Vertical seeding band cleaner

A cleaning device and vertical technology, which is applied to shovels, plows, agricultural machinery and tools, etc., can solve the problems of difficult entry of openers into the soil, high power consumption, and delayed farming time, so as to reduce cutting resistance and speed and prolong the life of tools , The effect of ensuring the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

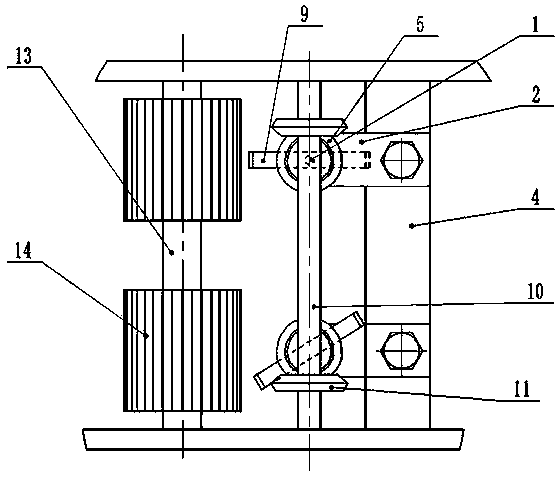

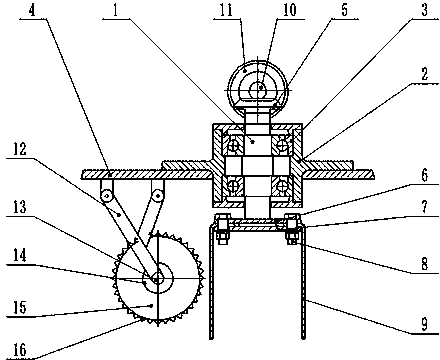

[0018] exist Figure 1~2 In the shown embodiment: the vertical shaft 1 runs through the vertical shaft base 2 and is fixed on the vertical shaft base 2 by two thrust ball bearings 3, the vertical shaft base 2 is fixedly installed on the frame 4, and a small bevel gear is fixedly installed on the upper end of the vertical shaft 1 5. The lower end of the vertical shaft 1 is fixedly installed with a connecting plate 6; a pressure plate 7 is set under the connecting plate 6, and the vertical rotary knife 9 is fixed between the connecting plate 6 and the pressure plate 7 by bolts 8, and the vertical rotary knife 9 is about the axis of the vertical shaft 1 Symmetrical; the two ends of the horizontal axis 10 are respectively connected to the two sides of the frame 4, which can rotate around the axis of the horizontal axis 10 and the large bevel gear 11 is fixedly installed on the horizontal axis 10, and the adjacent large bevel gear 11 installed on the horizontal axis 10 is reversed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com