Air channel system of self-suction device and manufacturing method of air channel system

A gas circuit system, self-priming technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of insufficient pumping pressure, complex pipe network, insufficient gas volume, etc., and achieve sufficient pumping pressure , simple pipe network and sufficient gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

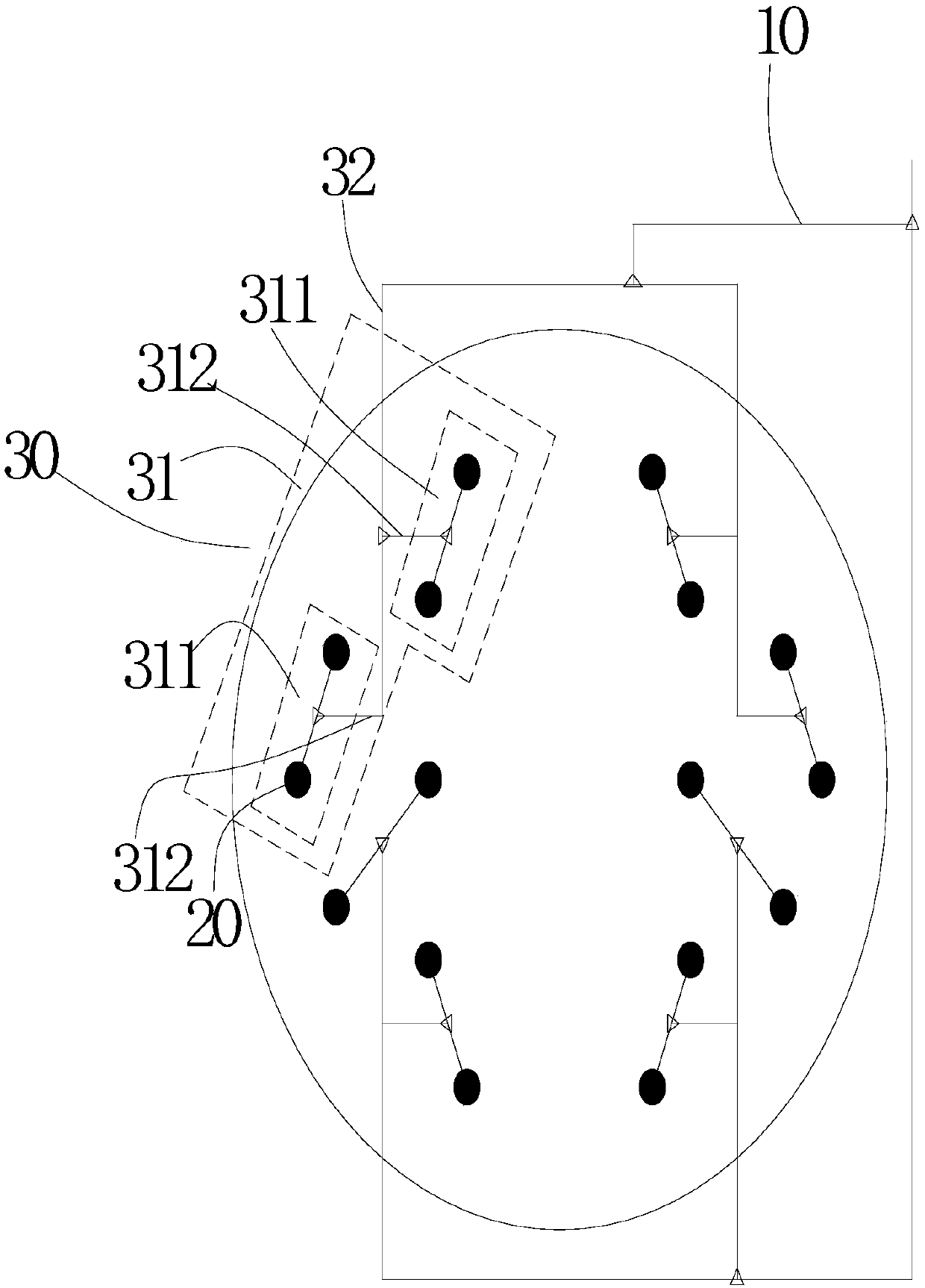

[0040] refer to figure 1 , an air circuit system for self-priming equipment, including an air source, an air supply main pipe 10 connected to the air source, several suction ports 20 respectively connected to the self-priming device, and a bronchial circuit assembly; the suction port When the number of 20 is M=4N, the bronchial circuit assembly includes N first bronchial circuits 30; wherein, N=4; the first bronchial circuit 30 includes two primary air circuit units 31 and primary connecting pipes 32, one The first-level air circuit unit 31 corresponds to the first-level connecting pipe 32; one end of each first-level connecting pipe 32 is connected to one end of the gas supply main pipe 10, and the other end of each first-level connecting pipe 32 is connected to a corresponding one. Stage gas circuit unit 31;

[0041] Each primary air circuit unit 31 includes two secondary air circuit units 311 and secondary connecting pipes 312, the secondary air circuit units 311 and the s...

Embodiment 2

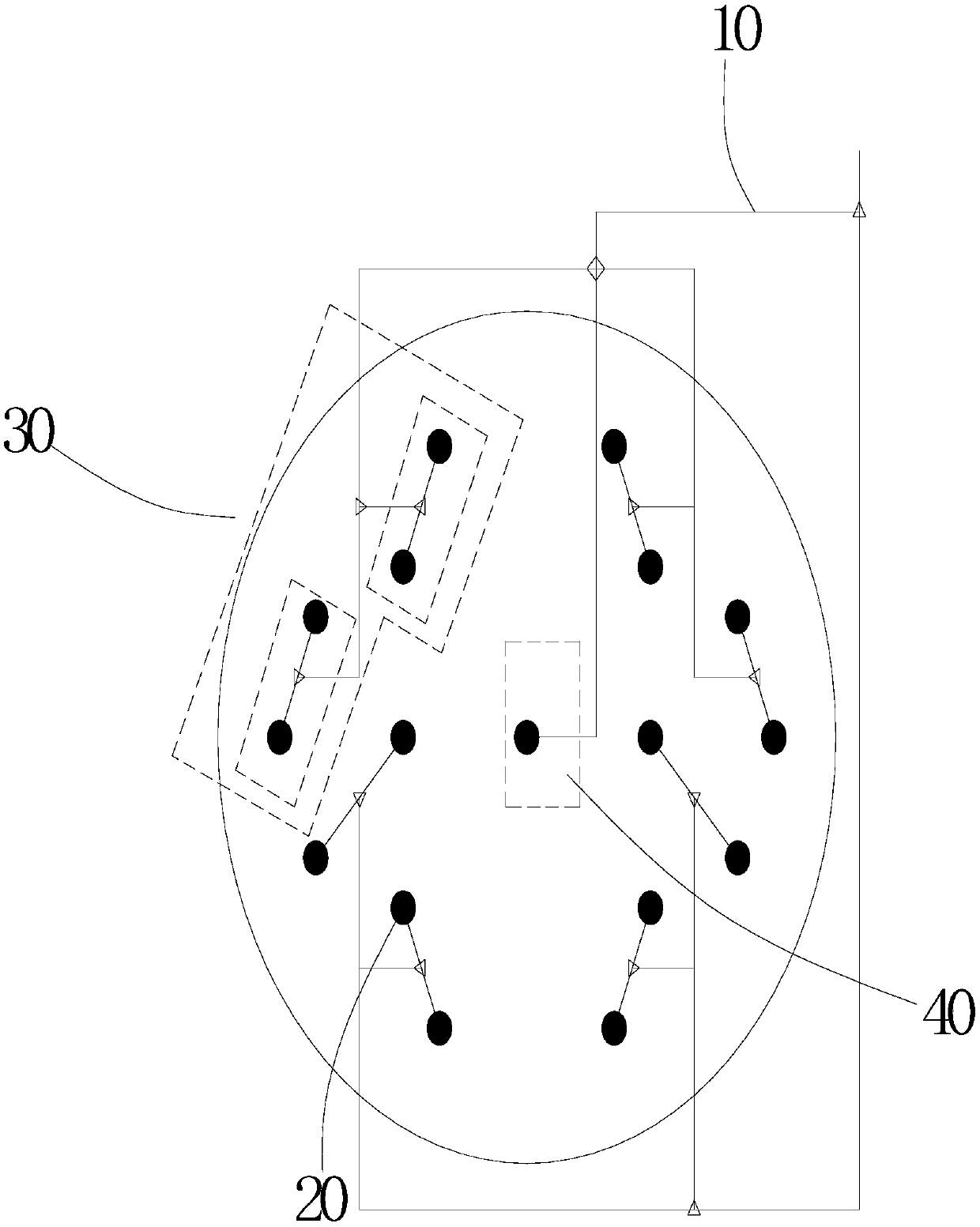

[0054] refer to figure 2 , the characteristics of this embodiment are: when the number of inspiratory ports M=4N+1, the bronchial pipeline assembly includes N first bronchial pipelines 30 and 1 second bronchial pipeline 40, wherein N=4; the second bronchial pipeline The road 40 includes an air suction port and a two-way pipe, and the air suction port of the second bronchial circuit is connected with the air supply main pipe through the two-way pipe.

[0055] As a preferred embodiment, the four first bronchial circuits are distributed in a ring, and the second bronchial circuit is placed in the middle.

[0056] Others are the same as in Example 1.

Embodiment 3

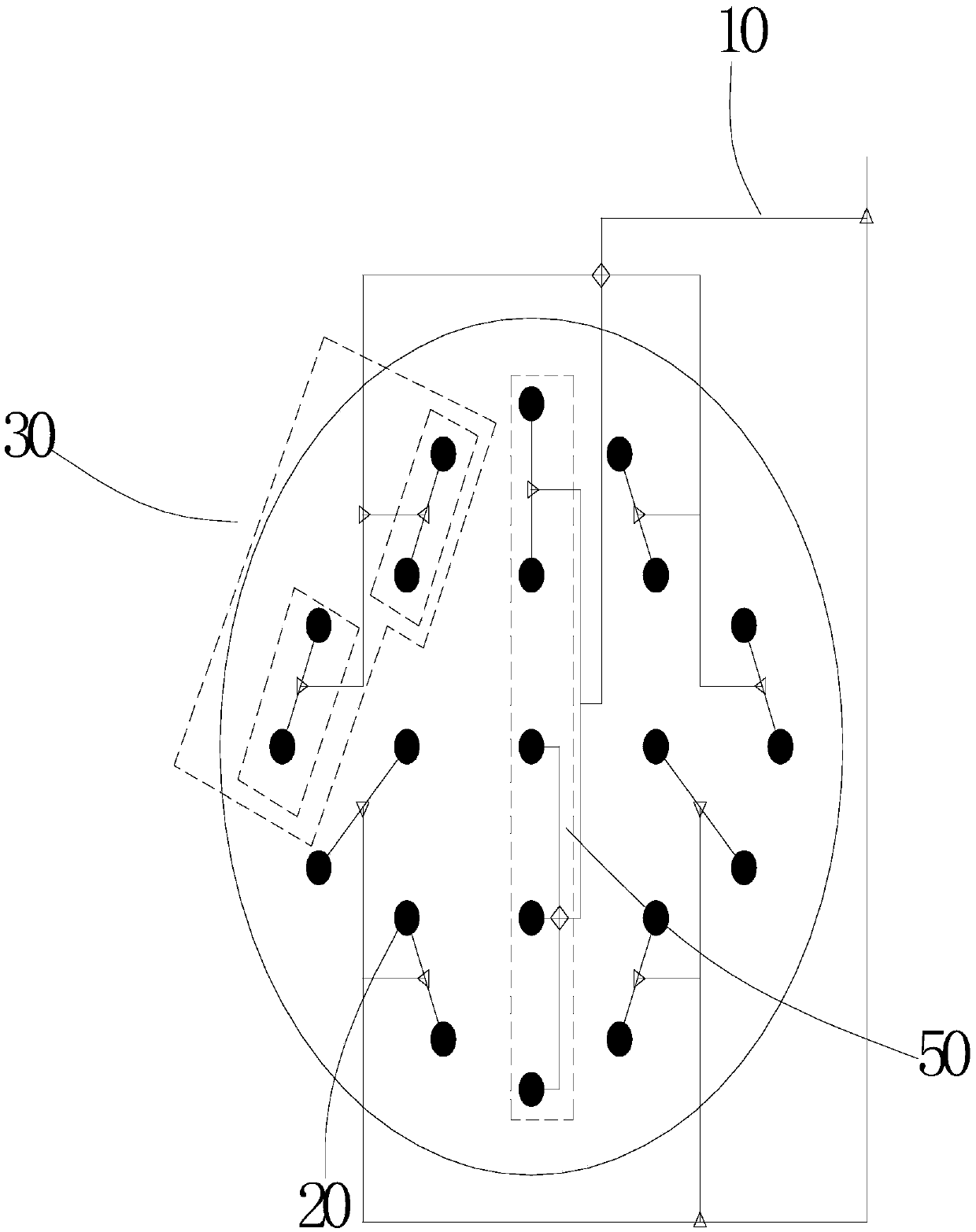

[0058] refer to image 3 , the characteristics of this embodiment are: when the number of inspiratory ports M=4N+1, the bronchial pipeline assembly includes 4 first bronchial pipelines 30 and 1 third bronchial pipeline 50, wherein N=5; the third bronchial pipeline The circuit includes five suction ports, a three-way pipe and a four-way pipe, two of the five suction ports are connected to one end of the air supply main pipe through the three-way pipe, and the other three of the five suction ports are The suction port is connected to one end of the gas supply main pipe through a four-way pipe.

[0059] As a preferred embodiment, the four first bronchial circuits are distributed in a ring, and the third bronchial circuit is placed in the middle.

[0060] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com