Manufacturing process of furniture cover

A technology for making crafts and furniture covers, which is applied in the field of making crafts for furniture covers, to achieve good effects, save labor costs and fabric costs, and achieve good plumpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

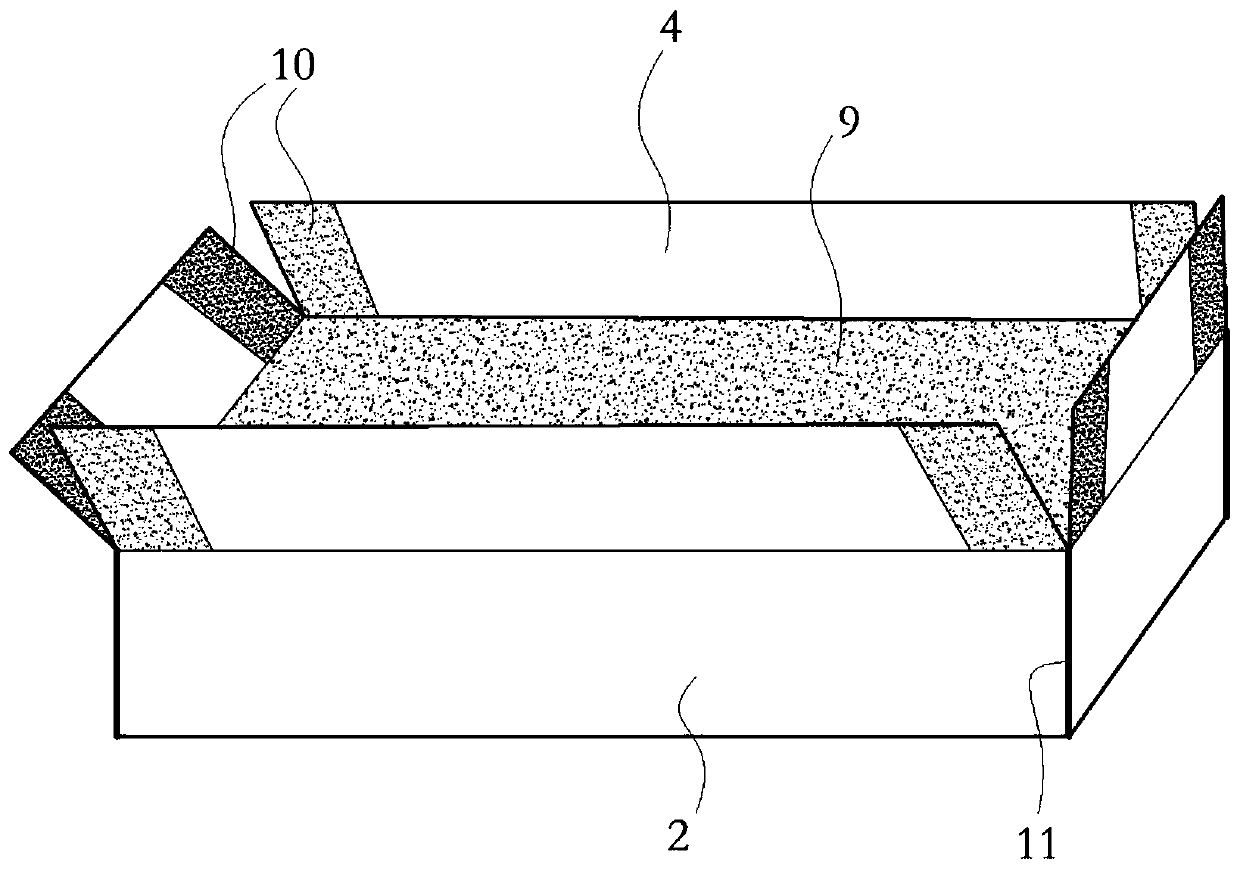

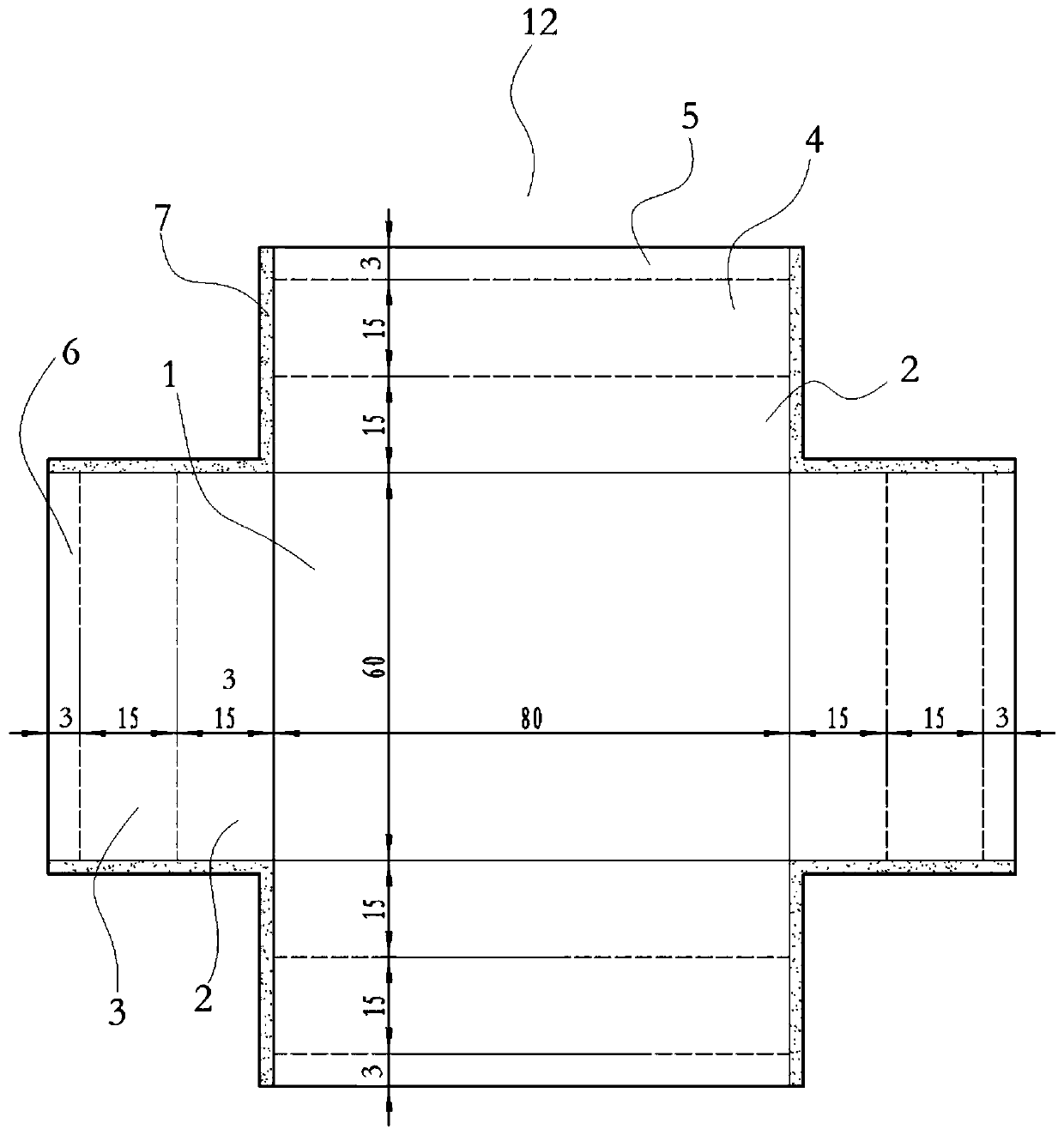

[0028] Such as figure 1 and image 3 Shown, embodiment of the present invention is a cushion cover cover, comprises the steps:

[0029] S1 measures the length, width and thickness of the core 9, the cushion core 9 has a length of 80cm, a width of 60cm, and a thickness of 15cm;

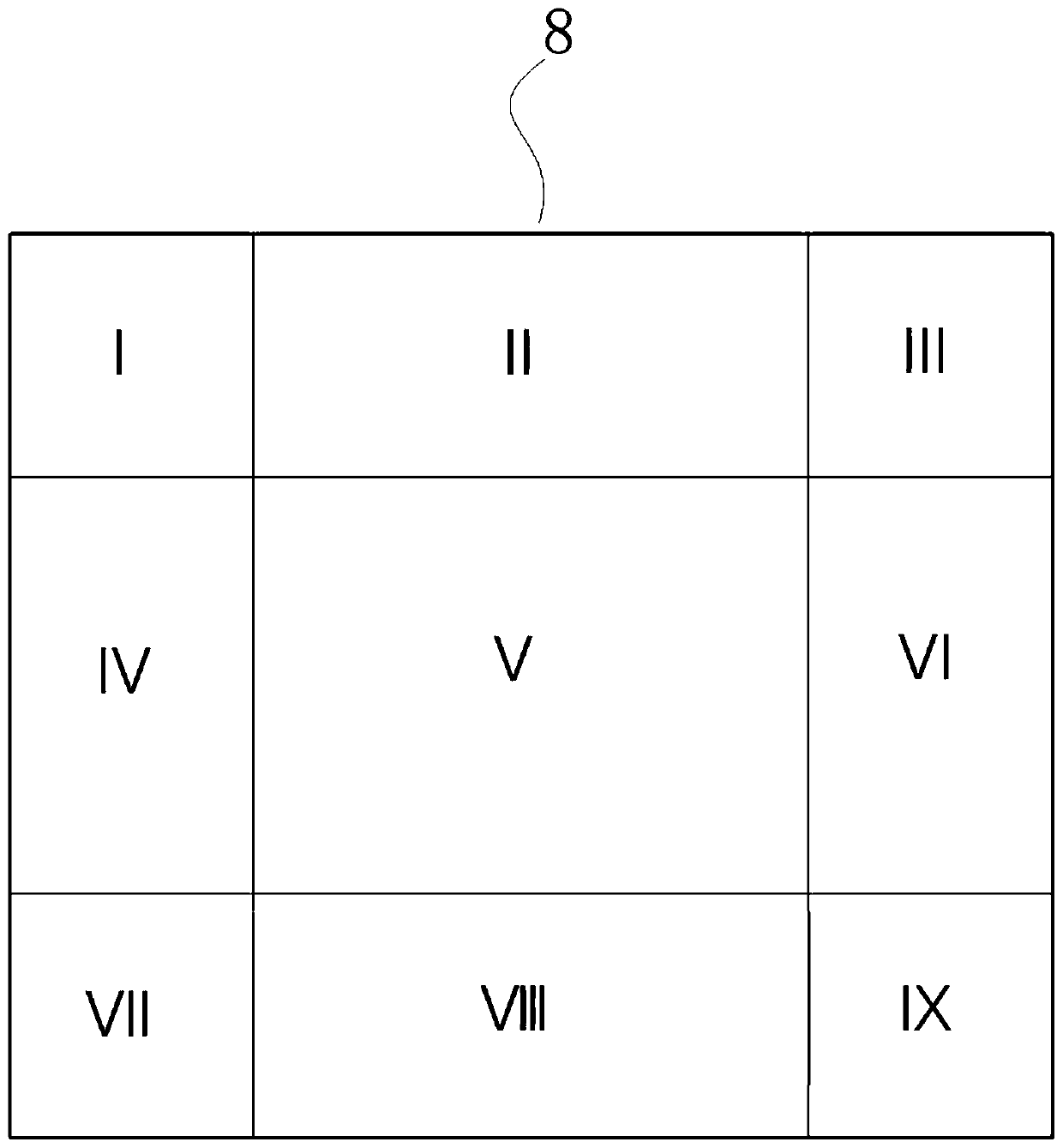

[0030] S2 cuts the wrapping layer into an initial shape 8 according to the data obtained by measuring the core body 9, and the initial state is a rectangle.

[0031] The length of initial form 8: the length 80cm of core 9+thickness 15cm*2 of core 9+the length 15cm*2 of back section 3 in longitudinal direction+the length 3cm*2 of loss section 6 in longitudinal direction=146cm; The core here The thickness of 9, the length of the back section 3 in the longitudinal direction and the length of the loss section 6 in the longitudinal direction all refer to the dimensional values in the same direction as the length of the core body 9.

[0032] The width of the initial form 8: the width 60cm of the core bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com