Full-automatic RGV robot cold pressing production line

A robot and fully automatic technology, applied in the direction of conveyors, mechanical conveyors, loading/unloading, etc., can solve the problems of laborious, incapable of intelligent operation, and large space occupied by the production line, so as to save manpower, realize full automation, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

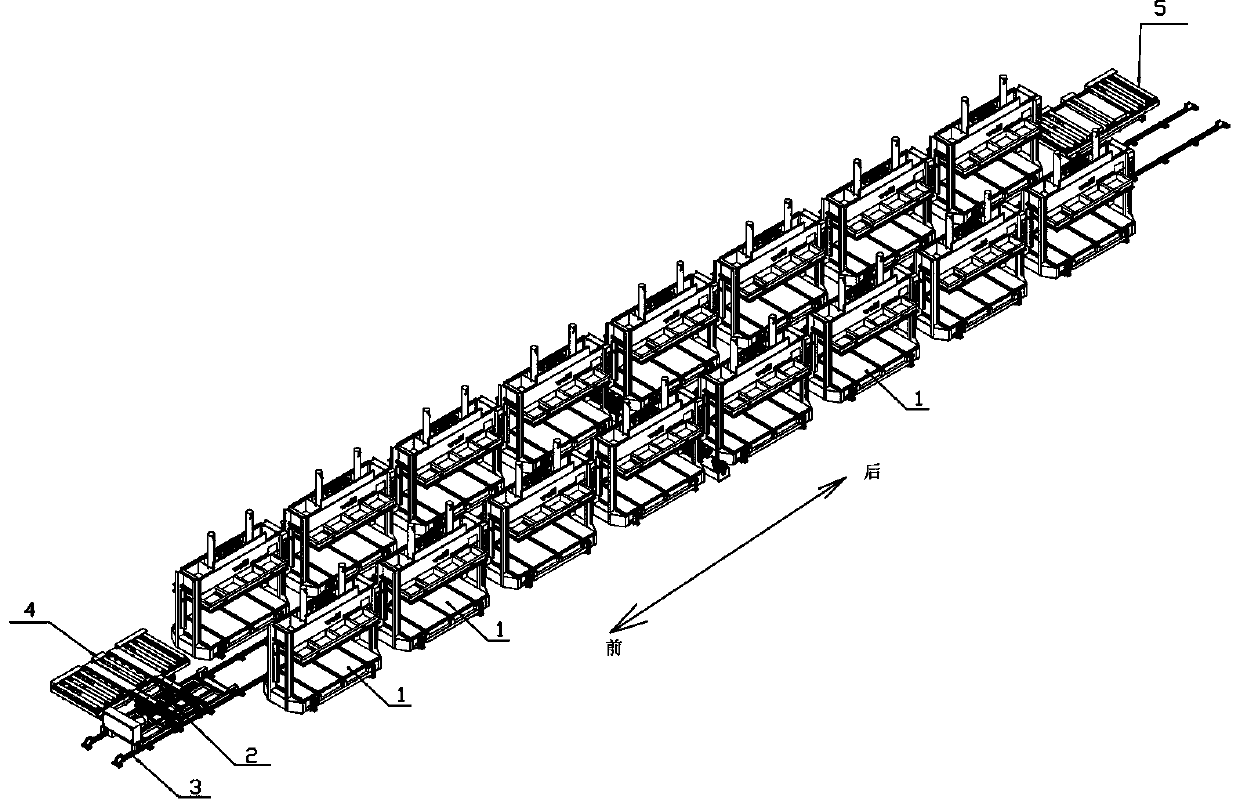

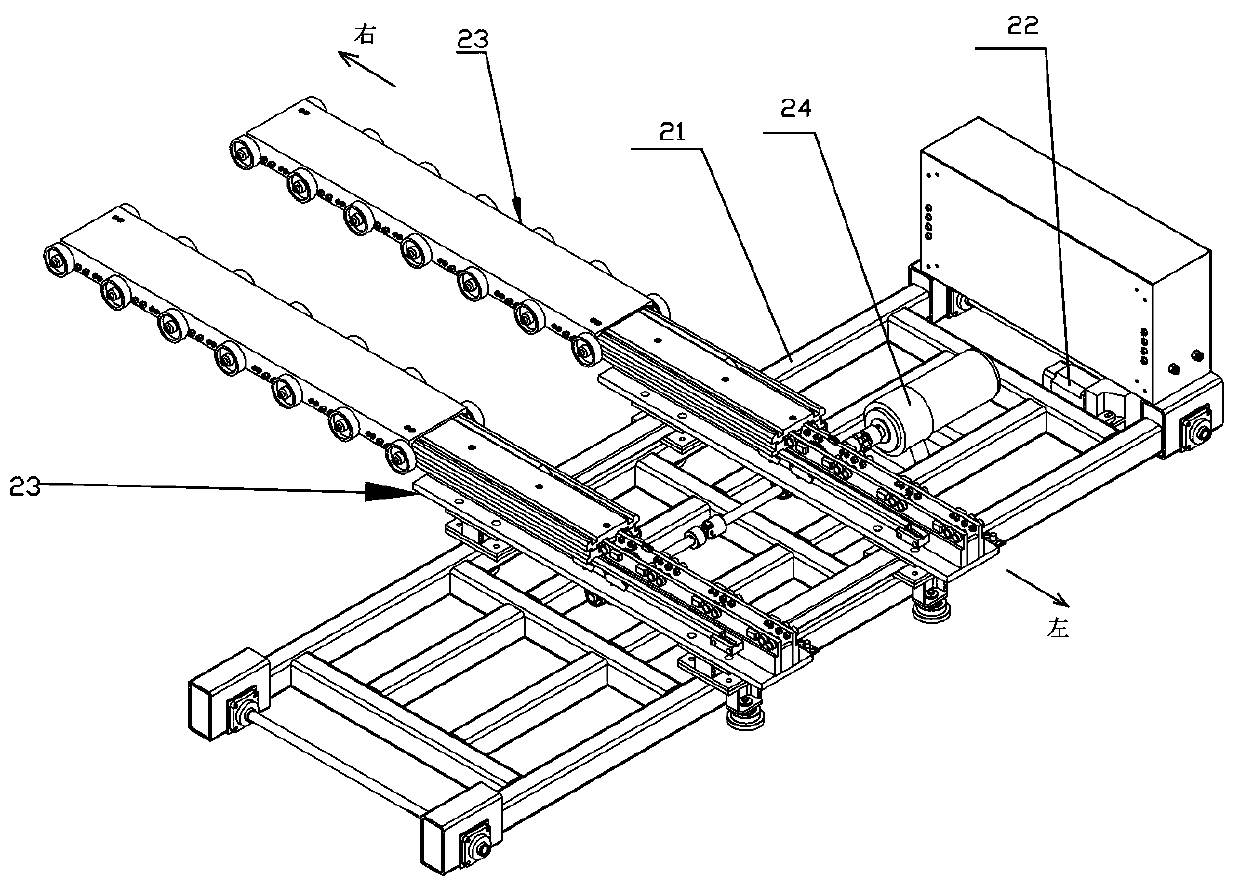

[0019] like figure 1 , 2 , 3, 4, 5 and 6, the automatic RGV robot cold pressing production line of the present invention includes several cold pressing machines 1, RGV conveying trolley 2, conveying track 3, input power elevating frame 4 and output power elevating frame 5 ;The cold press 1 is set on both sides of the conveying track 3, and the RGV conveying trolley 2 can move forward and backward along the conveying track 3; The loaded goods are transported to the workbench of the cold press 1 for cold pressing, and the cold-pressed goods are transported to the output power elevating frame 5 .

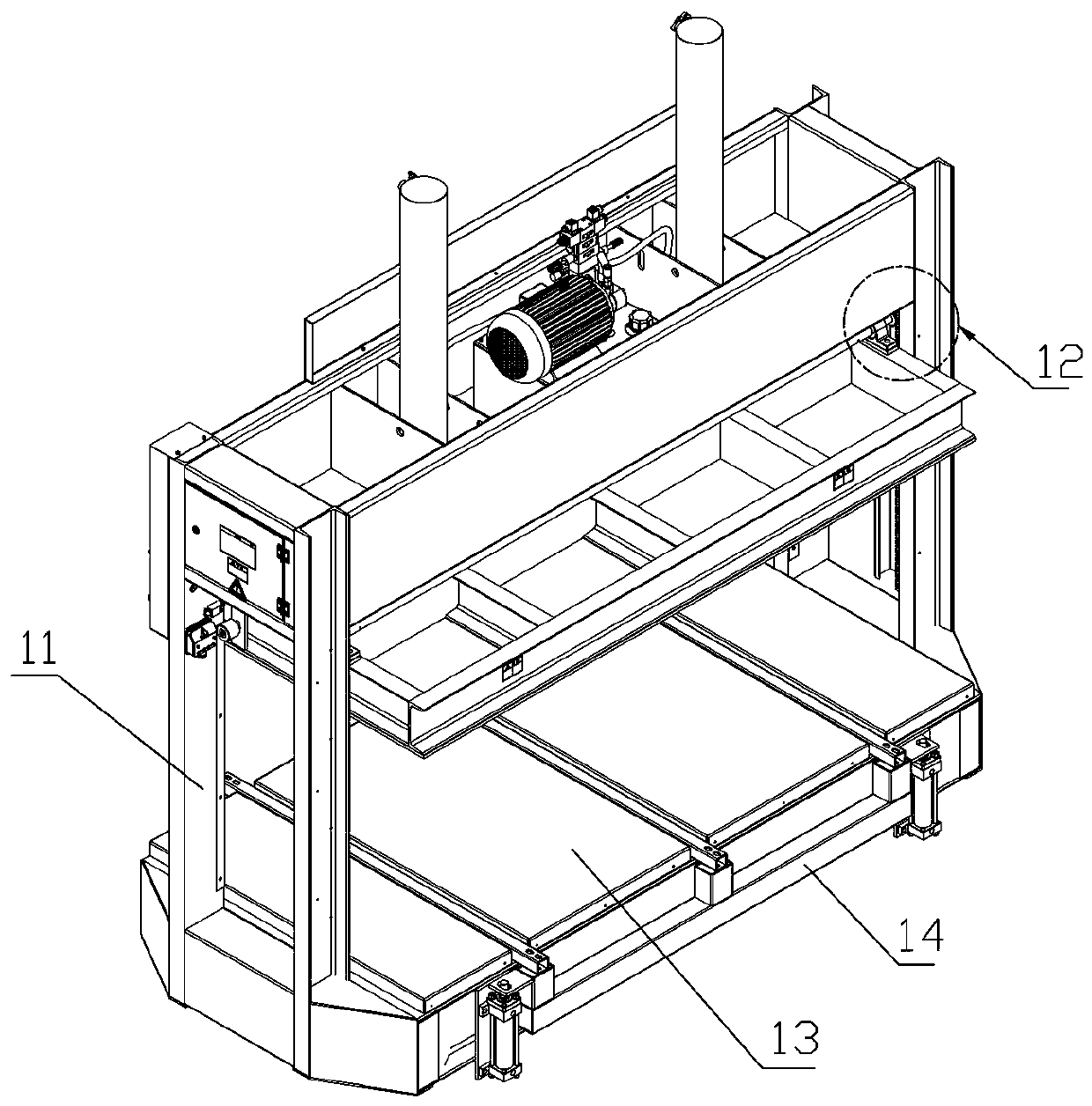

[0020] The cold press 1 includes a frame 11 and an extruding mechanism 12 for extruding plates, the bottom of the frame 11 is provided with a workbench 13, the ejector device 14 is installed at the bottom of the frame, and the extruding mechanism 12 is installed On top of rack 11.

[0021] The jacking device 14 includes a jacking frame 141 installed at the bottom of the frame of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com