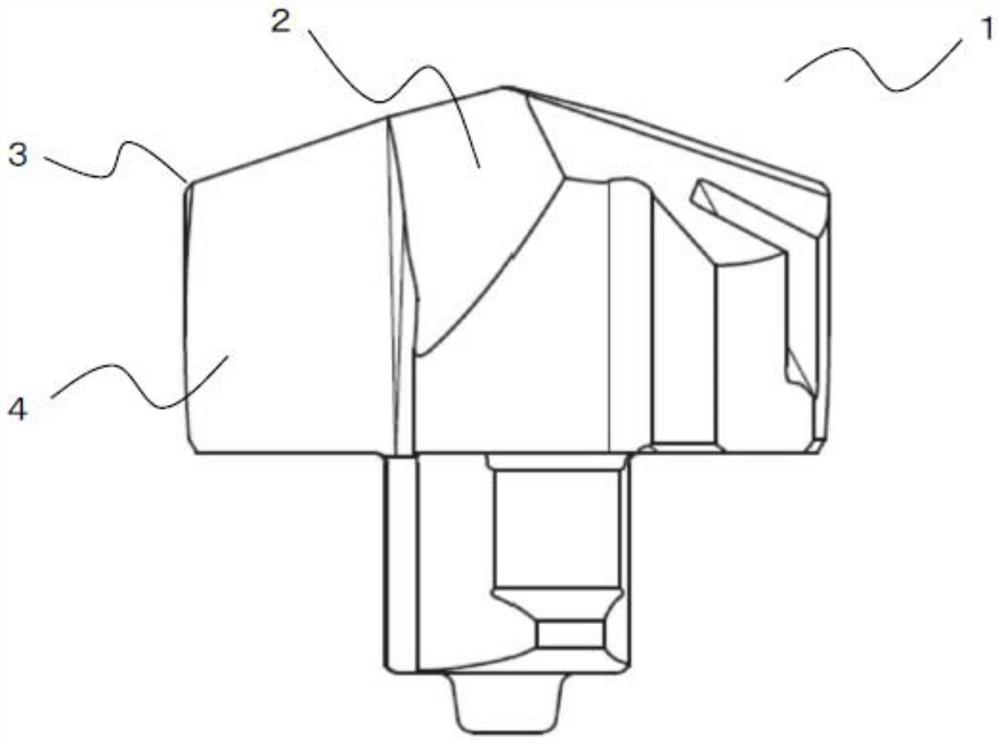

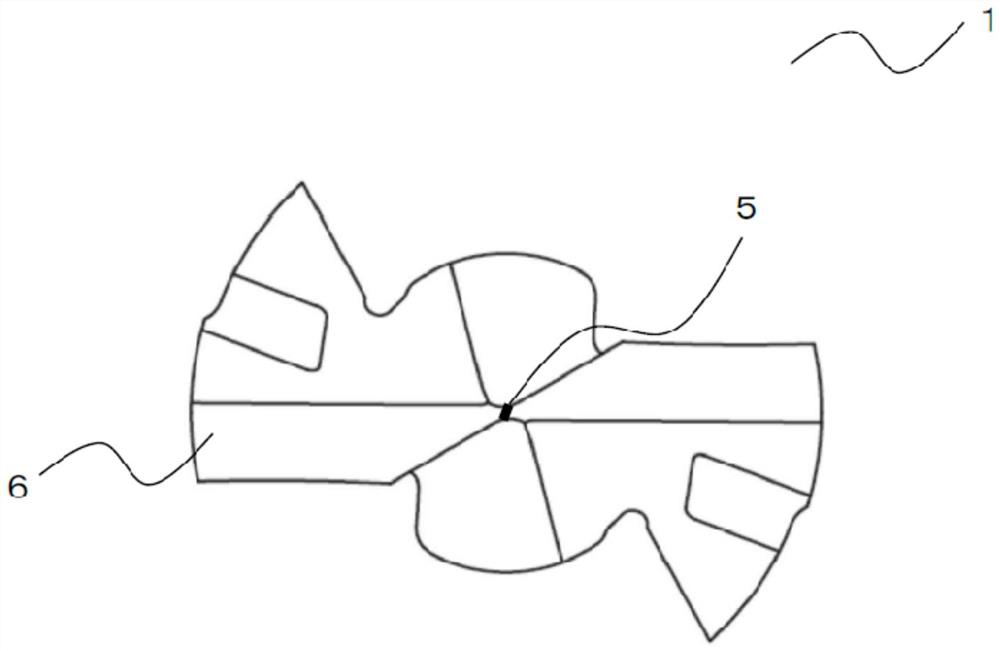

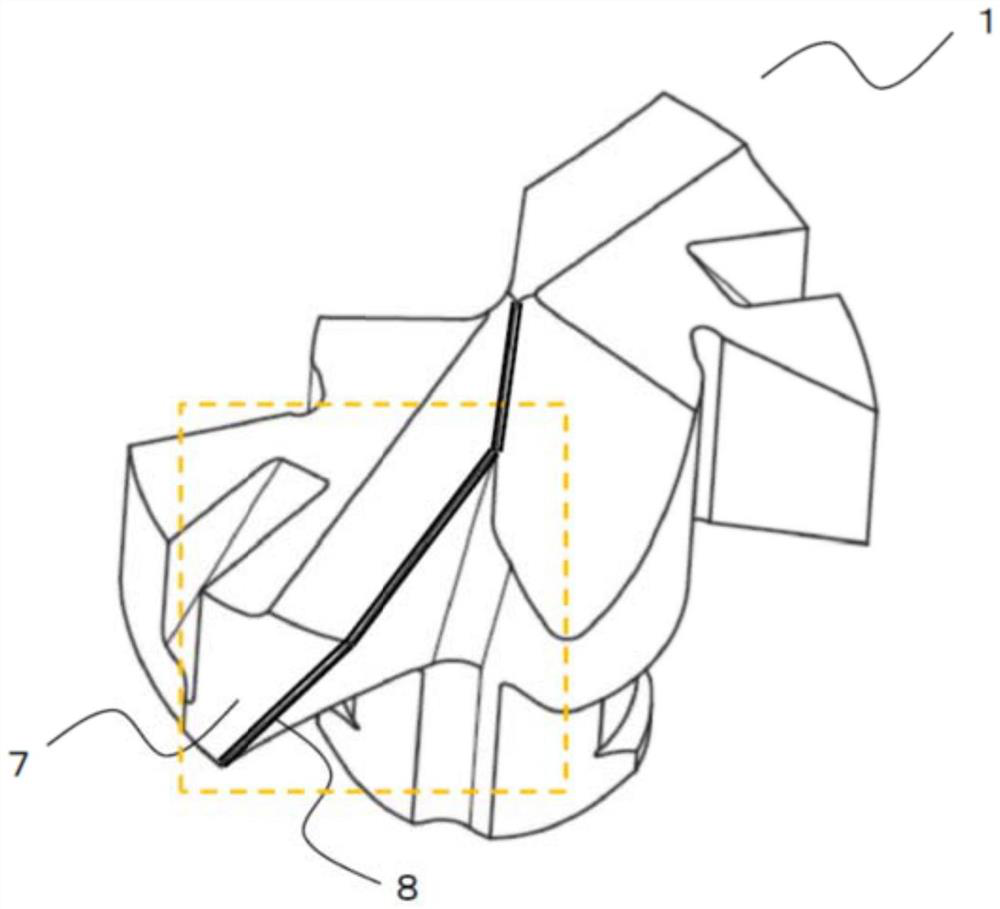

Drill bit

A drill bit and cutting edge technology, applied in the direction of drill repair, twist drill, drill tool accessories, etc., can solve the problems of increased cutting resistance, shortened tool life, difficulty in prolonging drill life, etc., and achieves excellent wear resistance and defect resistance , The effect of prolonging tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] As a base material, a cemented carbide was prepared which was machined into a head-replaceable drill of DMP120 insert shape (manufactured by Tungaloy Co., Ltd.) and had 89.5WC-10Co-0.5Cr 3 C 2 (above mass %) composition. In addition, each part of the insert was honed, and Table 1 shows the relationship between the honing widths of each part. In addition, in Table 1, [2nd cutting edge part] is simply represented as [cutting edge part].

[0157] A metal evaporation source was installed in the reaction vessel of the arc ion plating apparatus so that the coating layer had the composition shown in Table 2. Fix the prepared substrate on the fixing fitting of the turntable inside the reaction vessel.

[0158] Then, the inside of the reaction vessel was evacuated until the pressure reached 5.0×10 -3 vacuum below Pa. After evacuation, the substrate was heated to a temperature of 450°C by a heater in the reaction vessel. After heating, Ar gas was introduced into the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com