Automatic screening feeding mechanism for columnar parts

A technology for automatic screening and cylindrical parts, which is applied to conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of low screening efficiency of automatic screening and feeding mechanisms, reduce parts accumulation, improve screening efficiency, and reduce friction. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

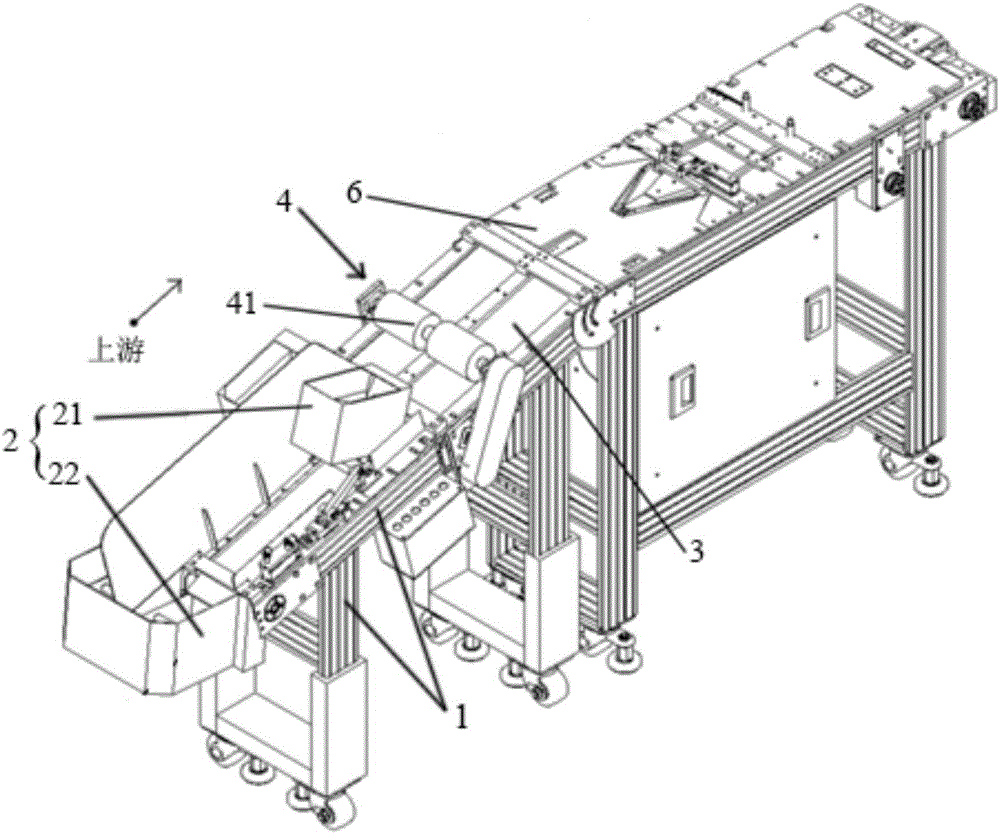

[0034] Such as figure 1 A specific embodiment of the automatic screening and feeding mechanism for cylindrical parts shown includes a machine base 1, a feeding device 2 arranged on the machine base 1, and a conveying track 3 for transferring parts, and it also includes at least one set of For the screening device 4 that screens the parts of the feeding device 2, the screening device 4 includes a roller 41 that is arranged on the machine base 1 through the shaft, and a part that is suitable for meeting the set state is arranged between the roller 41 and the transmission track 3. Clearance. In this embodiment, the automatic screening and feeding mechanism for cylindrical parts includes a set of screening devices 4 . In this embodiment, the roller 41 does not actively rotate.

[0035]The above-mentioned cylindrical parts automatically screen the feeding mechanism, the roller 41 of the screening device 4 is arranged above the conveying track 3, and a gap is set between the rolle...

Embodiment 2

[0038] Further, in this embodiment, on the basis of the above-mentioned embodiment 1, the roller 41 is driven to rotate by the driving motor, and the direction of the tangent of the closest point between the roller 41 and the conveying track 3 is opposite to the direction of movement of the conveying track 3, when When parts in different states are conveyed through the screening device 4 on the transmission track 3, the parts that meet the set state will enter the next process through the screening device 4. When the parts that do not meet the set state contact with the roller 41, due to the difference between the two The movement direction is opposite. On the one hand, the parts that do not meet the set state can be bounced to the downstream of the conveying track to a greater extent, reducing the accumulation of parts. On the other hand, the contact with the roller 41 and other parts during the rebound process is also reduced The state of the parts can be changed, that is, th...

Embodiment 3

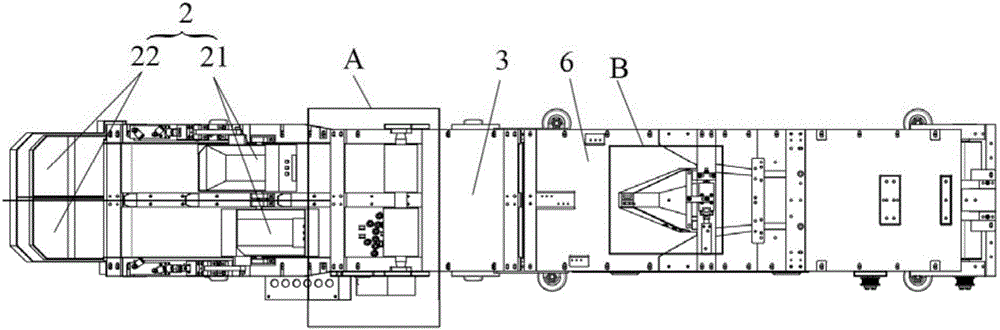

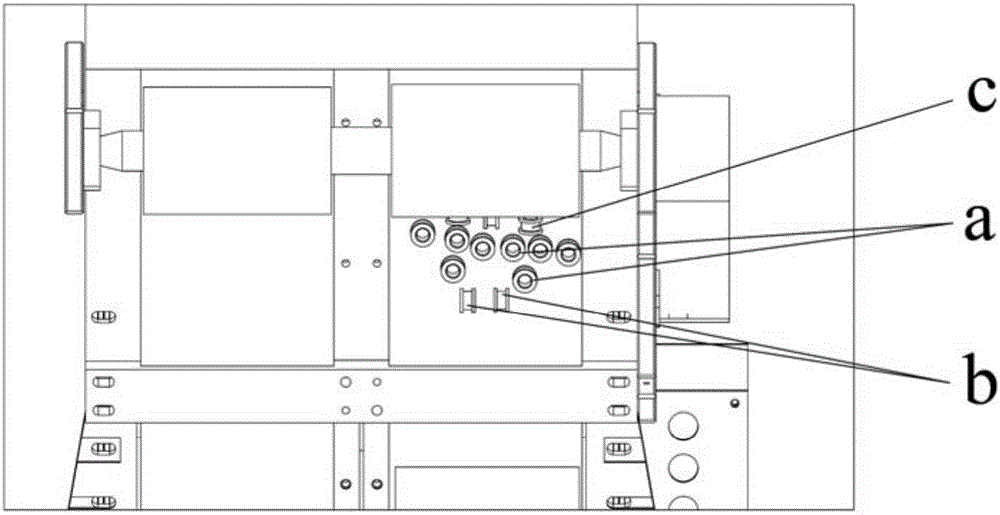

[0045] further, such as figure 2 with Figure 4 As shown, this embodiment also includes a sorting device 5 arranged downstream of the screening device 4 on the basis of the above-mentioned embodiment 1 or 2, and the conveying track 3 arranged below the sorting device 5 is horizontally arranged, and the sorting device 5 is suitable for a single part to pass through The preferred sorting device 5 includes a power cylinder 51 and a material lever 52 that is suitable for moving parts and is fixedly connected to the output end of the power cylinder 51; 53 and the auxiliary limit device 54, the shift rod 52 is suitable for pushing the shrapnel 53 to adjust the size of the parts passing and the distance between adjacent parts. Arranging the sorting device 5 to allow single parts to pass through can sort the parts that meet the set state after being screened by the screening device 4, which is convenient for the next step operation of a single part and saves the time for picking up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com