Pneumatic ejecting mechanism of welding jig

A welding fixture and top piece technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency, long time consumption, difficulty in taking out, etc. The effect of improving the efficiency of welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

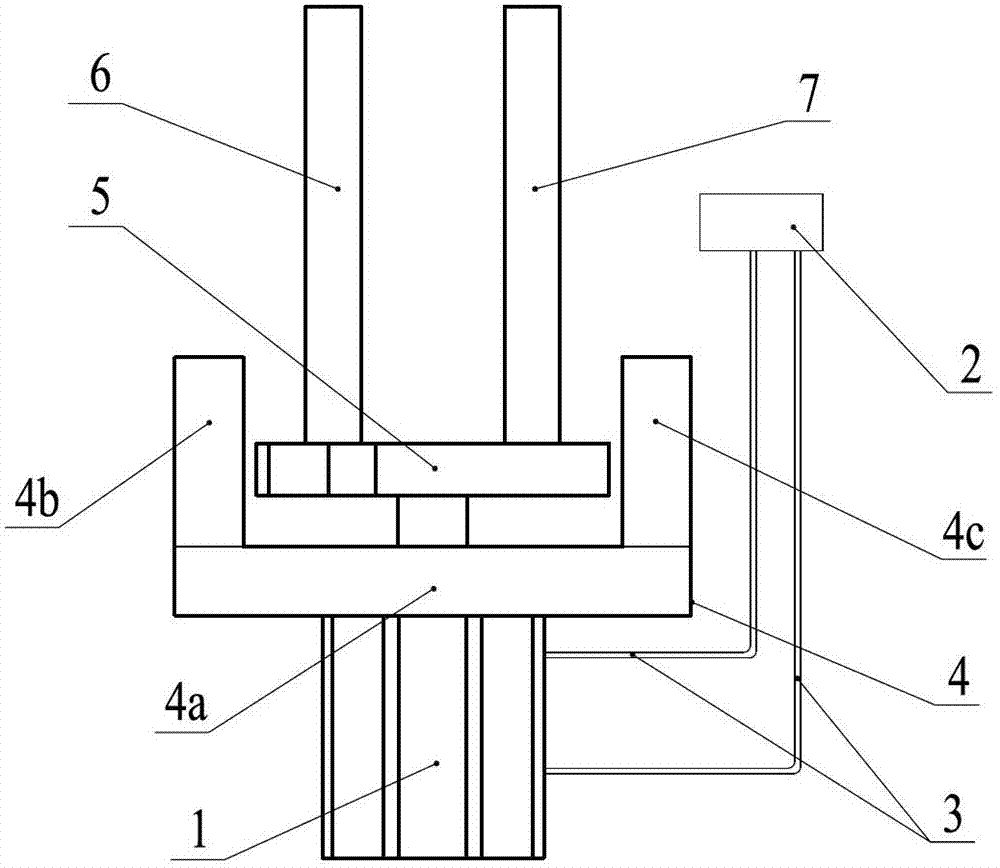

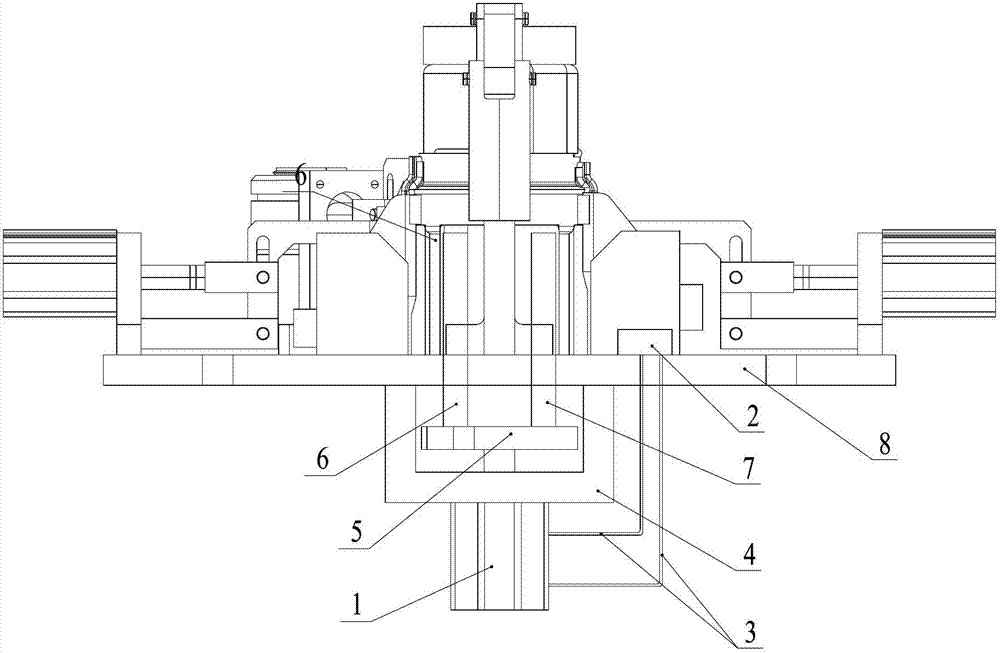

[0010] As shown in the figure: the pneumatic ejector mechanism of the welding fixture in the embodiment is mainly composed of a cylinder 1, a mechanical valve 2, an air pipe 3, a bracket 4, an ejector plate 5, a first ejector rod 6 and a second ejector rod 7, The support 4 is fixedly installed on the welding fixture, and the cylinder 1 is fixed on the support 4. The main function of the cylinder 1 is to provide power for the ejector plate 5 to lift up and down; the air inlet and the air outlet of the cylinder 1 pass through the air pipe 3 respectively Connect the mechanical valve 2, the mechanical valve 2 controls the expansion and contraction of the piston rod of the cylinder 1, the piston rod end of the cylinder 1 is connected to the ejector plate 5, and the first ejector rod 6 and the second ejector rod 7 are installed on the ejector plate 5, the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com