherein gaps suitable for parts which meet the set state to pass through exist between the rollers and the transfer track. According to the automatic screening feeding mechanism for columnar parts provided by the invention, by forming the gaps between the rollers and the transfer track to allow the parts which meet the set state to pass through, a plurality of parts which meet the set state can be screened simultaneously, so that the screening efficiency is improved. Moreover, the frictional loss of the parts is reduced, and the influence caused by powder falling from the parts on the cleanness of a product is reduced.

Owner:CWB AUTOMOTIVE ELECTRONICS

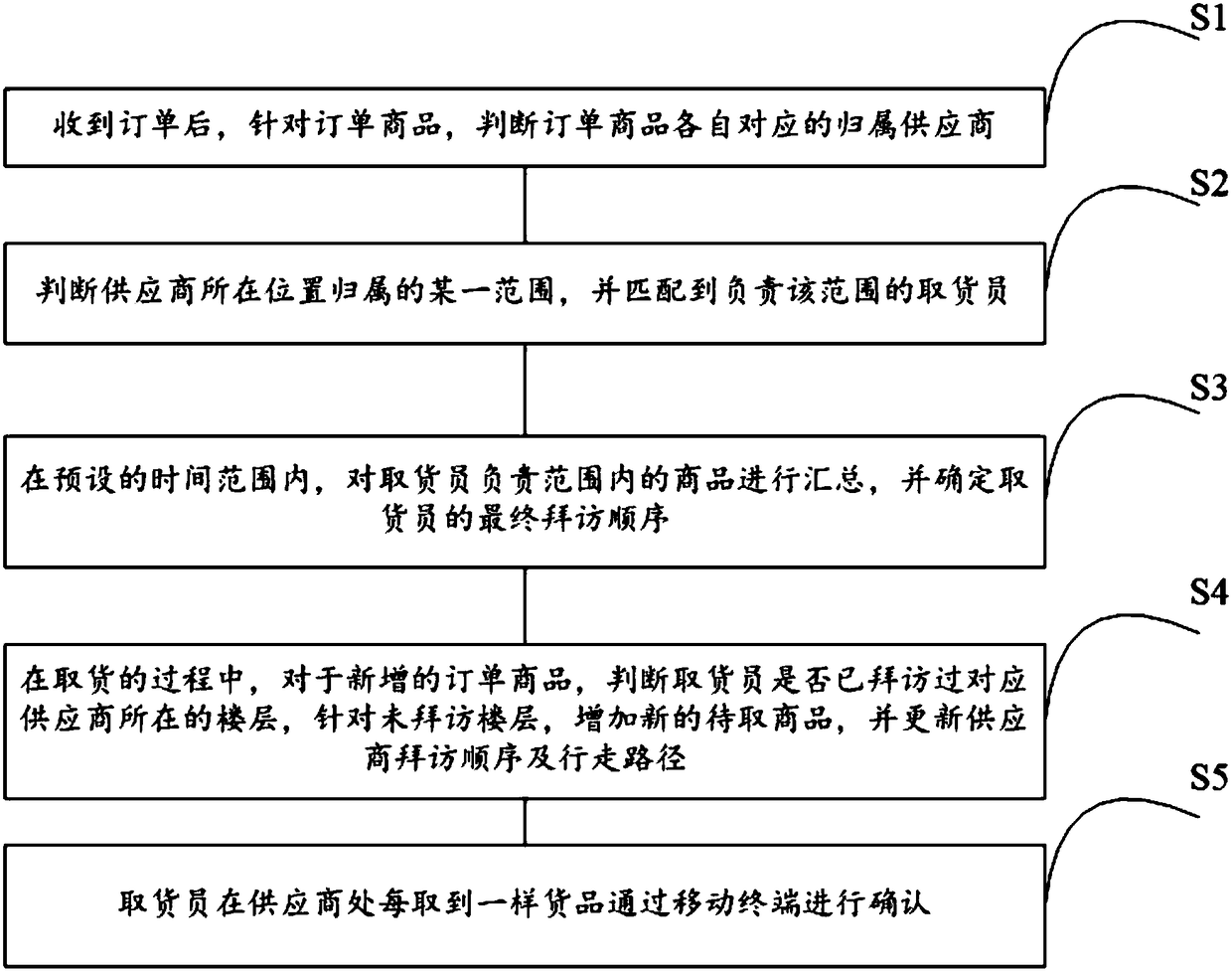

A commodity fetching method and system based on geographical location information

InactiveCN108090622ASave pickup timeEasy to pick up and take inventoryForecastingBuying/selling/leasing transactionsGeographic siteTime range

The invention provides a commodity fetching method based on geographical location information. The method comprises the steps of: S1, after receiving orders, judging respective suppliers correspondingto commodities in the orders, S2, judging the scopes to which the positions where the suppliers are located belong and matching the scopes with commodity fetching workers in charge of the scopes; S3,in a preset time range, gathering the commodities in the scopes in the charge of the commodity fetching workers and determining final visit orders of the commodity fetching workers; S4, during the process of commodity fetching, judging whether the commodity fetching workers have visited floors where the suppliers for newly-added order commodities are located, and, for unvisited floors, adding newto-be-fetched commodities and updating the supplier visit orders and walking routes; S5, performing confirmation via a mobile terminal every time a commodity fetching worker receives a commodity froma supplier.

Owner:创新无限信息技术(武汉)有限公司

Logistics object storage device, logistics object extraction method thereof and electronic equipment

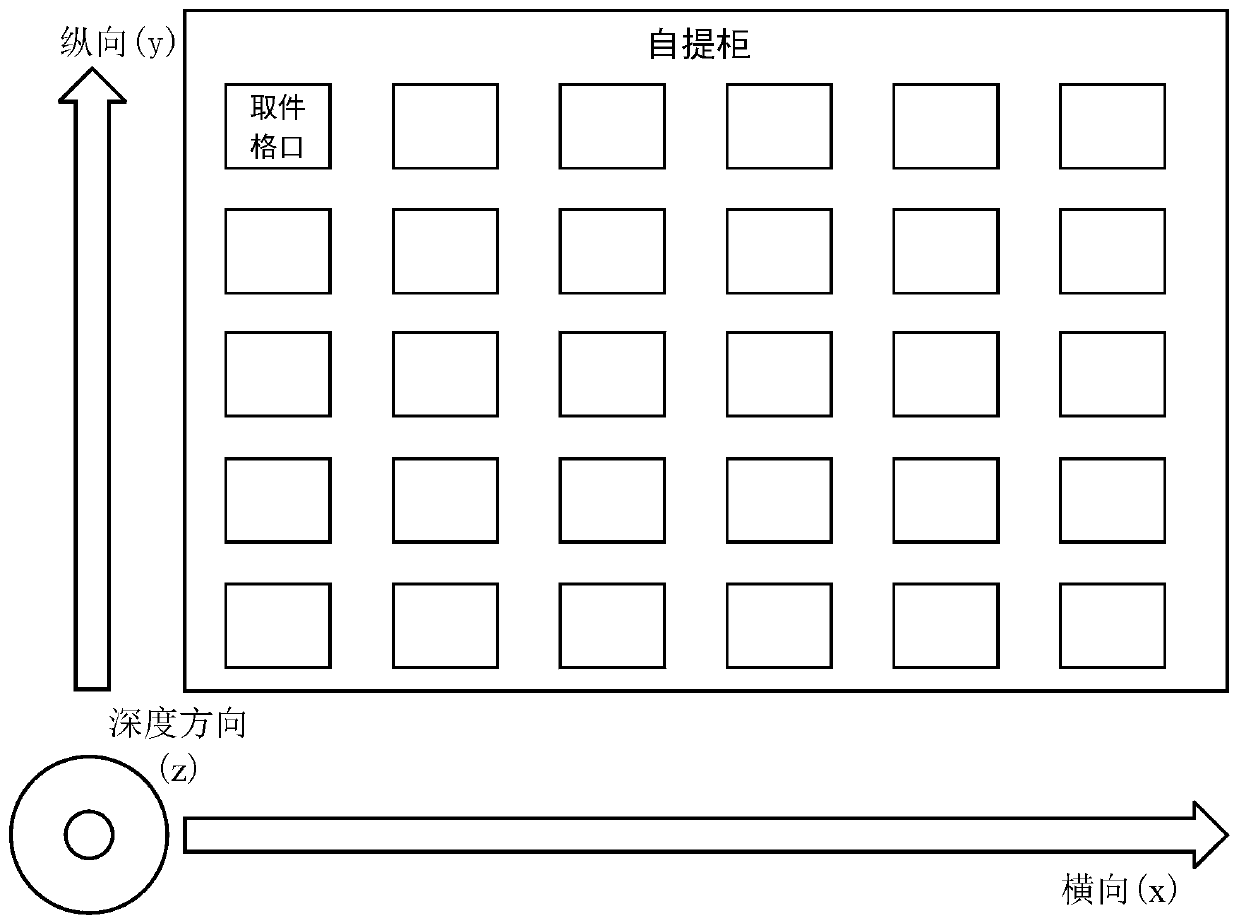

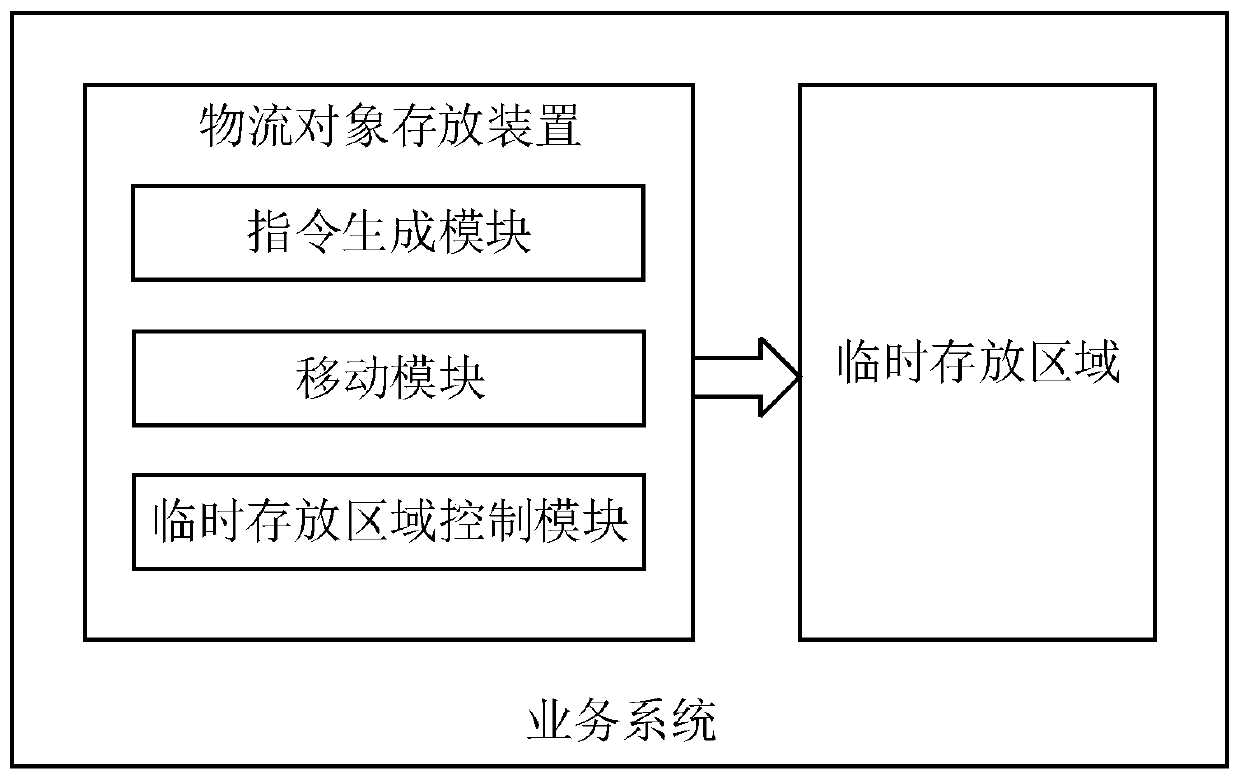

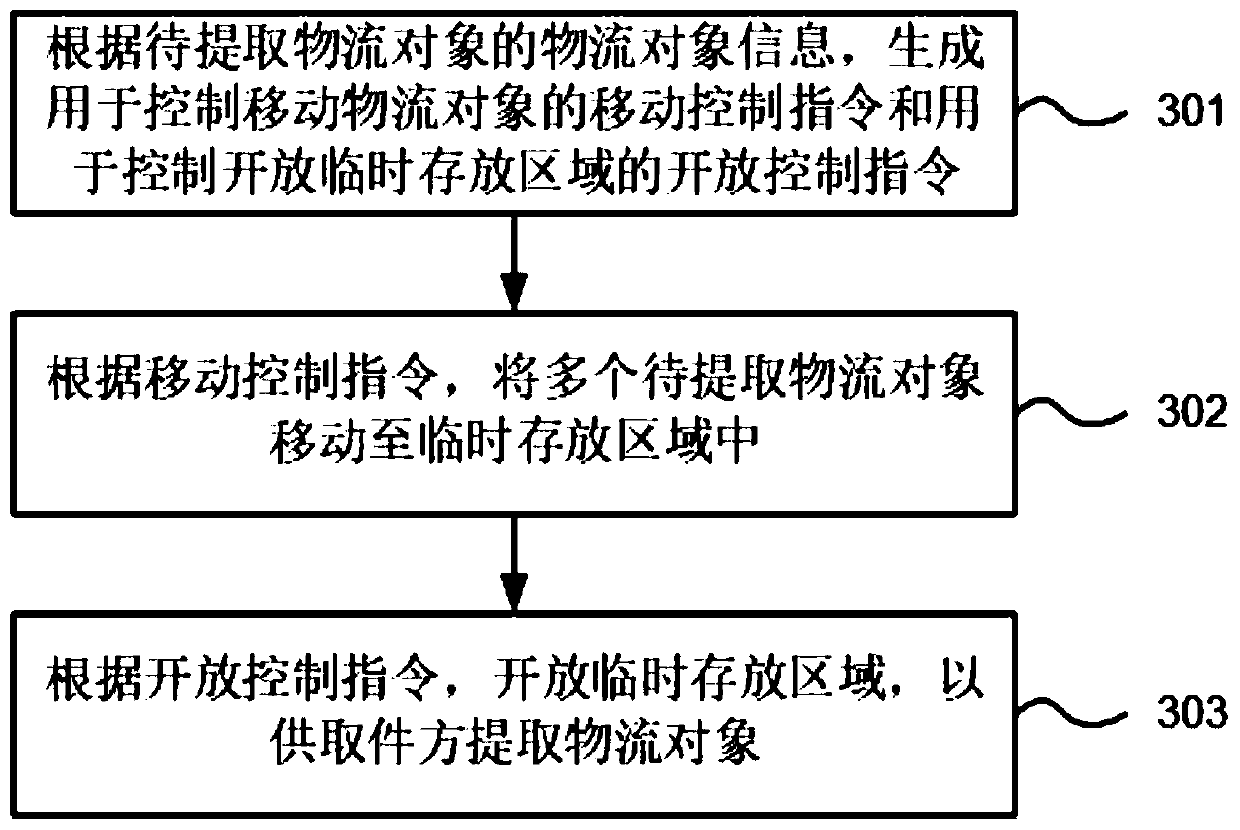

PendingCN111435467AReduce lateral movementSave pickup timeReservationsApparatus for meter-controlled dispensingObject storageMovement control

The embodiment of the invention provides a logistics object storage device, a logistics object extraction method thereof and electronic equipment. The method comprises the steps of generating a movement control instruction and an opening control instruction according to logistics object information of a to-be-extracted logistics object; moving the plurality of logistics objects to be extracted toa temporary storage area according to the movement control instruction; and opening the temporary storage area according to the opening control instruction so as to enable the pickup party to pick upthe logistics object. According to the embodiment of the invention, the temporary storage area is arranged to temporarily store the to-be-extracted logistics object of the pickup party; a plurality oflogistics objects of the pickup party are moved to at least one column of vertically and / or transversely arranged logistics object storage units in the temporary storage area, therefore, the situation that the pickup party goes back and forth between different pick-up grids for multiple times when picking up multiple logistics objects is avoided, transverse movement of the pickup party is reduced, the pick-up time of the pickup party is greatly saved, and the logistics object picking-up efficiency of the pickup party is improved.

Owner:CAINIAO SMART LOGISTICS HLDG LTD

Rotary taking type storage boxed meal automatic selling system

ActiveCN109615778AEasy to take outTake out accuratelyCoin-freed apparatus detailsApparatus for dispensing discrete articlesHeating timeHand held

The invention discloses a rotary taking type storage boxed meal automatic selling system. The rotary taking type storage boxed meal automatic selling system comprises a user hand-held terminal provided with boxed meal selling mobile phone APP, an automatic selling machine and a cloud server, the automatic selling machine is provided with a code scanning mechanism, the user hand-held terminal is connected with the cloud server through a network, and the automatic selling machine and the cloud server are connected through the GPRS; the automatic selling machine comprises a shell, a box door, a rotary drive device, a stand column, a storage bin, a taking device and a taking drive device; and the rotary drive device comprises a rotation motor and a groove wheel mechanism, and the taking devicecomprises an arc-shaped lifting rail and a taking device. By means of the automatic selling machine, a user can reserve foods in the automatic selling machine in a manner of ordering on the mobile phone APP. After the user receives the order of the user, the foods ordered by the user can be processed before the food taking time reserved by the user; and when the user takes the foods, the processed foods can be taken directly without waiting for the heating time.

Owner:ZHEJIANG UNIV OF TECH

Succession-type boxed meals vending system in time sequence and driven by geneva wheels

ActiveCN109615771AEasy to take outTake out accuratelyReservationsCoin-freed apparatus detailsNetwork connectionComputer terminal

The invention discloses a succession-type boxed meals vending system in time sequence and driven by geneva wheels. The system comprises a user handheld terminal with a mobile phone APP for boxed mealsvending, a vending machine and a cloud server; the vending machine is provided with a code scanning mechanism, the user handheld terminal and the cloud server are connected through network, the vending machine and the cloud server are connected through GPRS; the vending machine comprises a machine body, a machine door, a roller driving device, first roller, a second roller which are vertically disposed, a first synchronous belt sleeves the upper end of the first roller and the upper end of the second roller, a second synchronous belt sleeves the lower end of the first roller and the lower endof the second roller, a material extracting device, a heating device, a linear driving device and boxed meal placement cavity. According to the succession-type boxed meals vending system in time sequence and driven by the geneva wheels, a user can order foods in the vending machine with the mobile phone app.

Owner:ZHEJIANG UNIV OF TECH

Sheave driven boxed rice vending system of selling by date

InactiveCN109615772AGuaranteed rotational intermittent motionEasy to take outReservationsCoin-freed apparatus detailsNetwork connectionComputer terminal

The invention discloses a sheave driven boxed rice vending system of selling by date, which comprises a user handheld terminal with boxed rice sale APP, a vending machine, and a cloud server. The vending machine is provided with a scanning code mechanism, the user handheld terminal and the cloud server are connected through a network, and the vending machine and the cloud server are connected by GPRS. The vending machine comprises a casing, a door, a rotary driving device, columns, a storage chamber, a transport device, a linear drive device, and a heating mechanism. The casing and the door together constitute a vending box. A display screen, a control panel, and a discharge opening are arranged on the door. The rotary driving device comprises a rotating motor and a sheave mechanism. The transport device is mounted on the linear drive device. The vending machine enables a user to make a reservation for food in the vending machine by ordering it on the mobile phone app.

Owner:ZHEJIANG UNIV OF TECH

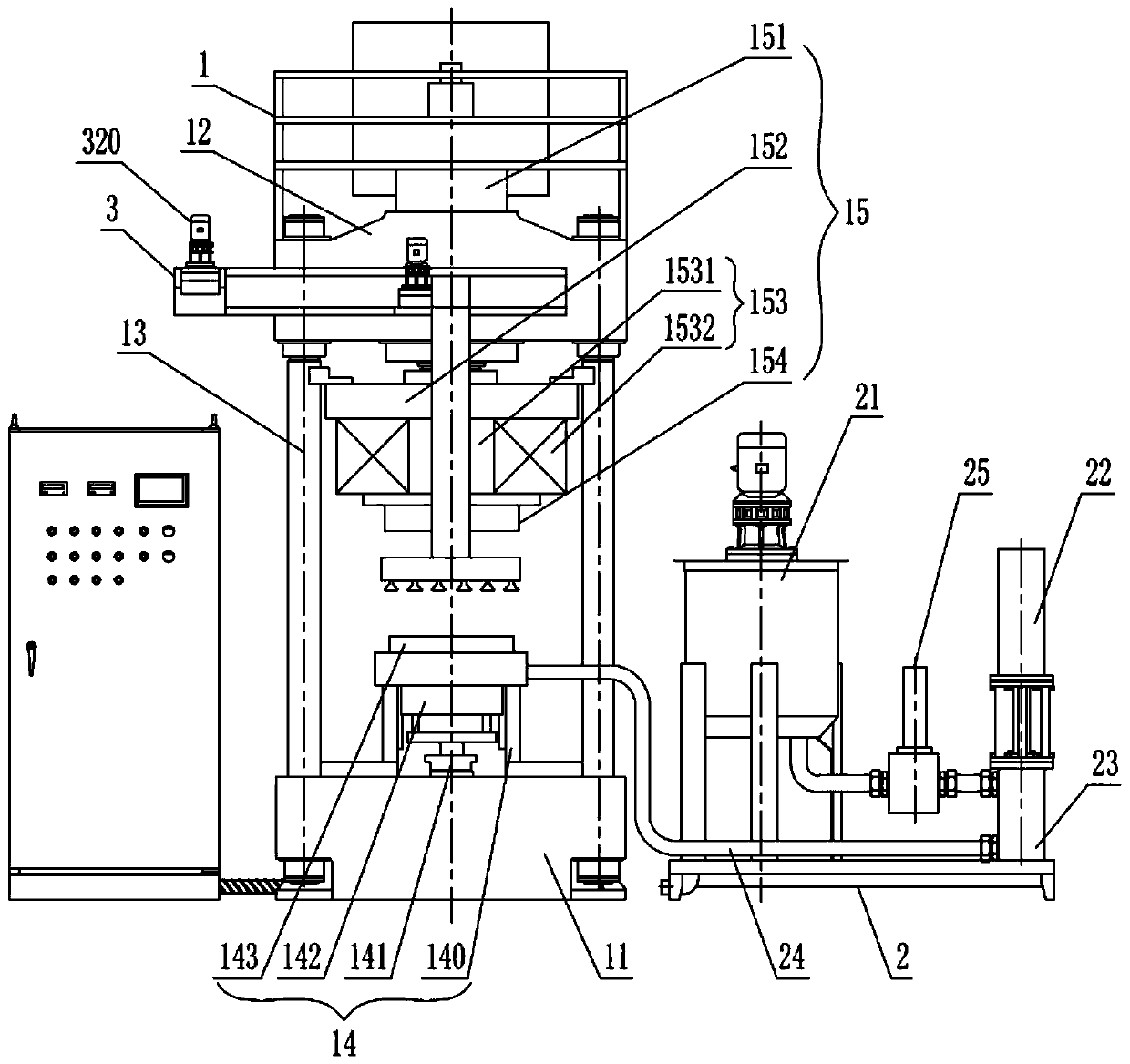

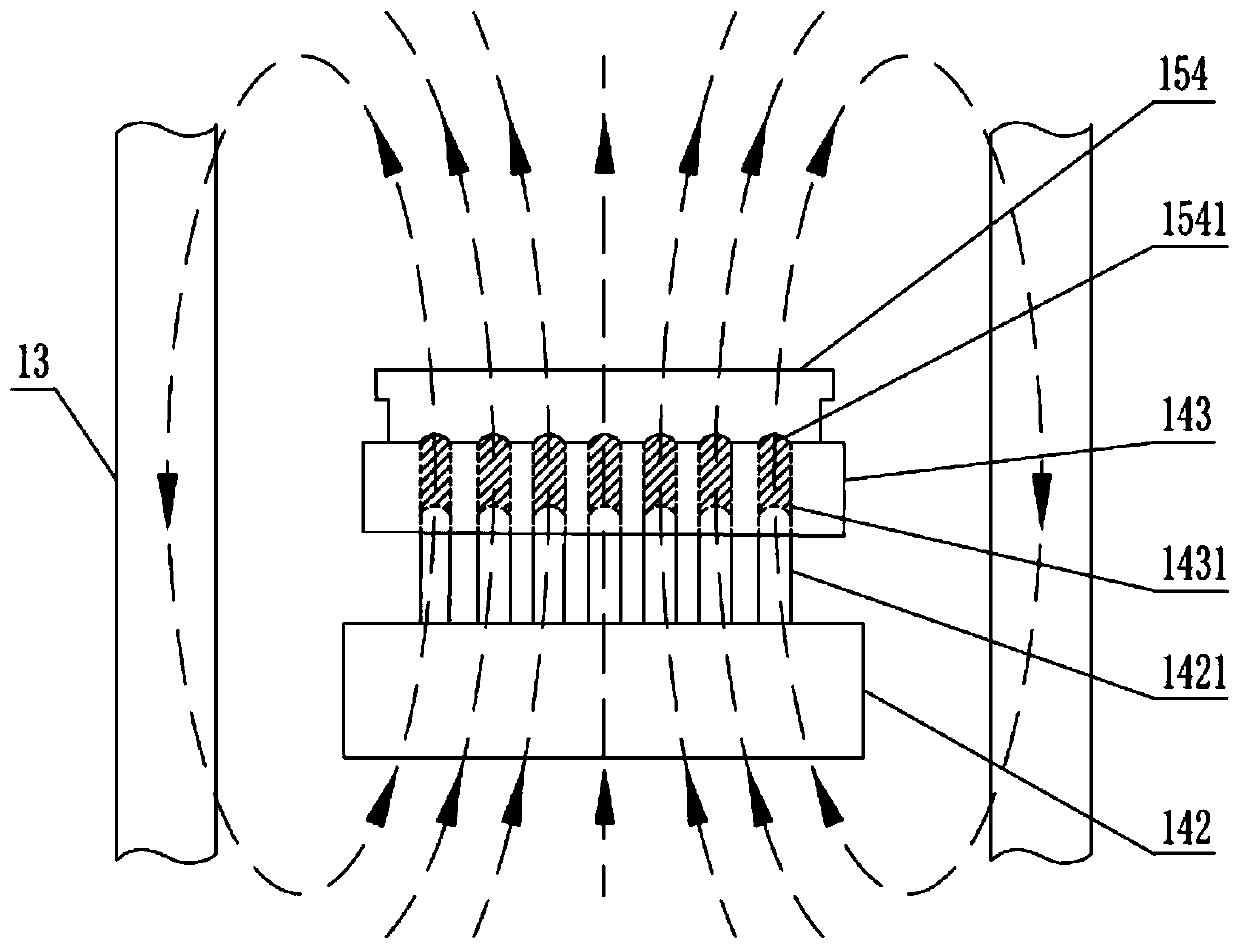

1,500 KN magnetic material wet type forming hydraulic machine and hydraulic forming process

PendingCN110181661AHigh Magnetic ConsistencyMagnetic homogeneityMagnetic film to substrate applicationShaping press ramDemagnetizing deviceHydroforming

The invention discloses a 1,500 KN magnetic material wet type forming hydraulic machine and a hydraulic forming process, and relates to the technical field of magnetic product production. The 1,500 KNmagnetic material wet type forming hydraulic machine comprises a hydraulic machine body. The hydraulic machine body comprises an upper workbench, a lower workbench, magnetism conducting vertical columns, a lower die part and an upper die part. The upper die part comprises an upper sliding block driven to slide up and down, a magnetizing and demagnetizing device fixed to the lower end of the uppersliding block, and an upper die fixed to the lower end of the magnetizing and demagnetizing device. The upper sliding block is slidingly connected with the magnetism conducting vertical columns on the periphery. The lower die part comprises a lower die support fixed to the lower workbench, a lower die fixed to the lower die support, and a lower sliding block arranged below the lower die and driven to slide up and down. The lower sliding block is slidingly connected with the lower die support, and the lower die support is connected with the magnetism conducting vertical columns on the periphery. A magnetism conducting circuit can be formed during magnetizing, and produced workpieces have good magnetism uniformity and stability; and in combination with the special hydraulic forming process,the produced products have uniform and stable magnetism and high mechanical performance and consistency.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

Double-track delivery system for goods delivery of high-rise buildings

InactiveCN107515609AShorten the timeImprove work efficiencyPosition/course control in two dimensionsVehiclesSystem structureButt joint

The invention discloses a double-track delivery system for goods delivery of high-rise buildings. The delivery system comprises delivery tracks, delivery trolleys and a delivery box. The delivery trolleys are connected with the delivery tracks. The delivery box is connected with one end of each main track. A plurality of storage boxes different in volume are arranged in the delivery box. The delivery tracks include two vertical tracks. The delivery trolleys are matched onto the vertical tracks. The vertical tracks comprise the main tracks and movable tracks, and the main tracks are matched with the movable tracks. The main tracks are distributed between any two layers of a building. The vertical movable tracks are matched between any two main tracks. One end of each movable track is connected with the corresponding main track rotationally. Collection tracks are erected beside the vertical tracks. When the movable tracks rotate relative to the main tracks, the other ends of the movable tracks are matched with the main tracks or the collection tracks, or the movable tracks on the two vertical tracks are matched and communicated in a butt joint mode. The delivery system has the advantages that the delivery system is simple in structure; delivery efficiency of the double-track delivery system for goods delivery of the high-rise buildings is improved; the 'last 100m' problem of logistics is solved.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com