Novel shield tunneling machine tool changing tail end executing device

An end effector and shield machine technology, applied in the field of robotics, can solve problems such as low work efficiency and personal safety injury of working environment staff, and achieve the effect of improving work efficiency and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings in the embodiments of the present invention.

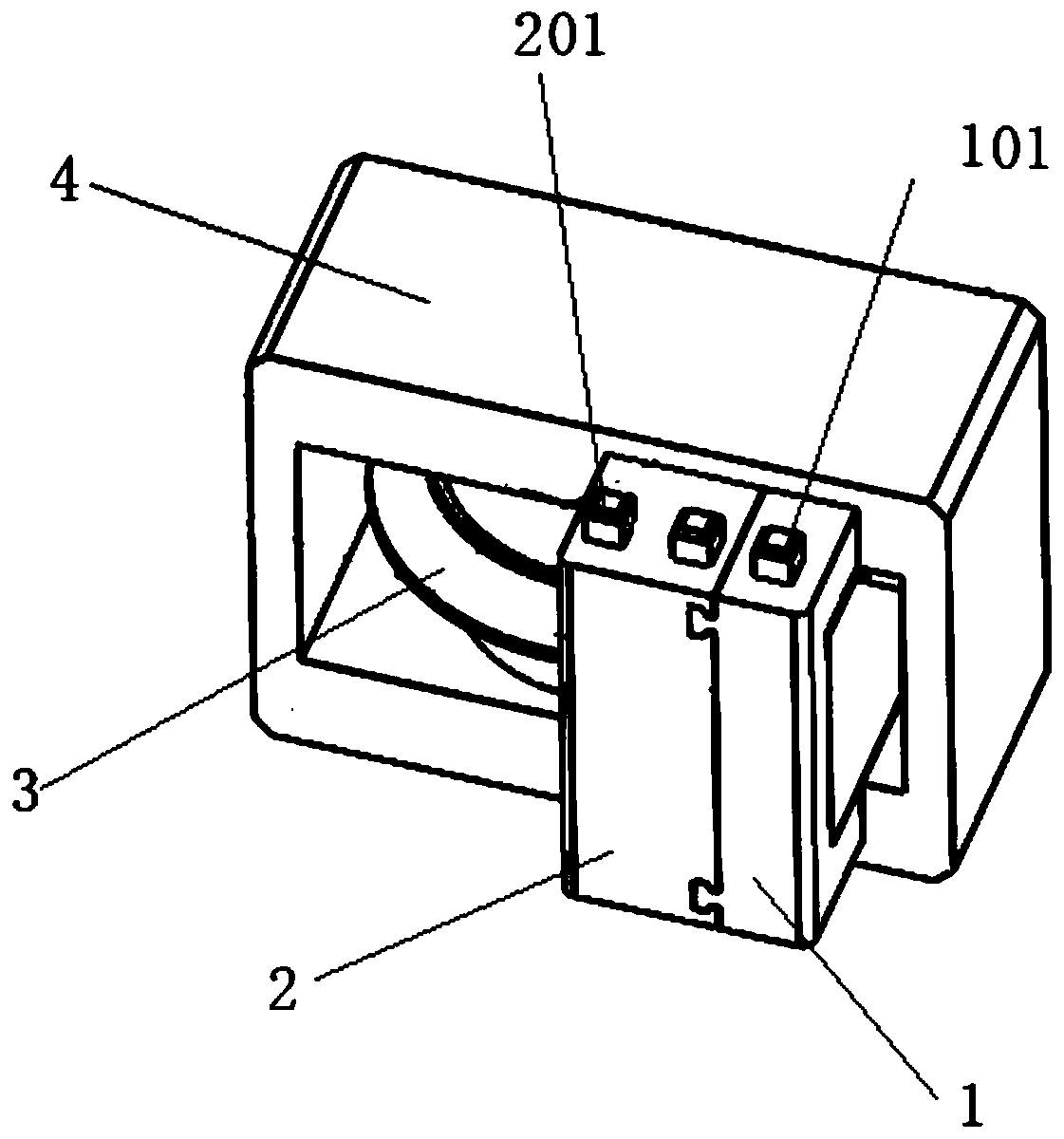

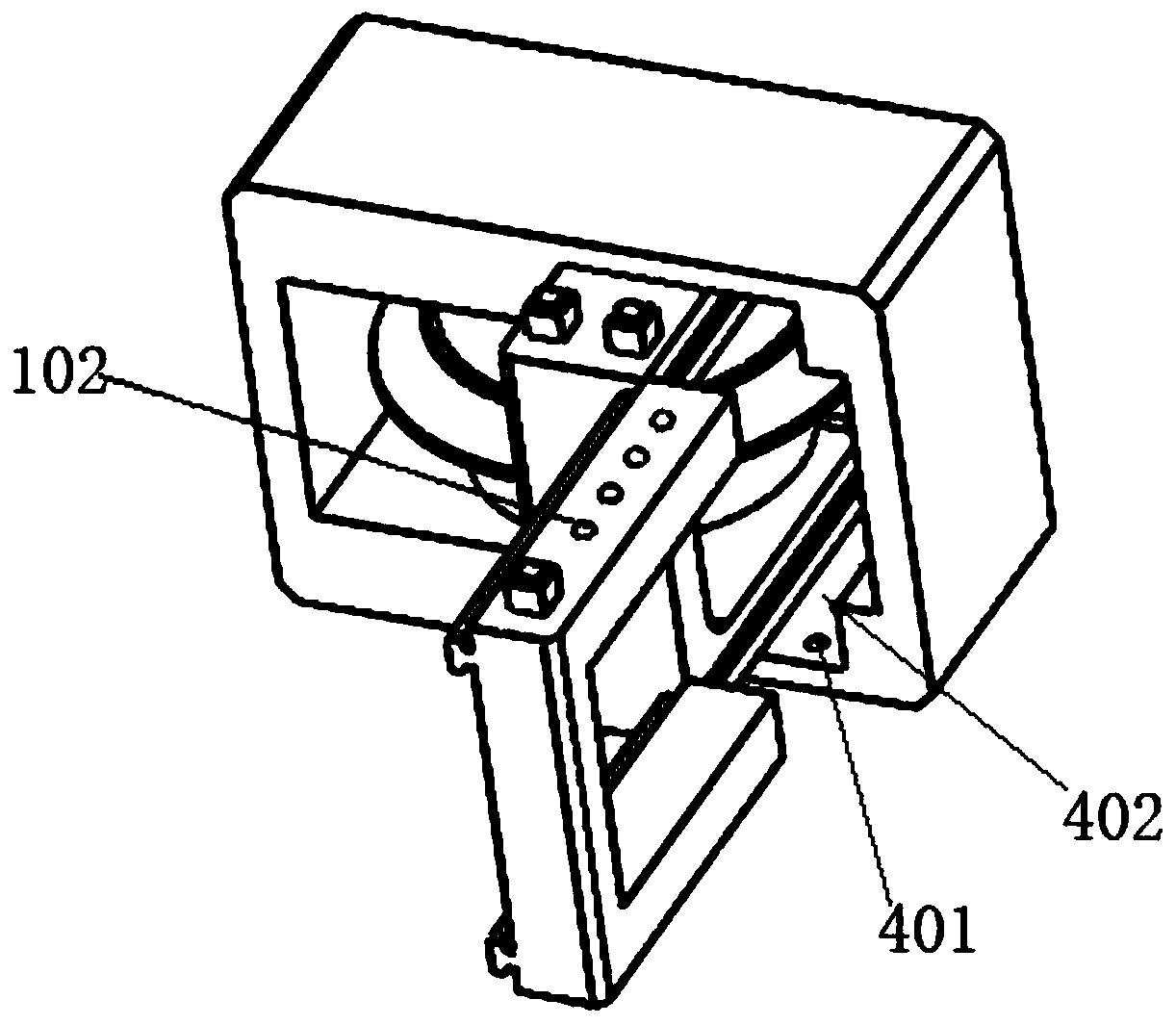

[0029] A new tool change end effector for a shield machine, including a large gripper module 5, a small gripper module 6, a guide module 8 and an axial movement module 7,

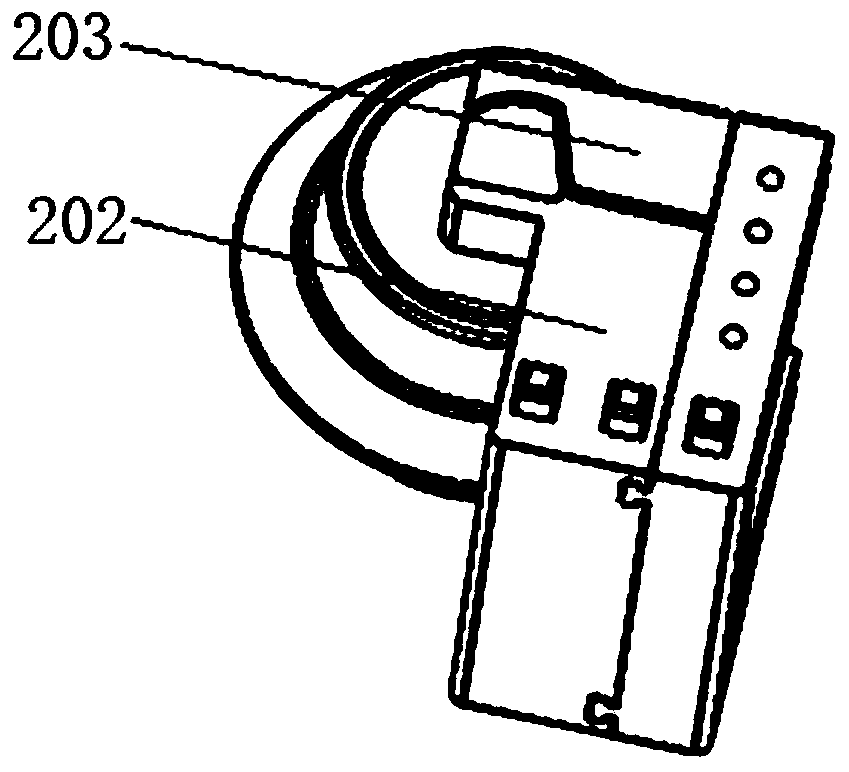

[0030] The large hand claw module 5 includes a first lower claw 22, a first pin 23, a first upper claw 18, a second pin 29, a first hydraulic cylinder 24, a first claw support frame 19 and a guide shaft fixing plate 20,

[0031] The first claw support frame 19 is welded on the rear end of the first lower claw 22, the rear end of the first upper claw 18 is rotatably connected with the upper end of the first claw support frame 19,

[0032] The guide shaft fixing plate 20 is welded on the first claw support frame 19, and the upper and lower ends of the first hydraulic cylinder 24 are respectively rotatably connected with the middle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap