Partitioned dental membrane and manufacturing method thereof

A production method and membrane technology, applied in dentistry, orthodontics, medical science, etc., can solve problems such as uneven thickness, cracking, and weak orthodontic appliances, and achieve the effect of uniform expression, not easy to crack, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

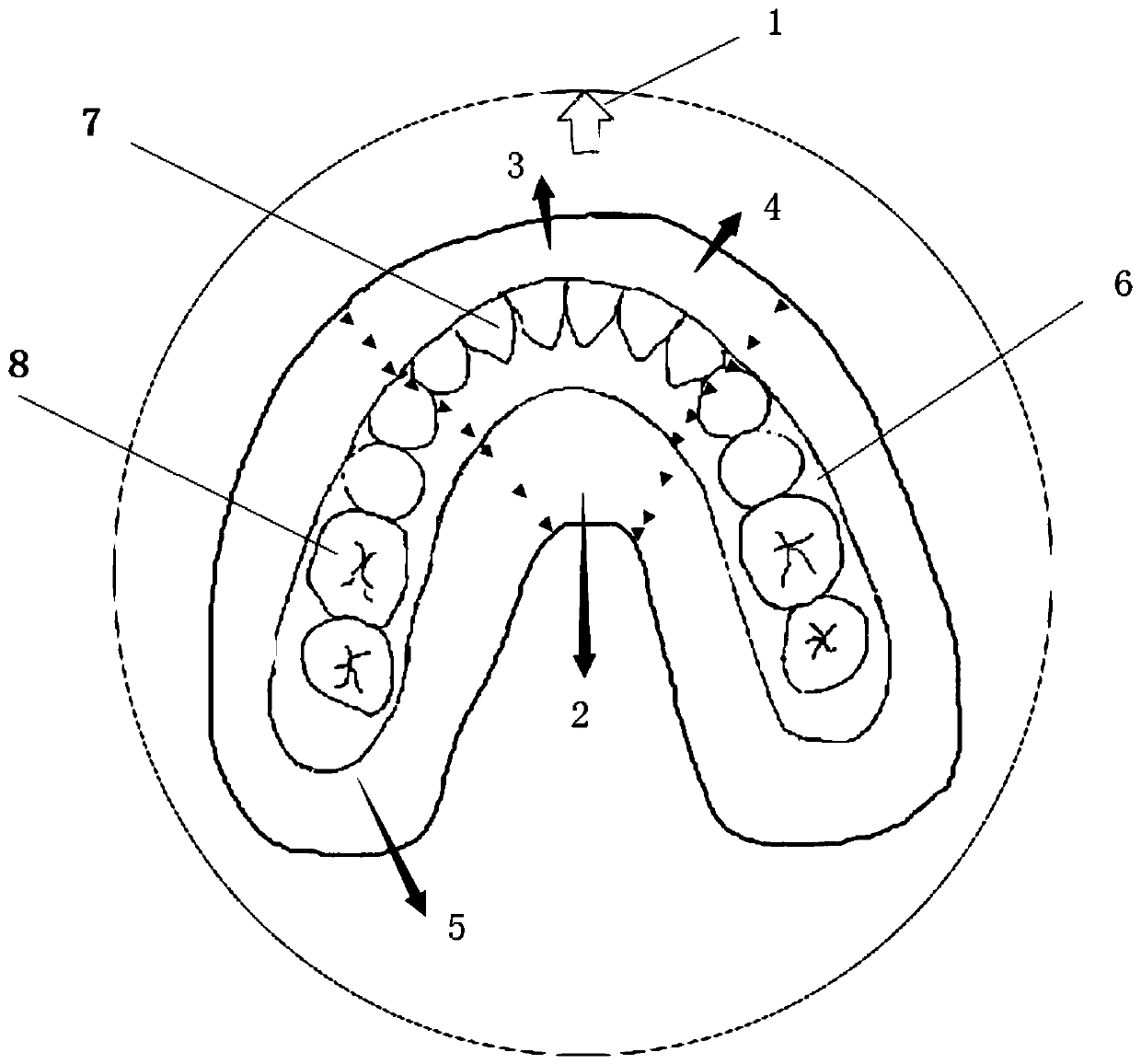

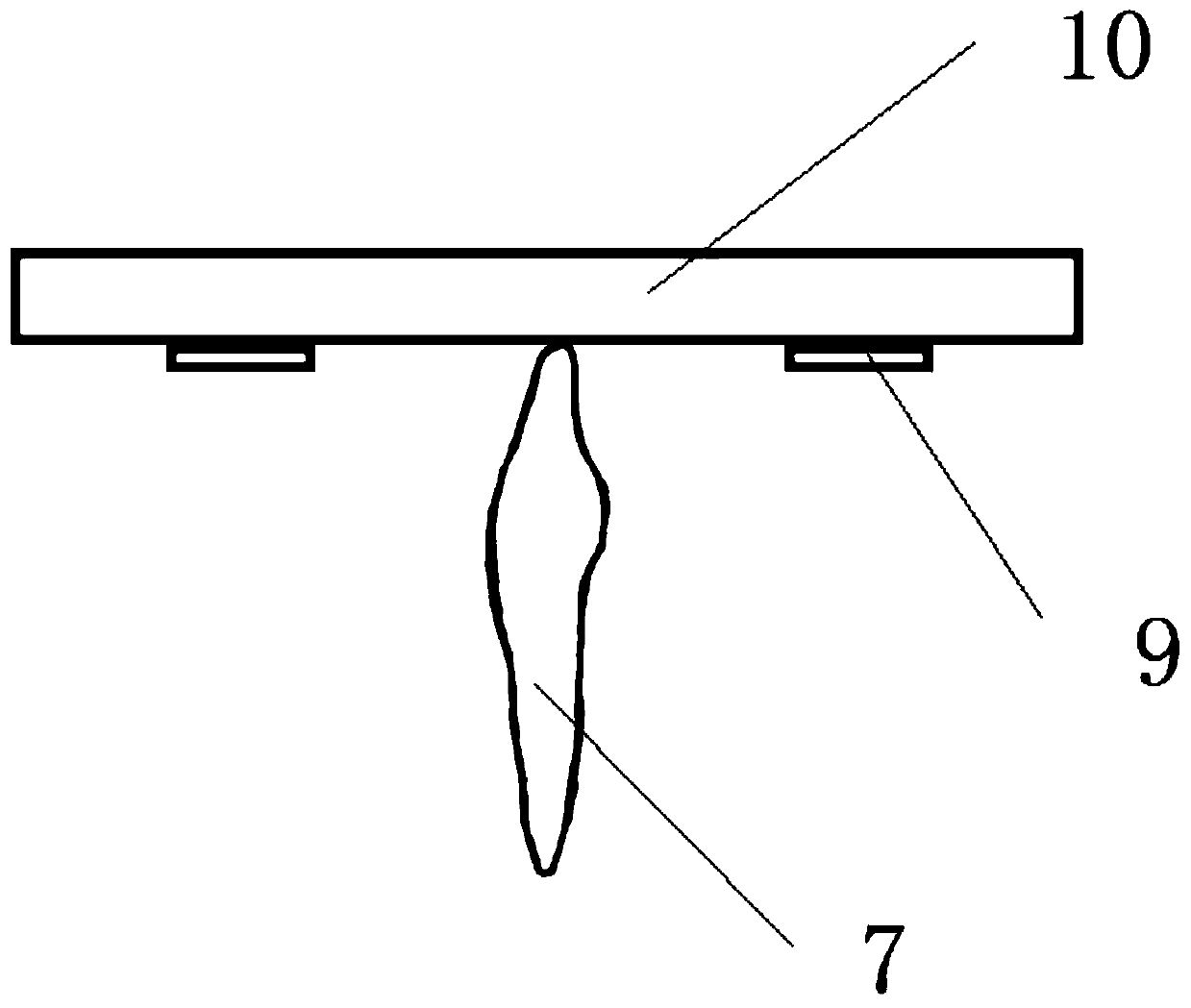

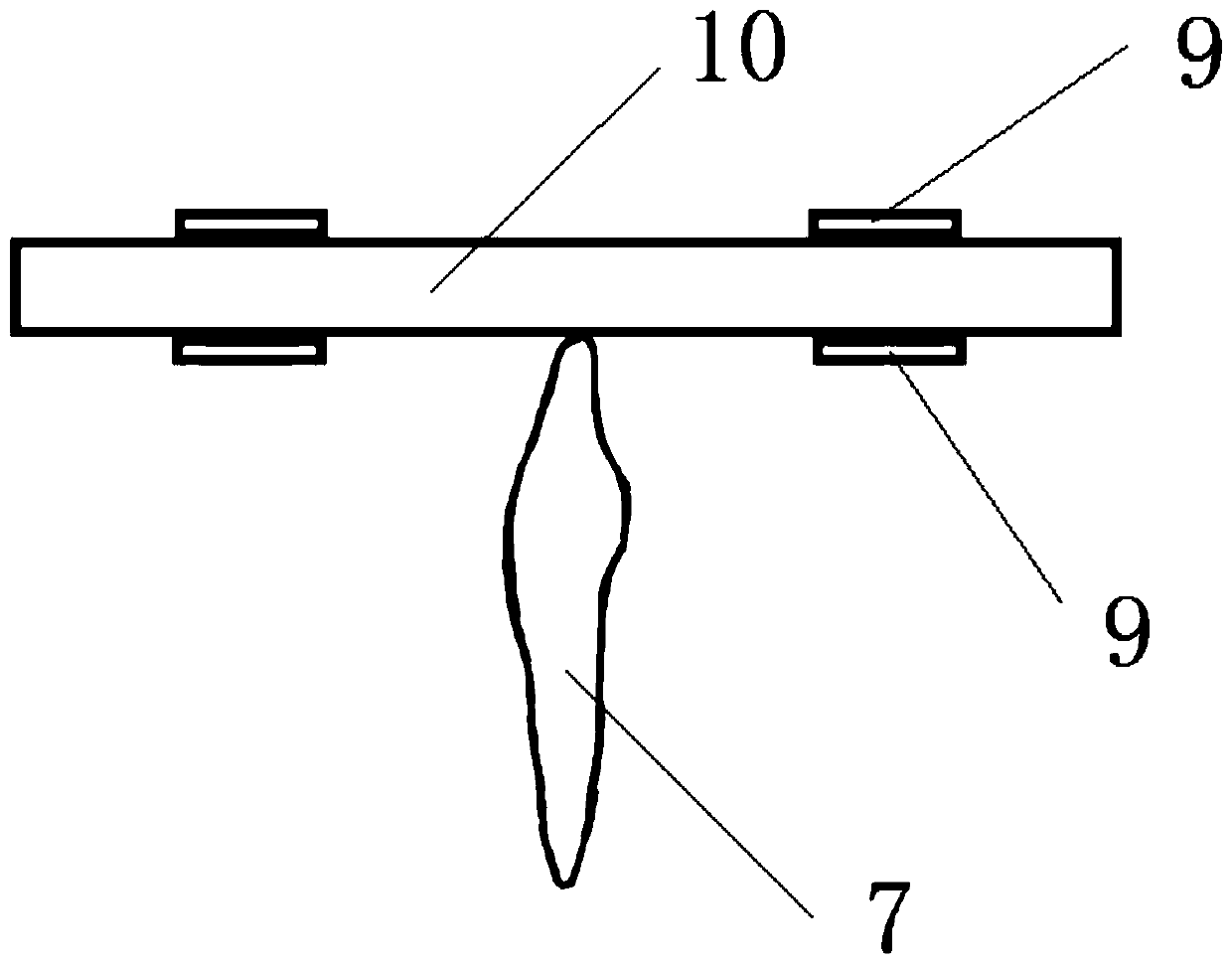

[0028] Such as figure 1 As shown, the present invention is a partitioned dental film, the film surface of the dental film is provided with a direction indicator mark 1; The corresponding different positions on the membrane surface of the dental membrane divide the membrane into regions, and set different membrane thicknesses for different regions; the specific division method is as follows:

[0029] According to the corresponding longitudinal position of the tooth model on the membrane surface of the dental membrane, the membrane surface of the dental membrane is divided into the inside of the midline 2 and the outside of the midline 3; wherein, the midline 6 is a line connecting the upper and lower rows of teeth, and the midline The inner side 2 is the inner area of a line where the upper and lower rows of teeth meet, and the outer side of the midline 3 is the outer area of a line where the upper and lower rows of teeth meet; according to the corresponding lateral positio...

Embodiment 2

[0038] Such as figure 1 As shown, the present invention is a partitioned dental film, the film surface of the dental film is provided with a direction indicator mark 1; The corresponding different positions on the membrane surface of the dental membrane divide the membrane into regions, and set different membrane thicknesses for different regions; the specific division method is as follows:

[0039] According to the corresponding longitudinal position of the tooth model on the membrane surface of the dental membrane, the membrane surface of the dental membrane is divided into the inside of the midline 2 and the outside of the midline 3; wherein, the midline 6 is a line connecting the upper and lower rows of teeth, and the midline The inner side 2 is the inner area of a line where the upper and lower rows of teeth meet, and the outer side of the midline 3 is the outer area of a line where the upper and lower rows of teeth meet; according to the corresponding lateral positio...

Embodiment 3

[0051] The present invention is a partitioned dental diaphragm, which is made of three layers of different materials superimposed and formed by hot pressing, and a direction indicating mark 1 is arranged on the film surface, and according to the dental diaphragm during use The stress points are different, and the diaphragm is divided into regions according to the corresponding positions of the tooth model on the dental diaphragm, and different thicknesses are set for different regions. The method for dividing the membrane area and the thicknesses used in different areas are the same as those described in Embodiment 1.

[0052] The partitioned dental film has a three-layer structure, and each layer is made of different materials.

[0053] The manufacturing method of the partitioned dental diaphragm is as follows: firstly, three layers of different materials are stacked together, and hot-pressed to form a hot-pressed laminated diaphragm; then, a direction is made on the film sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com