Novel powder feeding machine capable of being used by connecting negative pressure pump

A negative pressure pump and a new type of technology, applied in the field of powder feeders, can solve the problems of increasing the work intensity of workers, polluting the working environment, powder spillage, etc., and achieve the effects of reducing manual labor, reducing labor, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention will not be limited.

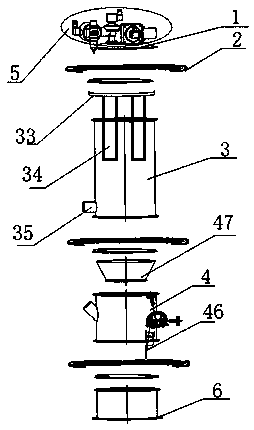

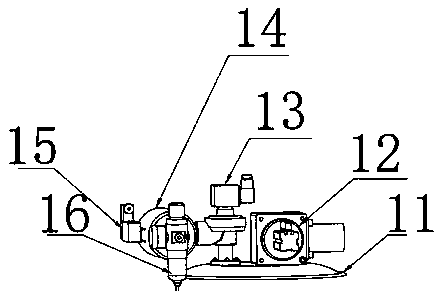

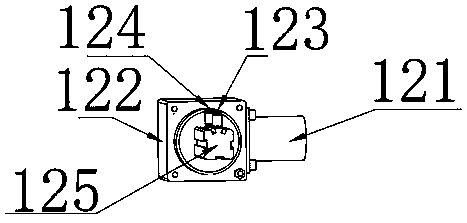

[0014] refer to Figure 1 to Figure 3 As shown, a new type of powder feeder that can be used by connecting a negative pressure pump, including a control part 5 connected by a clamp 2 from top to bottom, a filter bucket 3, a discharge door section 4 and a bottom section 6 Composition, the control part 5 includes a pulse blowback valve 13 and a vacuum reversing valve 12 communicated with the negative pressure pump, the vacuum reversing valve 12 includes a three-way reversing valve cavity 122 and a connecting nozzle connected to the negative pressure pump 121, the three-way reversing valve cavity 122 is provided with a linear cylinder 125, and the linear cylinder 125 is connected with two opening and closing straight-through air pipe joints 124 and closing straight-through air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com