Device and method for threaded fixation of metal part and plastic part

A technology for fixed equipment and plastic parts, applied in the field of plastic parts assembly equipment, can solve the problems that are not conducive to mass production and increase manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

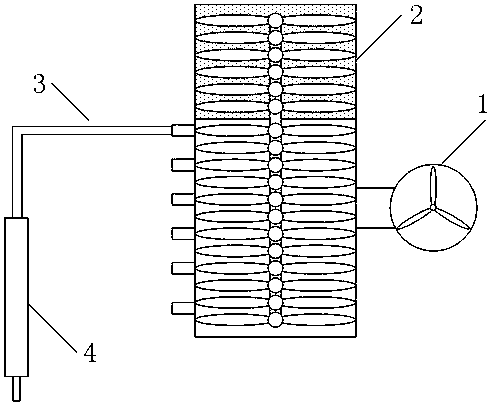

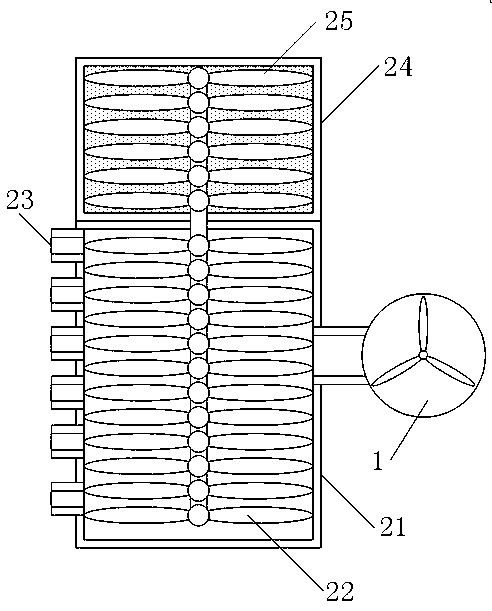

[0041] The air pump 1 is connected to the distributor 2, the port 23 of the distributor 2 is connected to the air gun 4 through the hose 3, the distributor 2 includes a main cavity 21, the inner wall of the main cavity 21 is provided with a first impeller group 22, the main cavity 21 The two ends of the side wall are respectively provided with the port 23 communicating with the hose 3 and the interface communicating with the air pump 1. The main cavity 21 is also fixed with a secondary cavity 24, and the secondary cavity 24 is provided with a first impeller. The second impeller group 25 coaxially fixed by the group 22, the auxiliary cavity 24 is filled with non-Newtonian liquid;

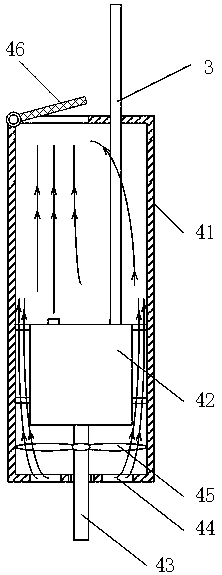

[0042] Pass the high-pressure gas with a limited flow rate into the air gun 4, drive the drill bit 43 to rotate, and screw the fixed metal parts and plastic parts. After the bolts are screwed, the gas flow rate inside the air motor 42 decreases sharply, and the speed of the first impeller group 22 dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com