Object delivery system based on high-rise building

A technology for buildings and objects, applied in conveyor objects, conveyor control devices, conveyors, etc., can solve the problems of low delivery efficiency, complicated control operations, and cumbersome collection of express items, and achieve work efficiency. time-wasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

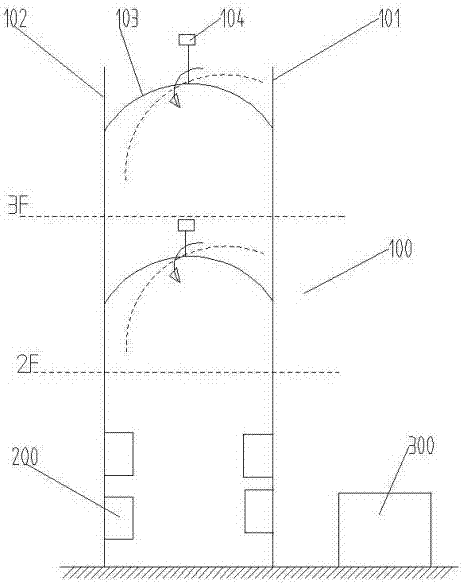

[0060]As shown in the accompanying drawings of the description, an object delivery system based on a high-rise building includes a delivery track 100, a delivery trolley 200 and a delivery box 300; the delivery track 100 is arranged vertically from bottom to top along the wall of the building; The delivery trolley 200 is connected with the delivery track 100, and walks on the delivery track 100 under the action of the driving device; the delivery box 300 is connected with one end of the main track, for the courier or the delivery robot to deposit and deliver Cargo trolley 200 pick-up.

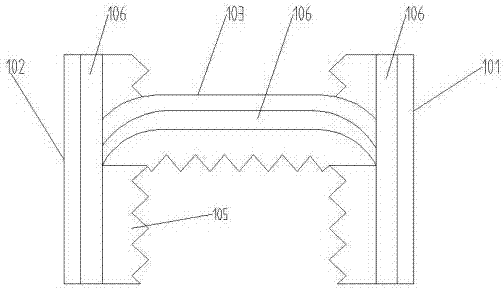

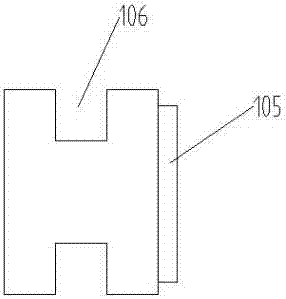

[0061] Such as figure 1 to Figure 4 As shown, the delivery track 100 includes two vertical tracks arranged and fixed along the vertical direction of the building. The two vertical tracks are arranged in parallel. They are the first vertical rail 101 and the second vertical rail 102 respectively. The delivery trolley 200 moves upward on the first vertical rail 101 to deliver the goods to the...

Embodiment 2

[0074] Refer to the attached Figure 14 with Figure 17 , this embodiment discloses a dispatching system based on the object delivery system of Embodiment 1; it includes a control center, a first vertical rail 101 and a delivery trolley 1001; wherein,

[0075] The first vertical rail 101 includes a position mark one 001, and the position mark one 001 corresponds to the destination of the corresponding delivery trolley one 1001 on the first vertical rail 101; the position mark one 001 is arranged on each building The floor corresponds to the position of the first vertical rail 101, and the destination is the floor that the delivery trolley 1001 will arrive at.

[0076] The delivery trolley 1001 is connected to the control center, receives a delivery signal, and starts to transport parcels along the first vertical rail 101; the delivery trolley 1001 includes an identification unit 006 for identifying the location identifier 001, and obtaining The location, that is, the locatio...

Embodiment 3

[0080] On the basis of Embodiment 2, this embodiment discloses another dispatching system; the system also includes: a second vertical rail 102, a transition rail 103 and a track changing device 104; the system also includes: an induction unit 005, electrically connected In the control center, it is used to sense the completion of the transition track 103 track change, and send a track change completion signal to the control center; sense the completion of the reset of the transition track 103, and send a reset completion signal to the control center; wherein,

[0081] The delivery trolley 1001 is also used to: send a delivered signal to the control center, the delivered signal is a confirmation signal that the package has been taken out; receive the return signal sent by the control center, and perform a return movement: move along the original delivered package Direction, starting from the destination, passing through the transition track 103, and then moving to the second ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com