Automobile component punching forming die

An auto parts and stamping forming technology, applied in the field of auto parts stamping, can solve the problems of reduced efficiency, reduced work efficiency, inconvenient operation, etc., and achieves the effect of convenient repeated operation, reduced investment cost and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

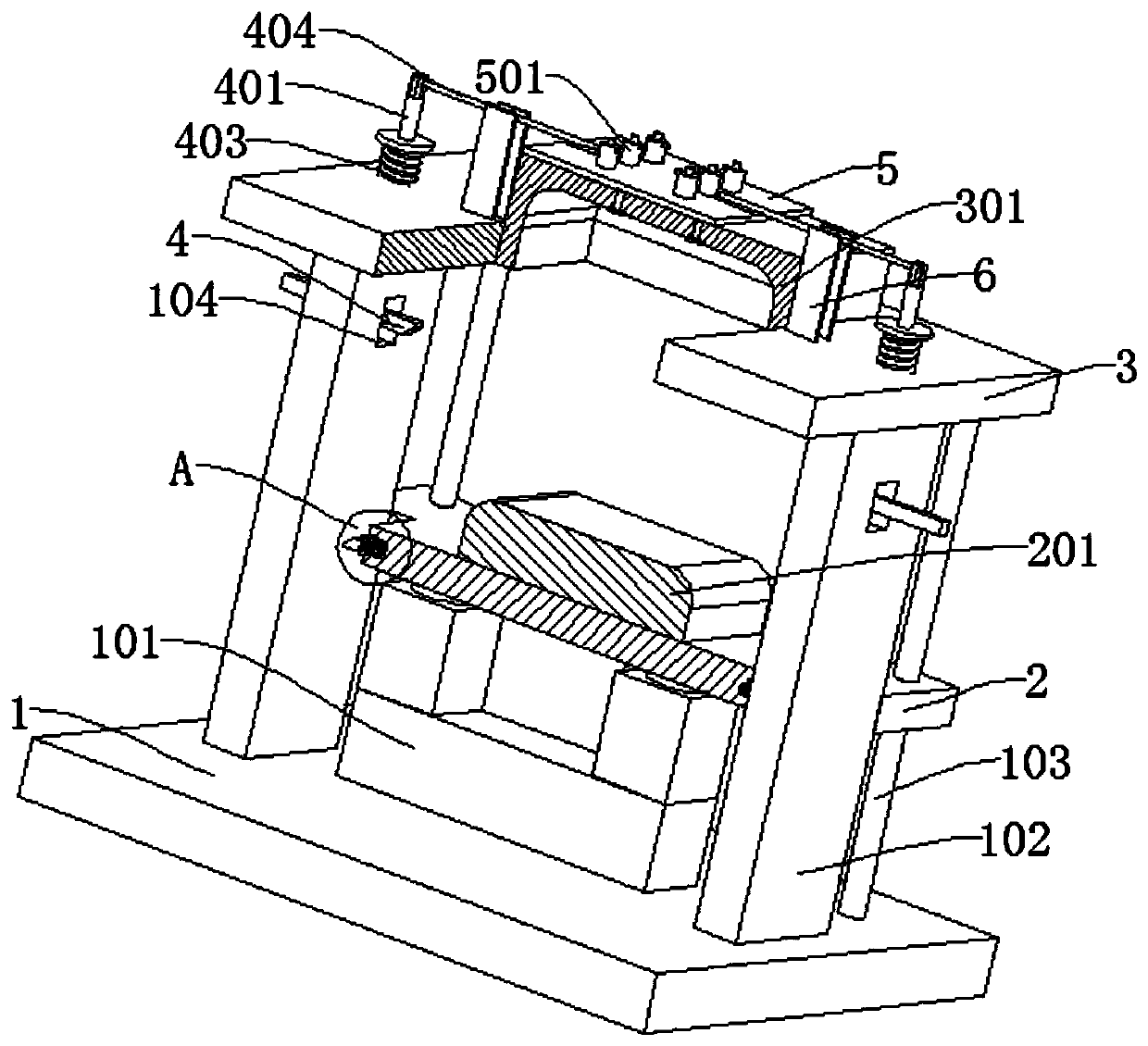

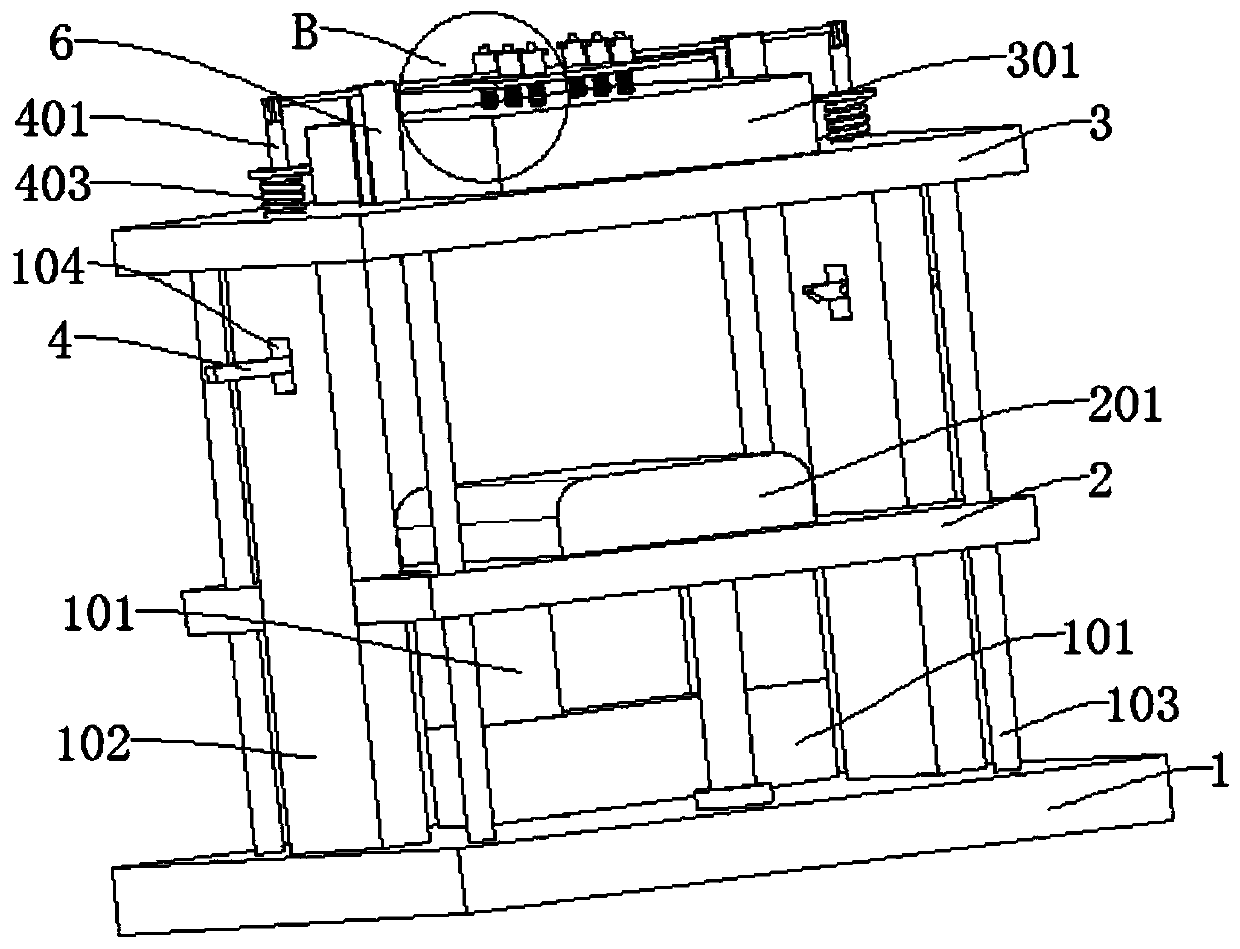

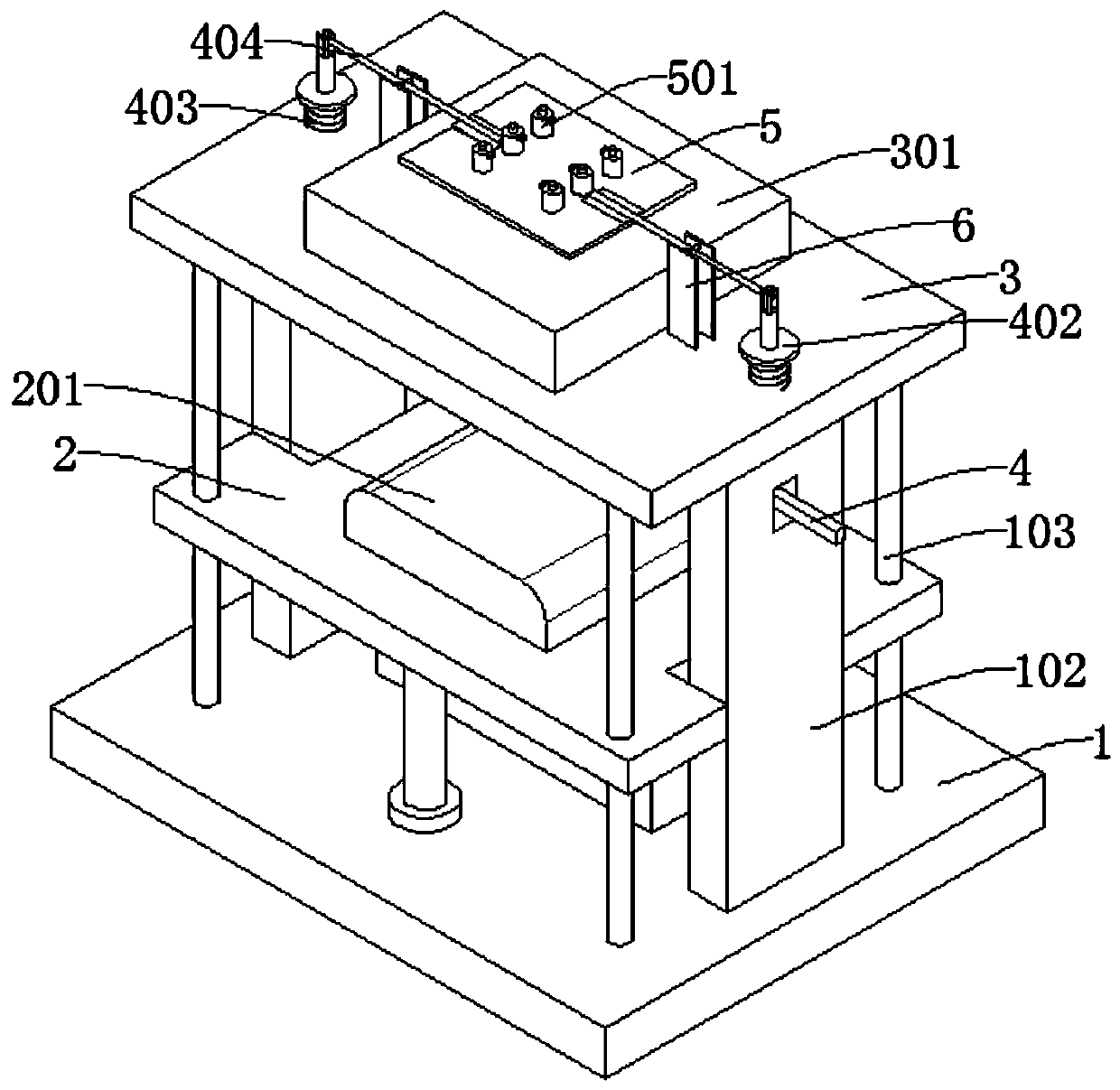

[0032] refer to Figure 1-8 , a stamping mold for auto parts, comprising a base plate 1, a first air pump 101, a punch 201, a top plate 3 and a die 301, the first air pump 101 is connected to the top of the base plate 1, and the die 301 is connected to the top plate 3, The end of the first air pump 101 away from the bottom plate 1 is connected to the slide plate 2, the punch 201 is connected to the outer wall of the slide plate 2, the inner wall of the die 301 is connected to the ejector pin 504, the top of the ejector pin 504 is connected to the pressure plate 5, and the top of the pressure plate 5 is connected to the The second air pump 501, the outer wall of the second air pump 501 is respectively connected with a vent valve 502 and a one-way valve 503, the end of the ejector pin 504 away from the die 301 passes through the second air pump 501 and is connected with a piston 507, the ejector pin 504 is placed One end in the die 301 is connected with a top sheet 506 .

[003...

Embodiment 2

[0036] refer to Figure 1-8 , a stamping mold for auto parts, comprising a base plate 1, a first air pump 101, a punch 201, a top plate 3 and a die 301, the first air pump 101 is connected to the top of the base plate 1, and the die 301 is connected to the top plate 3, The end of the first air pump 101 away from the bottom plate 1 is connected to the slide plate 2, the punch 201 is connected to the outer wall of the slide plate 2, the inner wall of the die 301 is connected to the ejector pin 504, the top of the ejector pin 504 is connected to the pressure plate 5, and the top of the pressure plate 5 is connected to the The second air pump 501, the outer wall of the second air pump 501 is respectively connected with a vent valve 502 and a one-way valve 503, the end of the ejector pin 504 away from the die 301 passes through the second air pump 501 and is connected with a piston 507, the ejector pin 504 is placed One end in the die 301 is connected with a top sheet 506 .

[0037]...

Embodiment 3

[0041] refer to Figure 1-7 , a stamping mold for auto parts, which is basically the same as that of Embodiment 1. Further, a groove is dug in the slot, a slider 202 is connected in the groove, and a baffle 203 is connected to the outer wall of the slider 202. Both the block 202 and the baffle 203 are slidably connected in the groove, and a first spring 204 is connected between the baffle 203 and the inner wall of the groove.

[0042] refer to Figure 1-4 , the outer wall of the limiting plate 102 is dug with a concave hole 104, the inner wall of the concave hole 104 is connected with a fixed shaft 105, the outer wall of the fixed shaft 105 is connected with a pull rod 4 matching with the slider 202, and the pull rod 4 is slidably connected to the concave hole through the fixed shaft 105 104 inside.

[0043] refer to Figure 4 and 7 , The outer walls of the slider 202 and the pull rod 4 are provided with inclined surfaces that cooperate with each other.

[0044] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com