Thread milling cutter

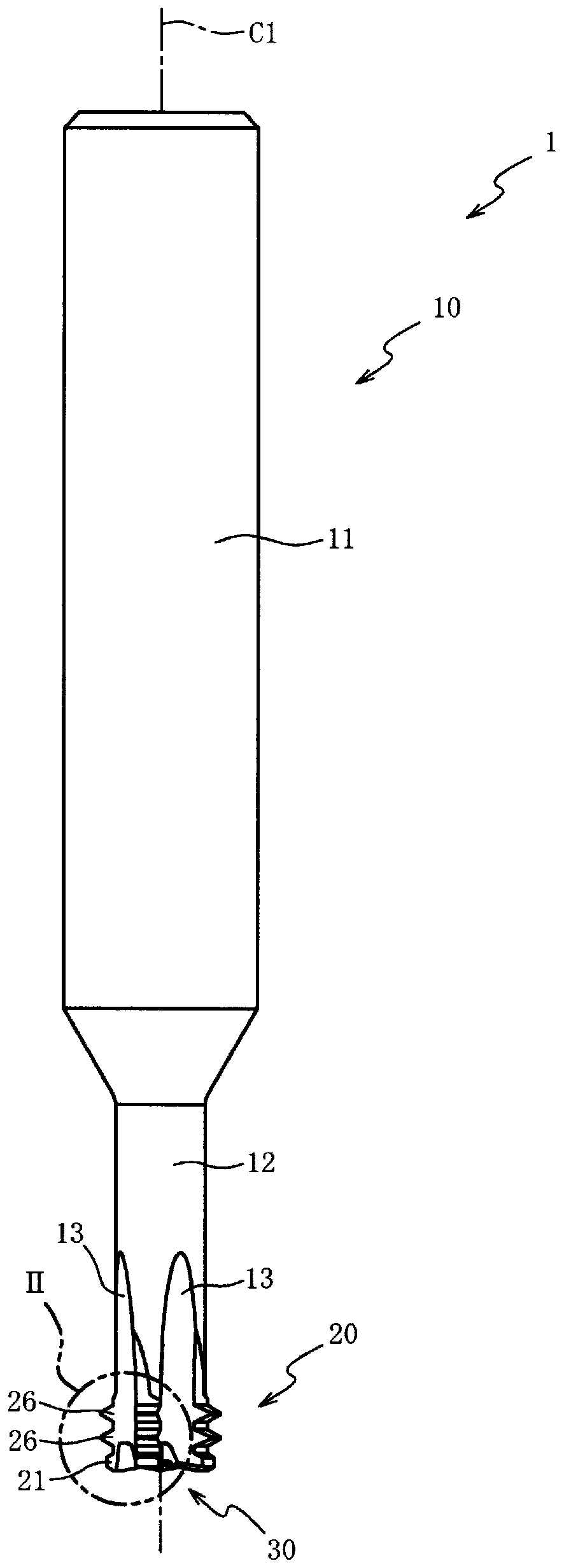

A thread milling cutter and thread tooth technology, applied in milling cutters, thread cutting tools, milling machine equipment, etc., can solve the problems of skewed central axis of thread milling cutters and short tool life of thread milling cutters, and achieve the effect of prolonging tool life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

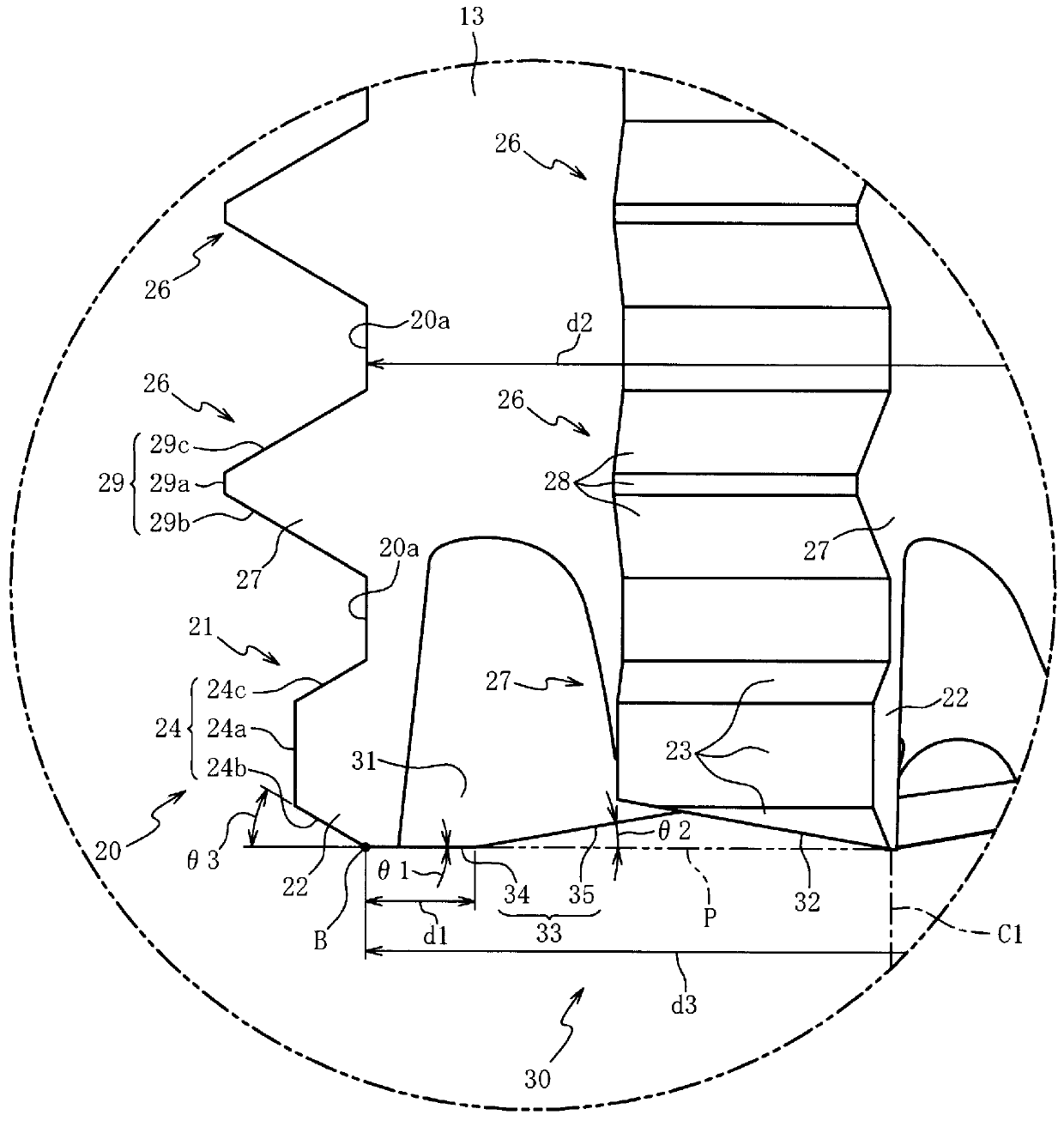

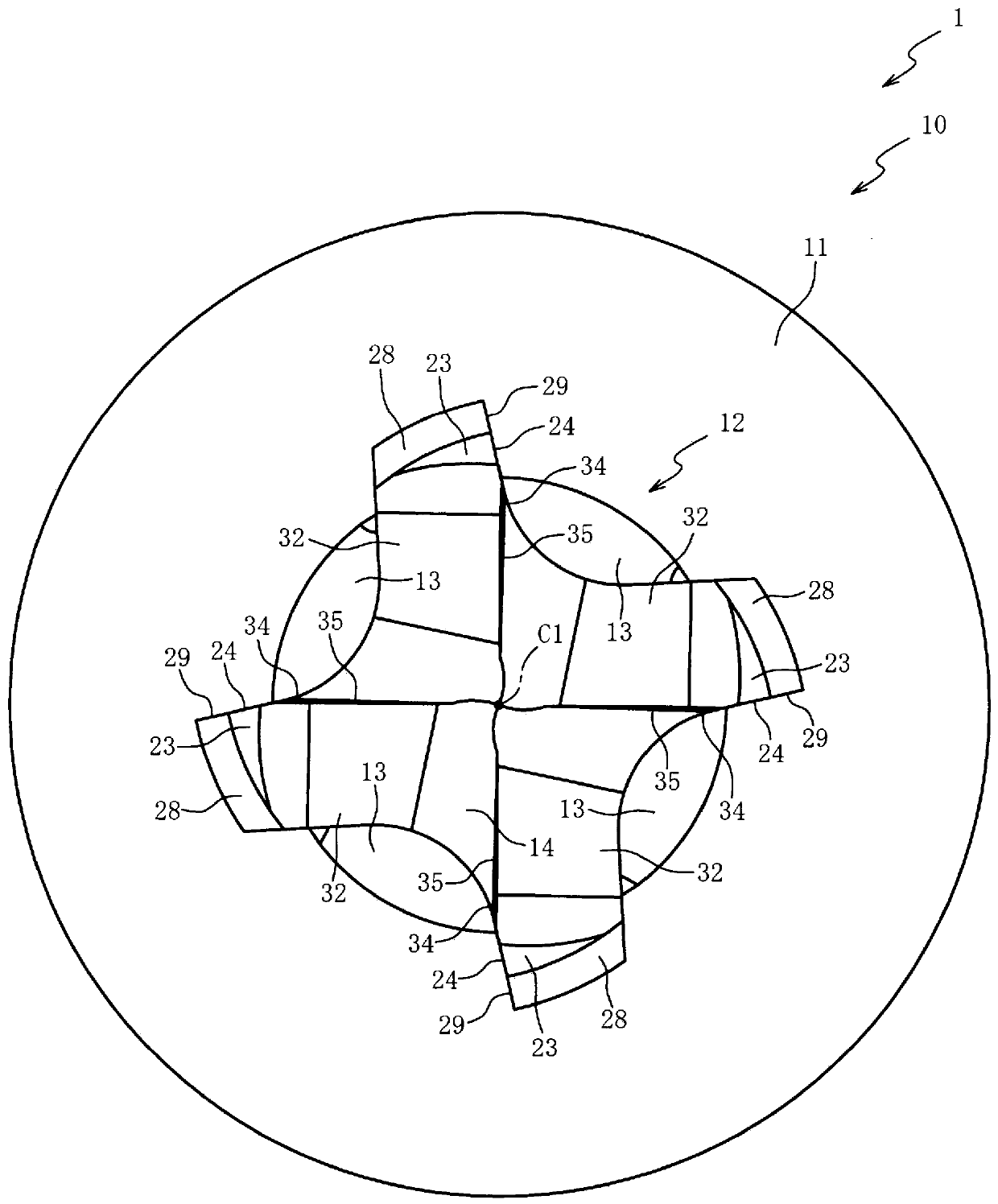

[0063] Hereinafter, the present invention will be described more specifically by way of examples. It should be noted that the present invention is not limited to the following examples. In the following examples, values embodying the values of the width d1 and the angle θ1 of the thread milling cutter 1 described in the above embodiment are used. In all the examples and comparative examples, the angle θ2 was set to 10°, and the angle θ3 was set to 30°.

[0064]First, Example 1 having the first bottom edge 34 and a comparative example not having the first bottom edge 34 are compared. Used in Example 1 and made: the angle θ1 is 0°~+1°, the width d1 is 0.19mm, and the root diameter d2 is 3.17mm, that is, the ratio d1 / d2 of the width d1 to the root diameter d2 is 6%. (error ±0.4%) thread milling cutter. It should be noted that "+" in the angle θ1 indicates that the first bottom edge 34 is inclined toward the rear end side as it moves toward the axis C1 side. In addition, t...

Embodiment 7

[0075] Embodiment 7 has the same configuration as Embodiment 6 except that the angle θ1 is made to be 1° to 2°. Embodiment 8 has the same configuration as Embodiment 6 except that the angle θ1 is made to be 3° to 4°. Embodiment 9 has the same configuration as Embodiment 6 except that the angle θ1 is made to be 5° to 6°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com